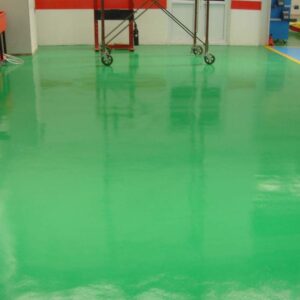

ES100 Solvent-Free Moisture-Resistant Epoxy Coating

ES100 is a high-performance solvent-free modified epoxy coating designed for heavy-duty anti-corrosion applications on steel surfaces. This environmentally friendly formulation can be directly applied to dry or wet surfaces, compatible with both new and old steel substrates. It adheres firmly to rust spots and sound existing coatings, serving as a primer, intermediate coat, or topcoat. With zero harmful solvent emissions, excellent impact resistance, non-flammability, superior chemical resistance, and no dew point or relative humidity restrictions, ES100 offers exceptional corrosion protection and strong substrate adhesion while reducing surface preparation costs.

SKU:

ES100 Solvent-Free Moisture-Resistant Epoxy Coating

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Overview

Wanhua ES100 is a high-performance solvent-free modified epoxy coating designed for heavy-duty anti-corrosion applications on steel surfaces. This environmentally friendly formulation can be directly applied to dry or wet surfaces, compatible with both new and old steel substrates. It adheres firmly to rust spots and sound existing coatings, serving as a primer, intermediate coat, or topcoat. With zero harmful solvent emissions, excellent impact resistance, non-flammability, superior chemical resistance, and no dew point or relative humidity restrictions, ES100 offers exceptional corrosion protection and strong substrate adhesion while reducing surface preparation costs.

Recommended Applications

- Marine & Offshore: Shipbuilding, 海港 (harbors), offshore metal structures.

- Infrastructure: Bridges, hydropower equipment, underground tunnels, concrete surfaces in underground plants.

- Transportation & Industrial: Vehicles, military facilities, pipelines (potable water, fuel, and oil transport), and storage tanks (internal/external surfaces).

Technical Specifications

| Property | Details |

|---|---|

| Color | White, gray, black |

| Surface Finish | Semi-gloss |

| Mix Ratio | Weight ratio: 5 (base material) : 1 (curing agent) |

| Curing Agent | CES1000 |

| Specific Gravity | ~1.4 kg/L |

| Volume Solids Content | 100% (theoretical) |

| Flash Point | Base material: >100°C (>212°F); Curing agent: >100°C (>212°F) |

| Pot Life | 40 minutes (23°C/73.4°F) |

| Coverage Rate | 6.7 m²/L at 150 microns (6 mils) dry film thickness |

| Film Thickness | Wet film: 150 microns (6 mils); Dry film: 150 microns (6 mils) |

| Application Methods | Brush, roller, airless spraying |

| Nozzle Size | 0.48–0.79 mm |

| Outlet Pressure | ≥25 MPa |

| Diluent/Cleaner | Diluent: None; Cleaner: UM-TH03 |

| VOC Content | 0% (100% solid epoxy product) |

| Drying Time | Surface dry: ~4 hours (23°C/73.4°F) |

| Recoat Interval | Minimum: 16 hours (23°C/73.4°F); Maximum: 5 days (surface roughening required if exceeded) |

| Recommended Primers | Self-priming or as recommended |

| Temperature Range | Ambient/substrate: 5°C (41°F) – 40°C (104°F) |

| Packaging | 25 kg two-component kit |

| Storage & Shelf Life | Store in well-ventilated areas, away from heat; tightly sealed containers. Shelf life: 1 year. |

Key Performance Data

| Test | Results |

|---|---|

| Abrasion Resistance (1kg/1000 cycles) | Weight loss ≤150 mg |

| Adhesion (Pull-off Test, Sa2.5 blasted steel) | >20 MPa |

| Salt Spray Test (single coat, 200 microns) | 3000 hours with no corrosion or blistering |

| Moisture Resistance (condensation test) | 3000 hours with no corrosion |

Application Guidelines

- Surface Preparation:

- High-pressure water jetting, dry/wet blasting, or mechanical treatment.

- Blast cleaning: Sa2 (ISO 8501-1:2007); Ultra-high-pressure water: Wj2-M (SSPC SP12-VIS4(I)/NACE No.7); Mechanical: St3 (ISO 8501-1:1988).

- Mixing Procedure:

- Stir base material until smooth (<2 minutes).

- Gradually add curing agent and mix continuously for 3 minutes using a variable-speed electric mixer. Avoid overmixing to prevent accelerated curing.

- Application:

- Airless spraying recommended (use 60:1 or higher pump ratio, 0.48–0.79 mm nozzle).

- Ensure equipment and fluid pathways are clean and free of water/solvents. Adjust pump ratio for long pipelines or low temperatures.

- Maintain proper ventilation for worker safety and coating performance.

Safety Precautions

- Hazards: May cause eye/skin irritation and respiratory irritation (vapors). Risk of skin allergy.

- Protective Equipment: Use eye/face protection, gloves, and respiratory masks.

- First Aid: Flush eyes with water for 15+ minutes if exposed. Wash skin with soap. Seek medical advice for persistent irritation.

- Handling: Avoid prolonged contact. Dispose of mixed material carefully due to exothermic reaction.

Disclaimer

The information herein is based on reliable formulations, but performance may vary under uncontrolled conditions. Data is provided for reference only and does not constitute a warranty. For professional use only. Contact Wanhua for technical support or inquiries.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|