EP117 Lead-Free Epoxy Primer

EP117 is a two-component environmentally friendly epoxy primer that contains no heavy metals such as lead or chromium. Meanwhile, it boasts exceptional wear resistance, high solid content, strong versatility, and outstanding anti-corrosion performance.

SKU:

EP117 Lead-Free Epoxy Primer

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Overview

WH-EP117 is a two-component environmentally friendly epoxy primer that contains no heavy metals such as lead or chromium. It complies with the environmental protection standards for metal primers in the EU and the United States. Meanwhile, it boasts exceptional wear resistance, high solid content, strong versatility, and outstanding anti-corrosion performance.

Product Features

- Environmentally friendly, free of heavy metals like lead and chromium.

- Exhibits excellent resistance to seawater.

- Compatible with cathodic protection systems.

- Forms strong adhesion with various substrates, including galvanized parts, carbon steel, stainless steel, and aluminum.

- Offers superior wear resistance.

- Compatible with various topcoats, such as epoxy topcoats, polyurethane topcoats, alkyd topcoats, chlorinated rubber topcoats, and one-component acrylic topcoats.

Technical Parameters

| Item | Details |

|---|---|

| Binder Type/Pigment Type | Epoxy resin/anti-rust pigment |

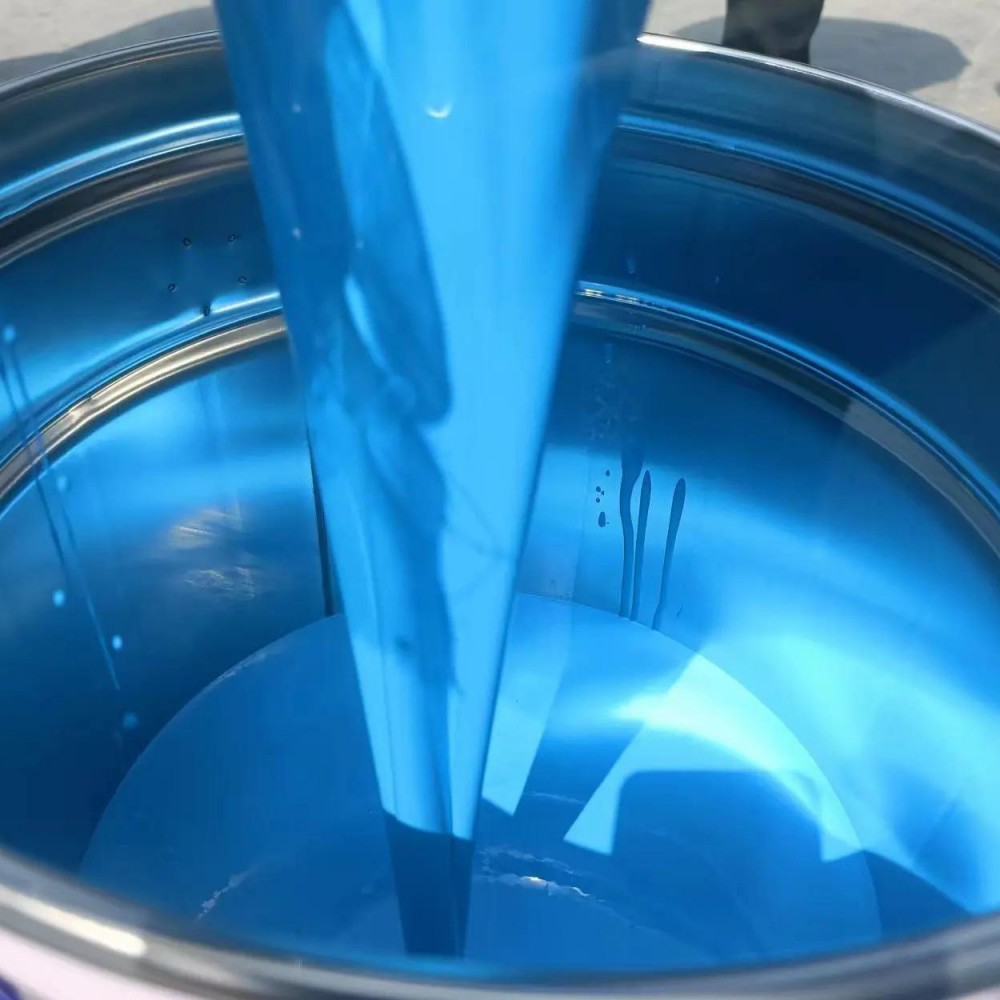

| Color | Light gray, black, and other colors |

| Surface Finish | Flat |

| Mixing Ratio | Weight ratio: 4.5 (base material) : 1 (curing agent) |

| Curing Agent | CEP1170 |

| Density | Approximately 1.4 kg/L |

| Volume Solids Content | 76±2% |

| Flash Point | 35℃ |

| Pot Life | 4 hours (23℃) |

| Theoretical Spread Rate | 7.6 m²/L (calculated at 100μm dry film thickness) |

| Single Coat Thickness | Wet film: 100μm; Dry film: 76μm |

| Application Methods | Brush painting, roller painting, airless spraying, air spraying |

| Airless Spraying Pressure | 17.5 MPa |

| Thinner | TH003 |

| Tool Cleaning Solvent | TH003 |

| Thinner Usage | Airless spraying: ≤25%; Air spraying: ≤50%; Brush painting: ≤5% |

| VOC Content | 450 g/L |

| Surface Dry Time | 1 hour (23℃) |

| Touch Dry Time | 2 hours (23℃) |

| Full Curing Time | 7 days (23℃) |

| Recoating Interval | 16 hours |

| Recommended Primer | Itself |

| Ambient Temperature | Minimum: 10℃ |

| Substrate Temperature | At least 3℃ above the dew point |

Packaging, Storage, and Shelf Life

- Two-component, packed in a 22 kg combination package.

- Storage must comply with national regulations. Store in a cool, well-ventilated place, avoiding excessive temperatures. Ensure the container is tightly sealed.

- Shelf life: 1 year.

Surface Preparation

- New Steel: Blast to Sa2.5 standard. Before final application, thoroughly clean the workshop primer damaged during storage and transportation and contaminated areas. Repair damaged parts with this product or other specified epoxy paints.

- Other Metals: Create a rough surface and clean the surface with a solvent to ensure it is dry and free of impurities.

- Maintenance: Remove grease with a suitable cleaner. Use high-pressure fresh water to remove salts and other contaminants. Remove loose rust and other loose materials by sandblasting or power tools. Smooth the edges, sweep away residues, and apply a complete paint film to achieve the original film thickness.

Mixing and Dilution

WH-EP117 is a two-component product with a specific component ratio. It is necessary to mix the entire contents of each paint bucket before use. First, stir the base material until uniform, which should not take more than 2 minutes. Then, slowly add the curing agent and stir for 3 minutes. A variable-speed power stirrer is recommended. Avoid over-stirring, as this will accelerate curing and shorten the product’s pot life. High temperatures will shorten the mixture’s pot life, while low temperatures will extend it.

Application

WH-EP117 can be applied by airless spraying, brush painting, and roller painting. In confined spaces, good ventilation is essential. Avoid applying in the presence of standing water or rain. When using airless spraying, a 0.53mm nozzle and an output pressure of 17.5 MPa are recommended to achieve a good spraying effect.

Safety Precautions

- Warning: Irritating to eyes and skin. Vapors may cause respiratory allergies in sensitive individuals. May cause skin allergic reactions.

- Avoid inhaling vapors. Do not contact eyes or skin. Wear protective equipment for ears, eyes, and skin. Use a suitable respirator to avoid potential respiratory irritation. Thoroughly wash skin after use. Wash clothes before reuse.

- In case of no breathing, perform mouth-to-mouth resuscitation and seek medical attention immediately. If eyes are accidentally exposed, rinse with clean water for at least 15 minutes and seek medical attention immediately.

Statement

The information listed in this document is reliable. Each provided value is a theoretical data calculated from the product formula. If needed, our company can inform you of the internal common measurement and determination methods for any of the above-given data. Since the usage conditions are beyond the control of the manufacturer, this information is not provided as a guarantee. The product is for professional use only. If you have any questions, please contact our company.

Our Technical Support and Customer Service Center is willing to provide you with consultations and application technical services regarding the product. Welcome to contact us by letter or phone.

Our Technical Support and Customer Service Center is willing to provide you with consultations and application technical services regarding the product. Welcome to contact us by letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|