WP161 Water-based Acrylic Polyurethane Topcoat

WH-WP161 water-based acrylic polyurethane topcoat has the advantages of low production cost, non-flammable, non-toxic, no pollution to the environment, and saving of organic solvents.

SKU:

WP161 Water-based Acrylic Polyurethane Topcoat

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Overview

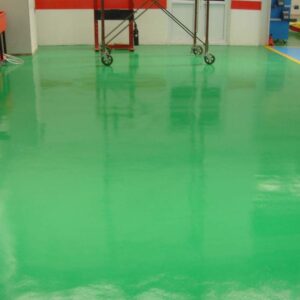

WH-WP161 Water-based Acrylic Polyurethane Topcoat is a type of coating based on water-based polyurethane resin with water as the dispersion medium. It offers advantages such as low production cost, non-flammability, non-toxicity, environmental friendliness, and organic solvent savings. Additionally, it retains some excellent properties of traditional solvent-based polyurethane coatings, demonstrating good adhesion to various substrates including paper, wood, fiberboard, plastic film, metal, glass, and leather. Compared with solvent-based polyurethane resins, it features low toxicity and excellent color retention.

Product Characteristics

- Non-flammable and non-explosive, facilitating safe transportation.

- Dilutable with tap water, and construction tools, equipment, and containers can be cleaned with tap water, significantly reducing coating costs.

- Fast drying time, improving work efficiency and lowering labor costs.

- Excellent light and color retention, as well as durability.

- Moderate water and oil resistance.

Recommended Applications

Suitable for industries such as automotive, marine, steel structure grids, machinery manufacturing, containers, railways, bridges, boilers, and steel structures.

Technical Parameters

| Item | Specification |

|---|---|

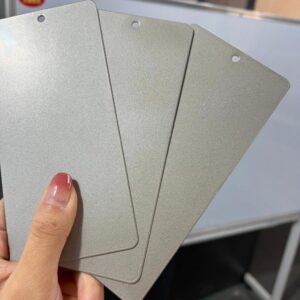

| Color | Available in various colors as per color cards |

| Specific Gravity (kg/L) | 1.2 – 1.4 |

| Coating Film Thickness (μm) | 40 – 60 |

| Coverage (㎡/L) | Theoretical value: 8.8 ㎡/L/40 μm; Actual value varies with surface treatment, spraying environment, construction method, and structure of the coated object |

| Flash Point | — |

| Surface Dry (≤) | 2h (23℃) |

| Through Dry (≤) | 24h (23℃) |

| Glossiness | As agreed upon |

| Fineness (μm) | ≤40 |

| Flexibility (mm) | ≤2 |

Application Guidelines

Surface Preparation

- Sandblast steel surfaces to Sa2.5 grade with a surface roughness of 30μm – 75μm.

- Remove rust with electric tools to achieve St3 grade.

Primer Compatibility

Can be directly applied to steel surfaces with rust removal quality meeting Sa2.5 grade.

Topcoat Compatibility

Compatible with water-based steel structure topcoats, water-based alkyd topcoats, water-based acrylic topcoats, water-based polyurethane topcoats, and water-based epoxy topcoats.

Application Instructions

- Mixing ratio (by weight): Base paint : Curing agent = 5 : 1.

- Strictly avoid contact with oily substances. Stir thoroughly according to the label ratio before use, and then appropriately dilute with deionized water as needed. Generally, adding 5-20% water is optimal. Adjust to suitable spraying viscosity according to the actual gun nozzle and pressure.

- Storage temperature ≥0℃. Store in a cool, dry place, protected from freezing and direct sunlight. Shelf life: 6 months.

Construction Parameters

| Item | Details |

|---|---|

| Construction Temperature | 5 ~ 40℃ |

| Pot Life | 4h. It is recommended to mix as much as needed to avoid gelling due to long-term storage after mixing. |

| Application Methods | Brush painting, air spraying, and roller coating are all applicable. |

| Recoating Interval | Substrate Temperature (℃):5-10;15-20;25-30 |

| Minimum Interval (h):2;0.6;0.4 | |

| Maximum Interval:No more than 7 days. | |

| Note | The substrate temperature must be at least 3℃ above the dew point. When the substrate temperature is below 5℃, the film curing time is significantly prolonged, and construction is not advisable. |

| Wet-on-Wet Coating Typical Process | After the water-based fast-drying epoxy primer is naturally dried for 20 minutes or low-temperature baked for 15 minutes, spray this topcoat, then naturally dry or low-temperature bake for 30 minutes. It is recommended to test the performance after at least 48 hours of complete film drying. |

Precautions

All operations involving the application and use of this product must comply with relevant national health, safety, and environmental protection regulations and standards. If there are any questions about whether to use this product, please consult our company’s technical service department for details.

Transportation and Storage

- Store the product in a cool, ventilated place, protected from direct sunlight. The storage temperature should be maintained between 0-40℃.

- During transportation, prevent 雨淋 (rain), 日光曝晒 (direct sunlight), and collision, and comply with the relevant regulations of the transportation department.

Safety Protection

- The construction site should have good ventilation facilities. Painters should wear glasses, gloves, masks, etc., to avoid skin contact and inhalation of paint mist.

- Warning: Irritating to eyes and skin. Vapors may cause respiratory allergies in sensitive individuals. May cause skin allergic reactions. Avoid inhaling vapors. Do not contact eyes or skin. Protective equipment for ears, eyes, and skin is required. To avoid potential respiratory irritation, it is recommended to use a suitable respirator. Thoroughly wash skin after use. Clothes should be washed before wearing again. If breathing stops, perform mouth-to-mouth artificial respiration and seek medical attention immediately.

- First Aid: If accidentally in contact with eyes, immediately rinse with clean water for at least 15 minutes, remove contaminated clothing and shoes, and wash the contact area with soap.

Declaration

The information listed in this document is reliable. Each provided value is calculated as theoretical data from the product formula. If needed, our company can inform the internal common measurement and determination methods for any of the above-given data. Since the usage conditions cannot be controlled by the manufacturer, this information does not constitute a guarantee. The product is only for professional use. In case of any questions, please contact our company.

Our company’s technical support and customer service center are willing to provide you with consulting and application technical services regarding the product. Welcome to contact us by letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|