AC112 Acrylic Primer

WH-AC112 is a primer formulated with acrylic resin and anti-rust pigments, featuring excellent adhesion and anti-rust performance. It offers good construction properties, fast drying, and superior anti-corrosion performance.

SKU:

AC112 Acrylic Primer

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

AC112 Acrylic Primer

| Overview | WH-AC112 is a primer formulated with acrylic resin and anti-rust pigments, featuring excellent adhesion and anti-rust performance. It offers good construction properties, fast drying, and superior anti-corrosion performance. |

| Product Characteristics | Fast-drying, good corrosion resistance, excellent construction performance |

| Recommended Uses | Suitable for medium to severe corrosion environments |

| Technical Parameters | |

| Resin Type / Pigment Type | Acrylic resin / anti-rust pigments |

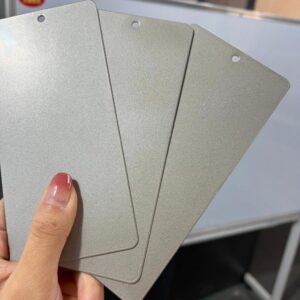

| Color | Iron red, light gray, or customized according to user requirements |

| Surface Finish | Semi-gloss |

| Density | Approximately 1.4 kg/L |

| Flash Point | 25°C (77°F) |

| Theoretical Coverage Rate | 12.5 m²/L at 40μm dry film thickness |

| Single Coat Film Thickness | Wet film: 80μm; Dry film: 40μm |

| Application Methods | Airless spraying, brushing, roller coating |

| Nozzle Size (Airless Spraying) | 0.33-0.48mm |

| Outlet Pressure (Airless Spraying) | 15 MPa |

| Thinner | TH015 |

| Tool Cleaning | TH015 |

| Volatile Organic Compounds (VOC) | 590 g/L |

| Drying Time | Touch-dry: 1 hour (23°C) |

| Recoating Time | Minimum 4 hours at 23°C, maximum no limit |

| Substrate Temperature | Minimum: 3°C above dew point; Packaging: Single-component, 20 kg packaging. |

| Storage and Shelf Life | The product must be stored in accordance with national regulations. Store in a cool, well-ventilated place away from excessive heat. Containers must be tightly sealed. Shelf life: 1 year. |

| Application Guidelines | |

| Surface Preparation | AC112 is designed for direct application to steel surfaces pre-treated by sandblasting to Sa2.5 standard. Surfaces should be free of grease, moisture, dust, and other impurities. |

| Mixing and Dilution | AC112 is a single-pack product. Stir the coating to obtain uniform viscosity, with stirring time not exceeding 2-3 minutes. Dilution is generally not required or recommended. If necessary for construction purposes, a small amount of thinner (5% or less) may be added, subject to local regulations on VOCs and air quality. |

| Application | AC112 can be applied by traditional spraying, roller coating, or airless spraying. Nozzle size: 0.33-0.48mm, outlet pressure: Yantai Wanhua Energy Conservation and Environmental Protection New Materials Co., Ltd. 1/2 |

AC112 Acrylic Primer

15 MPa. For optimal results, ensure equipment and fluid lines are clean and free of water and solvents. Carefully control to achieve correct and uniform film thickness. Ventilation: Good ventilation in all parts of enclosed areas is critical for the safety of applicators and the proper performance of this product. It is recommended that AC112 should not be applied too thickly.

Safety Measures

Warning: May cause eye and skin irritation. Vapors may cause respiratory irritation in sensitive individuals. May cause skin allergic reactions. Avoid breathing vapors. Do not contact eyes or skin. Use eye, ear, and skin protection equipment. Use a suitable mask to avoid potential respiratory irritation. Wash skin thoroughly with water after use. Consult a doctor if discomfort occurs. Wash clothing before reuse. If breathing stops, give artificial respiration, preferably mouth-to-mouth, and seek medical attention. If eyes are accidentally exposed, rinse immediately with water for at least 15 minutes and seek medical help promptly.

Statement

The information listed in this document is reliable. Each value provided is a theoretical data calculated from the product formula. If needed, our company can inform the internal common measurement and determination methods for any of the above data. Since the conditions of use are beyond the control of the manufacturer, this information does not constitute a guarantee. The product is for professional use only. If you have any questions, please contact our company.

Our Technical Support and Customer Service Center is willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|