ES210 Solvent-Free Underwater Epoxy Coating

ES210 is a special two-component epoxy solvent-free coating that can be applied underwater with conventional tools. ES210 can be directly applied to steel structures and concrete.

SKU:

ES210 Solvent-Free Underwater Epoxy Coating

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Overview

WH-ES210 is a specialized two-component solvent-free epoxy coating, designed for underwater application using conventional tools. It can be directly applied to steel structures and concrete substrates, offering versatile corrosion protection solutions for submerged environments.

Product Features

- Superior Corrosion Resistance: Provides long-lasting protection against underwater corrosion.

- Underwater Applicability: Easily applied using traditional tools in submerged conditions.

- Eco-Friendly: Free of harmful solvent volatile gases, compliant with strict environmental standards.

- Cathodic Protection Compatibility: Works synergistically with cathodic protection systems.

- Excellent Adhesion: Bonds effectively to substrates with poor surface preparation.

Recommended Applications

Suitable for underwater steel structures and concrete surfaces, such as marine facilities, submerged pipelines, and hydraulic engineering components.

Technical Specifications

| Item | Details |

|---|---|

| Coating Type/Pigment | Modified epoxy resin/amine-special pigment |

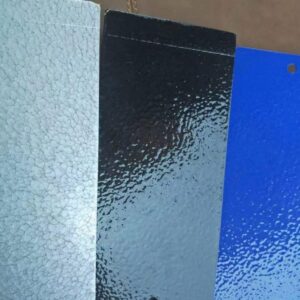

| Color | White, gray |

| Surface Finish | Semi-gloss |

| Mix Ratio | Weight ratio: 5 (base material) : 1 (curing agent) |

| Curing Agent | CES2100 |

| Specific Gravity | Approx. 1.4 kg/L |

| Volume Solids | 100% (theoretical value) |

| Flash Point | Base material: >100°C (>212°F); Curing agent: >100°C (>212°F) |

| Pot Life | 40 minutes (23°C/73.4°F) |

| Coverage Rate | 3.57 m²/L at 200 microns dry film thickness |

| Film Thickness | Wet film: 200 microns; Dry film: 200 microns |

| Application Method | Brush coating, roller coating |

| Diluent | None; Cleaner: TH003 |

| VOC Content | VOC-free, 100% solid epoxy product |

| Drying Time | Surface dry: Approx. 12 hours (23°C/73.4°F) |

| Recoat Interval | Minimum: 24 hours (23°C/73.4°F); Maximum: 7 days (surface roughening required if exceeded) |

| Recommended Primer | Self-priming or as recommended |

| Ambient Temperature | Min: 5°C (41°F) – Max: 40°C (104°F) |

| Substrate Temperature | Min: 5°C (41°F) – Max: 40°C (104°F) |

| Packaging | Two-component, 24 kg combined packaging |

| Storage & Shelf Life | Store in accordance with international guidelines; keep in well-ventilated areas, protected from high temperatures; tightly seal containers. Shelf life: 1 year. |

Application Guidelines

Surface Preparation

- Remove loose coatings, oil, and contaminants. For grease-contaminated surfaces, use soap or detergent to ensure thorough cleaning.

- Mechanically prepare the surface using pneumatic rotary equipment to remove all loose soil, dirt, and ensure a sound substrate profile.

Mixing & Dilution

- Mixing Procedure:

- Stir the base material for no more than 2 minutes until smooth and homogeneous.

- Slowly add the curing agent while continuously stirring for 3 minutes using a variable-speed electric mixer. Avoid overmixing to prevent accelerated curing and reduced pot life.

- Dilution: Do not dilute the material. Higher temperatures shorten pot life, while lower temperatures extend it.

Application

- Use brush or roller coating with solvent-resistant tools. Short, stiff bristle brushes or medium-fine nap rollers are recommended to ensure penetration into irregular surfaces.

- Visible brush marks are acceptable, but ensure proper film thickness. Apply a second coat to edges, bolt heads, flanges, and other complex areas to prevent pinholes or voids.

Safety Precautions

- Hazards: May cause eye and skin irritation. Vapors may irritate the respiratory tract of sensitive individuals and may cause skin allergic reactions.

- Protective Measures: Wear eye, ear, and skin protection; use appropriate respiratory masks to avoid inhalation of vapors. Wash skin thoroughly with water after use.

- First Aid:

- In case of eye contact: Flush with 清水 (clean water) for at least 15 minutes and seek medical advice.

- In case of skin contact: Remove contaminated clothing, wash with soap and water, and consult a physician if irritation persists.

- In case of inhalation: Move to fresh air; if breathing stops, perform mouth-to-mouth resuscitation and seek immediate medical attention.

- Handling Note: Exercise caution when handling mixed material, as exothermic reactions may generate heat. Use gloves to avoid direct contact.

Disclaimer

The information herein is provided in good faith, with each value derived from theoretical calculations based on the product formulation. Since the conditions of use are beyond the manufacturer’s control, no warranty is implied. This product is intended for professional use only. For inquiries, contact our Technical Support and Customer Service Center.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|