WANSHIELD®62103 Anti – static Water – based Epoxy Primer for Floor Coating

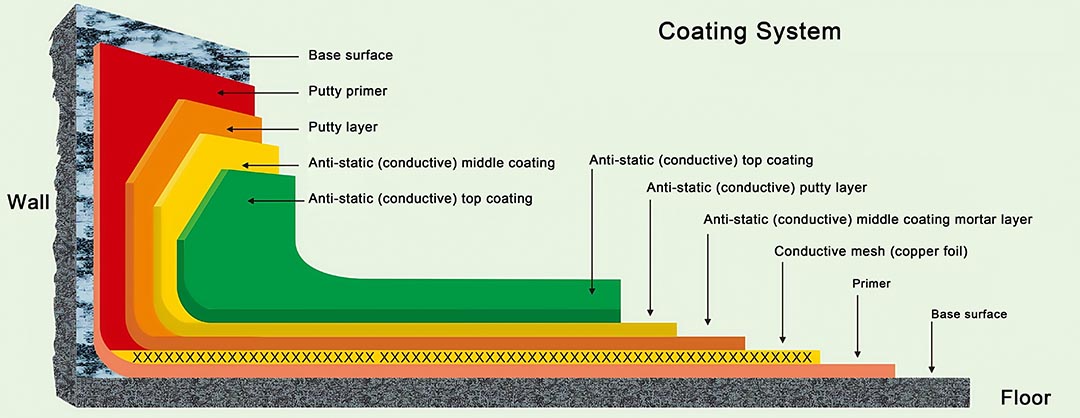

WANSHIELD® 62103 Antistatic Water-Based Epoxy Primer is a two-component, water-based epoxy resin adhesive with reactive curing properties. As an environmentally friendly coating, it serves as a conductive black primer for antistatic epoxy flooring and can be combined with quartz sand or other fillers to formulate conductive epoxy mortar intermediate coatings.

Product Overview

WANSHIELD® 62103 Antistatic Water-Based Epoxy Primer is a two-component, water-based epoxy resin adhesive with reactive curing properties. As an environmentally friendly coating, it serves as a conductive black primer for antistatic epoxy flooring and can be combined with quartz sand or other fillers to formulate conductive epoxy mortar intermediate coatings.

Key Features

- Eco-friendly: Benzene-free with extremely low VOC (Volatile Organic Compounds) content.

- Superior Adhesion: Excellent bonding to damp substrates. Ensuring the stability and durability of the coating system.

- Deep Penetration & Sealing: Provides robust sealing performance. Preventing the penetration of moisture and other substances.

- Durable Conductivity: Offers long-lasting electrical conductivity. Meeting the anti – static requirements of relevant applications.

Applications

Suitable for concrete substrates and properly treated steel surfaces.

Physical & Chemical Properties

| Parameter | Specification | Test Standard |

|---|---|---|

| Appearance (mixed) | Homogeneous, free of lumps | Visual inspection |

| Surface Drying Time (h) ≤ | 8 | GB/T 22374-2018 |

| Full Curing Time (h) ≤ | 24 | GB/T 22374-2018 |

| VOC Content (g/L) ≤ | 60 | GB/T 23985-2009 |

| Alkali Resistance | Film remains intact; no blistering/delamination; slight discoloration allowed | GB/T 22374-2018 |

| Tensile Bond Strength (MPa) ≥ | 2.0 | GB/T 22374-2018 |

| Surface Resistivity (Ω) | 5×10⁴ – 1×10⁶ (electrostatic conductive type) | GB/T 1410-1989 |

Note: Data provided are typical values; actual results may vary under different environmental conditions. Specifications are not legally binding.

Surface Preparation

Substrate Requirements

- For Concrete Floors: Minimum compressive strength ≥ C25; pull-off strength ≥ 1.5 MPa.

- Remove all contaminants (oil, grease, loose particles, old coatings) to expose sound concrete.

- Grind the surface to achieve a profile of CSP3-6 using shot blasting or mechanical abrasion.

- Ensure flatness ≤ 3mm (checked via 2m straightedge). Repair low areas with epoxy mortar.

- Substrate moisture content must be <6%; curing period completed.

Application Conditions

- Ambient Temperature: 10–35°C.

- Substrate Temperature: ≥3°C above dew point.

- Humidity: <85% RH.

- Pot Life: 50–60 minutes (23°C).

- Ventilation: Dust-free environment; avoid strong airflow.

Application Guidelines

| Parameter | Specification |

| Mixing Ratio (A:B) | 3:1 by weight; mix thoroughly. |

| Water Dilution | Max. 35% of Component A weight. |

| Pot Life (at 23°C) | 50 minutes. The higher the temperature, the shorter the pot life. When the ambient temperature during construction is higher than 40°C, construction is generally not recommended. |

| Application Methods | Roller, brush. |

| Cleaner | Water. |

| Drying Time | Surface dry: 8h; Full cure: 48h (23°C, 60% RH). |

| Recoat Interval | ≥24h (ensure full curing before overcoating). |

Note: Drying times vary with temperature, humidity, film thickness, and ventilation. Test under job-site conditions prior to full-scale application.

Packaging & Storage

Safety Precautions

PPE Requirements:

NIOSH-approved respirator

Chemical goggles + nitrile gloves

First Aid:

Skin: Soap/water → seek medical help if irritation persists.

Eyes: 15-min flush → immediate ophthalmologist visit.

Fire Rating:

This product is not classified as a flammable liquid, explosive, oxidizer, corrosive, toxicant, or radioactive hazardous material during storage and transportation, and is not a hazardous product.

NFPA 704: 0-1-0

Extinguishing: CO₂/dry chemical

- In the absence of other fire-fighting agents, a large amount of fog-like water can also be used for spraying. After the fire is extinguished, the spilled materials should be cleaned up (refer to the leakage and spillage treatment section).

Leakage and Spillage Treatment

Disclaimer

Contact:

| Weight | 12 kg |

|---|