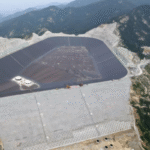

Hydraulic Asphalt for Dam Body

Wanhua hydraulic asphalt is mainly used for rolled dam surface and poured asphalt concrete construction in water conservancy and hydropower projects such as earth-rock dams, concrete dams, masonry dams, pumped storage reservoirs, and channels, and has excellent anti-seepage performance.

Description

Product Introduction

Wanhua Hydrotechnical Asphalt is carefully selected from low-wax, naphthenic base crude oil. The product is characterized by low wax content, excellent anti-seepage performance, appropriate components, and a low brittle point. It is mainly used in the construction of rolled and cast asphalt concrete in water conservancy and hydropower projects such as earth-rock dams, concrete dams, masonry dams, pumped storage reservoirs, and canals, with outstanding anti-seepage performance.

Performance Characteristics

- It is a flexible waterproof material.

- It has excellent durability. The flow value of the prepared asphalt concrete is less than 0.8mm when kept at 70°C for 48 hours.

- It has good adhesion to aggregates, meeting the Class 5 usage requirements.

- It can coat evenly without looseness and has excellent anti-seepage performance.

Main Performance Indicators

Product Execution Standard: DL/T 5411--2009 Design Specification for Asphalt Concrete Face and Core Walls of Earth-Rock Dams

| Item | Index |

|---|---|

| Penetration (100g, 5s, 25°C, 0.1mm) | 68 |

| Ductility at 15°C (5cm/min), cm | ≥ 150 |

| Ductility at 4°C (1cm/min), cm | 70 |

| Softening Point, °C | 50.5 |

| Brittle Point, °C | -19 |

| Flash Point (COC), °C | 290 |

| Wax Content (Pyrolysis Method), % | 1.9 |

| Solubility (Trichloroethylene), % | 99.70 |

| Mass Change, % | -0.012 |

| Residual Penetration Ratio (25°C), % | 77.2 |

| Residual Ductility (15°C), cm | 101 |

| Residual Ductility (4°C), cm | 40 |

| Increase in Softening Point, °C | 1.5 |

| Dynamic Viscosity at 60°C, Pa·s | 396 |

| Dynamic Viscosity at 135°C, Pa·s | 0.61 |

The values provided in this document are typical test values. Specific data may vary slightly due to environmental conditions. For our company's products, the listed data have no legal binding force.

Construction Technology

1. Construction Conditions

- When constructing hydrotechnical asphalt concrete, the wind force should preferably be less than Level 4, and the daily rainfall should be less than 5mm.

- Rolled asphalt concrete should be constructed during non-rainy periods. When constructing a rolled core wall, the temperature should be above 0°C, and when constructing a rolled impervious face slab, the temperature should be above 5°C.

- When constructing cast asphalt concrete, the temperature should be not lower than -20°C, and the daily snowfall should be less than 5mm.

2. Construction Methods

- Rolled hydrotechnical asphalt concrete should be constructed by mechanical methods. Local connection parts can be constructed by manual cooperation with mechanical methods.

- Cast asphalt concrete can be constructed by mechanical or manual methods. For dams over 30m in height, mechanical methods are preferred.

3. Mixing and Transportation

- Hydrotechnical asphalt concrete is preferably produced at a standardized mixing plant. The mixing plant is preferably of the batch type, equipped with a storage bin of appropriate volume and good heat preservation performance. Its production capacity should meet the requirements of the peak paving intensity.

- When mixing asphalt concrete, dry-mix the aggregates and fillers for 15 seconds, then add hot hydrotechnical asphalt and mix for at least 45 seconds. The hydrotechnical asphalt concrete should have a uniform color, no segregation, and no streaks.

- Hydrotechnical asphalt concrete is preferably transported in heat-insulated material tanks.

4. Construction of Rolled Hydrotechnical Asphalt Concrete

- Subgrade Treatment: The subgrade needs to be renovated and compacted. Herbicides should be sprayed on the soil subgrade. The crushed stone cushion should be filled and compacted in layers according to the particle size distribution, and then rolled along the slope with a vibratory roller, vibrating during the upward run and not vibrating during the downward run. Before paving, spray a layer of emulsified asphalt on the surface of the cushion. After the emulsified asphalt dries, pave the hydrotechnical asphalt mixture.

- Material Paving: For planar paving, a segmented paving method that reduces cold joints is preferred. When the length of the inclined surface paving is greater than 120m, hierarchical paving can be adopted. The paver is equipped with a vibrating screed compactor. Manual paving is used for areas where mechanical equipment cannot reach, such as around the face slab and in dead corners.

- Material Compaction: After paving and pre-compaction by the paver, a vibratory roller is used for compaction. When rolling on slopes, the vibratory roller should vibrate during the upward run and not vibrate during the downward run. The joint parts are compacted by small-scale compaction equipment closely following the paver.

- Face Slab Sealing: The sealing layer material should meet the requirements of no flow at high temperatures in summer, no brittle cracking at low temperatures in winter, and no peeling during the operation period.

5. Construction of Cast Hydrotechnical Asphalt Concrete

- Base Course Treatment: Remove the laitance and impurities from the inner surface of the protective face slab, brush with 0.15−0.20kg/m2 of diluted asphalt, and let it dry. Before installing the protective face slab, brush the upstream dam surface clean with a steel brush. Chisel and clean the protruding parts of the dam surface. Chisel away the loose parts of honeycombs and pitted surfaces and backfill with cement mortar. Dry the wet dam surface with an infrared heater or a blowtorch. Brush the dam surface with 0.15−0.20kg/m2 of diluted asphalt and let it dry.

- Material Pouring: The steel formwork method or the paver method can be used. For low dams, the method of laying precast concrete blocks with asphalt mortar can be adopted. For asphalt mixtures with low fluidity, the vibration method can be used for construction. The pouring temperature of hydrotechnical asphalt concrete should not be lower than 150°C, and in severe cold seasons, it should not be lower than 170°C. When pouring, do not concentrate the feed in one place. The pouring height of each layer can be 20 - 30cm. After pouring, use a tamping rod to tamp until the surface is oily and no bubbles are discharged. When pouring the core wall, the feed should be uniform, and the pouring height of each layer is preferably 20 - 50cm. Tamp the edges with a tamping rod while pouring.

Packaging Specification

Packaged and transported by special tank trucks.

Storage (Use) Precautions

Store in a special storage tank with heating and heat preservation functions.

Shelf Life

The shelf life is 12 months.

For more information, please refer to the safety technical specification of our company's products or contact our company's customer service center. The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their intended processes and uses and to achieve the intended purpose. Further applications and processing of our company's products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company's products as raw materials. Our company's technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie