One-Component Solvent-Based Polyurea Waterproof Coating

One-component solvent-based polyurea waterproof coating is an aliphatic and high-strength product. The effect of this product on environmental temperature and humidity

It undergoes a polymerization reaction and can be cured into an elastic film. It has excellent adhesion to concrete, natural stone, ceramics, mortar, masonry structures, steel structures, epoxy and other substrates, as well as outstanding water resistance and abrasion resistance

SKU:

One-Component Solvent-Based Polyurea Waterproof Coating

Category: Polyurea Coating

Tags: Coating, Polyurea Coating

Description

1. Product Overview

This aliphatic high-strength one-component solvent-based polyurea waterproof coating is formulated with modified resin, special latent curing agent, and ester solvents. Triggered by ambient temperature and humidity, the product undergoes polymerization to form an elastic waterproof membrane, exhibiting excellent adhesion to substrates such as concrete, natural stone, ceramic, mortar, masonry structures, steel structures, and epoxy coatings. It offers superior waterproofing and impact-abrasion resistance. With easy application, it is widely suitable for spillways, overflow channels, dam surfaces, expansion joints, construction joints, and other scenarios.

2. Performance Features

- High thixotropy and low viscosity for excellent constructability

- High-strength mechanical properties and impact resistance for demanding load environments

- Excellent impact-abrasion and chemical corrosion resistance for strong water flow and chemical erosion scenarios

- Long gel time and short surface-dry time for multi-coat application

3. Application Fields

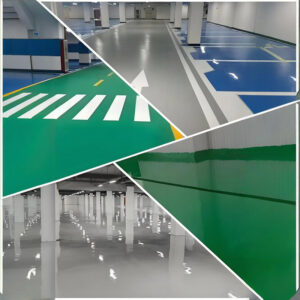

One-component design for ready-to-use application. Mainly used in hydraulic engineering, industrial workshops, factory buildings, civil residences, etc., especially suitable for waterproofing, seepage control, and corrosion protection in hydraulic environments such as dam projects.

4. Key Performance Indicators

| Test Item | Technical Index | Unit | Test Standard |

|---|---|---|---|

| Appearance | One-component viscous liquid | – | JC/T 2435-2018 |

| Solids Content | ≥82 | % | JC/T 2435-2018 |

| Surface-Dry Time | ≤3 | h | JC/T 2435-2018 |

| Through-Dry Time | ≤6 | h | JC/T 2435-2018 |

| Tensile Strength | ≥20 | MPa | JC/T 2435-2018 |

| Elongation at Break | ≥200 | % | JC/T 2435-2018 |

| Tear Strength | ≥60 | N/mm | JC/T 2435-2018 |

| Bond Strength | Concrete substrate ≥3 Steel substrate ≥8 | MPa | JC/T 2435-2018 |

5. Substrate Preparation Requirements

5.1 General Preparation

All substrates shall be surface-treated by grinding, sandblasting, or shot blasting to ensure cleanliness, soundness, and freedom from oil and loose layers.

5.2 Concrete Substrate

Remove loose surface layers to expose a sound base, requiring dryness (moisture content <6%), no dampness, and free from standing water. Plug holes with special repair putty and apply compatible primer before coating.

5.3 Steel Substrate

Sandblast or shot blast to Sa2.5 standard, thoroughly remove dust, and apply compatible primer.

5.4 Other Substrates

For special substrates, please consult Wanhua Energy Saving Technology Department in advance.

6. Construction Environment Conditions

- Temperature Range: 5-35°C, substrate temperature shall be at least 3°C above the air dew point temperature

- Humidity Control: Ambient humidity ≤80%RH, concrete substrate moisture content <6%

- Ventilation Requirement: Ensure good ventilation at the construction site, avoid strong wind to prevent dust contamination and affect coating compactness

7. Application Methods

Support multiple application methods including brush coating, roller coating, and spray coating, flexible to project requirements.

8. Packaging Specifications

- 5kg/barrel

- 20kg/barrel

One-component product, ready to use after stirring evenly, no on-site mixing required.

9. Storage and Transportation Precautions

9.1 Storage Requirements

Store in a cool, ventilated, and dry warehouse, protected from rain, sunlight, fire sources, and heat sources. Storage temperature shall be controlled at 10-35°C. Under unopened original packaging, the shelf life is 6 months from the production date. Overdue products can be used if they meet the standards after inspection.

9.2 Transportation Requirements

The product contains organic solvents and shall be transported in compliance with dangerous goods transportation regulations, protected from rain and sunlight to ensure safe transportation.

10. Shelf Life

Under specified storage conditions, the shelf life is 6 months from the production date.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

One-Component Polyurea vs. Two-Component Polyurea: Key Differences

| Comparison Item | One-Component Polyurea | Two-Component Polyurea |

|---|---|---|

| Components & Mixing | Single component, ready to use, no mixing required | Two components (A & B), must be mixed in precise ratio |

| Curing Mechanism | Moisture-curing (reacts with moisture in the air) | Chemical reaction curing (reacts instantly when A & B are mixed) |

| Curing Speed | Slow, 30–60 minutes to touch dry, fully cures in hours | Extremely fast, gels in seconds, walkable in minutes |

| Application Method | Brush, roller, trowel, or regular spray; no specialized equipment needed | Requires high-pressure spray equipment; professional application |

| Single Film Thickness | Relatively thin, typically 0.5–1 mm | Thick, can reach 1–3 mm in one application |

| Application Environment | Relatively tolerant to humidity and temperature | Requires controlled temperature and humidity |

| Overall Performance | Good elasticity, waterproofing, and corrosion resistance; slightly lower strength | Superior strength, abrasion resistance, weatherability, and impact resistance |

| Typical Applications | Small areas, repairs, details, residential/small projects | Large areas, industrial, municipal, heavy-duty protection projects |

| Cost & Threshold | Moderate material cost, low application threshold | High material and equipment cost, requires professional team |

Detailed Key Differences

1. Curing & Application

- One-Component: Cures via moisture, with a long working time. Ideal for small areas, complex details, and repairs; accessible for DIY users.

- Two-Component: Reacts instantly upon mixing, enabling fast, continuous large-area application, but demands specialized equipment and trained applicators.

2. Performance Focus

- One-Component: Excellent elasticity and adhesion, sufficient for general waterproofing and light corrosion protection in civil applications.

- Two-Component: High cross-link density delivers superior strength, abrasion/weather resistance, and chemical resistance, suitable for heavy-duty corrosion and high-wear environments.

3. Application Scenarios

- One-Component: Roofs, bathrooms, balconies, pools, pipe repairs, small-area corrosion protection.

- Two-Component: Large storage tanks, bridges, tunnels, sports surfaces, industrial flooring, marine engineering.

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|