PRR Line Board

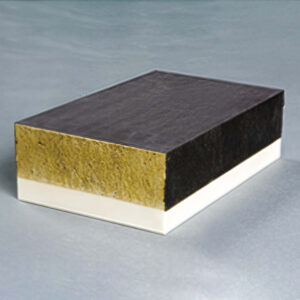

PRR Line Board decorative lines not only have the effect of exterior wall decoration, but also have Class A fireproof grade, good thermal insulation effect, high tensile strength, high compressive strength, good crack resistance and long service life.

SKU:

PRR Line Board

Categories: Panels, Insulation Panels

Tags: Panels, Insulation Panels, PRR Line Panel

Description

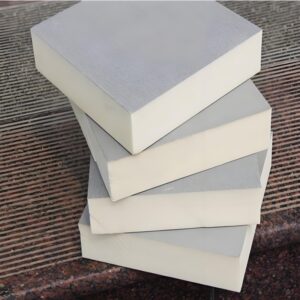

Product Introduction

Article 6.7.12 of the “Code for Fire Protection Design of Buildings” GB 50016 – 2014 (2018 Revised Edition) states that the decorative layer of the building exterior wall should adopt materials with a combustion performance of Class A. However, when the building height is not more than 50m, Class B1 materials can be used. This requires that the decorative profiles for exterior wall insulation must simultaneously consider both fire protection and insulation functions. In buildings designed with a Class A exterior wall insulation system, once a large number of decorative profiles are involved, design units usually require the use of decorative profiles with a Class A fire protection performance. The most common EPS decorative profiles now face limitations in terms of building height and combustion performance. Among Class A fire – rated inorganic insulation and decorative materials, vertical – filament rock wool is gradually coming into the public eye.

Based on this technical background and market demand, the company has developed and launched vertical – filament rock wool profile boards with a Class A fire rating, which can simultaneously meet the functional requirements of insulation, heat insulation, sound insulation, waterproofing, and beautification. This product works best when used in conjunction with the Wanhua PRR board thin – plastering system.

Product Features

This decorative profile not only has an exterior wall decoration effect but also features a Class A fire rating, good insulation effect, high tensile strength, high compressive strength, excellent crack – resistance, and a long service life.

Production Process

PRR profile boards adopt advanced domestic continuous production processes and are pre – fabricated in the factory. The entire production process is under real – time dynamic monitoring, ensuring stable and controllable product quality. The production efficiency is 10 times higher than that of traditional production processes.

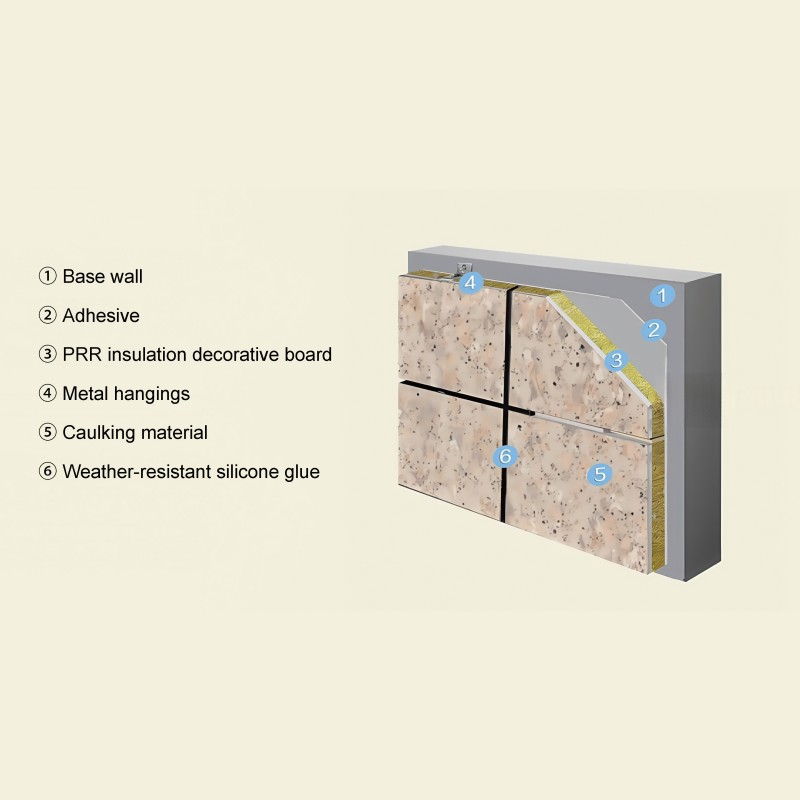

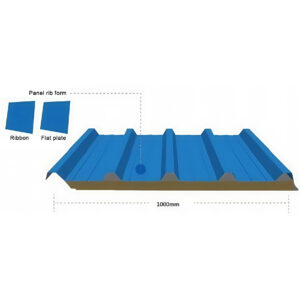

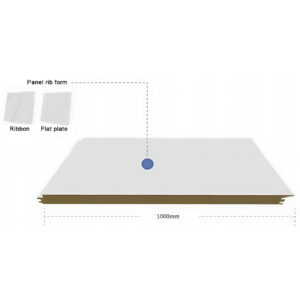

System Process

It is commonly used in the PRR board thin – plastering system and adopts the “adhesion + anchoring” process for double – layer protection.

It can be directly wet – pasted on – site, which is convenient for installation. The finish coating can be directly applied on the outer surface of the profile. The construction operation is simple, ensuring that the exterior wall of the main building does not have cold or hot bridge effects.

It can be directly wet – pasted on – site, which is convenient for installation. The finish coating can be directly applied on the outer surface of the profile. The construction operation is simple, ensuring that the exterior wall of the main building does not have cold or hot bridge effects.

Wanhua Energy Conservation Technology (Yantai) Co., Ltd.

For more information, please refer to the safety technical specifications of our company’s products or contact our company’s customer service center.

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their respective intended processes and uses and to achieve the intended goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume liability for indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product – related consultation and application technical services. Welcome to contact us by letter or by phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 5485.71 kg |

|---|