XPS Wet Floor Heating Board

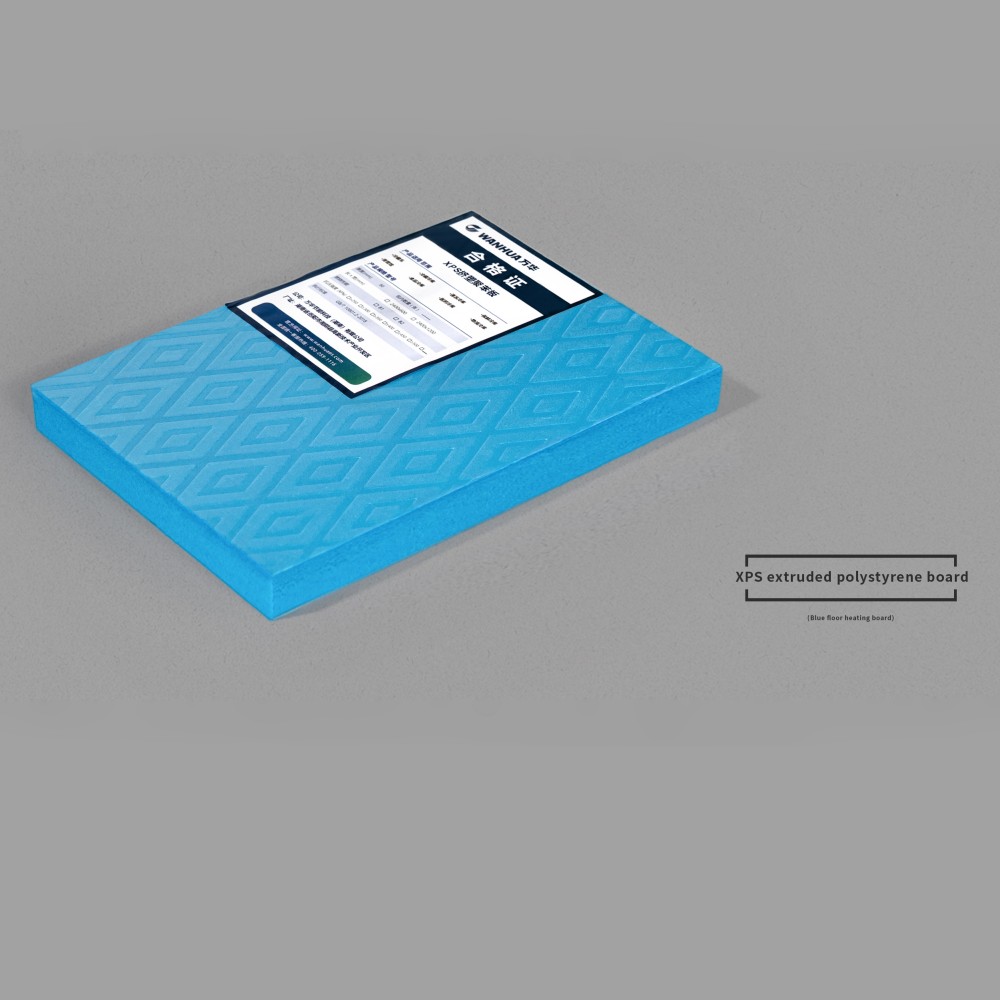

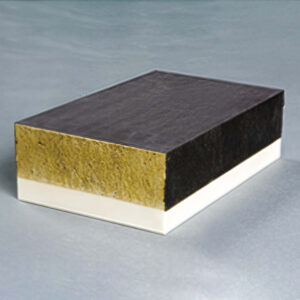

The XPS wet floor heating board is manufactured by advanced extrusion technology, using high-quality polystyrene resin as the base material, added with special additives and formed by high-temperature extrusion. Its unique closed-cell honeycomb structure endows the product with excellent thermal insulation performance, good compressive strength and outstanding moisture-proof and waterproof capabilities. Compared with traditional floor heating materials, the XPS wet floor heating board ensures the efficient operation of the floor heating system and effectively reduces heat loss, making it an ideal choice for wet floor heating projects in modern buildings.

SKU:

XPS Wet Floor Heating Board

Categories: Panels, XPS Board/Crack-Resistant Panel

Tags: Panels, XPS Board/Crack-Resistant Panel

Description

Product Introduction

The XPS wet floor heating board is manufactured by advanced extrusion technology, using high-quality polystyrene resin as the base material, added with special additives and formed by high-temperature extrusion. Its unique closed-cell honeycomb structure endows the product with excellent thermal insulation performance, good compressive strength and outstanding moisture-proof and waterproof capabilities. Compared with traditional floor heating materials, the XPS wet floor heating board ensures the efficient operation of the floor heating system and effectively reduces heat loss, making it an ideal choice for wet floor heating projects in modern buildings.

Application Scenarios

- Residential Buildings: Widely used in various family houses, especially suitable for severe cold areas in the north and residential projects with high requirements for indoor temperature stability, creating a warm and comfortable living environment for residents.

- Commercial Buildings: Applicable to commercial places such as shopping malls, office buildings and hotels, meeting the heating needs of large areas, improving indoor comfort and helping to create high-quality commercial space environments.

- Public Facilities: Can be used in public buildings such as schools, hospitals and libraries, providing warm activity spaces for personnel, and meeting the requirements of public buildings for environmental protection, safety and durability.

Performance Indicators

| Item | Parameters |

|---|---|

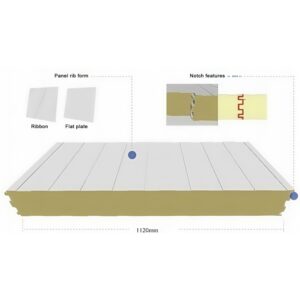

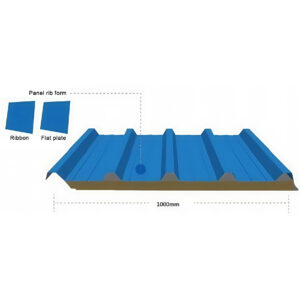

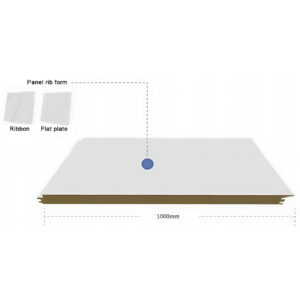

| Size Specification | 1670×600×20mm and 1670×600×30mm, meeting the requirements of different building structures and floor heating system designs for board thickness and area. |

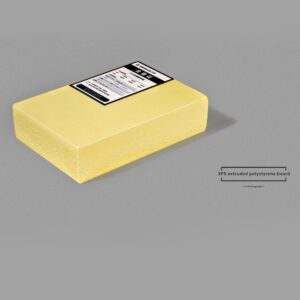

| Color Options | Standard colors are blue, white and bright white, with a simple and beautiful appearance; personalized color customization is also supported to adapt to diversified decoration styles. |

| Compressive Strength | 250~350kPa, capable of withstanding the pressure during the operation of the floor heating system and the conventional ground load, ensuring the stable operation of the floor heating system and not easy to deform or damage. |

| Thermal Conductivity | ≤0.030W/(m·K), effectively preventing heat from conducting downward, reducing energy consumption and improving the thermal efficiency of the floor heating system. |

| Water Absorption | ≤1.0%, with excellent moisture-proof and waterproof performance, which can prevent the moisture from the foundation from rising and avoid the reduction of thermal insulation performance or damage of the board due to moisture. |

| Environmental Protection Indicators | The product meets the national environmental protection standards, has stable chemical properties, and does not release harmful substances during production and use, ensuring the indoor air quality and providing a healthy living environment for users. |

Usage Precautions

Before Installation

- Conduct a comprehensive inspection of the installation ground to ensure that the ground is flat, dry, free of debris and sharp protrusions. If the ground is uneven, it must be leveled to ensure the installation effect and service life of the floor heating board.

- Check the construction environment temperature, and it is recommended to carry out the installation work above 5℃ to avoid the impact of low temperature on the installation quality.

During Installation

- Strictly follow the design scheme of the floor heating system and the construction specifications. When laying the floor heating board, ensure that the boards are tightly spliced and use special fixing materials to firmly fix the floor heating board on the ground to prevent displacement.

- When installing the floor heating pipes, ensure that the pipes are firmly fixed to avoid twisting, folding and other conditions. After the installation is completed, a pressure test shall be carried out to ensure that there is no leakage problem.

During Use

- When starting the floor heating system for the first time or restarting it after a long period of shutdown, the temperature should be raised slowly, and the heating rate should not exceed 5℃/h to prevent the floor heating board from cracking or deforming due to sudden temperature changes.

- In daily use, avoid placing heavy or sharp objects on the ground to prevent damage to the floor heating board and floor heating pipes; at the same time, regularly check the operation status of the floor heating system and deal with any abnormalities in time.

Packaging Specifications

- Packaging Materials: The floor heating board is wrapped as a whole with moisture-proof plastic film to effectively prevent moisture during transportation and storage, and corner protectors are added at the corners. When necessary, wooden pallets are used for reinforcement to ensure that the product is not damaged during transportation.

- Packaging Quantity: The packaging quantity per pack is determined according to the product size. For the 1670×600×20mm specification, there are 20 pieces per pack, and for the 1670×600×30mm specification, there are 13 pieces per pack.

Storage (Usage) Precautions

- Storage Environment: The product should be stored in a dry, ventilated and cool indoor environment, avoiding open-air stacking and direct sunlight. The storage temperature should be controlled between -10℃ and 28℃ to prevent the board from deforming due to high temperature exposure or affecting the product performance due to low temperature freezing.

- Stacking Requirements: The stacking height should not exceed 2 meters, and it should be stacked flat. Products of different specifications, colors and batches need to be stacked separately for easy management and access. It is strictly forbidden to stack heavy objects on the boards to prevent the boards from being compressed and deformed.

- Service Life: Under the conditions meeting the storage requirements, the product is recommended to be used within 6 months from the date of production to ensure its best performance. If it is used beyond the period, the product performance needs to be tested, and it can be used only after confirming that it is qualified.

Warranty Period

The warranty period of this product is 1 year, calculated from the date of product delivery. During the warranty period, if the product is damaged or fails to meet the performance standards due to its own quality problems, our company will provide free maintenance or replacement services; problems caused by improper use, human damage or force majeure factors (such as earthquakes, floods, etc.) are not within the warranty scope.

Safety Precautions

- Electrical Safety: The floor heating system involves electrical equipment, and the installation and maintenance should be operated by professional personnel. It is strictly forbidden for non-professional personnel to disassemble and repair without authorization to prevent safety accidents such as electric shock.

- Fire Safety: Although the product has certain flame retardancy, during storage and use, it still needs to be kept away from open flames and high-temperature heat sources. Smoking is prohibited at the construction site, and necessary fire-fighting equipment should be equipped.

- Health Safety: If abnormal conditions such as damage or deformation of the product are found, it should be replaced in time to avoid increased indoor energy consumption and air quality problems caused by the decrease of thermal insulation performance.

Statement: The indicators and data in this material are based on our existing technical knowledge and practical experience for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their own proposed processes and uses and to achieve the intended purpose. The further application and processing of our company’s products are beyond our control, so our liability for the products provided is limited to the part delivered by us and used by you. The technical support and customer service center of our company are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or telephone.

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|