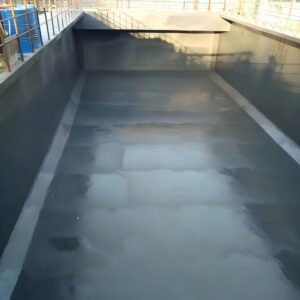

Spray polyurea waterproof coating

Low module pure aromatic polyurea elastomeric system, applied by high pressure spray equipment, particularly suitable for suface protection (metal, wood, EPS and PU foams) and waterproofing on cement surfaces and damaged coating.

Comprehensive Specification for Spray Polyurea Waterproof Coating (Wanshield® 9862)

1. Product Overview

Product Applications:

This product is a two-component, high-solids, high-strength elastic coating widely used in water conservancy, transportation, construction, chemical, power, metallurgy, and marine applications. It effectively addresses waterproofing, anti-seepage, and corrosion issues on substrates such as concrete and steel structures, extending their service life.

Performance Characteristics:

1. High solids content, low viscosity;

2. Excellent mechanical properties and impact resistance;

3. Good chemical resistance;

4. Long gel time and fast dry time, facilitating multiple coats.

Packaging Specifications:

Component A, net weight 220 kg/drum; Component B, net weight 200 kg/drum.

Mix ratio A:B = 1:1 (volume ratio)

2. Component Information

| Component Type | Main Components | Percentage |

| Component A | MDI | 40% |

| Polyether Polyol Modified MDI | 60% | |

| Component B | Chain Extender | 30% |

| Amino Polyether | 60% | |

| Color Paste, Additives, etc. | 10% | |

| Product Technical Specification | Specific components and their percentages are not mentioned, only that Component A and Component B are mixed in a volume ratio of 1:1 | – |

3. Hazard Overview

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Hazard Category | Category 3 |

| Routes of Exposure | Can enter the human body through inhalation, ingestion and skin contact |

| Health Hazards | Irritating to eyes, respiratory system and skin; inhalation and skin contact may cause sensitization |

| Environmental Hazards | May cause pollution to water areas |

| Fire and Explosion Hazards | Store in a sealed, low-temperature and dry place, avoid long-term exposure to sunlight, strictly prohibit approaching fire sources and heat sources, and prevent static electricity |

4. First-Aid Measures

| Situation | Treatment Method (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Heavy Inhalation | Immediately move the patient away from the contaminated area to breathe fresh air. If the patient still feels unwell, immediately send him/her to the hospital for medical treatment |

| Accidental Ingestion | Immediately send the patient to the hospital. If the patient is unconscious, do not give anything by mouth to ensure smooth breathing, do not induce vomiting, lay the body flat, and immediately send to the hospital |

| Contact with Eyes | Rinse with a large amount of clean water for at least 20 to 30 minutes, do not use any medicine on the affected area, and immediately seek medical attention |

| Tips for Physicians | Component A: Solvent-free, mixture of isocyanate MDI, etc.; Component B: Solvent-free, mixture of amino polyether, etc. |

5. Fire-Fighting Measures

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Hazardous Characteristics | Can be ignited by static electricity or open fire, and toxic fumes will be released when heated to decomposition temperature |

| Extinguishing Agents | Use Class B extinguishing agents (such as chemical dry powder, carbon dioxide, etc.) |

| Fire-Fighting Methods | Wear appropriate protective clothing and a fully equipped respirator |

6. Emergency Treatment for Leakage

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Emergency Treatment | Ventilate the workplace with fresh air, recover the spilled material, and remove the powder with a vacuum cleaner or water to avoid dust generation |

| Personal Protection | Emergency response personnel should wear protective clothing, protective glasses and protective masks |

7. Storage and Handling

| Item | Component A | Component B | Product Technical Specification |

|---|---|---|---|

| Handling Precautions | Enhance ventilation. Operators must receive special training and strictly abide by the operating procedures. Operators should wear chemical safety goggles, protective masks and dust-proof clothing; keep away from fire sources and heat sources, smoking is strictly prohibited in the workplace, and handle with care during transportation to prevent damage to packaging containers | Consistent with Component A | Smoking and open fire are prohibited in storage, transportation and construction sites; no details related to operation are mentioned |

| Storage Precautions | Abide by the storage rules, keep away from fire sources; store in a well-ventilated and dry place; the storage temperature should not exceed 35°C; there should be no free water in the storage environment; seal the container tightly with a lid immediately after use, as it reacts with moisture to generate carbon dioxide and gel | Abide by the storage rules, keep away from fire sources; store in a well-ventilated and dry place, avoid direct contact with sunlight; the storage temperature should not exceed 35°C | Should be stored in a cool, well-ventilated and dry warehouse, strictly prohibited from being exposed to rain and sunlight, isolated from fire sources and heat sources, and the storage temperature should be 10-35°C; under the condition of not opening the original packaging, the storage period is 12 months from the date of production. Beyond the storage period, the product can be inspected according to the items specified in the product standard, and can still be used if it meets the technical requirements; it contains no organic solvents and can be transported as non-dangerous goods. During transportation, it is strictly prohibited from being exposed to rain and sunlight, and must comply with the relevant regulations of the transportation department |

8. Exposure Control/Personal Protection

| Item | Component A | Component B | Not Mentioned in Product Technical Specification |

|---|---|---|---|

| Process Control | Wash hands and take a bath after contacting this substance or finishing work; timely replace wet or contaminated clothing, and do not take work clothes out of the workplace | Consistent with Component A | – |

| Hand Protection | Wash hands thoroughly immediately after handling this substance | Consistent with Component A | – |

| Eye Protection | Avoid eye contact; wear one or more types of protective equipment to prevent eye contact, such as safety glasses with protective lenses and ventilated goggles | Consistent with Component A | – |

| Respiratory Protection | Avoid inhaling the gas generated in the fluidization cycle | Consistent with Component A | – |

| Ingestion | Do not eat, drink or smoke when using this product, and thoroughly clean the contact parts with soap and water | Consistent with Component A | – |

| Body Protection | 1. Wear personal protective equipment when using this product; 2. Personnel who are frequently in contact with this product should eat more vegetables, fruits, etc. | 1. Long-term contact with this product may have a degreasing effect on the skin, so personal protective equipment should be worn when using this product; 2. Personnel who are frequently in contact with this product should eat more vegetables, fruits, etc. | – |

9. Physical and Chemical Properties

| Item | Component A | Component B | Product Technical Specification |

|---|---|---|---|

| Appearance and Properties | Viscous liquid | Viscous liquid | Component A: Light yellow viscous liquid; Component B: Viscous liquid (color can be adjusted) |

| Odor | Slight odor | Slight odor | Not mentioned |

| Molecular Formula | Unknown | Unknown | Not mentioned |

| Curing Conditions | 5-35°C | 5-35°C | Not mentioned |

| pH Value | Weakly alkaline | Weakly alkaline | Not mentioned |

| Relative Density | 1.05-1.15 | 1.05-1.15 | 1.05g/cm³ |

| Upper Explosion Limit | No data | No data | Not mentioned |

| Lower Explosion Limit | No data | No data | Not mentioned |

| Water Solubility | Insoluble | Insoluble | Not mentioned |

| Solubility | Soluble in polar organic solvents such as alcohols, ketones and toluene | Soluble in polar organic solvents such as alcohols, ketones and toluene | Not mentioned |

| Solid Content | Not mentioned | Not mentioned | 100% (Test Method: GB/T 23446-2009) |

| Gel Time | Not mentioned | Not mentioned | 13s (Test Method: GB/T 23446-2009) |

| Surface Drying Time | Not mentioned | Not mentioned | 28s (Test Method: GB/T 23446-2009) |

| Tensile Strength | Not mentioned | Not mentioned | 17MPa (Test Method: GB/T 23446-2009) |

| Elongation at Break | Not mentioned | Not mentioned | 480% (Test Method: GB/T 23446-2009) |

| Tear Strength | Not mentioned | Not mentioned | 70N/mm (Test Method: GB/T 23446-2009) |

| Impact Resistance | Not mentioned | Not mentioned | 1.5kg·m (Test Method: GB/T 23446-2009) |

| Salt Spray Resistance | Not mentioned | Not mentioned | No corrosion, no blistering, no peeling after 2000h (Test Method: HG/T 3831-2006) |

| Water Impermeability | Not mentioned | Not mentioned | 0.4MPa, no water penetration for 2h (Test Method: GB/T 23446-2009) |

| Low-Temperature Flexibility | Not mentioned | Not mentioned | -40°C (Test Method: GB/T 23446-2009) |

10. Reactivity and Stability

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Reactivity | Component A: Reacts with amine and hydroxyl-containing organic substances to form block solids; Component B: Reacts with epoxy and isocyanate-containing organic substances to form block solids |

| Stability | This compound is stable under normal laboratory conditions |

| Conditions to Avoid Contact | Solvents, high heat, fire sources and heat sources |

| Polymerization Hazard | No hazardous polymerization reaction will occur |

| Hazardous Decomposition Products | Carbon monoxide, carbon dioxide |

11. Toxicological Information

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Acute Toxicity | Heavy inhalation may cause poisoning, with symptoms such as dizziness and nausea |

| Carcinogenicity | Unknown |

| Irritation | Has a certain degree of irritation to the skin, eyes and respiratory tract |

12. Ecological Information

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Ecotoxicity | Not determined |

| Ecological Enrichment or Bioaccumulation | Not determined |

| Biodegradability | Not determined |

| Non-Biodegradability | Not determined |

13. Disposal

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Waste Disposal Method | Do not dispose of residues by landfill or incineration. It is better to consult the environmental protection department to obtain an appropriate disposal method |

| Packaging Material Disposal Method | Dispose in accordance with local regulations. Packaging materials contaminated by the product should be disposed of as residual products |

14. Transportation Information

| Item | MSDS of Component A and Component B | Product Technical Specification |

|---|---|---|

| Transportation Precautions | 1. During transportation, the product must be strictly inspected. Products with insecure packaging, damaged and contaminated packaging, unclear product name labels and vehicles that do not meet safety requirements shall not be transported; 2. Handle with care to prevent collision, dragging and dumping; avoid exposure to sunlight and transport in a sealed manner at room temperature | It contains no organic solvents and can be transported as non-dangerous goods. During transportation, it is strictly prohibited from being exposed to rain and sunlight, and must comply with the relevant regulations of the transportation department; smoking and open fire are prohibited in storage, transportation and construction sites |

15. Regulatory Information

| Item | Details (Consistent for Component A and Component B, not mentioned in Product Technical Specification) |

|---|---|

| Relevant Regulations | The Regulations on the Safety Management of Hazardous Chemicals have made corresponding provisions on the safe production, use, storage, transportation and handling of hazardous chemicals |

16. Other Information

| Item | MSDS of Component A and Component B | Product Technical Specification |

|---|---|---|

| Description | The data and content recorded in this manual are obtained through tests and investigations by our company and are for reference only. However, we cannot guarantee the specific usage of users. In addition, the product may vary due to different purposes, materials and usage conditions. Therefore, we hope that users will conduct tests before formal use | 1. The product is widely used in water conservancy, transportation, construction, chemical industry, electric power, metallurgy, marine and other fields. It can effectively solve the waterproof, seepage-proof and anti-corrosion problems of concrete, steel structure and other substrates and improve the service life; 2. Packaging Specification: Component A: Net weight 220Kg/barrel; Component B: Net weight 200Kg/barrel, and the mixing ratio of Component A to Component B is 1:1 (volume ratio); 3. Shelf Life: From the date of production, under the condition of storage in accordance with regulations, the shelf life of Wanshield® 9862 two-component spray polyurea is 12 months; 4. For information on safety and environmental protection, please refer to the safety data sheet of our company’s products or contact our customer service center; 5. First Release Date: March 3, 2020, Version Number: V1.0; 6. The performance data in this manual are obtained by our company under standard test conditions: using Graco HXP-3 and AP gun, adopting AF2929 mixing chamber, equipped with FT0438 nozzle, the spray pressure is set to 2000psi, the heating temperature of the main machine heater and material pipe is set to 65°C, and the sample is cured under standard conditions for 7 days. If the equipment used is different from the above-mentioned equipment, a spray test verification must be carried out before the formal use of the product. Our company shall not be liable for any performance differences caused by the use of non-Graco special polyurea spraying equipment and related supporting components, or failure to cure under standard conditions; 7. With the continuous improvement of the product, our company reserves the right to modify this manual without prior notice. For the technical description and safe use instructions of the product, please contact the technical service department for suppo |

| Weight | 25 kg |

|---|