Spray Polyurea Waterproof Coating

The Spray Polyurea Waterproof Coating is a new-generation polyurea elastomer material formed by on-site spray curing of raw materials including semi-prepolymer, resin, amine chain extender, additives, and pigments. This solvent-free and pollution-free material features convenient construction, and forms a continuous, dense, and seamless coating with excellent physical and chemical properties and stability.

SKU:

One-Component Solvent-Based Polyurea Waterproof Coating-1

Category: Polyurea Coating

Tags: Coating, Polyurea Coating

Description

Product Overview

The Spray Polyurea Waterproof Coating is a new-generation polyurea elastomer material formed by on-site spray curing of raw materials including semi-prepolymer, resin, amine chain extender, additives, and pigments. This solvent-free and pollution-free material features convenient construction, and forms a continuous, dense, and seamless coating with excellent physical and chemical properties and stability.

Performance Characteristics

- Mechanized construction effectively avoids engineering quality hazards caused by manual operation;

- The coating gels within 8 seconds and can bear loads within 30 minutes after completion, significantly mitigating the impact of cross-construction;

- Suitable for vertical and curved surfaces without sagging, ideal for irregular components;

- Seamless integral film formation fundamentally eliminates leakage hazards;

- Dense coating effectively prevents the penetration of corrosive media, providing overall protection and extending the service life of construction projects;

- Free of VOC emission and heavy metals, compliant with international development trends of waterproof materials, and classified as a green environmental protection product;

- All test indicators meet or exceed the requirements of GB/T 23446-2009 Spray Polyurea Waterproof Coating.

Applications

- Waterproof renovation of old rooftops;

- Integrated waterproofing and thermal insulation projects for rooftops of factories, hotels, etc.;

- Waterproof and anti-corrosion projects for metal components, steel structures, color steel plates, etc.;

- Large-span rooftop waterproof and anti-corrosion projects for museums, libraries, factories, etc.;

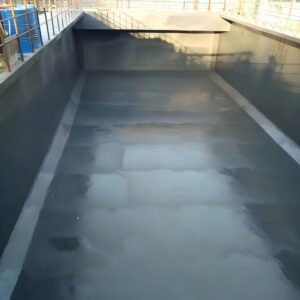

- Waterproof and anti-seepage projects for stadium stands, urban pipe trenches, underground spaces, etc.;

- Waterproof and anti-seepage projects for artificial lakes, rivers, landfills, sewage treatment tanks, landscape ponds, etc.

Physical and Chemical Properties

| Item | Technical Index | Test Standard |

|---|---|---|

| Color and Appearance | Gray viscous liquid | GB/T 23446-2009 |

| Surface Dry Time (s) | ≤120 | |

| Gel Time (s) | ≤10 | Spray Polyurea Waterproof Coating |

| Tensile Strength (MPa) | ≥16 | |

| Elongation at Break (%) | ≥450 | |

| Tear Strength (N/mm) | ≥65 | |

| Adhesive Strength (MPa) | ≥2.5 | |

| Hardness (Shore A) | ≥90 |

Note: The values in this document are typical test results, and specific data may vary slightly due to environmental conditions. The listed data do not constitute legal binding.

Surface Preparation Before Construction

- Steel: Sandblasting rust removal shall not be lower than Sa2.5 grade, and manual rust removal shall reach St3.0 grade. The coating surface shall be free of oil, clean, dry, and free of soluble salts. Primer shall be applied within 4 hours after surface rust removal.

- Old Floors with Coatings: Completely grind off loose or incompatible old coating layers until solid concrete surface is exposed. It is recommended to sandblast the base surface with a sandblaster or shot blasting machine, and then remove dust and clean.

- Oily Floors: Oil seriously affects the adhesion of the coating to the base surface, so oily floors shall be completely cleaned and ground.

- New Concrete Subfloor: The concrete shall be cured and dry (moisture content ≤6%) before surface treatment. If the surface flatness is unqualified, it shall be leveled with a grinder.

- Sealing Primer: Spray or roll 1-2 coats of special matching sealing primer, with an interval of not less than 4 hours between coats.

- Intermediate Repair Putty: Repair holes and pinholes in the substrate to avoid pinholes and bulging during subsequent polyurea spraying.

- Top Coat Spraying: It is recommended to use special polyurea spraying equipment for construction. The film thickness per spray is 1-2 mm, and the material consumption is 1.2-2.5 kg/m². For multiple sprays, the minimum interval between coatings is unlimited, and the maximum interval shall not exceed 4 hours.

Construction Conditions

- Ambient Temperature: 5-35°C, and the base surface temperature shall be at least 3°C higher than the air dew point temperature.

- Ambient Humidity: 30-80%.

- Ventilation Conditions: The construction site shall be ventilated and dust-free, but strong winds shall be avoided to prevent dust from affecting the appearance.

- Note: This product is not suitable for direct sunlight or high UV intensity areas.

Construction Method

Spraying with special polyurea spraying equipment.

Construction Parameters

| Item | Parameters |

|---|---|

| Mix Ratio (Weight Ratio) | A Component: B Component = 1.1:1, mixed by special spraying equipment |

| Material Temperature During Spraying | 50-80°C |

| Diluent | Addition of diluent is prohibited |

| Cleaning Agent | Use equipment cleaning agent to clean spraying equipment |

| Drying Time | Surface dry: ≤120s; Through dry: ≤10s (standard conditions: 25°C, 60% humidity) |

Explanation: The drying time is measured under standard conditions and is for reference only. The actual drying rate is significantly affected by temperature, humidity, film thickness, ventilation conditions, and underlying coatings. The buyer must conduct tests under the same construction conditions as the project before formal construction to ensure the reliability of the material system. Failure to do so shall result in all responsibilities being borne by the buyer.

Packaging Specifications

- Component A (Isocyanate Component): Packed in iron drums, 220kg/drum;

- Component B (Amino Polyether Component): Packed in iron drums, 200kg/drum;

- Use as a 整套混合 (whole set mixture) according to the factory packaging.

Storage, Transportation Conditions and Shelf Life

- Storage and Transportation Conditions: Store in a sealed manner in a dry, cool, and well-ventilated environment at 5-35°C, away from high temperatures and fire sources. During transportation, ensure the carriage is dry and closed, and the materials are stacked steadily.

- Shelf Life: Original sealed packaging, stored under the above conditions, the shelf life is 12 months from the production date.

Safety Precautions

- Read the construction instructions and warning labels on the packaging containers carefully before use.

- Use in a well-ventilated environment. Open flames (such as welding, grinding, smoking, etc.) are strictly prohibited at the construction site.

- Wear a gas mask and other protective equipment during construction. Avoid inhaling paint mist or skin contact with the coating. If the coating splashes on the skin, rinse immediately with soap and plenty of water; if it enters the eyes, rinse thoroughly with water and seek medical attention immediately.

- Under normal construction conditions, the dried coating is non-toxic and can be used safely. For detailed information on toxicity, safety, and first aid, please refer to the Material Safety Data Sheet (MSDS).

Fire and Explosion Hazards

This product is not classified as flammable liquid, explosive, oxidizer, corrosive, toxic, or radioactive hazardous material during storage and transportation.

- Extinguishing Media: Carbon dioxide, foam, or chemical dry powder fire extinguishers can be used. In the absence of other extinguishing agents, a large amount of fog water can be sprayed. After the fire is extinguished, the spilled materials shall be cleaned up (refer to leakage and spillage handling).

- Firefighting Procedures: Take normal protective measures.

Leakage and Spillage Handling

- Small Leakage: Can be flushed away with water.

- Large Leakage: Collect and recycle, and wash the contaminated ground with water or detergent. Disposal of waste mixture shall comply with local environmental protection regulations.

Additional Information

The indicators and data in this document are based on current technical knowledge and practical experience for reference only. Specific guaranteed indicators shall be subject to the quality guarantee certificate or supply contract. Users are responsible for testing to verify whether the product is suitable for their intended processes and applications. Our company shall not be liable for indirect losses caused during the production process using our products as raw materials. For technical support or consultation, please contact our customer service center.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|