WANSHIELD®62201 Solvent-Free Epoxy Primer for Floor Coating & Steel Surfaces

WANSHIELD® 62201 is a solvent-free, low-viscosity, two-component coating system composed primarily of epoxy resin, reactive diluents, and amine-based curing agents. It exhibits high adhesion to substrates, low hardening shrinkage, and excellent crack resistance.

Product Overview

Key Features

- Low viscosity with strong penetration capability and superior workability.

- Dense film formation with exceptional adhesion to concrete substrates.

- Excellent resistance to acid/alkali corrosion, chemical stability, and mechanical strength.

- Free of volatile solvents, environmentally friendly, and compliant with green standards.

Applications

Suitable for concrete substrates and properly prepared steel surfaces.

Physical & Chemical Properties

| Parameter | Specification | Test Standard |

|---|---|---|

| Appearance (mixed) | Homogeneous, free of lumps | Visual inspection |

| Surface Drying Time (h) ≤ | 6 | GB/T 22374-2018 |

| Full Curing Time (h) ≤ | 24 | GB/T 22374-2018 |

| VOC Content (g/L) ≤ | 60 | GB/T 23985-2009 |

| Alkali Resistance | Film remains intact; no blistering/delamination; slight discoloration allowed | GB/T 22374-2018 |

| Tensile Bond Strength (MPa) ≥ | 2.0 | GB/T 22374-2018 |

| Surface Resistivity (Ω) | 5×10⁴ – 1×10⁶ (electrostatic conductive type) | GB/T 1410-1989 |

Note: The values provided in this document are typical test values. The specific data may vary slightly due to different environmental conditions. For our company’s products, the listed data have no binding force in legal terms.

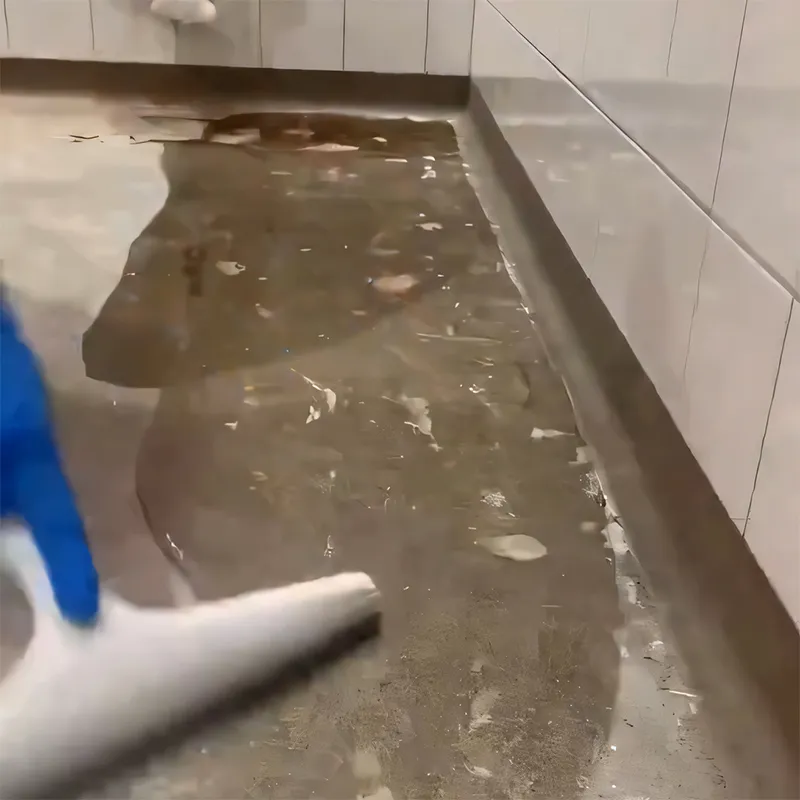

Surface Preparation

- For new and old concrete floors, the concrete strength should reach C25 and the pull – out strength should be greater than 1.5MPa. Thoroughly remove all surface debris, oil stains, old paint layers, loose soil, and other contaminants that may affect good adhesion until the solid and firm concrete is exposed.

- Grind the concrete substrate with a grinder and continuously check the flatness of the substrate with a 2m straightedge and feeler gauge. Grind down high – convex areas with a grinder, and repair and level low – lying areas with epoxy mortar to ensure that the flatness of the ground does not exceed 3mm.

- Use mobile shot – blasting tools or grinding equipment to treat the surface, completely remove the laitance layer, and make the surface roughness of the concrete meet the requirements of “CSP 3 – 6”.

- For new concrete floors, ensure that the floor has passed the curing period and the moisture content is less than 6%. It is crucial to use mobile sandblasting tools and grinding equipment to treat the concrete surface to achieve the appropriate surface roughness.

Construction Conditions

- Construction Environment Temperature: 10 – 35°C.

- Construction Substrate Temperature: The substrate temperature must be at least 3°C higher than the air dew – point temperature.

- Construction Environment Humidity: The relative humidity of the construction environment should be less than 85%.

- Construction Pot Life: 50 – 60 minutes (at 23°C).

- Substrate Moisture Content: There should be no visible water on the substrate surface.

- Ventilation Conditions: Ensure that the construction site is well – ventilated and dust – free. However, there should be no strong wind to avoid bringing in dust and affecting the appearance.

Construction Parameters

| Parameter | Specification |

|---|---|

| Mixing ratio (by weight) | A:B = 2:1; mix thoroughly. |

| Pot life at 25°C | 20 min (30 min after pouring). Shortens at higher temperatures. Avoid use above 35°C. |

| Thinner | Not permitted. |

| Recoat interval | ≥24 h under standard conditions (25°C, 60% RH). Adjust for temperature/humidity variations. |

Note: Conduct pre-construction trials under actual conditions to validate suitability. The drying time is measured under standard conditions (23°C, 60% humidity) and is for reference only. The drying speed varies greatly under different temperatures and humidities, and is also affected by factors such as film thickness, ventilation conditions, and underlying coatings. Generally, the drying time shortens as the temperature rises and lengthens as the temperature drops.

Packaging

Iron drum packaging:

- Component A: 20 kg

- Component B: 10 kg

Storage & Shelf Life

- Storage: Keep sealed at 5–35°C in dry, ventilated areas away from heat/flames.

- Transport: Ensure dry, enclosed conditions; protect from moisture/freezing.

- Shelf life: 12 months from production date in original packaging.

Safety Precautions

- Read warnings and instructions before use.

- Use in well-ventilated areas; avoid open flames (e.g., welding, smoking).

- Wear PPE (respirator, gloves). Rinse skin/eyes immediately if exposed; seek medical aid if needed.

- Cured film is non-toxic. Refer to MSDS for detailed safety guidelines.

Fire & Explosion Hazards

- Non-flammable, non-explosive, and non-hazardous during storage/transport.

- Extinguishing media: CO₂, foam, or dry chemical powder. In the absence of other fire – fighting agents, a large amount of fog – like water can also be used for spraying.

- For large spills, contain and recover material.

Leakage and Spillage Treatment

Disclaimer

Contact:

| Weight | 12 kg |

|---|