Coach Insulation Brochure

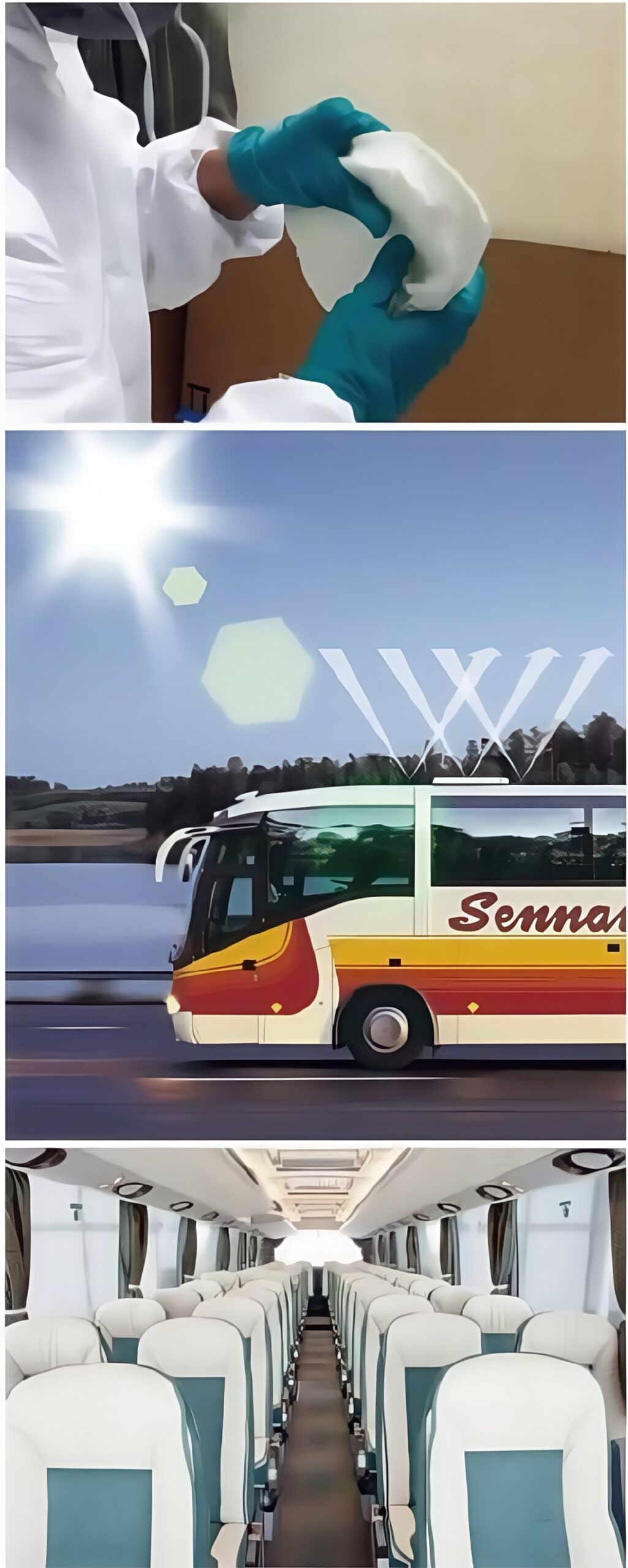

Product Introduction

WANEFOAM®904 (commonly known as white material) is a fully water-based spray soft foam polyurethane composite material. Its main components are polyether/polyester polyols and other additives. The foaming agent is 100% water, fluorine-free, and does not contain other foaming agents. When used with WANNATE®2208 in a 1:1 ratio, green and environmentally friendly soft polyurethane foam can be obtained.

Testing and certification

Wanhua’s fully water-based soft polyurethane foam uses 100% water for foaming, does not contain fluorine compounds, is construction-friendly, and the finished foam is white and odorless. It has excellent flame retardant properties and has passed the testing of authoritative institutions such as the National Materials Testing Center and CTI. Its flame retardancy can reach the A-o level standard of “Combustion Characteristics of Automotive Interior Materials” (GB8410-2006). Its TVOC is far less than the national standard requirement, and its physical and chemical properties meet the requirements of relevant industry standards.

Wanhua’s all-water-based soft polyurethane foam test results

| Test items | Test results | According to the standard | Grade |

| Density (g/cm³) | 7.7 | GB/T6343-2009 | Pass |

| Thermal conductivity (W/m.k) 25℃ | 0.04 | GB/T10294-2008 | Pass |

| Combustion characteristics of automotive interior materials | A-omm/min | GB8410-2006 | Grade A |

| Tensile strength (kPa) | >25 | GB/T6343-2009 | Pass |

| TVOC value (μgC/g) | <300 | VDA277 | Pass |

| Toluene and xylene (g/kg) | Not detected | GB18583-2008 | Pass |

| Free formaldehyde (g/kg) | Not detected | GB18583-2008 | Pass |

| Total volatile organic compounds (g/kg) | Not detected | GB18583-2008 | Pass |

Product Use

WANEFOAM®904 (commonly known as white material) is a fast curing system that can be used in insulation fields such as bus ceilings, car bodies, building curtain walls, sandwich walls, etc. The product has no load-bearing capacity and is suitable for most spraying and pouring constructions that do not require load-bearing.

Material introduction

Spray polyurethane is made by mixing polyether and isocyanate through high-pressure spray equipment and then spraying and foaming on site. It has many excellent properties.

Excellent thermal insulation performance

Polyurethane foam has a low thermal conductivity and is the best thermal insulation material that can be industrially produced at present. It can effectively reduce the impact of cold and hot environments on the temperature inside the bus. A thinner thickness can meet the requirements of thermal insulation of the bus.

Spraying foaming operation, integrated with the body

Spraying polyurethane is sprayed on the bus roof and side panels through high-pressure atomization.

It foams in a few seconds to form polyurethane foam, fills the body, and is 100% bonded to the bus roof, skin and steel.

Excellent anti-mold performance

The temperature and humidity inside the bus roof and side panels are suitable, which is easy for microorganisms to grow and mold spots to form. The molecular structure of polyurethane foam itself can destroy the growth environment of microorganisms and has excellent anti-mold performance.