Rigid Polyurethane Foam Composite Board For Roof

The foaming agent of polyurethane rigid foam spray combination for roof is an environmentally friendly foaming agent with ultra-low thermal conductivity. It can be constructed on cement surface, brick surface, wood surface and other substrates. It has strong bonding force, good product dimensional stability and excellent flame retardant performance.

SKU:

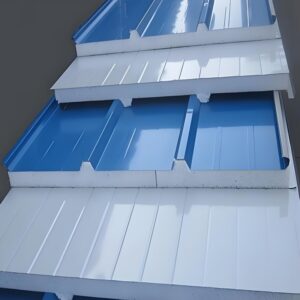

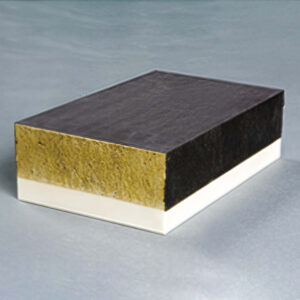

Rigid Polyurethane Foam Composite Board For Roof

Categories: Panels, Insulation Panels

Tags: Panels, Insulation Panels, Rigid Foam Polyurethane Panel

Description

Product Introduction

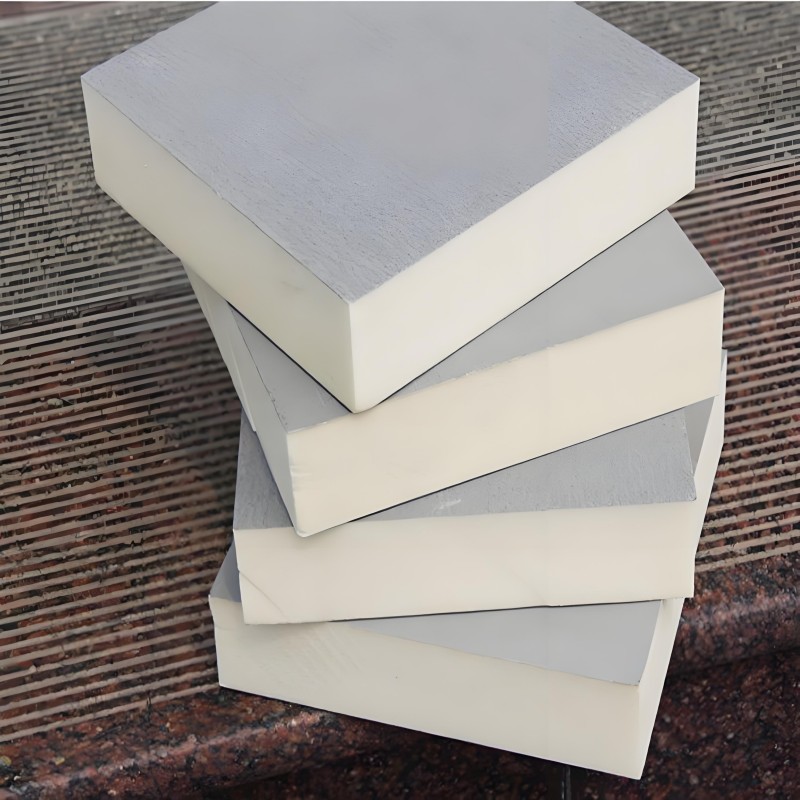

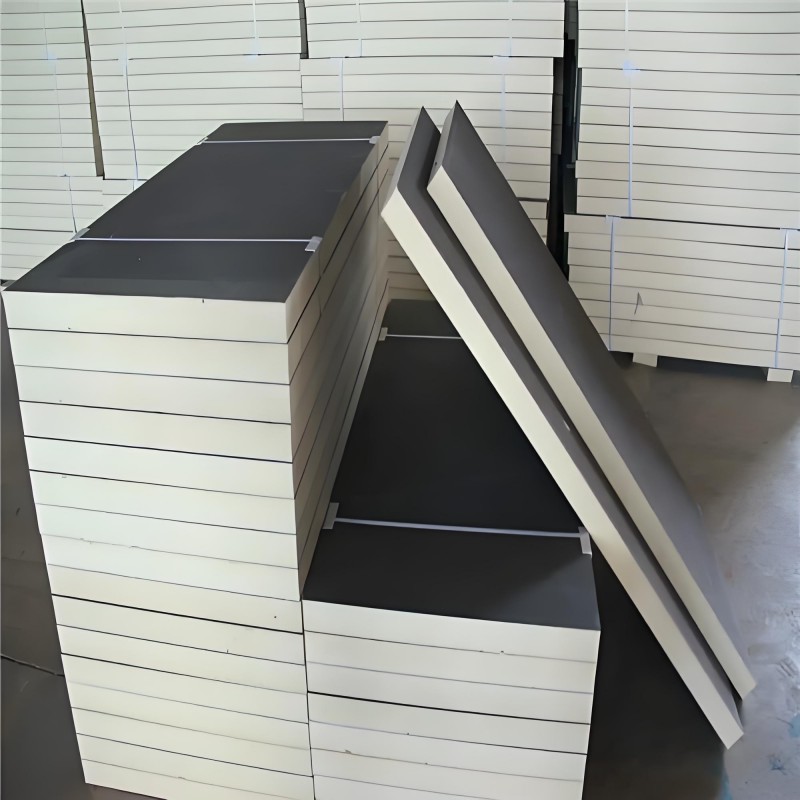

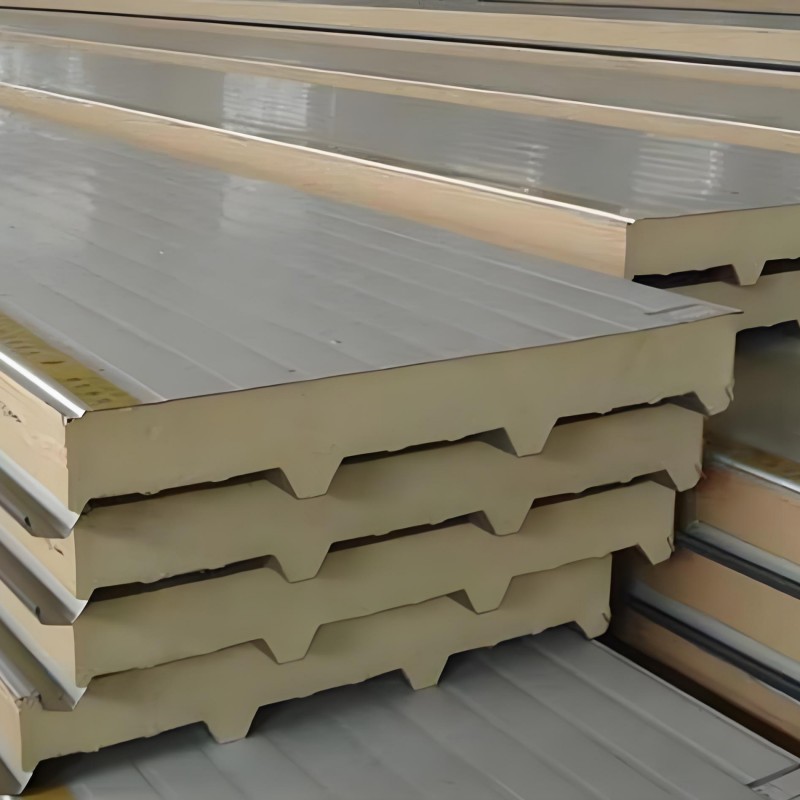

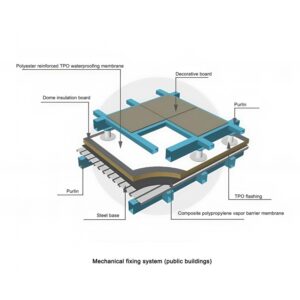

The rigid polyurethane foam composite board for roofing is a kind of heat – insulating board. It is made by processing and compounding polyurethane insulation core material and cement – based interface reinforcement coil together through a professional continuous production line in the factory (hereinafter referred to as PIR board for short).

Standard Size: 1200mm * 600mm (customizable)

Insulation Layer Thickness: 20mm – 120mm

Standard Size: 1200mm * 600mm (customizable)

Insulation Layer Thickness: 20mm – 120mm

Product Features

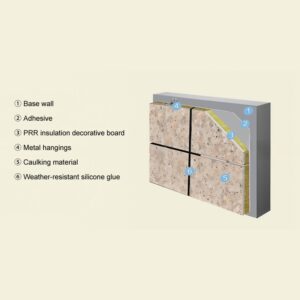

- Multi – functional Material: It has the functions of waterproofing, heat preservation and heat insulation.

The rigid polyurethane foam is a high – density closed – cell foam compound with low water absorption, excellent energy – saving and heat – insulation performance. It has the lowest thermal conductivity, the highest thermal resistance and the best energy – saving effect, making it the best choice among waterproof and heat – insulating integrated materials. - Excellent Impermeability and Strong Adhesion:

The rigid polyurethane foam has strong fluidity and permeability and can foam in the gaps of the roof base course. Its bonding strength exceeds the tear strength of the rigid polyurethane foam itself, so that the rigid foam layer and the roof base course become an integral body, which is not easy to delaminate and has good wind – uplift resistance and negative wind pressure resistance. - Light Weight and High Compressive Strength:

When the thickness is ≥ 40mm, it can meet the requirement of 65% energy – saving. The compressive strength of the rigid polyurethane foam is ≥ 300Kpa, and it can be increased to more than 600Kpa according to actual situations to meet various requirements of projects. - Wide Temperature Range for Anti – aging Strength:

The rigid polyurethane foam will not become brittle at temperatures below – 50°C and will not flow or stick at high temperatures of + 150°C. It can be used normally and is resistant to the erosion of weak acids, weak alkalis and other chemical substances. - Advanced Fluorine – free Foaming Technology, Green and Environment – friendly:

During the production of rigid polyurethane foam, the technology of water foaming instead of Freon foaming is used. The entire production process does not generate any ozone – depleting substances. It has passed the three – star China Green Building Materials Certification and is green, energy – saving, safe and environmentally friendly. - Simple and Quick Construction:

Especially for the renovation of old roofs, when the old base course has not delaminated or bulged, the old base course can be directly sprayed without being removed, which reduces the project strength and difficulty and saves project costs and construction time.

Production Process

The rigid polyurethane foam composite board for roofing adopts the advanced domestic continuous production process. Compared with traditional production processes such as the mold method and bonding method, the continuous method is easier to achieve cavity – free bonding between the rock wool layer and the interface layer. The entire production process is under real – time dynamic monitoring, with stable and controllable product quality, and the production efficiency is 10 times higher than that of traditional production processes.

For more information, please refer to the safety technical specification of our company’s products or contact our company’s customer service center.

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and uses and can achieve the intended goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

For more information, please refer to the safety technical specification of our company’s products or contact our company’s customer service center.

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and uses and can achieve the intended goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact Information

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

Additional information

| Weight | 5485.71 kg |

|---|