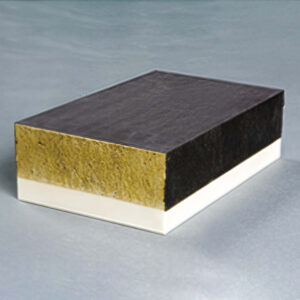

Polyisocyanurate (PIR) Thermal Insulation Sandwich Panel

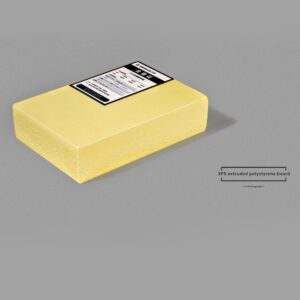

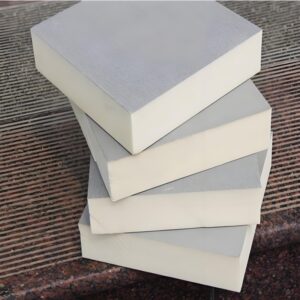

The polyisocyanurate (PIR) thermal insulation sandwich panel series cold storage panels are high-end cold storage panels that are continuously produced using the industry’s most advanced imported seven-component foaming machine HENNECKE-OMS. They use refrigerator-grade insulation material polyurethane modified isocyanurate foam (PIR) as the insulation core material. Its fireproof, heat-insulating, and earthquake-resistant properties are superior to those of general polyurethane foam (PUR). They are suitable for non-load-bearing exterior wall panels, partition panels, ceiling panels, and other fields for assembled cold storage for food storage, temperature-controlled food processing workshops with artificial refrigeration and cooling, and corresponding supporting building ancillary rooms.

Product Introduction

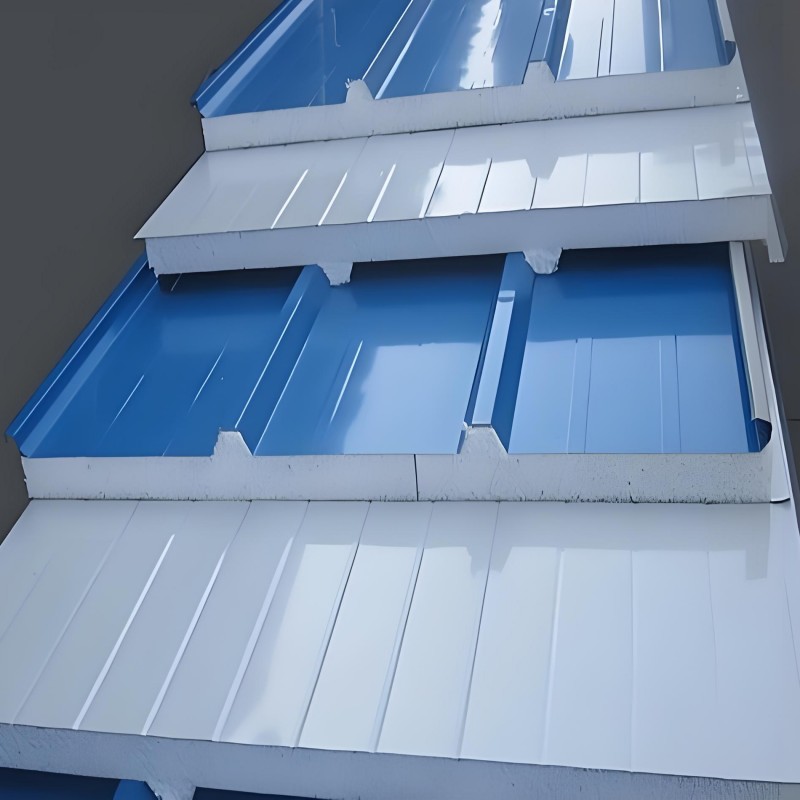

The polyisocyanurate (PIR) thermal insulation sandwich panel series cold storage panels are high-end cold storage panels that are continuously produced using the industry’s most advanced imported seven-component foaming machine HENNECKE-OMS. They use refrigerator-grade insulation material polyurethane modified isocyanurate foam (PIR) as the insulation core material. Its fireproof, heat-insulating, and earthquake-resistant properties are superior to those of general polyurethane foam (PUR). They are suitable for non-load-bearing exterior wall panels, partition panels, ceiling panels, and other fields for assembled cold storage for food storage, temperature-controlled food processing workshops with artificial refrigeration and cooling, and corresponding supporting building ancillary rooms. Our company can provide customized services according to customer needs for plate steel material (color-coated steel, stainless steel, galvanized steel, etc.), profiling method (flat or ribbed), flame retardant grade (B1 or B2), specifications and dimensions, etc. This series of cold storage panels includes polyisocyanurate (PIR) sandwich panel single-slot cold storage panel, polyisocyanurate (PIR) sandwich panel double-slot cold storage panel, polyisocyanurate (PIR) sandwich panel hook lock box cold storage panel, polyisocyanurate (PIR) sandwich panel hook lock box frame cold storage panel 4 major products.

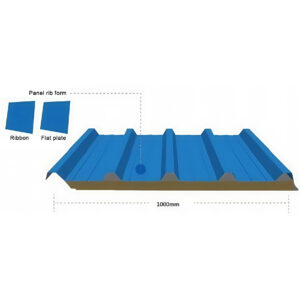

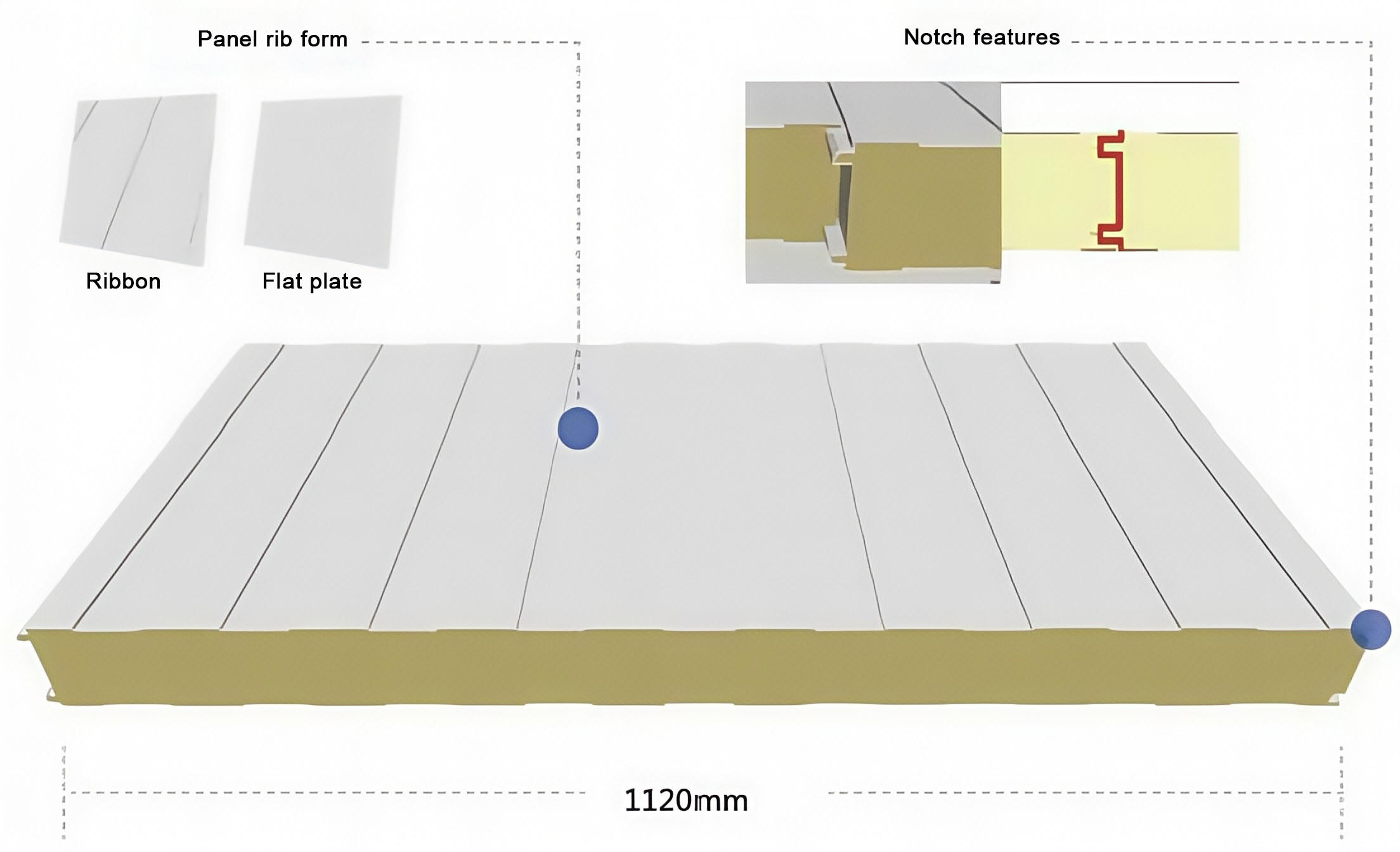

Polyisocyanurate (PIR) insulation sandwich panel single slot cold storage panel

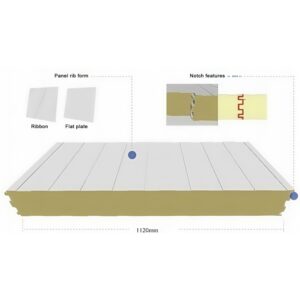

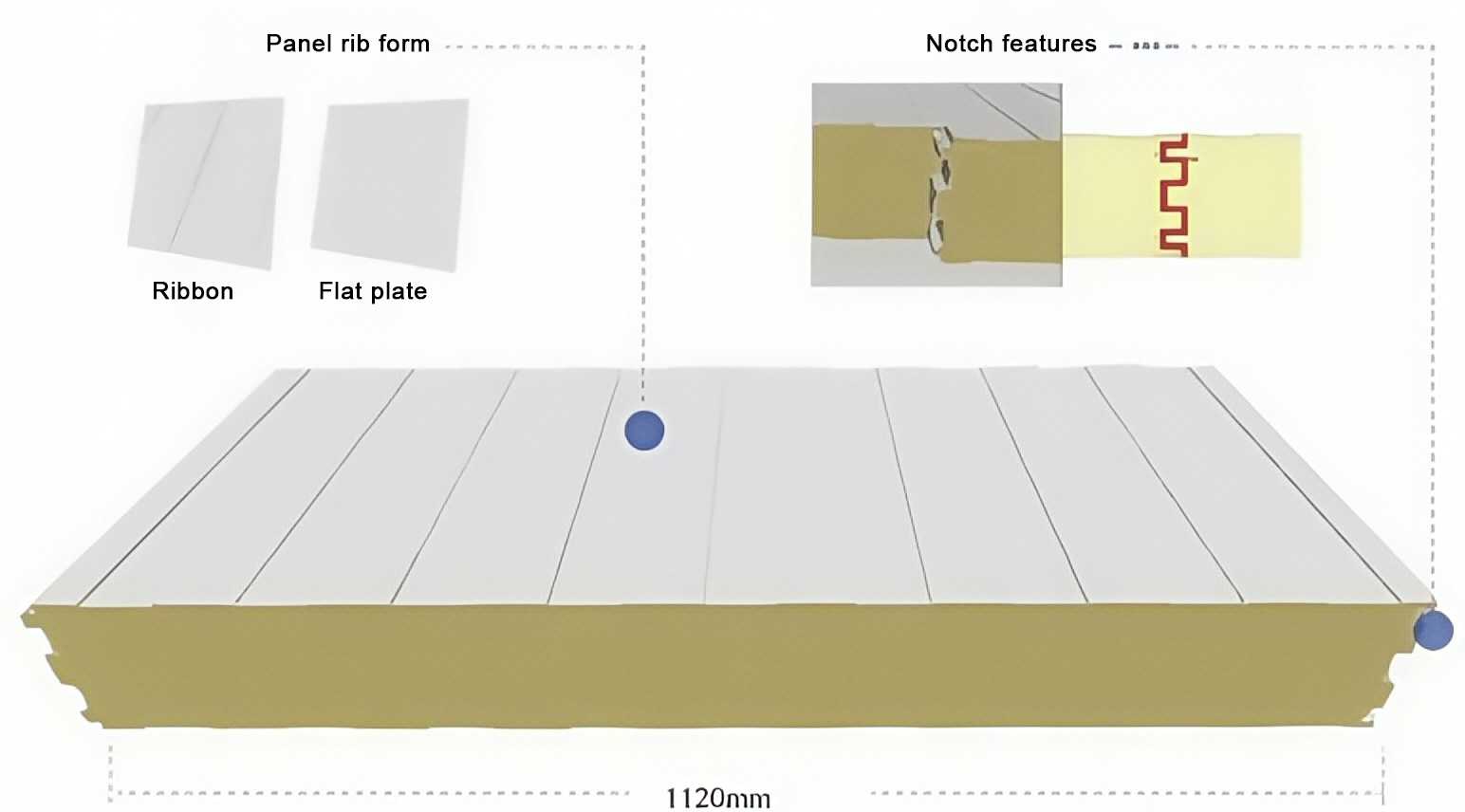

Polyisocyanurate (PIR) insulation sandwich panel double slot cold storage panel

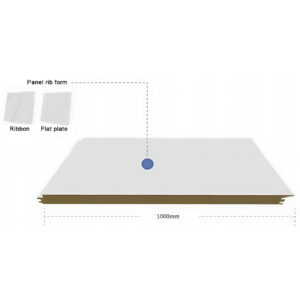

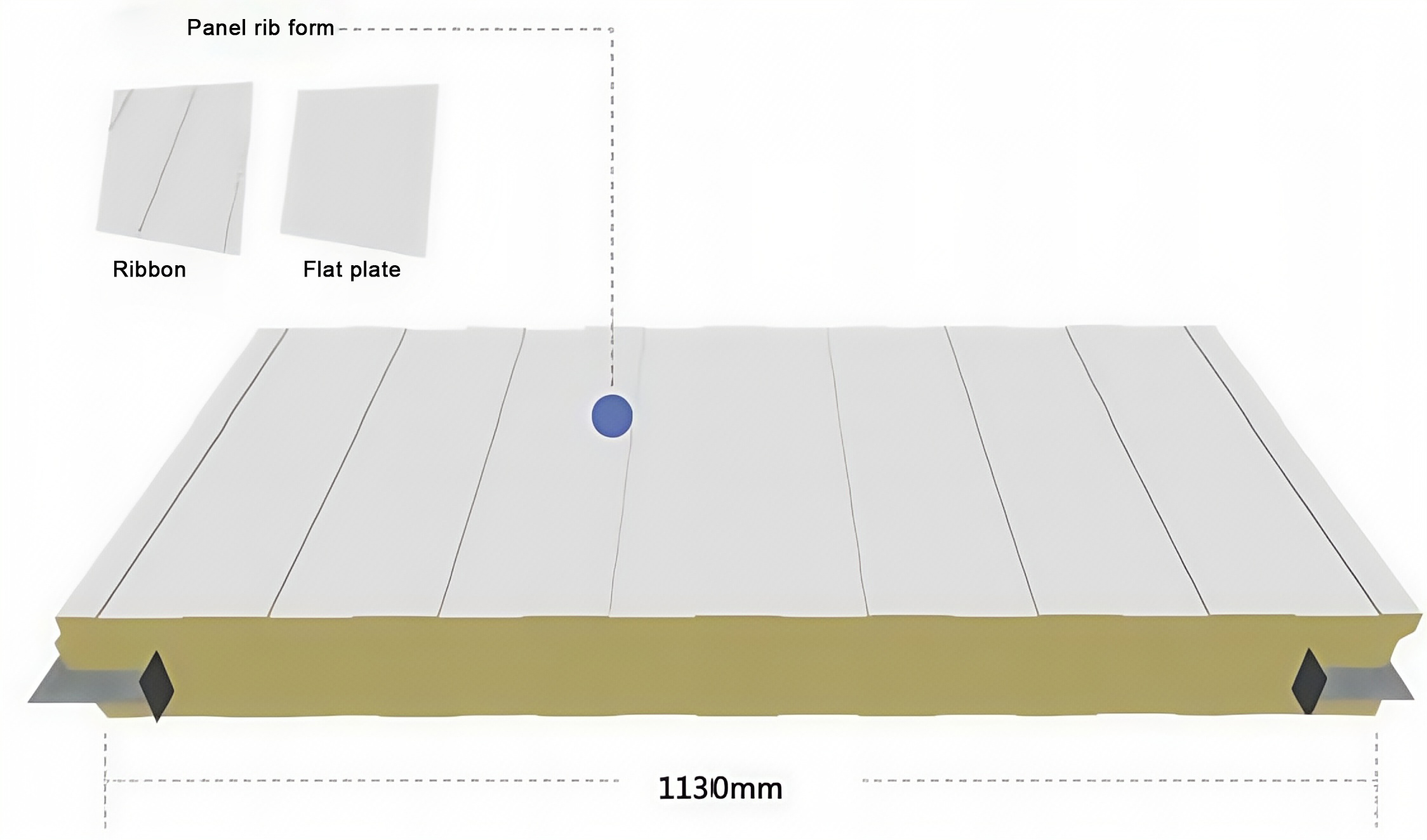

Polyisocyanurate (PIR) insulation sandwich panel hook lock box cold storage panel

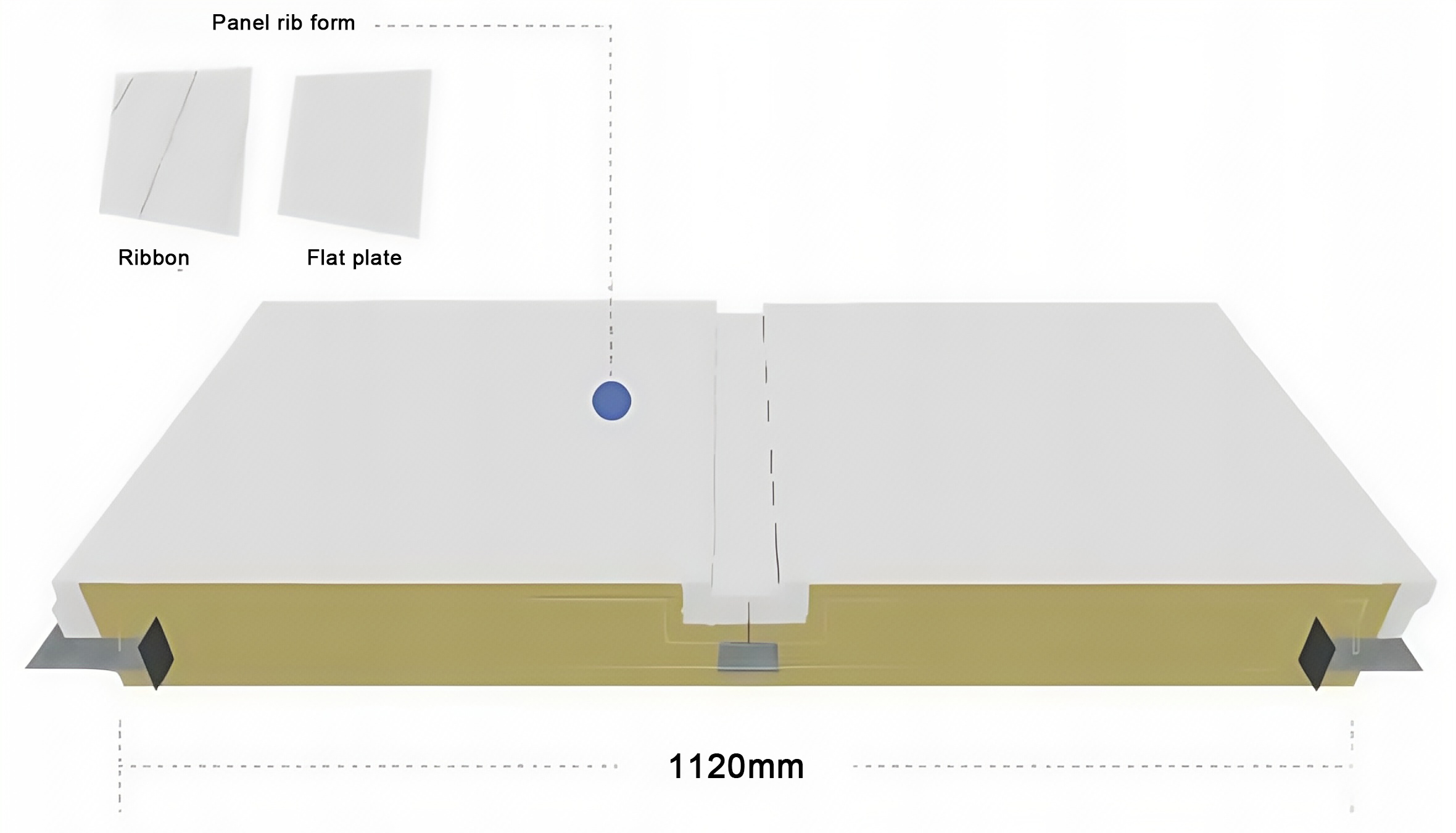

Polyisocyanurate (PIR) insulation sandwich panel hook lock box frame cold storage panel

Product Application and Features

| Name | Applicable Temperature Difference between Inside and Outside the Warehouse (℃) | Product Features |

| Single - groove Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 20/30/40/55 | The concave - convex groove structure design improves the insulation airtightness at the plate joints. It is specially designed for refrigerators and warehouses. The steel plate wraps the groove opening, making the groove shape less likely to be damaged, deformed, or disengaged, and at the same time, increasing the bending strength. |

| Double - groove Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 40/55/70 | The double - groove design makes the plates uniform and stable, with better heat - insulation and waterproof performance. It has a light weight and a beautiful appearance, effectively solving the temperature difference problem in the refrigeration industry. |

| Hook - lock Box - type Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 20/30/40/55 | It is specially designed for assembling small and medium - sized cold storage, insulated rooms, and boxes. High - strength locks are embedded around each prefabricated panel, making assembly very convenient. |

| Hook - lock Box - frame - type Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 20/30/40/55 | It is a building envelope panel with good heat - insulation performance and high strength. Within a certain modulus, the cold storage body can be freely changed in the length, width, and height directions. It can be expanded or reduced as needed, and the assembled panels can also be disassembled and reinstalled in other places. |

Product Specifications

| Name | Thickness Specification (mm) | Plate Weight (Kg/m³) | Simple - supported Height of Wall Panels (m) | Simple - supported Height of Wall Panels (m) |

| Single - groove Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 50/100/150/200 | 10/12.5/15/17.5 | 3/3.8/4.2/5 | 2.5/3/3.6/4.2 |

| Double - groove Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 150/200/250 | 15/17.5/20 | 3.8/4.2/5 | 2.5/3/3.6/4.2 |

| Hook - lock Box - type Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 50/100/150/200 | 10.6/13.1/15.6/18.1 | 3/3.8/4.2/5 | 2.5/3/3.6/4.2 |

| Hook - lock Box - frame - type Cold Storage Panel made of Polyisocyanurate (PIR) Insulated Sandwich Panels | 50/100/150/200 | 10.6/13.1/15.6/18.1 | 3/3.8/4.2/5 | 2.5/3/3.6/4.2 |

Precautions for Use

- During the installation process, pay attention to labor protection to prevent the panels from falling and causing injury, as well as scratches from the edges of the panels.

- The construction site should be a fire - prohibited area, keep away from fire sources, and smoking is strictly prohibited. When there is hot work nearby, the hot work approval system must be strictly implemented, and corresponding safety measures should be taken with dedicated personnel for supervision.

Panel Packaging

- For bulk packaging, classify by panel length, protect the edges with angle iron, and fix with ropes.

- For boxed packaging, materials such as section steel, metal thin plates, or wooden boards are preferably used as packaging boxes.

- The packaging height shall be jointly determined by the supply and demand parties, and in principle, it shall not exceed 2.8m.

- It is advisable to line with polyethylene film or kraft paper between the sandwich panels for isolation, and cover the outer surface with a protective film.

Transportation

- The product can be transported by cars, trains, ships, or containers. Cars can transport in bulk, while other transportation tools should transport in boxes or bundles. During transportation, the stacking height and width should comply with the road transportation regulations of various regions.

- During the transportation process, the sandwich panels should not be heavily pressed, dropped violently, or collided with sharp objects. They should be laid flat and firmly, tightened with ropes, etc., and supported reasonably to avoid being pressed or mechanically damaged. Fire and fireworks are strictly prohibited.

- The storage place should be flat, with reduced vibration and prevention of collision. It should avoid being pressed or mechanically damaged, and there should be rain - proof measures. Fire and fireworks are strictly prohibited.

- When handling long sandwich panels, in order to prevent the panels from breaking, it is strictly prohibited to lift them horizontally at both ends.

- It is strictly prohibited to transport together with chemically active substances and damp materials in the same carriage or ship.

- When loading and unloading the product, avoid collision and do not throw it.

Storage

- The sandwich panels should be stored in a clean, dry, ventilated warehouse without corrosive environment and protected from rain and snow. When stored outdoors, it should be isolated from corrosive media, and waterproof and moisture - proof measures should be taken to avoid direct sunlight.

- The storage site should be solid and flat. The height of bulk stacking should not exceed 2.8m. The bottom of the sandwich panels should be padded with wooden blocks or foam boards. The distance between the wooden blocks should not be greater than 2.0m, and the padding points should ensure that the sandwich panels do not produce bending deformation.

- Store away from heat sources and fire sources, and do not contact with chemical drugs.

- Store in an environment with a temperature above 15℃. When the temperature is lower than 10℃, it should be cured at room temperature before being moved outdoors.

Fire and Explosion Hazards

The core material of this product can self - extinguish when the fire source is removed, and there is a steel plate on the outside for protection. Under normal circumstances, a fire will not occur. In case of a fire, this product can be extinguished with water, carbon dioxide, foam, or chemical dry powder fire extinguishers.

Fire - fighting Procedure: Normal protection

Solid Waste Treatment

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their respective planned processes and uses and to achieve the intended purpose. Further application and processing of our company's products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company's products as raw materials. Our company's technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or telephone.

Contact Information

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

| Weight | 5485.71 kg |

|---|