Polyurea Coatings Application Manual

Polyurea

Black technology in the coating industry

Spray Polyurea Elastomer (SPUA) technology is a new type of solvent-free, pollution-free green construction technology developed and developed in foreign countries in the past decade to meet environmental protection needs, following low (non-)pollution coating technologies such as high-solid coatings, water-based coatings, radiation-cured coatings, and powder coatings. It is known as the greatest discovery and technological revolution in the field of coating coating technology. SPUA technology has comprehensively broken through the limitations of traditional environmentally friendly coating technology. Therefore, this technology has developed rapidly since its launch. It combines new technologies, new materials, and new processes, and is a revolutionary leap in traditional construction technology.

Polyurea technology will provide a most advanced super-heavy anti-corrosion, waterproof, wear-resistant and decorative material as well as the most convenient and quickest construction for the construction of large-scale infrastructure in my country in the future, such as chemical protection, pipeline anti-corrosion, marine anti-corrosion, tunnel waterproofing, dam maintenance, bridge protection, foundation reinforcement, roof planting, prop production, fender manufacturing, large-scale municipal engineering and water treatment anti-corrosion.

Performance advantages of polyurea

Convenient construction

★ Fast curing, no sagging

★ Short construction period, high efficiency

★ Low requirements for construction environment

★ One-time construction to achieve thickness

Safe and environmentally friendly

★ 100% solid content

★ No organic volatilization

★ Non-toxic and pollution-free

★ Adjustable color

★ Adjustable hardness and softness

★ Adjustable formula system

Excellent performance

Adaptable on demand

★ Waterproof and anti-seepage

★ Pressure and wear resistance

★ Anti-corrosion and weather resistance

★ Strong adhesion

Water Conservancy Project

On the basis of improving the density of concrete itself, water conservancy projects construct protective materials with better anti-seepage and anti-wear properties on the dam surface to repair concrete surface defects and prevent water vapor from expanding into the interior. Spraying polyurea materials as a protective layer for water conservancy project dams can well solve such problems and effectively extend the service life of concrete.

HYDROELECTRIC DAMS

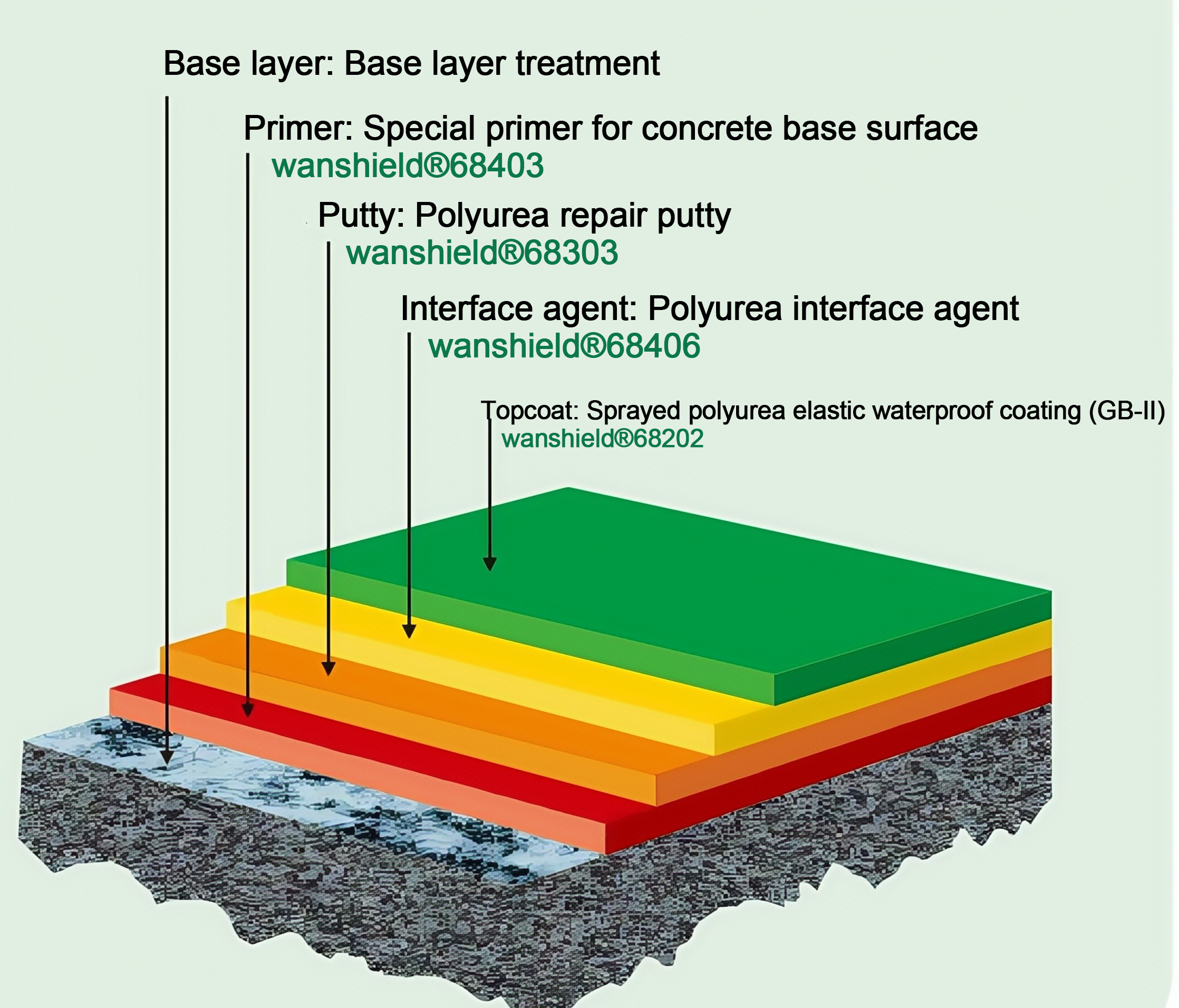

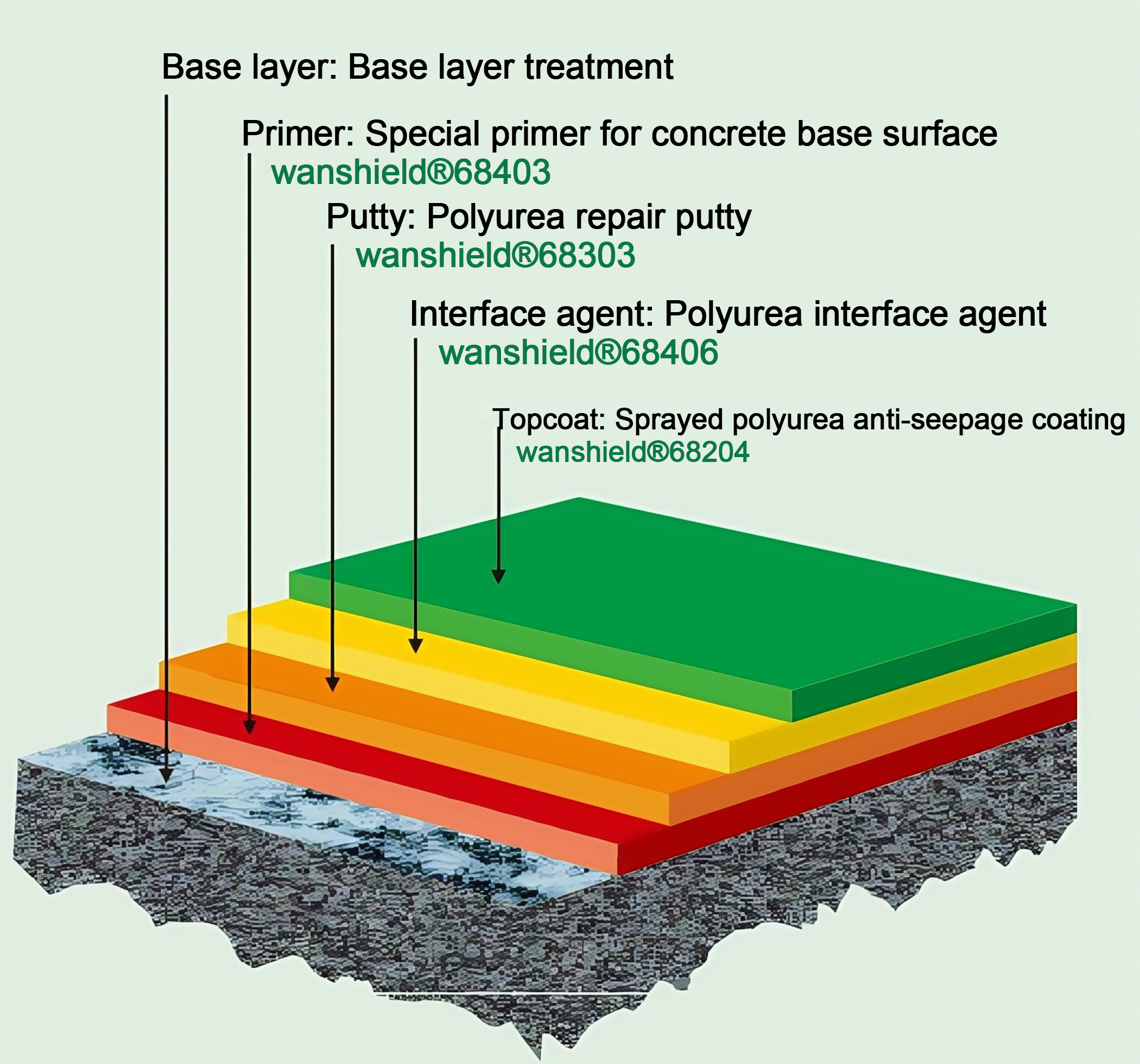

Spray polyurea coating system

Dam surface waterproof and anti-seepage

Applicable to coating of dam surface (upstream dam surface, gate piers, dam top, etc.)

Dam concrete anti-seepage and anti-cracking

Applicable to anti-seepage measures to enhance the anti-cracking performance of dam concrete itself, and anti-seepage protection treatment of concrete cracks on the upstream dam surface

Dam spillway anti-water erosion

Applicable to coating of overflow channels, overflow surfaces, flood discharge tunnels, water discharge holes, energy dissipation pools and other structures

Manual polyurea coating system

Waterproof and anti-seepage of dam surface

Applicable to coating of small areas such as dam surface, factory floor, building roof, roof, etc.

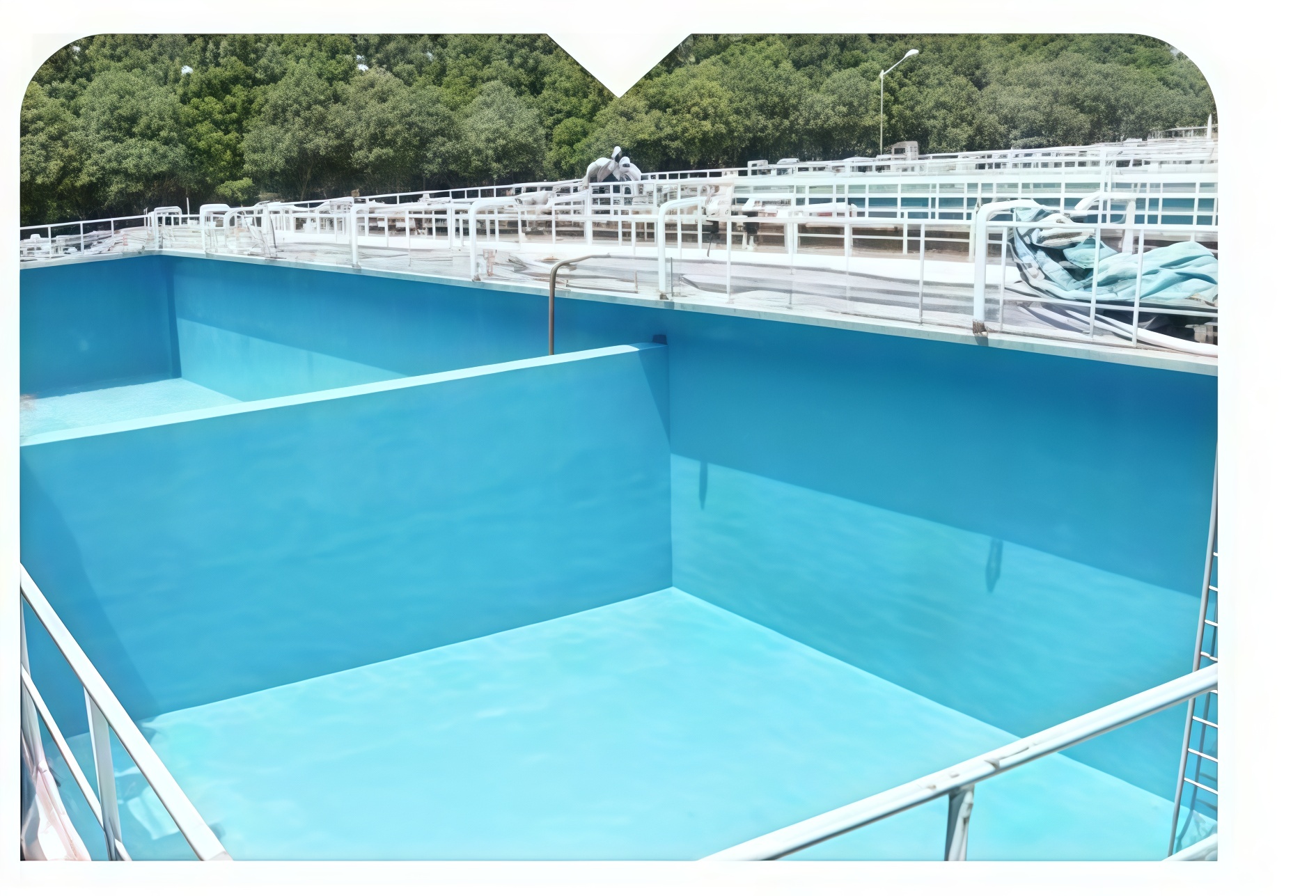

Water Park

Polyurea materials have rapidly developed into the most mature and widely used anti-seepage application for concrete coatings in water parks due to their excellent anti-slip properties, so there is no need to worry about falling; good chemical resistance, no corrosion and no discoloration after being scrubbed with algaecide disinfectant (sodium hypochlorite), etc.

WATER WORLD

Spray polyurea coating system

Children’s water play anti-slip weather-resistant

Applicable to children’s water play area, slide area pool, wave pool, adventure pool, leisure massage pool, swimming pool

The breeding area is waterproof and weather-resistant

Suitable for marine biological breeding pools, viewing pools, and performance pools

Water circulation waterproofing and anti-seepage

Applicable to power pools, fire pools, wastewater pools

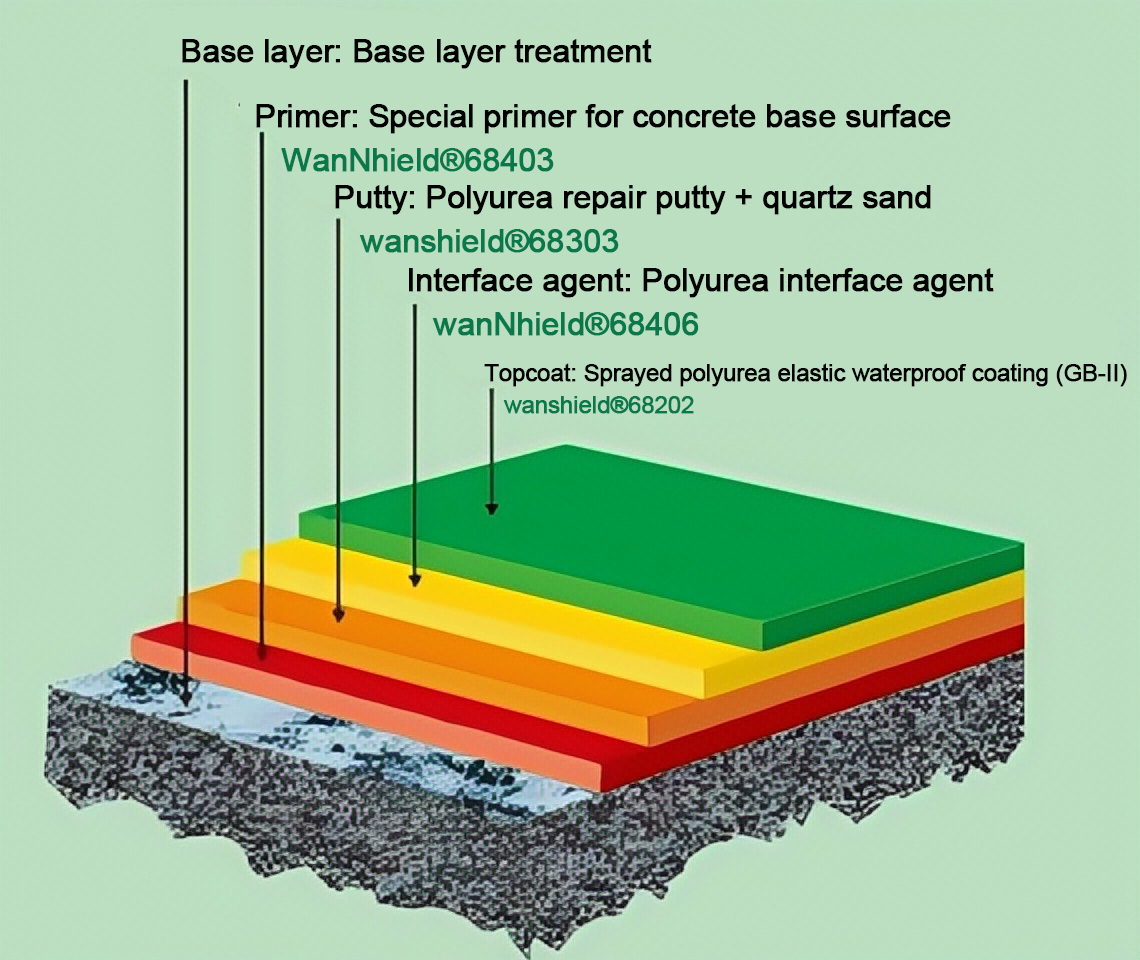

Manual polyurea coating system

Landscape river channel anti-slip and weather-resistant

Applicable to park/water park amusement pools, landscape rivers, landscape pools, artificial lakes

Anti-slip and weather-resistant beach area

Suitable for simulated beaches in water parks

Painted design and decoration area

Suitable for parks/water parks with decoration needs, amusement pools, landscape rivers, landscape pools, artificial lakes

Zhuhai Chimelong Hengqin Bay Hotel

Construction area 9,000 square meters

Rich marine elements and amazing dolphin theme style, created by the world’s top design team. While improving the decorative effect of the swimming pool, the reasonable use of color matching will not affect the visual judgment of the lifeguard. The very interesting dolphin theme makes people feel like they are in a magical ocean world.

Guangzhou Chimelong Hotel

Construction area 2,000 square meters

The design concept of natural symbiosis, hand-painted tropical rain forest and animal world elements, show the concept of Chimelong theme park. While improving the decorative effect of the swimming pool, the reasonable use of color matching will not affect the visual judgment of the lifeguard. It has won the praise of the World Hotel Association and the China Best Theme Hotel Award.

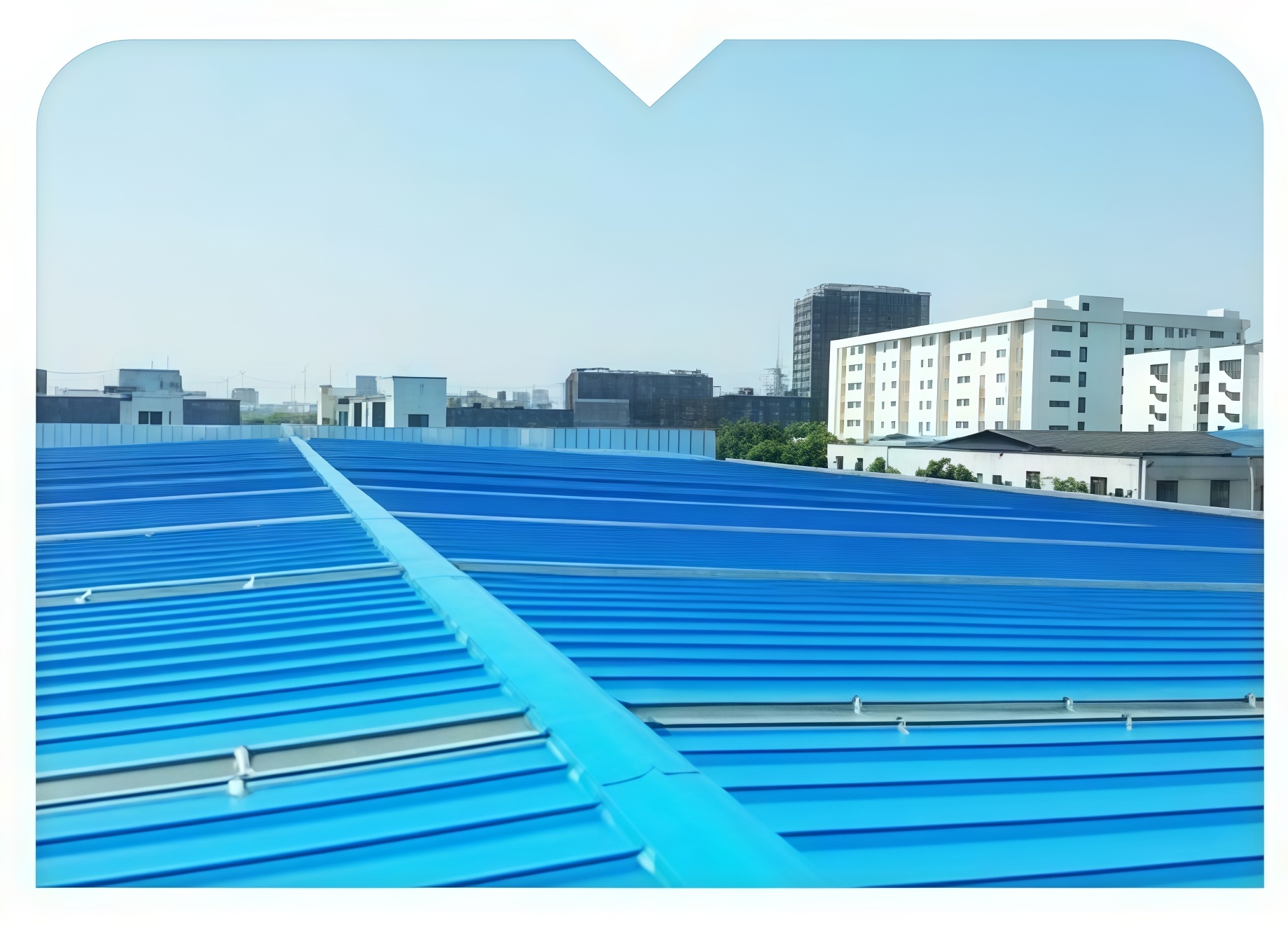

Roof waterproofing

The polyurea coating is seamless as a whole and adheres closely to the roof to form a “skin-like” waterproofing system. It fully adapts to the complexity of the roof curve and can form a complete waterproofing system for the overlap, connection and perforated components of the roof. It has excellent aging resistance, fatigue resistance, low-temperature bending resistance and high elasticity. It is fully suitable for waterproofing applications on roofs in open-air environments, and its service life is much longer than that of high-performance waterproof membranes.

ROOF WATERIOOFING

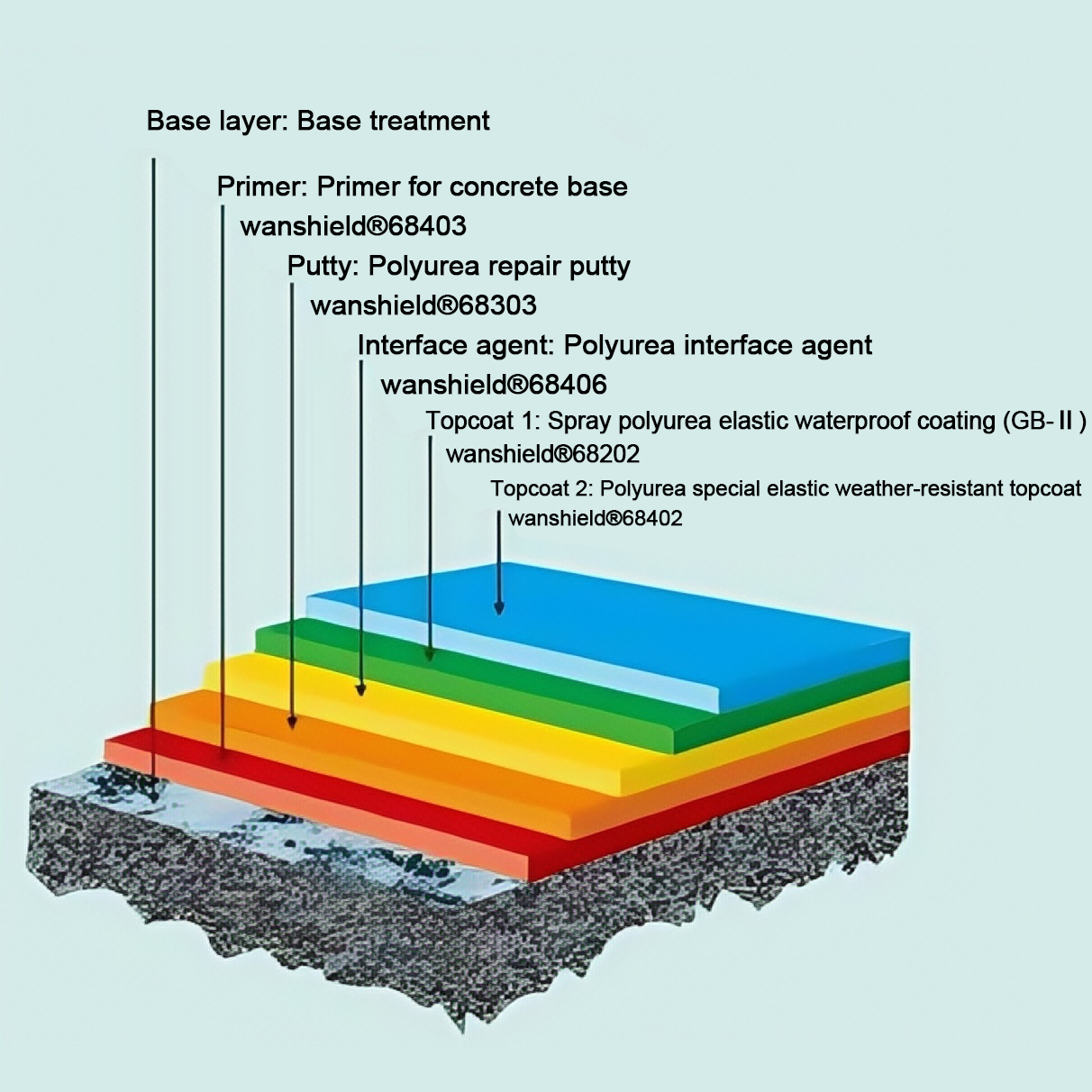

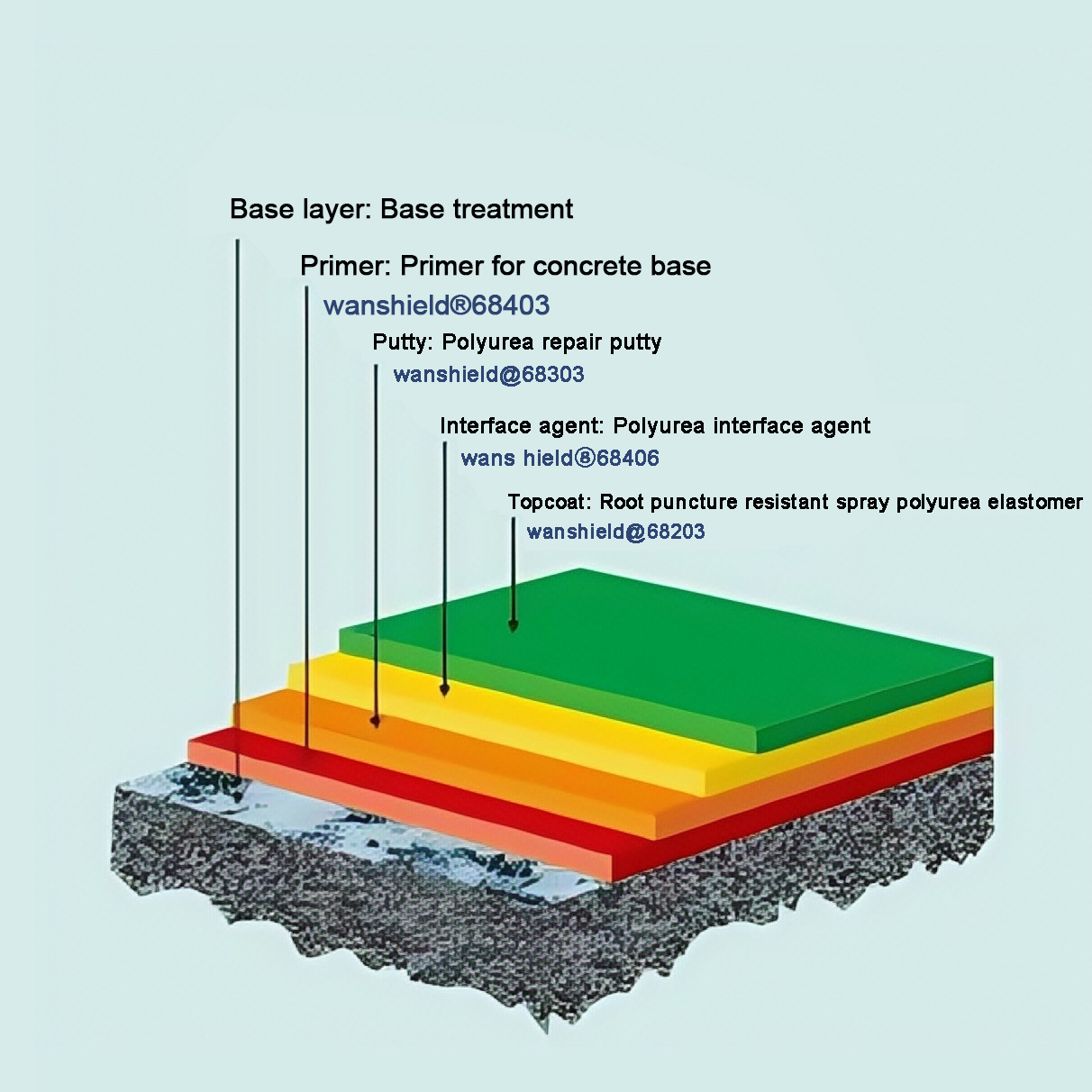

Spray polyurea coating system

Roof waterproofing and thermal insulation integration

Applicable to roofs of factories, hotels, buildings, communities and other buildings

Green roof root puncture resistance waterproofing

Applicable to roofs with planted vegetation

Large-span roof waterproofing and anti-corrosion

Applicable to large-span building roofs such as museums, libraries, and factories

Manual polyurea coating system

Old roof renovation, overall seamless waterproofing

Applicable to old roof renovation, overall seamless waterproofing

Roof parking lot wear-resistant and waterproof

Applicable to roof parking lot

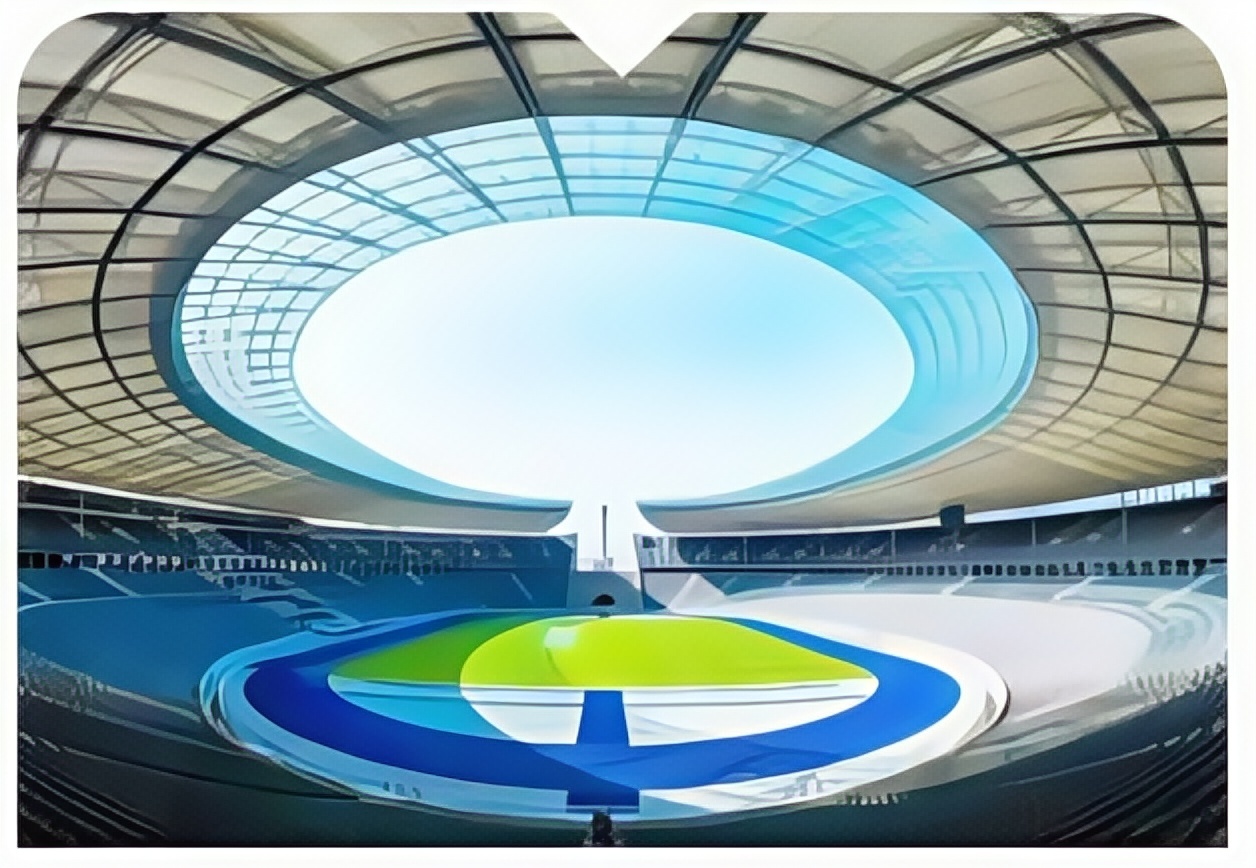

Sports Stand

As we all know, stadium stands have many steps and large curvatures, which makes coating construction difficult. However, due to the fast curing speed of polyurea materials, the facade can be sprayed continuously without sagging, the construction cycle is fast, and it can be put into use quickly. At the same time, polyurea coatings also have excellent wear resistance, waterproof and anti-slip effects, and can achieve reasonable color matching, beautiful and durable.

SPORTS AUDITORIUM

Spray polyurea coating system

Waterproof and anti-seepage for sports stands

Applicable to indoor sports stands

Sports stands are waterproof and weather-resistant

Applicable to outdoor sports stands

Sports stands are waterproof and weather-resistant

Applicable to outdoor sports stands

Petrochemical

Commonly used anti-corrosion materials in the petrochemical industry are generally divided into linings and coatings. Linings need to be heated and vulcanized on site, and the construction process is very complicated, and the quality is difficult to guarantee. Spray polyurea cures quickly, and the facade is continuously constructed without sagging. It has outstanding media resistance and can resist erosion by water, acid, alkali, salt, oil and other media. It has good adhesion, is resistant to ultraviolet aging, and has a wide range of uses.

PETROCHEMICAL

Spray polyurea coating system

Waterproof and anti-corrosion for chemical smelting equipment

Applicable to storage tank cofferdams, pickling tanks, electroplating tanks, carbonization towers, evaporation tanks, neutralization tanks, sewage treatment tanks, drainage ditches, etc. in the petrochemical, smelting and other industries

Waterproof and anti-corrosion for steel structures

Applicable to corrosion protection for pipelines, desalted water tanks and other steel structures

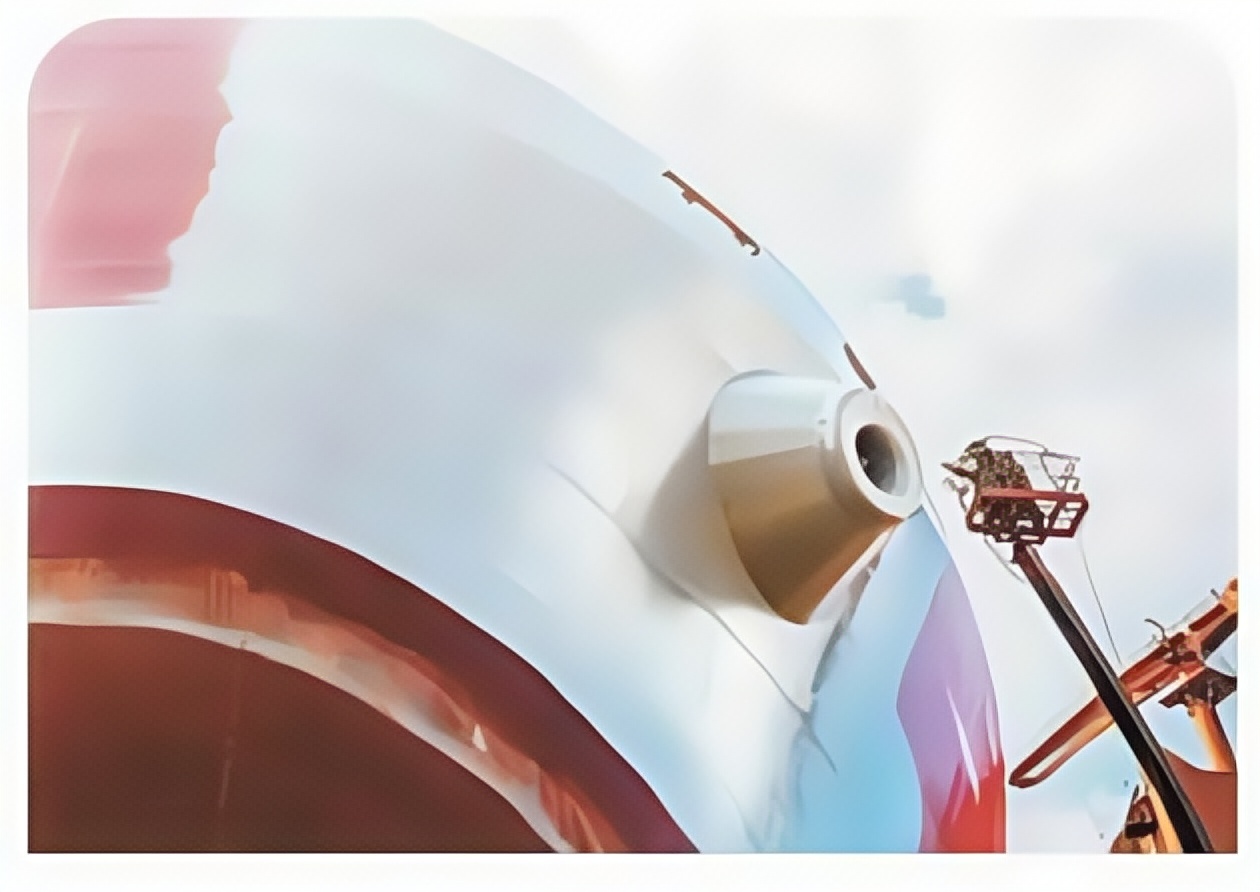

Waterproof and anti-corrosion for marine facilities

Applicable to corrosion protection for offshore oil and gas collection platforms, subsea equipment and offshore facilities

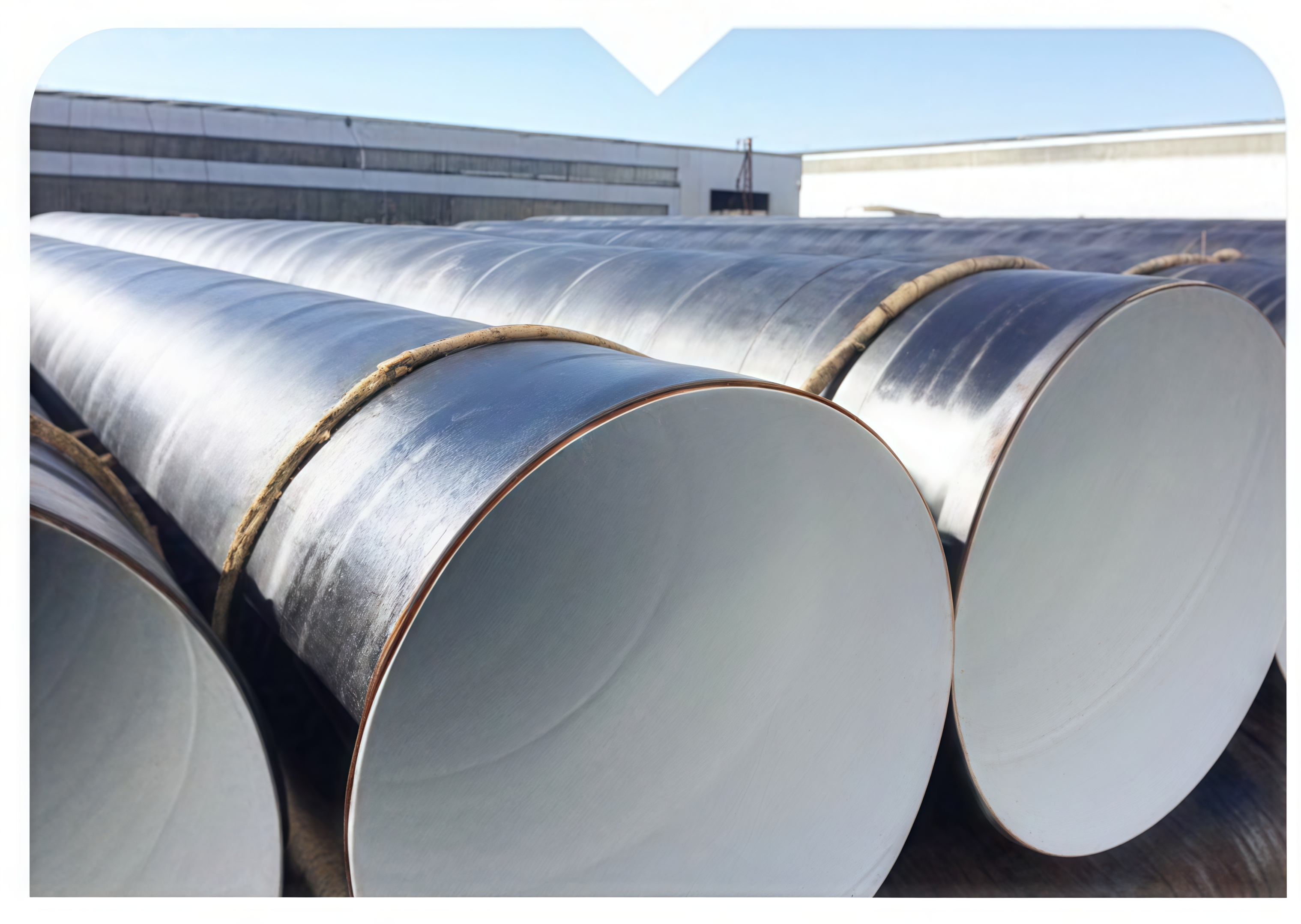

Waterproof and anti-corrosion of inner and outer walls of pipelines

Applicable to the anti-corrosion of inner and outer walls of various overhead and buried pipelines such as long-distance pipelines, oil pipelines, and insulation pipelines

Anti-corrosion of chemical workshop floors

Applicable to the floors of workshops in petrochemical, smelting plants, etc. that are subject to chemical corrosion

Municipal Engineering

Waterproofing is a very important part of municipal engineering. Whether in design or construction, it is necessary to ensure that buildings and structures are not corroded and the internal structure of the building is not harmed. The service life of the building can be effectively extended through the correct design and construction of waterproof materials. Polyurea materials have strong adhesion and can form a dense, impermeable elastic coating, thereby protecting the building structure well.

UNUIPAL ENGIREEBING

Spray polyurea coating system

Concrete bridge deck compression and waterproofing

Applicable to highways, urban elevated roads, urban expressways and other elevated bridge concrete decks

Tunnel concrete seepage and waterproofing

Applicable to all kinds of tunnel concrete lining seepage and waterproofing

Underground building waterproofing and seepage

Applicable to urban trenches, underground space buildings and other waterproofing and seepage

Pipeline inner and outer wall anti-corrosion and waterproofing

Applicable to insulation pipes, municipal sewage pipes and other types of overhead and direct buried pipes inner and outer wall anti-corrosion

Large steel structure anti-corrosion

Applicable to steel bridges and large steel structure anti-corrosion

Industrial flooring

Polyurea flooring retains the advantages of epoxy flooring, and its physical properties and construction performance are greatly improved compared to the latter.

Specifically:

(1) Better impact resistance and flexibility. Epoxy flooring has high hardness but insufficient flexibility, and is prone to cracking under external impact or temperature changes.

(2) Good wear resistance. Polyurea is called “wear-resistant rubber” and its wear resistance can reach 3 to 5 times that of epoxy flooring.

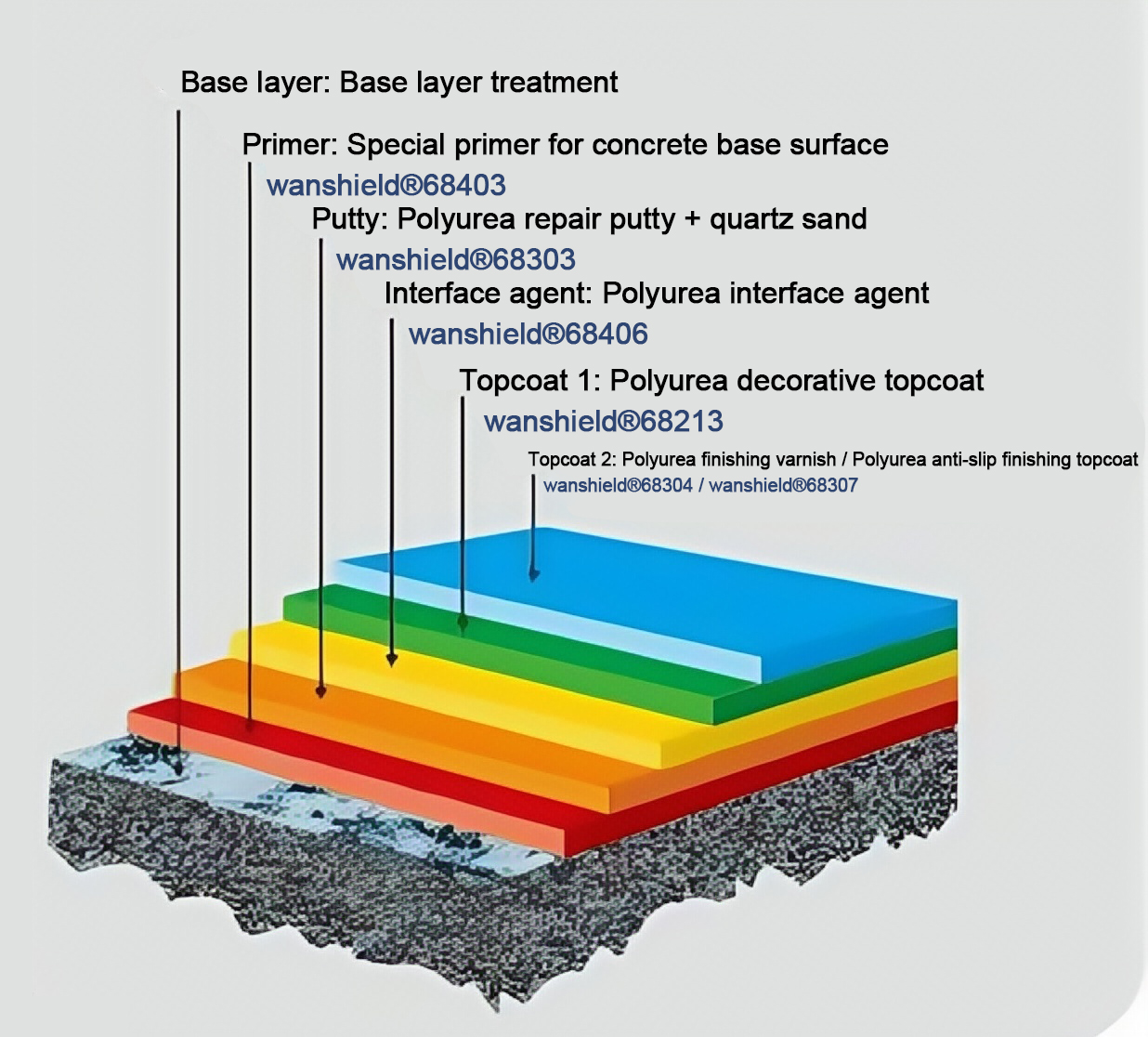

INDUSTRIAL FLOOR

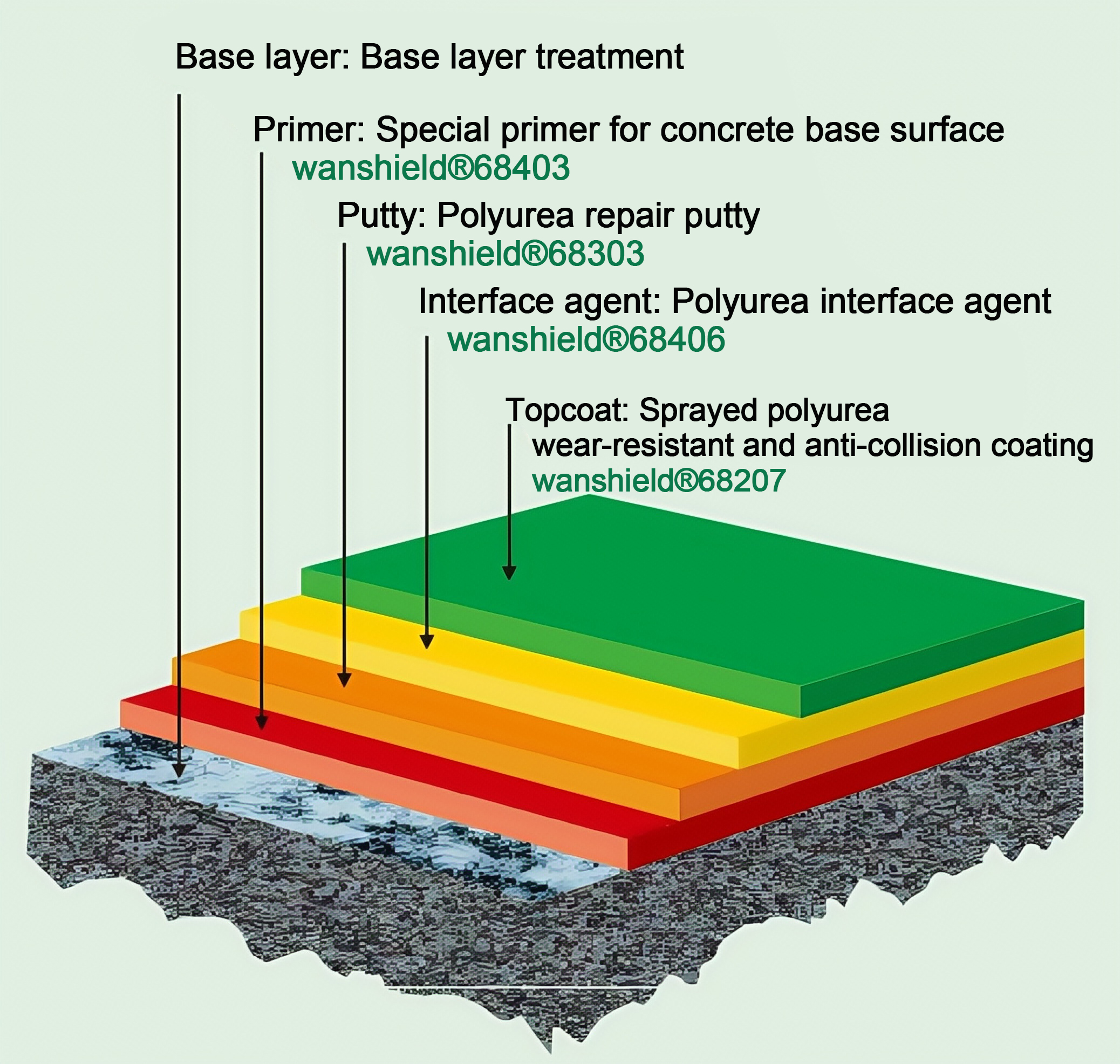

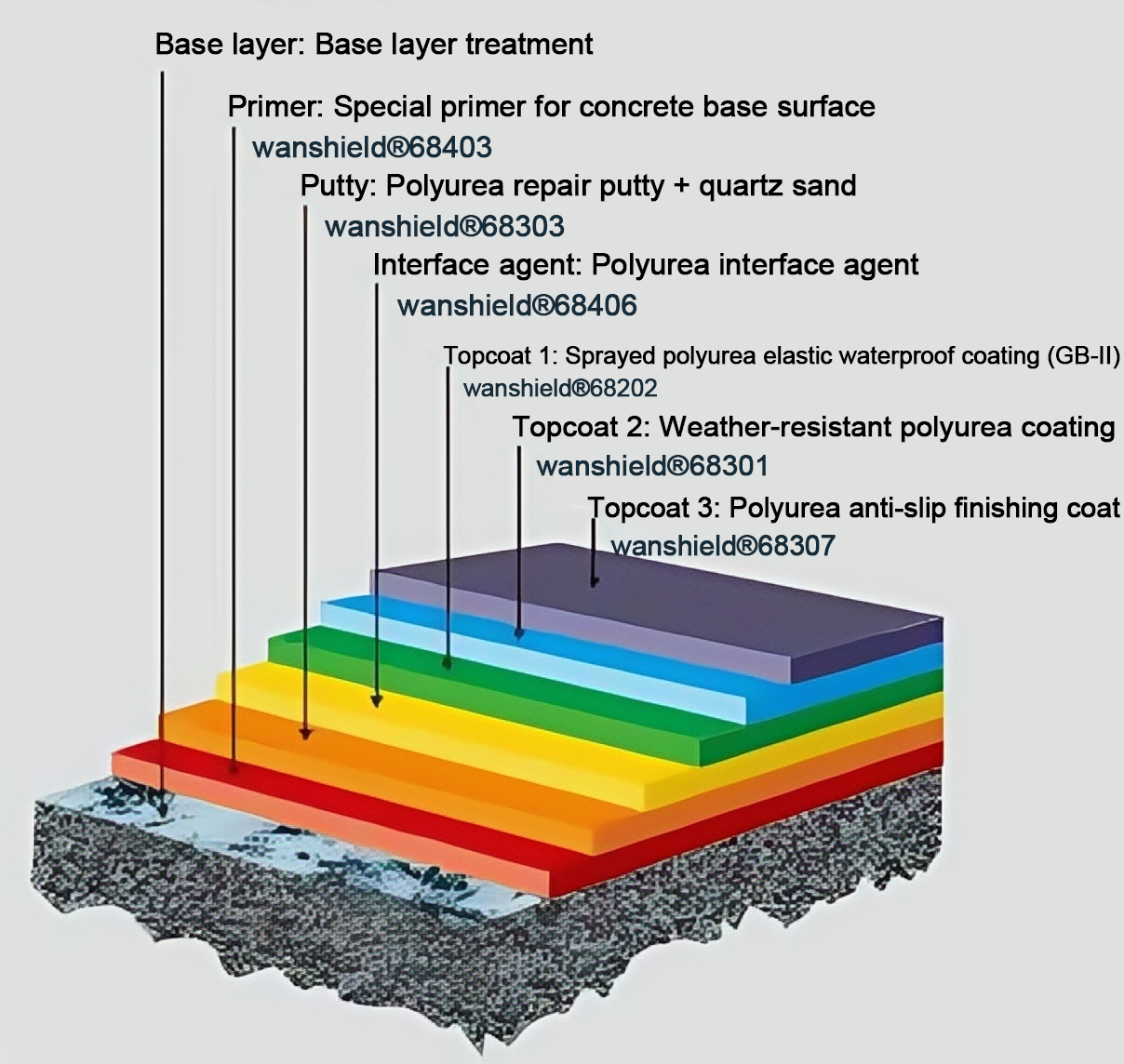

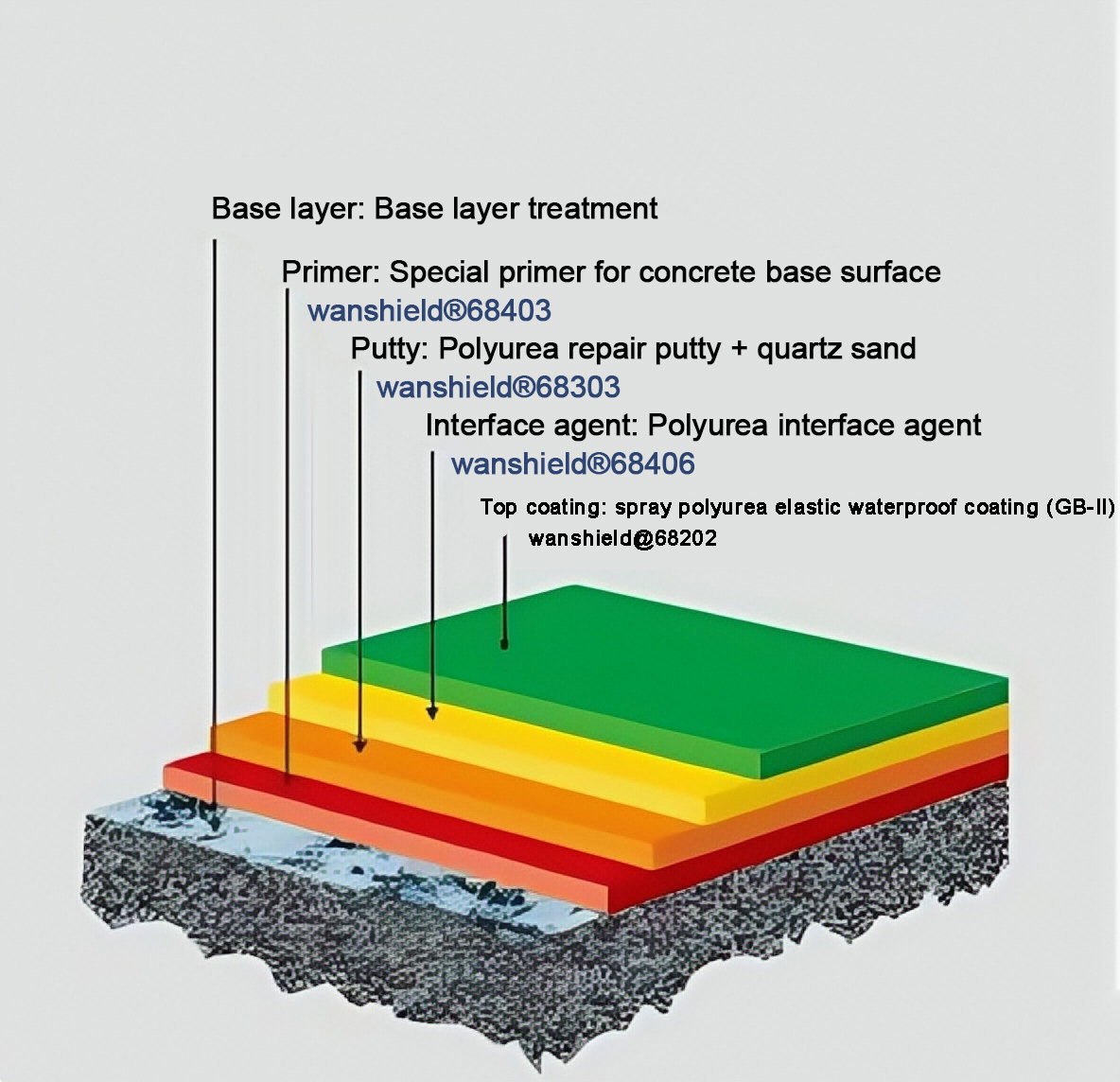

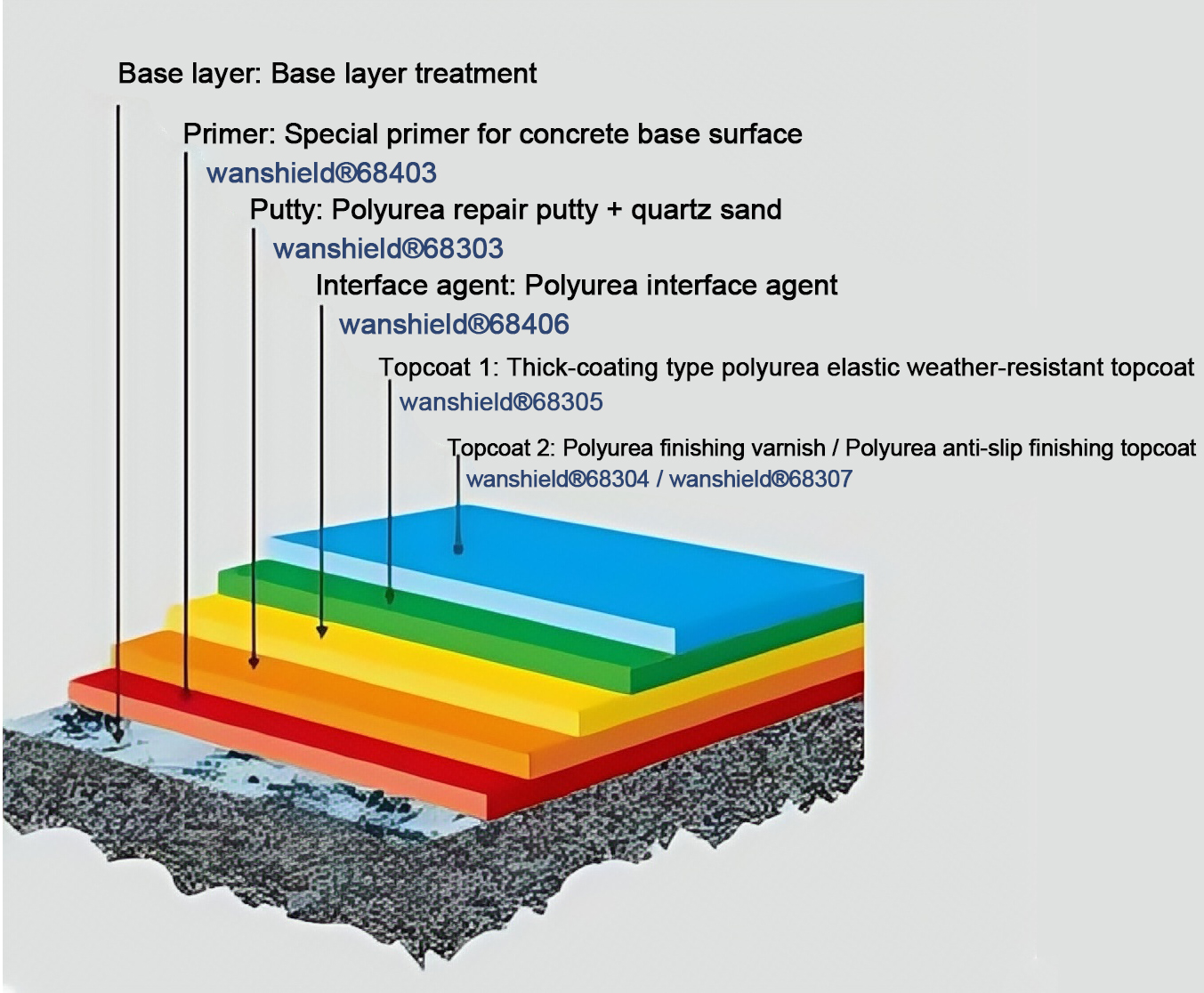

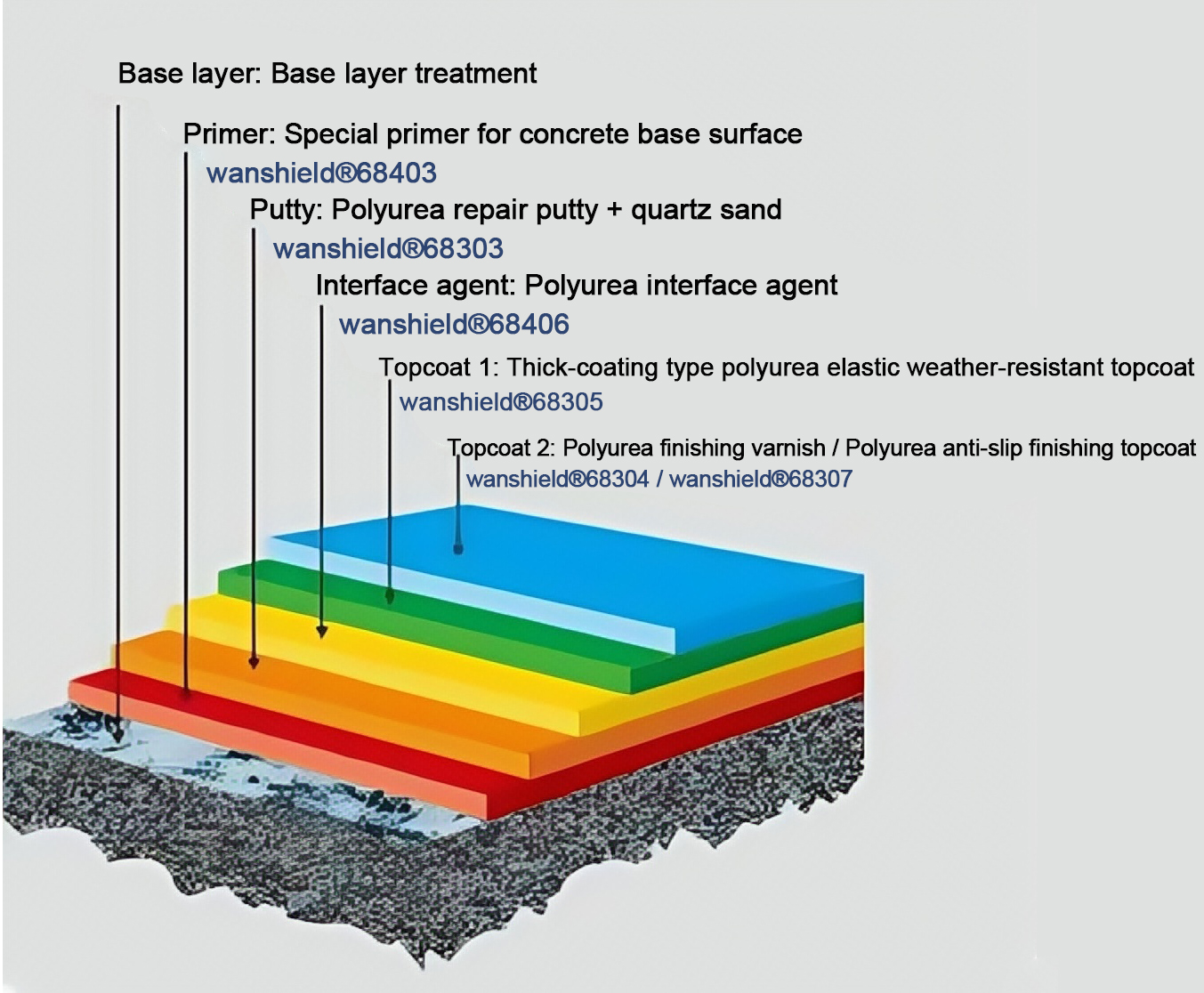

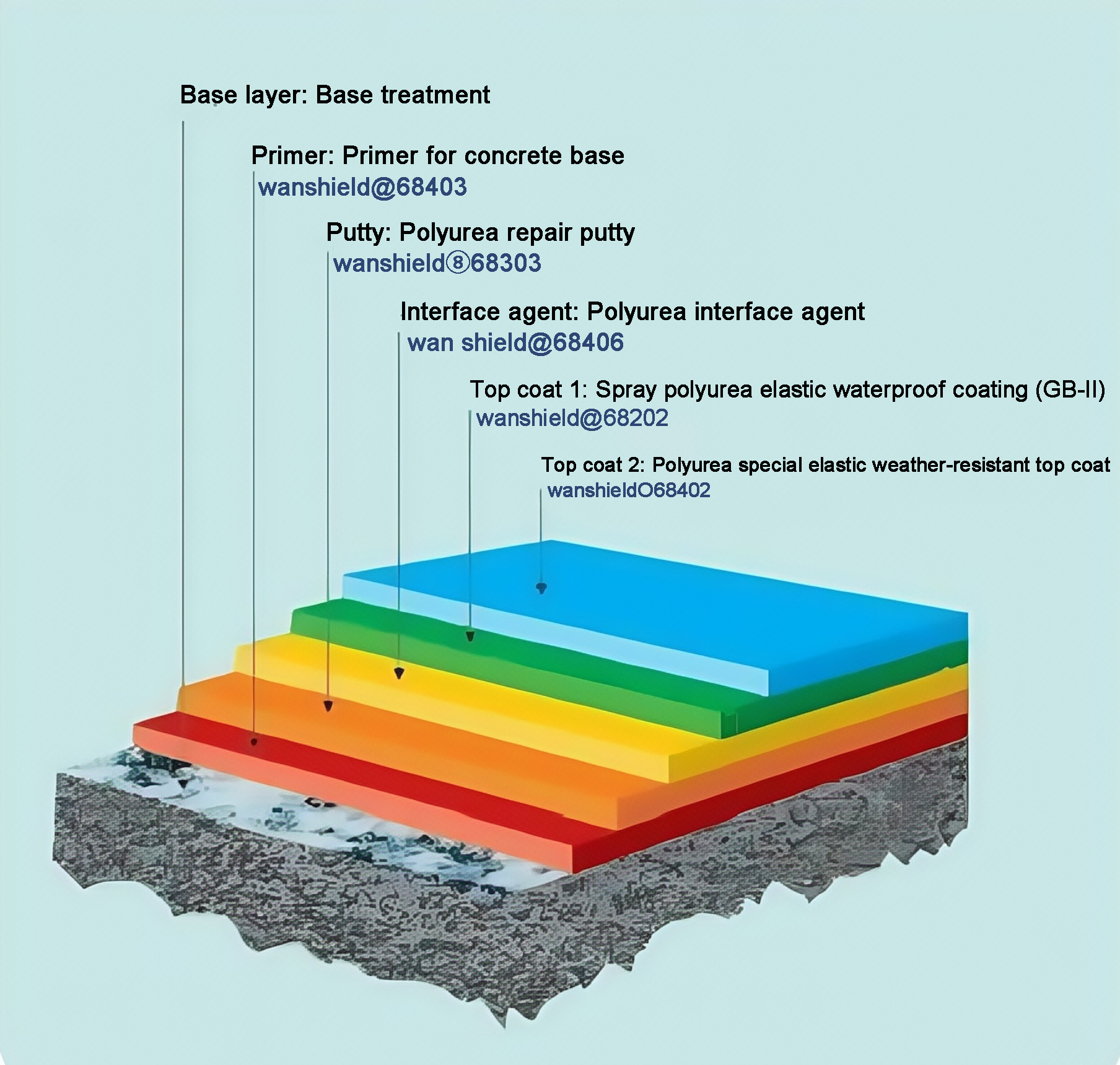

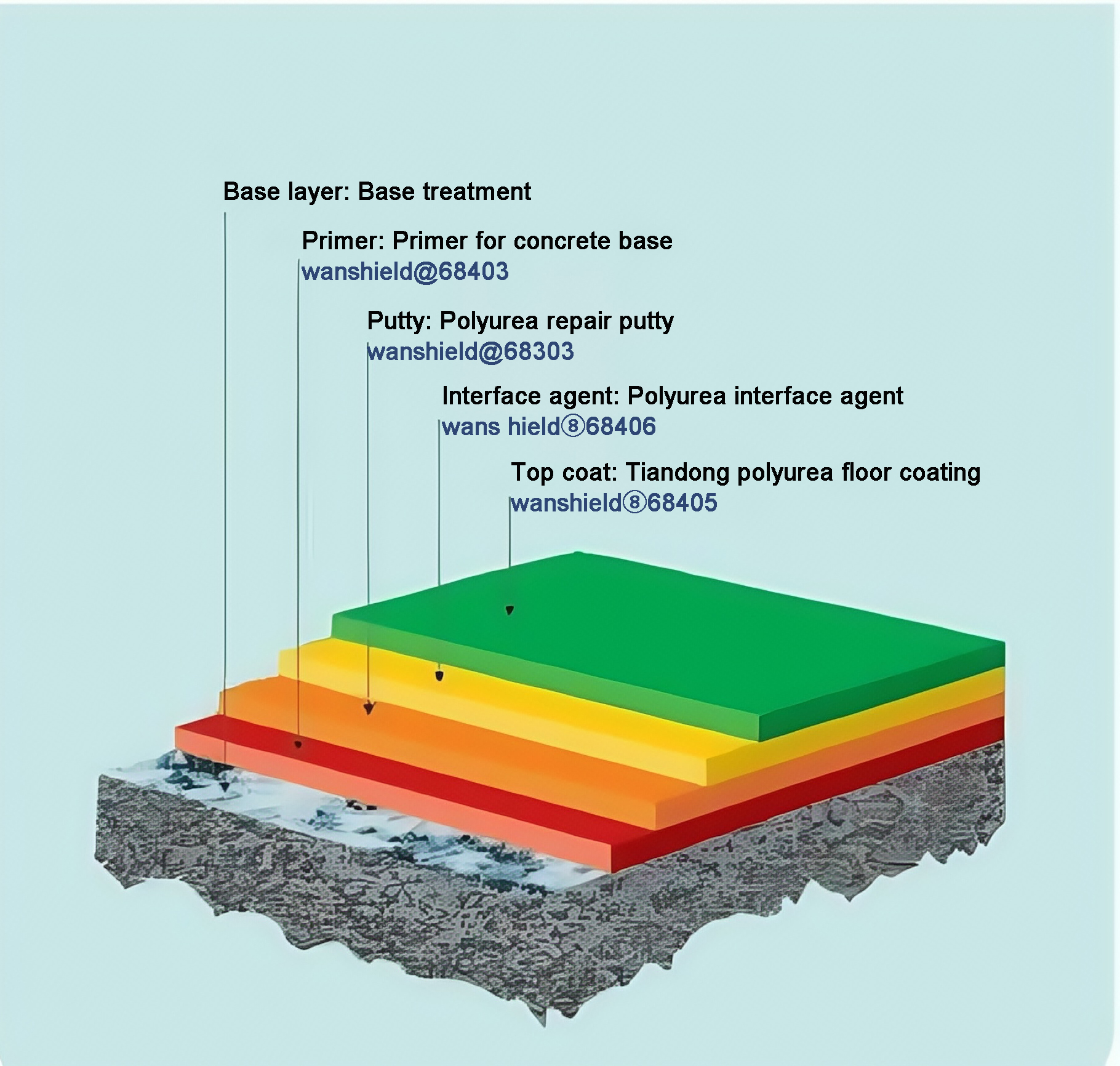

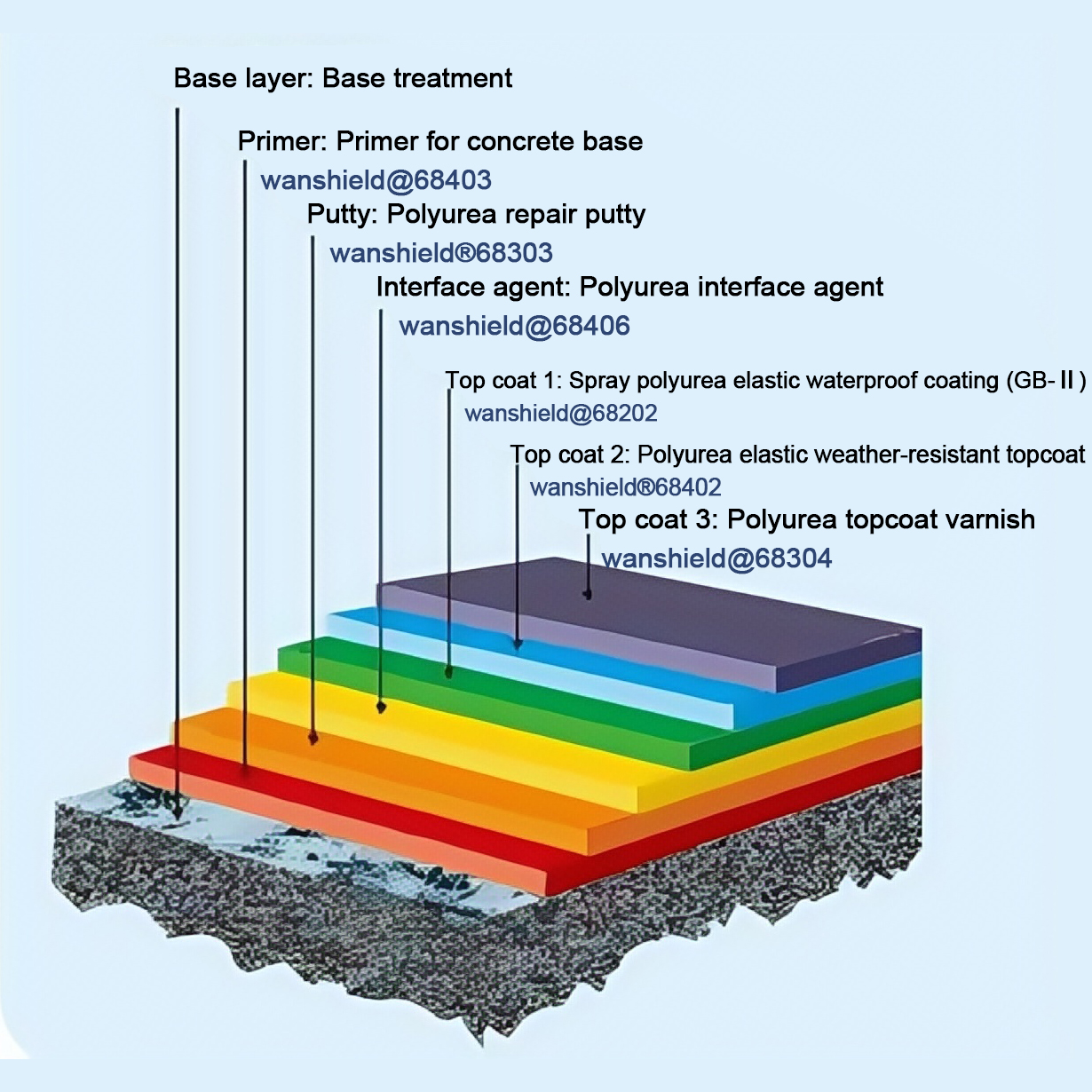

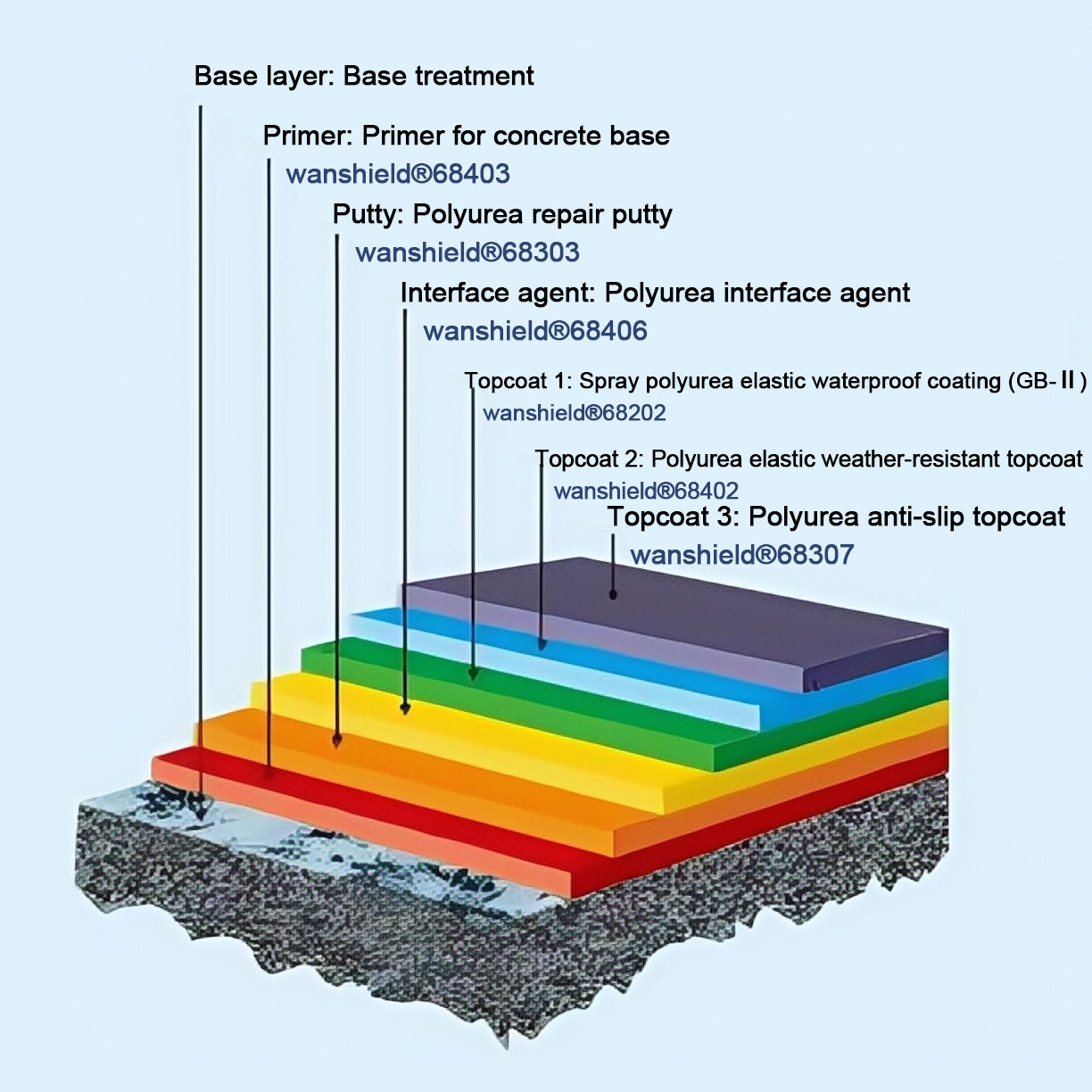

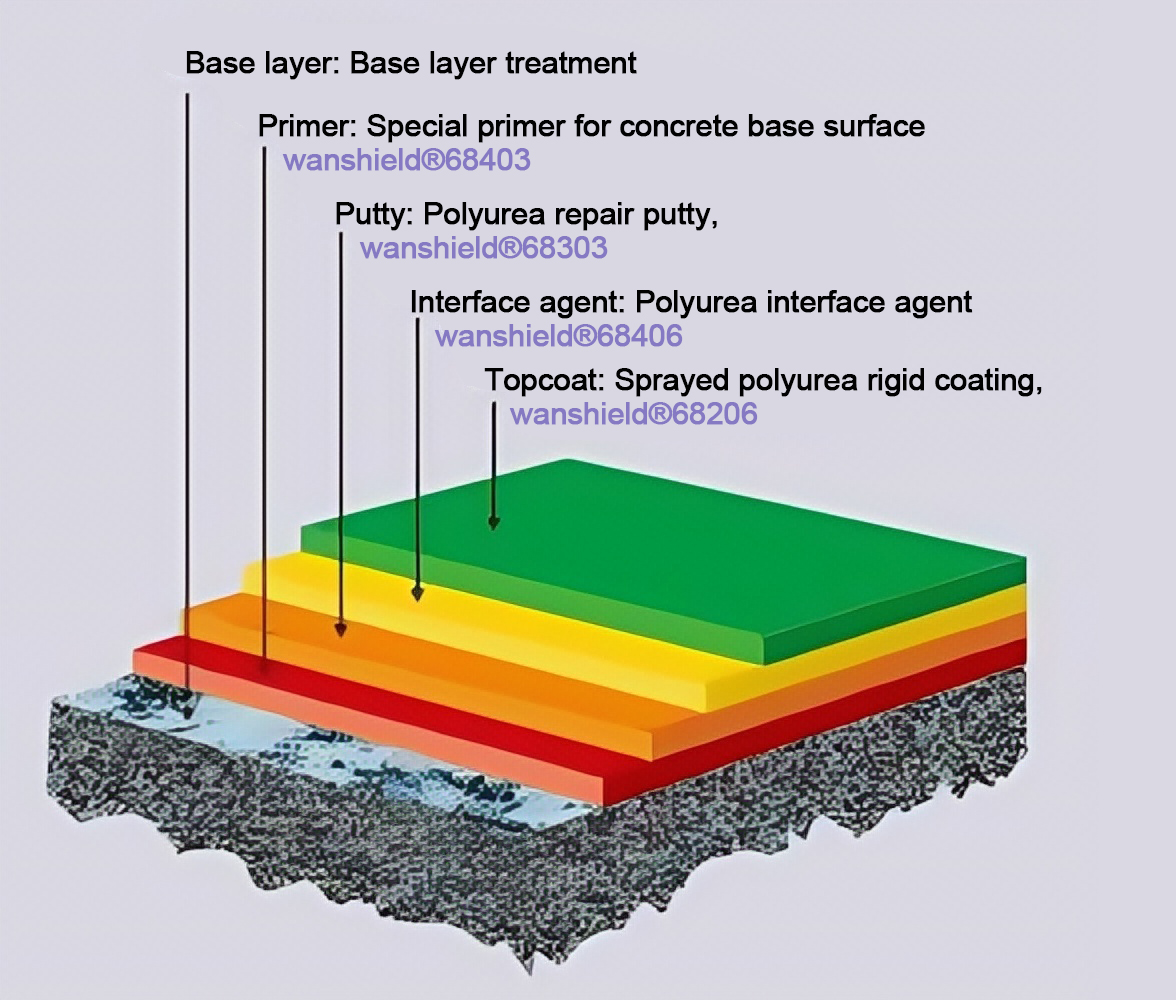

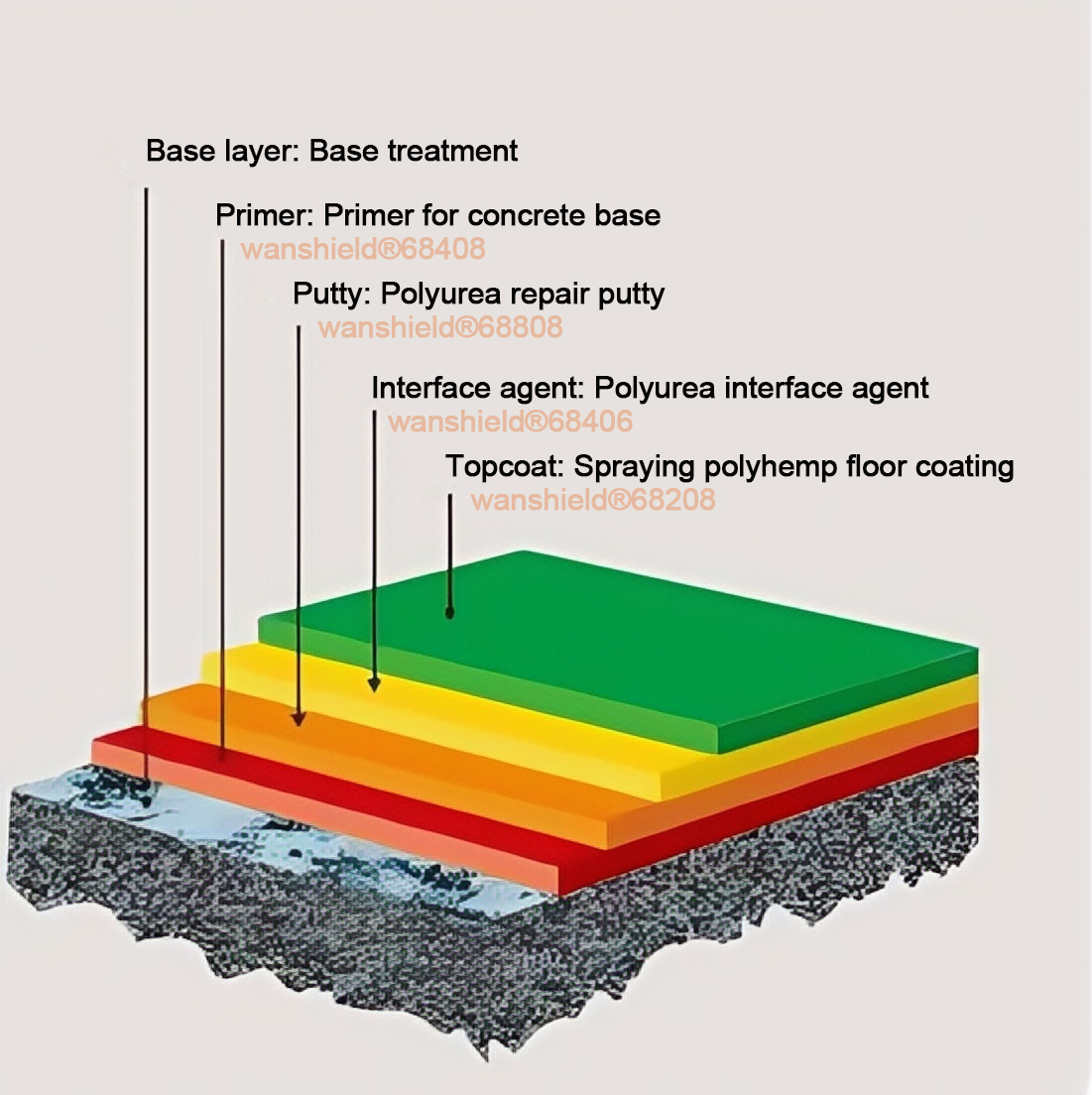

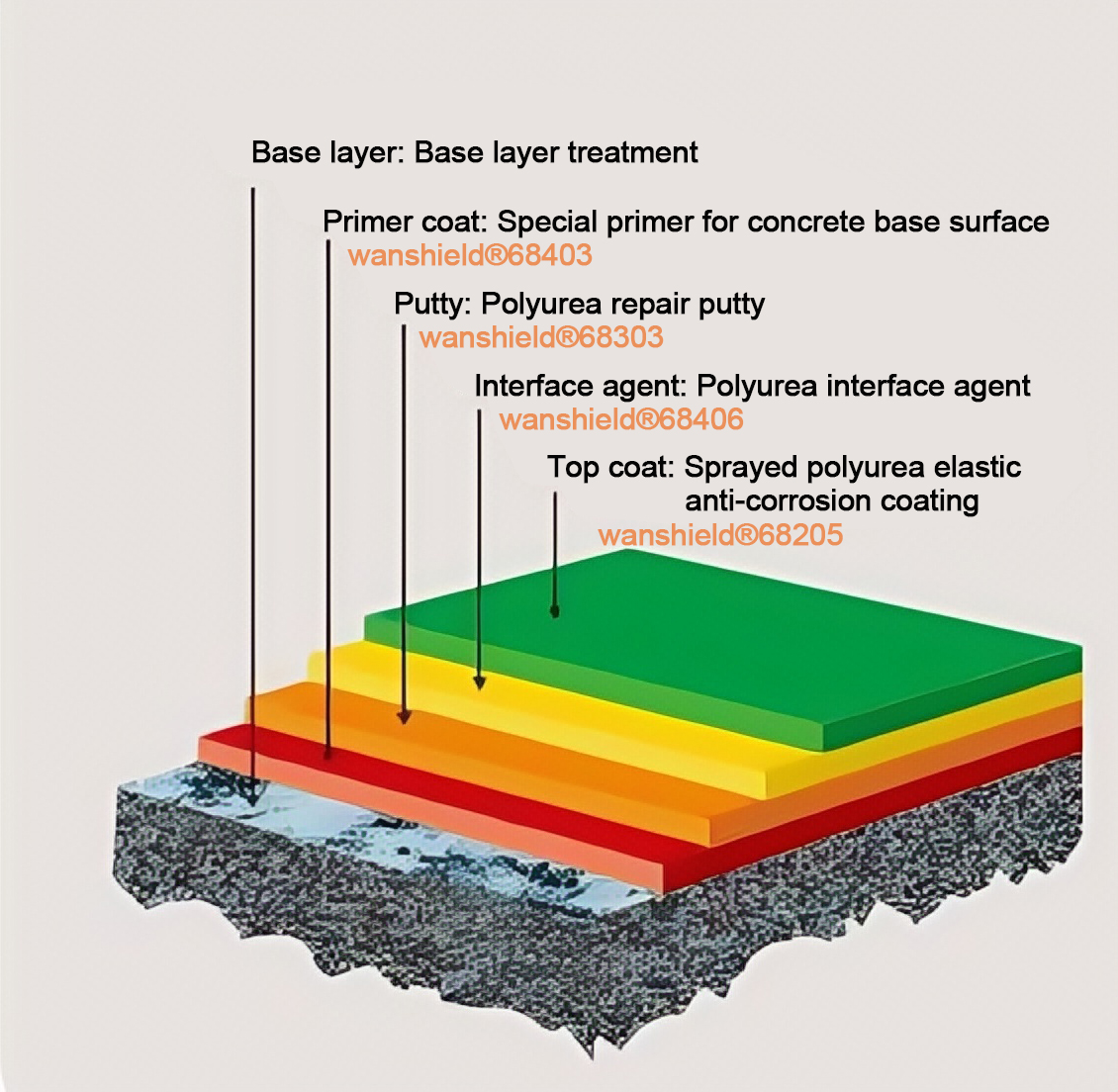

Spray polyurea coating system

Wear-resistant and compression-resistant in industrial areas

Applicable to sites with heavy friction and high impact resistance, such as production workshops, auto repair shops, parking lots, aircraft aprons, freight terminals, warehouses and other ground projects

Anti-slip and wear-resistant in commercial areas

Applicable to sites that require anti-slip and wear-resistant coatings, such as sidewalks, pedestrian bridges, department stores, office buildings and other floor coatings

Anti-corrosion and wear-resistant in industrial areas

Applicable to workshop floors in petrochemicals, smelters and other chemically corroded

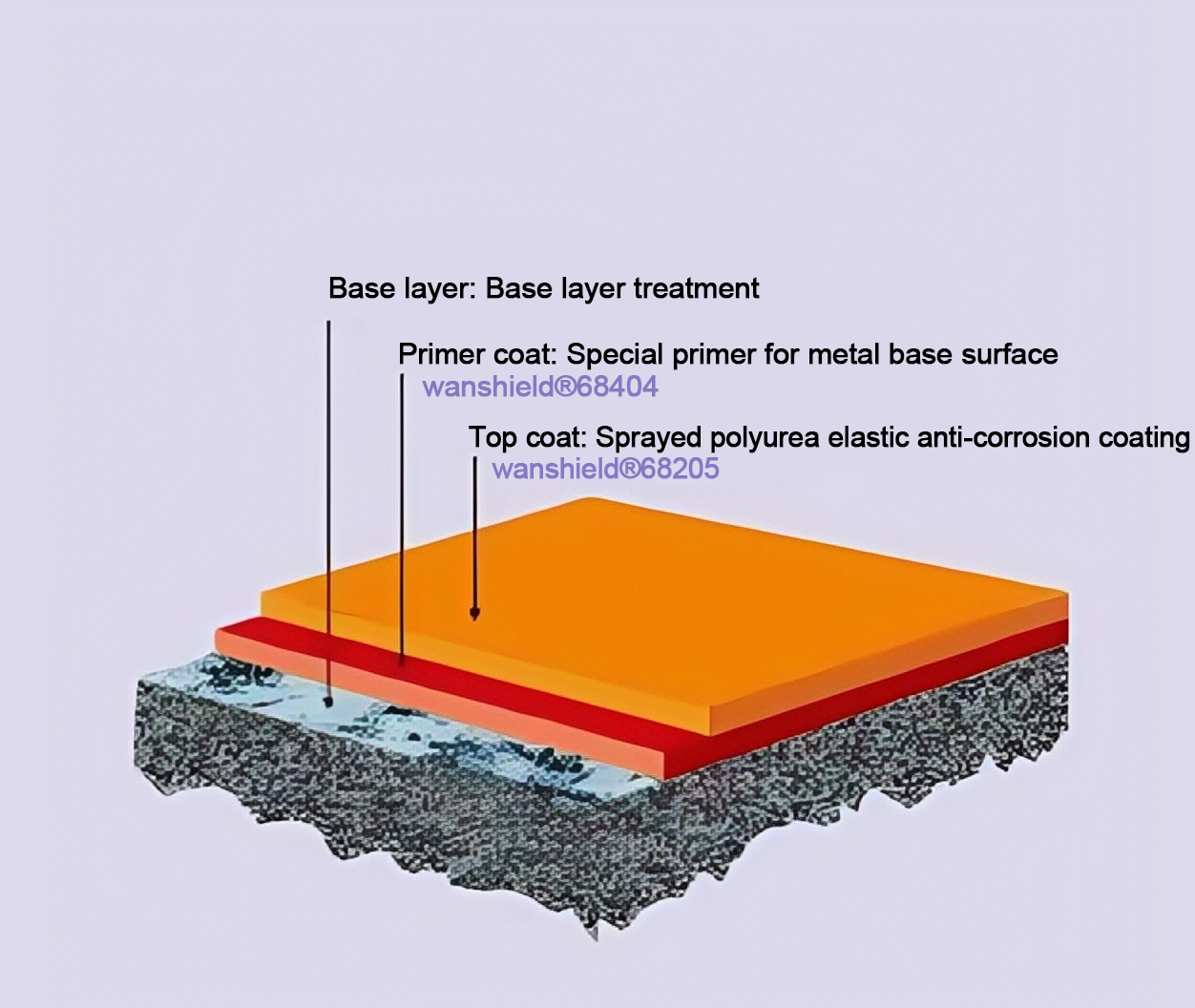

Metal speaker protection

Polyurea can also be applied to the surface of speakers, steel structures, and the bodies and chassis of various types of vehicles such as civilian trucks, vans, and military vehicles, playing a role in wear resistance, corrosion resistance, stone impact resistance, and decoration.

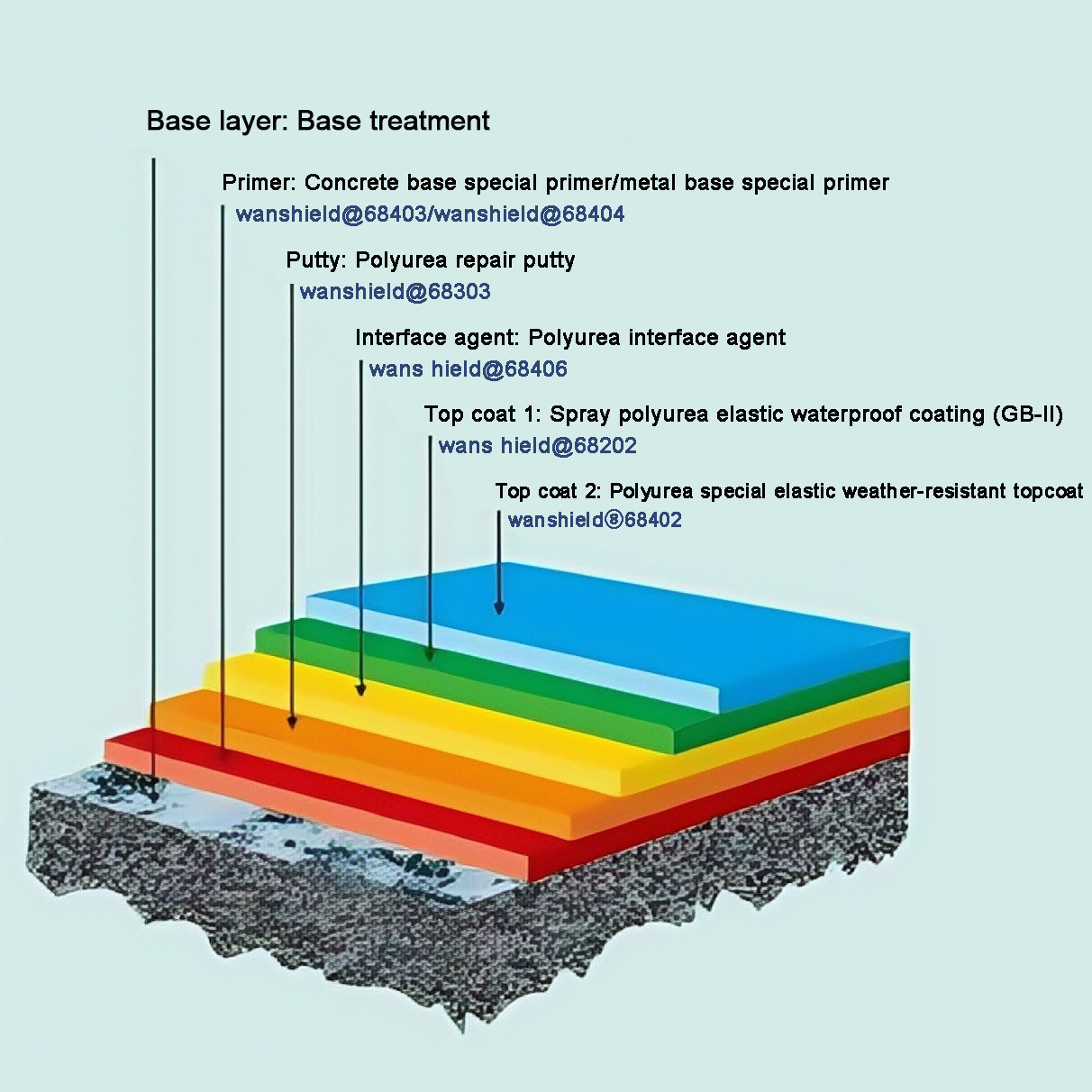

METAL, SPEAKER PROTECTION

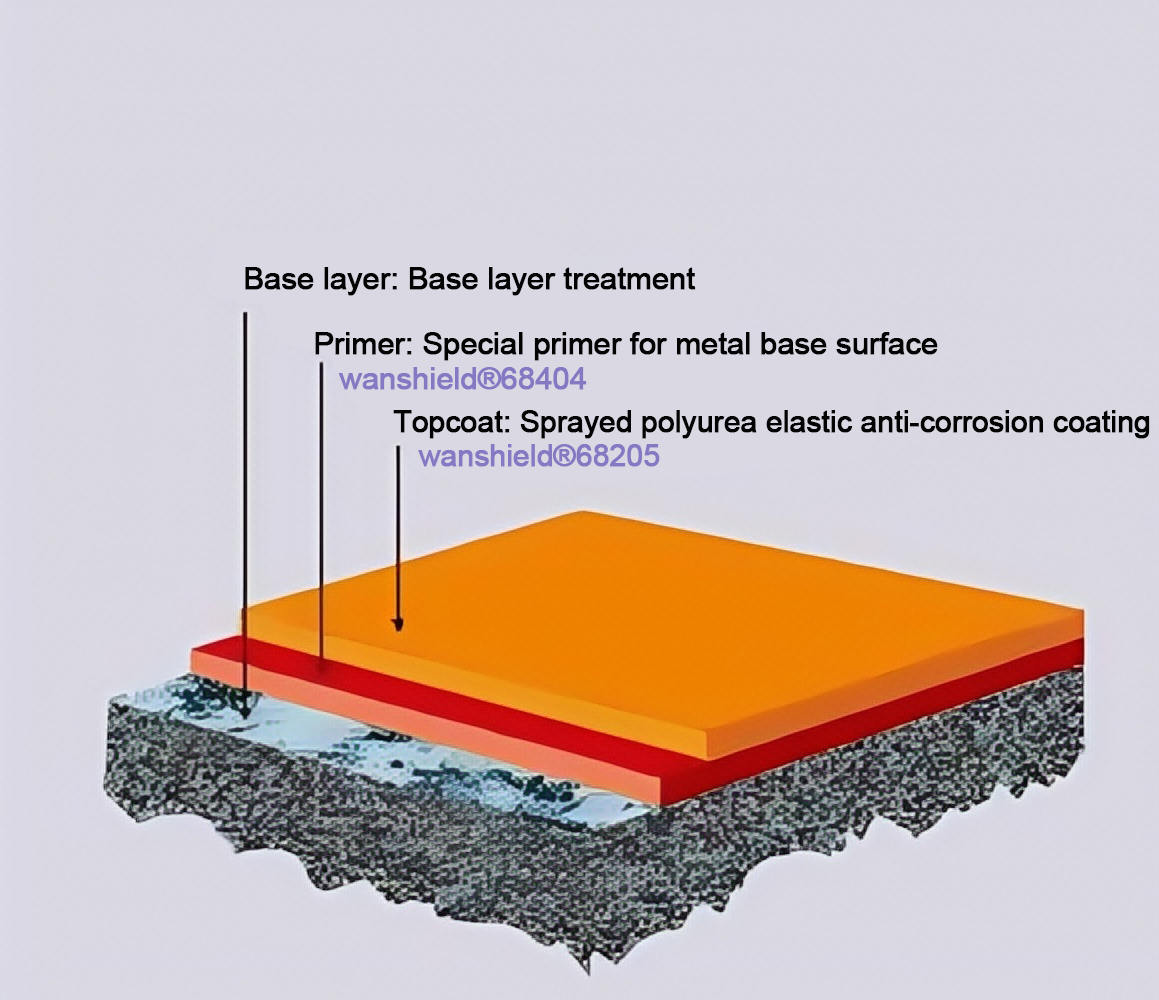

Spray polyurea coating system

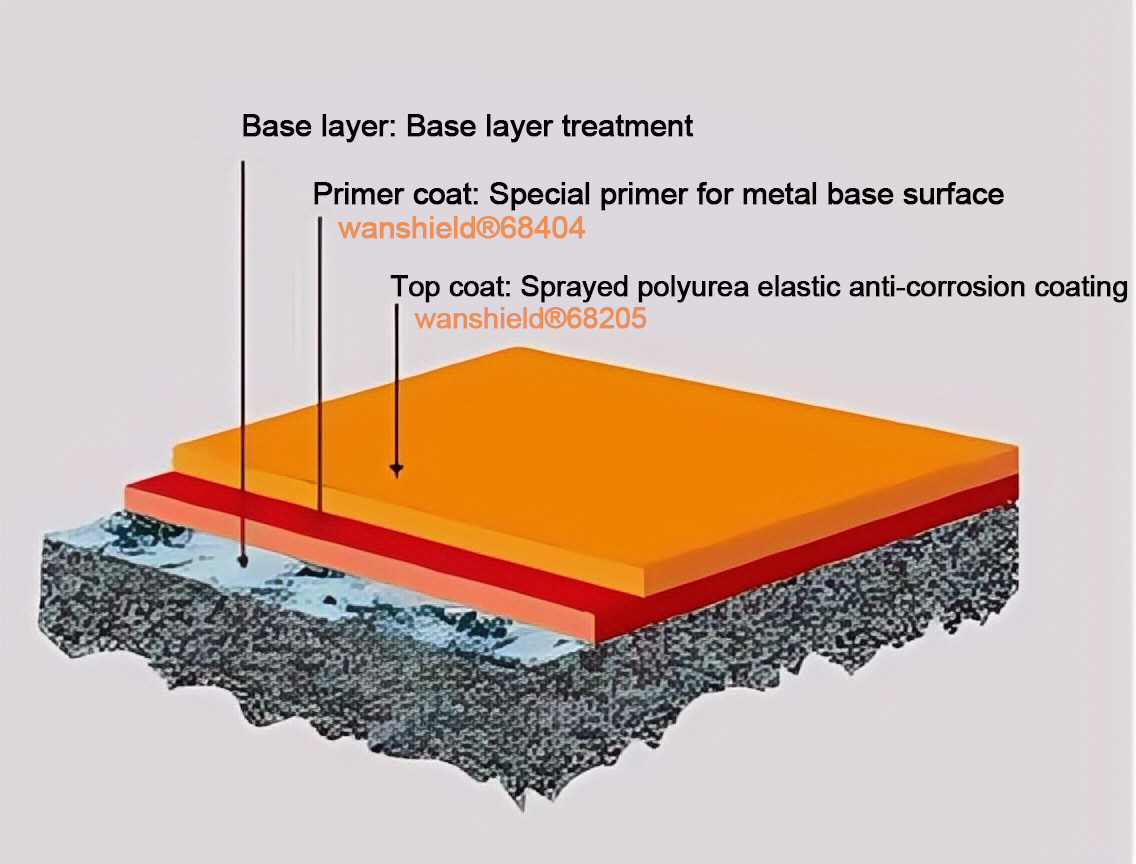

Metal surface anti-corrosion

Applicable to metal components, steel structures, color steel plates and other surface anti-corrosion projects

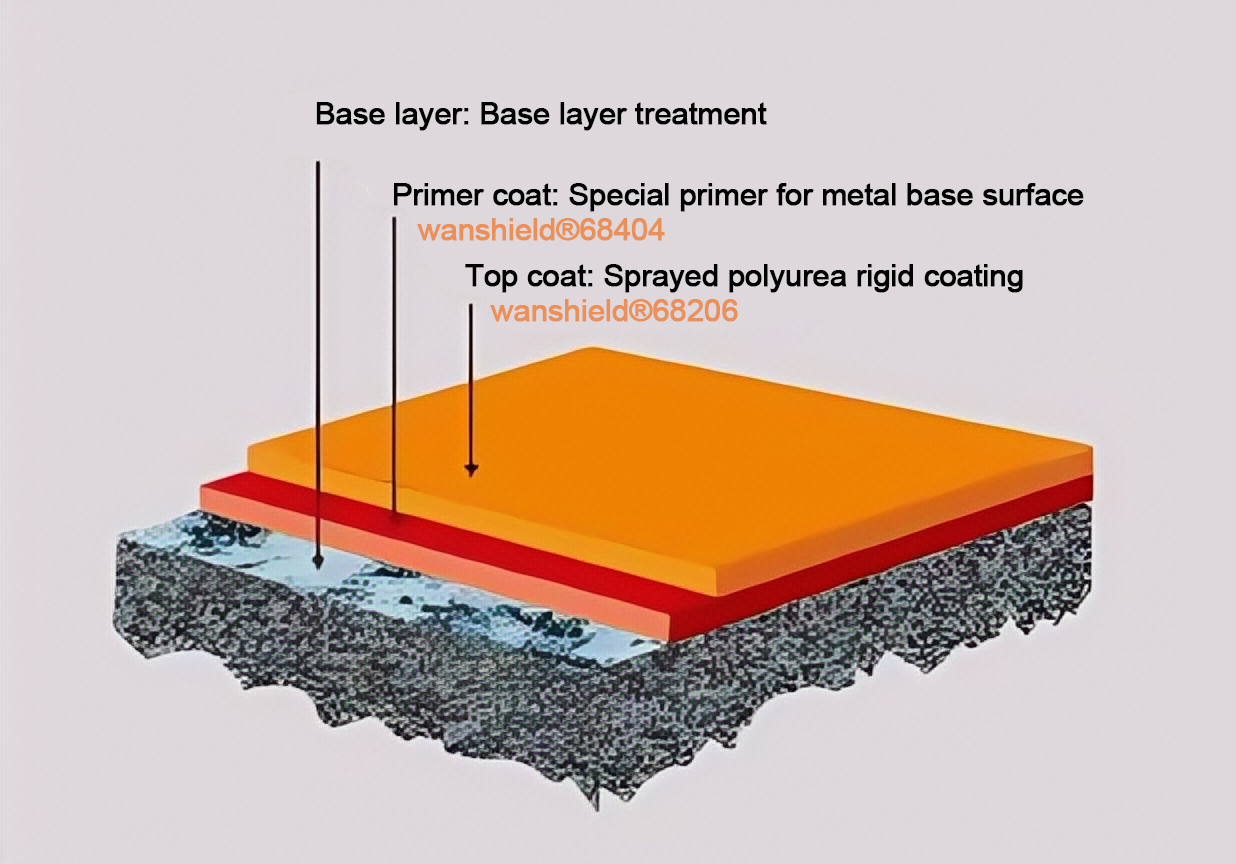

Metal substrate wear resistance

Applicable to metal substrates with requirements for anti-corrosion, wear resistance, and collision resistance

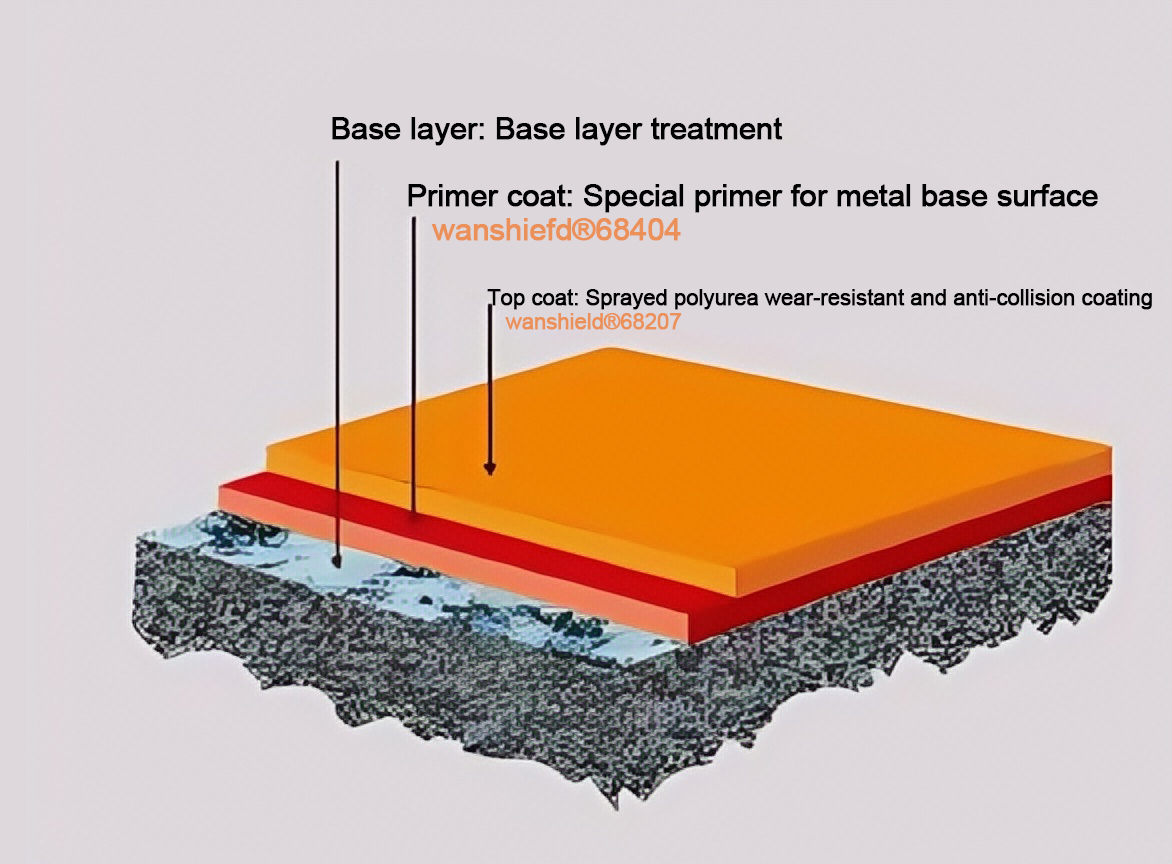

Automobile surface wear resistance and collision resistance

Applicable to surface protection mainly used for pickup truck compartments, car chassis, etc.

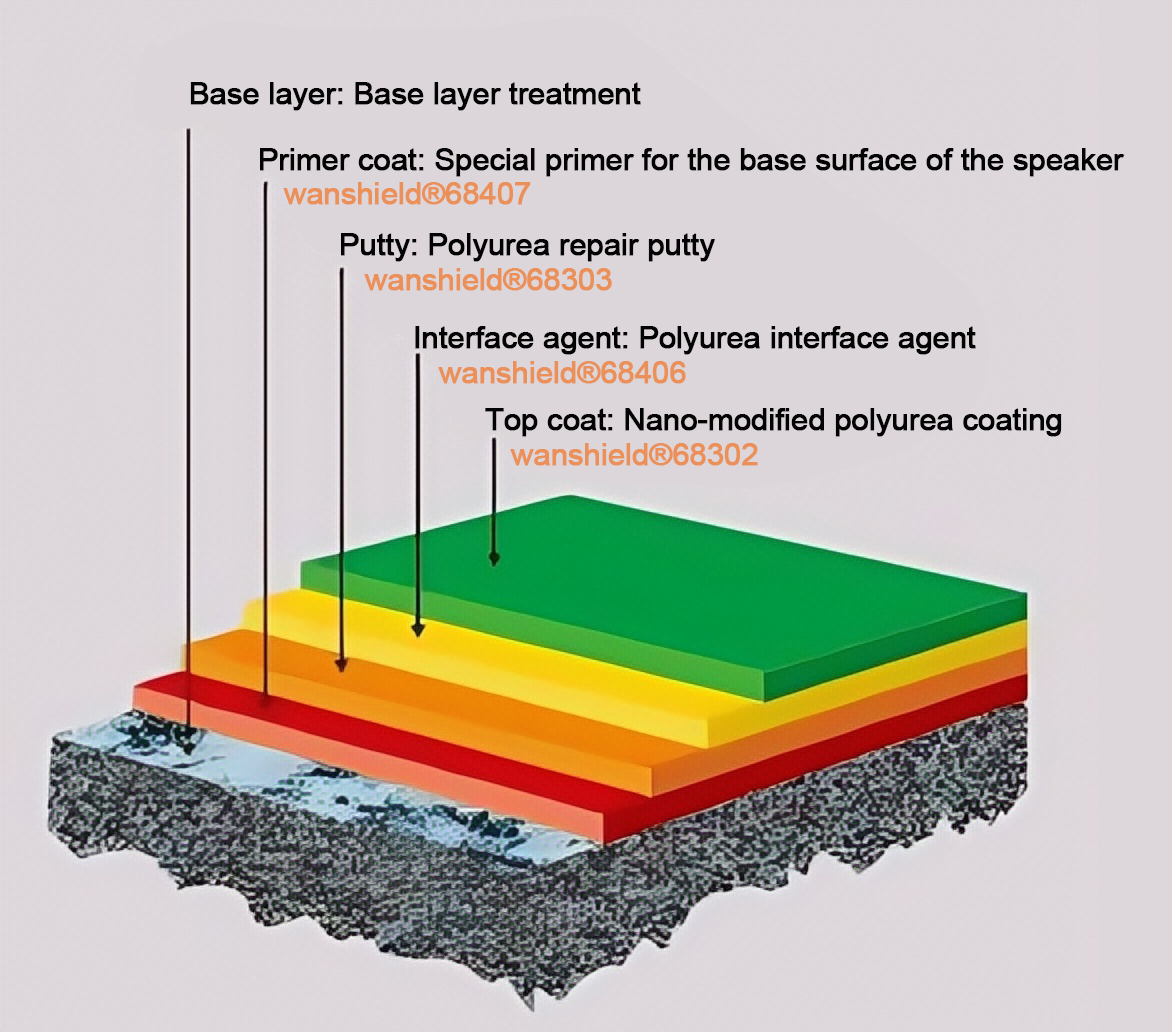

Speaker surface waterproof and wear resistance

Applicable to wooden speaker surface applications, waterproof, wear resistance, decorative effects, etc.

Metal substrate weathering protection

Applicable to outdoor occasions with weather resistance requirements, such as polyurea coating protection or other metal substrate protection