Rigid Foam Polyurethane Composite Board

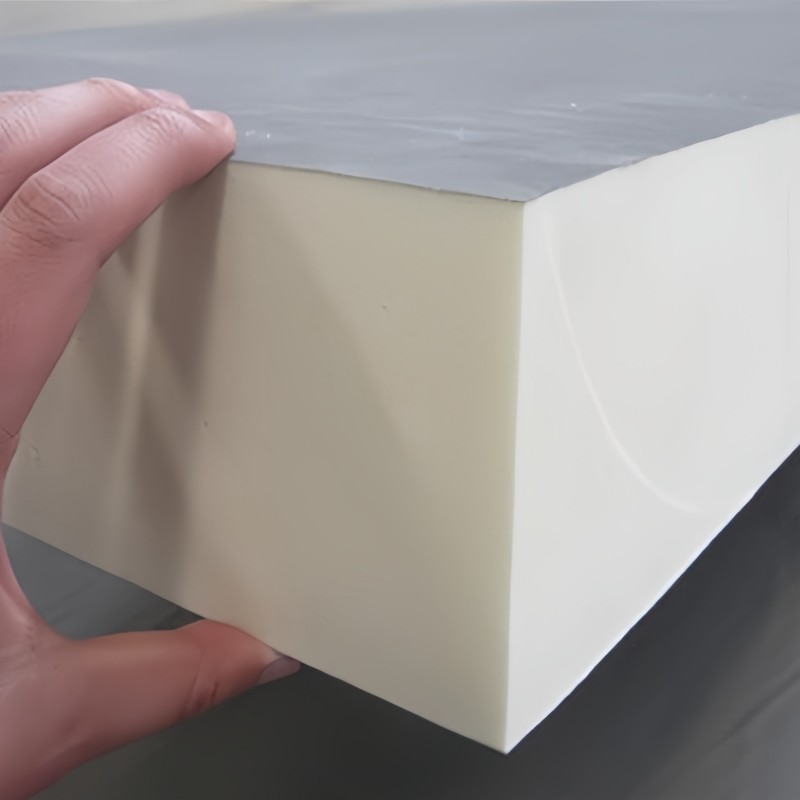

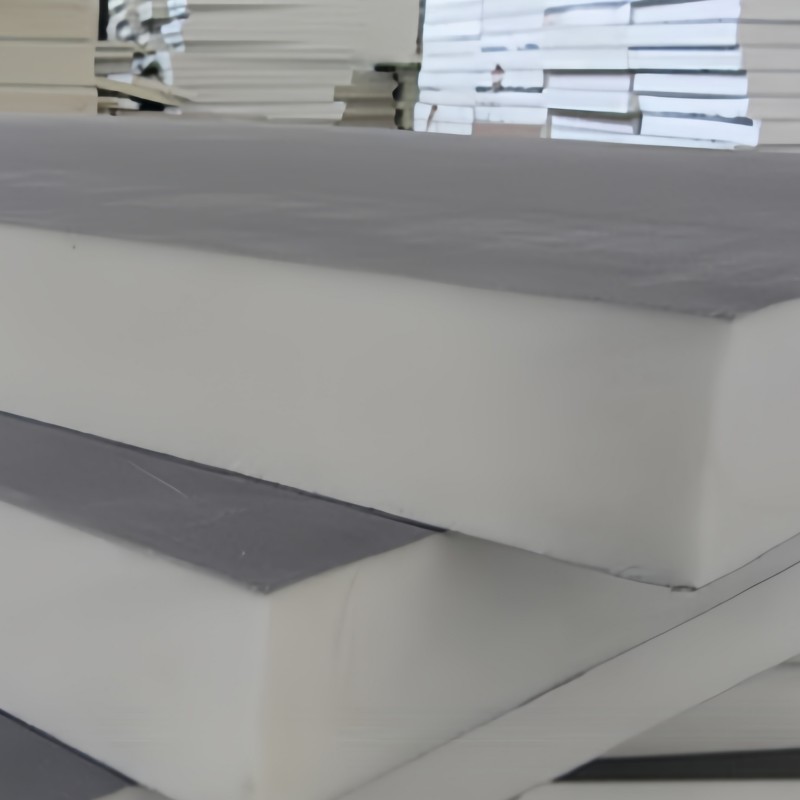

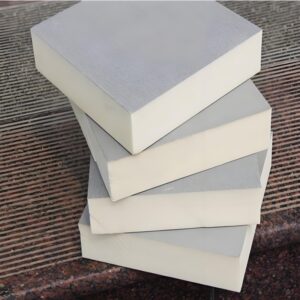

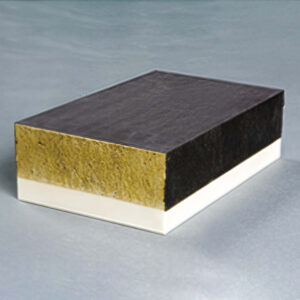

Rigid polyurethane foam composite board is a board with thermal insulation function that is made by compounding polyurethane thermal insulation core material and cement-based interface reinforcement coiled material in the factory through a professional continuous production line.

SKU:

Rigid foam polyurethane composite board

Category: Insulation Panels

Tags: Panels, Insulation Panels, Rigid Foam Polyurethane Panel

Description

Product Introduction

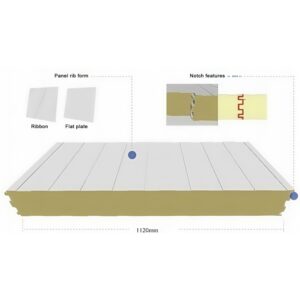

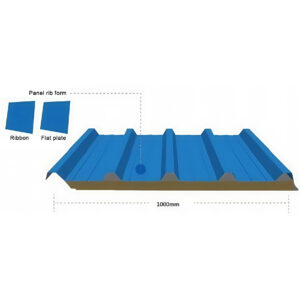

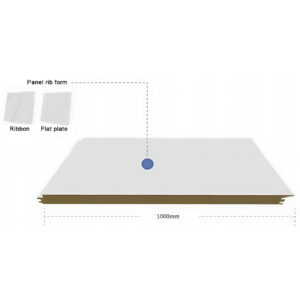

The rigid polyurethane composite panel is a kind of insulated panel, which is produced by laminating the polyurethane insulation core material and the cement – based interface – enhanced coil together through a professional continuous production line in the factory (abbreviated as: PIR panel).

Standard Size: 1200mm×600mm (customizable)

Insulation Layer Thickness: 20mm – 120mm

Standard Size: 1200mm×600mm (customizable)

Insulation Layer Thickness: 20mm – 120mm

Product Features

- Excellent Thermal Insulation Performance with a Thin Insulation Layer

- The thermal conductivity is ≤0.024 W/(m·K). To achieve the same insulation effect, the insulation layer can be made thinner, with a smaller self – gravity moment, which greatly improves safety.

- Good Fire – Retardant Performance

- Rigid polyurethane is a thermosetting insulation material. When its surface is exposed to fire, a carbonized char layer is formed, and it self – extinguishes after the fire source is removed, effectively preventing the spread of fire.

- Wide Operating Temperature Range

- The operating temperature range of rigid polyurethane is – 50°C~150°C. It can withstand a short – term operating temperature of up to 250°C without any damage, making it a versatile insulation material with a wide temperature range.

- Good Weather Resistance

- Rigid polyurethane has good physical and chemical stability and can have the same service life as the building.

- Low Water Absorption and Good Waterproof Performance

- Rigid polyurethane has a closed – cell structure, with a closed – cell rate of over 95%. It has an extremely low water absorption and good waterproof performance.

Performance Indicators

| Item | Unit | Technical Indicator |

| Thermal Conductivity (Average Temperature 25°C) | W/(m·K) | ≤0.024 |

| Density | kg/m³ | ≥30 |

| Compressive Strength (Compressive Deformation 10%) | kPa | ≥150Kpa |

| Tensile Strength Perpendicular to the Plate Surface | MPa | ≥0.1 |

| Water Absorption (Volume Fraction) | % | 0.30% |

| Combustion Performance | – | B1 Grade |

Production Process

WANHUA’s rigid polyurethane composite panel adopts the advanced domestic continuous production process. Compared with traditional production processes such as the mold method and bonding method, the continuous method is more conducive to achieving cavity – free bonding between the rock wool layer and the interface layer. The entire production process is under real – time dynamic monitoring, ensuring stable and controllable product quality. The production efficiency is 10 times higher than that of traditional production processes.

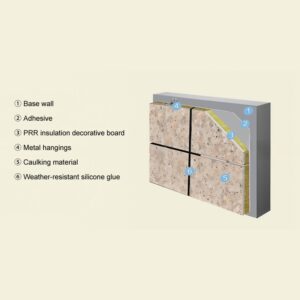

System Process

The thin – plastering system for rigid polyurethane panels adopts the “adhesion + anchoring” process, providing double – layer protection.

For more information, please refer to the safety technical specification of our company’s products or contact our customer service center.

The indicators and data provided in this document are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their intended processes and applications and to achieve the desired goals. Further applications and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part we deliver and that is used by you. We do not assume liability for indirect losses caused during the production process when our company’s products are used as raw materials. Our technical support and customer service center are willing to provide you with product – related consultations and application technical services. Please feel free to contact us by letter or phone.

For more information, please refer to the safety technical specification of our company’s products or contact our customer service center.

The indicators and data provided in this document are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their intended processes and applications and to achieve the desired goals. Further applications and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part we deliver and that is used by you. We do not assume liability for indirect losses caused during the production process when our company’s products are used as raw materials. Our technical support and customer service center are willing to provide you with product – related consultations and application technical services. Please feel free to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 5485.71 kg |

|---|