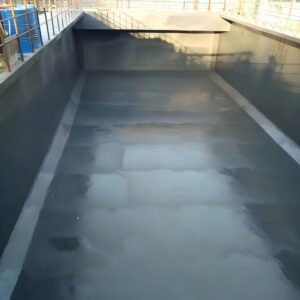

Two-component hand-brushed polyurea waterproof coating

This product is a two-component, high-solid, high-strength elastic coating that can be widely used in water conservancy, transportation, construction, chemical industry, electric power, metallurgy, ocean and other fields. It can effectively solve the waterproofing, anti-seepage and anti-corrosion problems of substrates such as concrete and steel structures, and improve service life.

Description

1. Product Introduction

Wanshield® 9882 is a two-component brushable polyurea waterproof coating. As a two-component, high-solid-content, and high-strength elastic coating, it has a wide range of applications, covering water conservancy, transportation, construction, chemical industry, electric power, metallurgy, marine engineering, and other fields. This product can effectively solve the waterproofing, seepage prevention, and anti-corrosion problems of substrates such as concrete and steel structures, significantly extending the service life of the substrates.

2. Performance Features

- High solid content and low viscosity, combining environmental protection performance and construction convenience;

- Excellent mechanical properties and impact resistance, capable of withstanding a certain degree of external force without being easily damaged;

- Good chemical corrosion resistance, able to resist the erosion of various chemical substances;

- Long gel time, facilitating construction operations, and short surface drying time, supporting multiple coats to improve construction efficiency.

3. Product Applications

It is mainly applicable to various places such as workshops, factories, and residential buildings. Especially in small-area areas or enclosed spaces, it has significant application advantages in waterproofing, seepage prevention, and anti-corrosion projects for substrates like concrete and steel structures.

4. Main Performance Indicators

| Item | Indicator | Unit | Testing Method |

|---|---|---|---|

| Appearance | Component A: Light yellow viscous liquid Component B: Viscous liquid (color can be customized on demand) | – | GB/T 16777-2008 |

| Solid Content | 100 | % | GB/T 16777-2008 |

| Gel Time | 30 | Minute (Min) | GB/T 16777-2008 |

| Surface Drying Time | 4 | Hour (h) | GB/T 16777-2008 |

| Density | 1.15 | Gram/cubic centimeter (g/cm³) | GB/T 16777-2008 |

| Tensile Strength | 12 | Megapascal (MPa) | GB/T 16777-2008 |

| Elongation at Break | 200 | % | GB/T 16777-2008 |

| Tear Strength | 50 | Newton/millimeter (N/mm) | GB/T 16777-2008 |

| Impact Resistance | 1.5 | Kilogram·meter (kg·m) | GB/T 16777-2008 |

| Water Impermeability | No water penetration for 2 hours under the condition of 0.4 MPa | – | GB/T 16777-2008 |

5. Substrate Preparation

- The substrate shall be pre-treated by processes such as grinding, sandblasting, and shot blasting to ensure the surface is clean and smooth.

- Concrete substrate: The loose part on the surface shall be removed to expose the solid substrate; the substrate shall be free of moisture and visible water. For surface holes, special repair putty shall be used for plugging, and then the matching primer shall be applied.

- Steel substrate: It shall be treated to Sa2.5 grade standard by sandblasting and shot blasting. After dust removal, the corresponding primer shall be applied.

- For other types of substrates, please consult the Technology Department of Wanhua Energy-Saving Company for professional guidance before construction.

6. Construction Conditions

- Temperature: The ambient temperature shall be controlled at 5-35℃, and the substrate temperature shall be more than 3℃ higher than the air dew point temperature.

- Humidity: The relative ambient humidity shall be ≤80% RH, and the moisture content of the concrete base surface shall be less than 6%.

- Ventilation: Strong wind shall be avoided at the construction site to prevent dust from entering and affecting the compactness of the coating, and good ventilation of the construction environment shall be ensured.

7. Construction Methods

Three construction methods can be adopted: brushing, rolling, and spraying. The specific method can be selected according to the construction scenario and requirements.

8. Packaging Specification

- The packaging can be customized according to customer requirements.

- The weight ratio of Component A to Component B of the product is 1.5:1.

9. Storage (Usage) Precautions

- Storage environment: It shall be stored in a cool, ventilated, and dry warehouse, protected from rain and direct sunlight; it shall be kept away from fire sources and heat sources, and the storage temperature shall be controlled at 10-35℃.

- Storage period: Under the condition of unopened original packaging and compliance with the specified storage conditions, the storage period of the product is 12 months from the date of production; after the expiration of the storage period, the product shall be tested in accordance with the items specified in this product standard. If the test results meet the technical requirements, it can still be used continuously.

- Transportation requirements: This product contains no solvents and can be transported as a non-hazardous material; during transportation, it shall be protected from rain and direct sunlight, and relevant regulations of the transportation department shall be followed.

- Safety regulations: Smoking and open flame operations are strictly prohibited in storage, transportation, and construction sites.

10. Shelf Life

Under the premise of strictly following the specified storage conditions, the shelf life of Wanshield® 9882 two-component brushable polyurea waterproof coating is 12 months from the date of production.

For detailed information on product safety and environmental protection, please refer to the company’s product Safety Data Sheet (SDS) or contact the customer service center directly for consultation.

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|