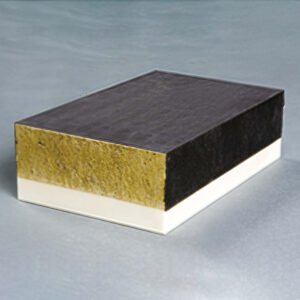

Lightweight Plastering Gypsum

Lightweight plastering gypsum is a new type of gypsum suitable for efficient leveling of indoor walls and ceilings. The product uses selected gypsum as raw material, which is high in strength and makes the wall more durable and solid.

SKU:

Lightweight plastering gypsum

Categories: Coatings, Architectural Coatings

Tags: Coatings, Architectural Coatings, Light Gypsum Plaster

Description

Product Introduction

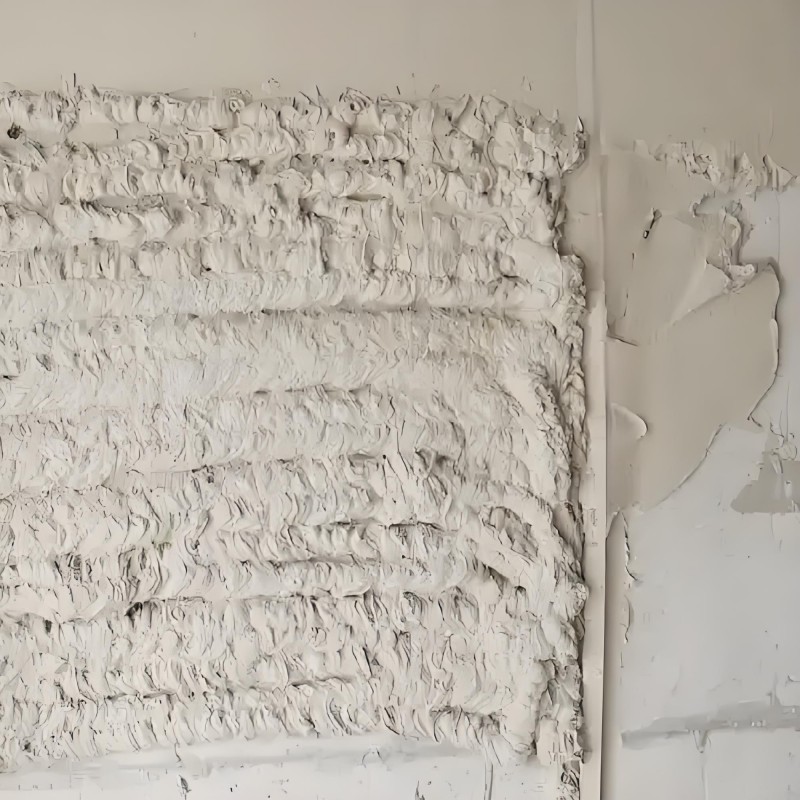

Lightweight plaster gypsum is a brand – new gypsum product suitable for efficient leveling of interior walls and ceilings. The product uses selected gypsum as raw material, which has high strength and makes the walls more durable and solid. Compared with traditional interior wall and ceiling leveling materials, this product has more stable performance, better leveling effect, and can effectively shorten the construction period.

Superior Performance

It is green and environmentally friendly, can regulate humidity, has sound – insulation and heat – preservation properties, has strong adhesion and does not crack. It can effectively reduce the building’s self – weight and improve building energy – saving effect.

Construction Method

- Premix the powder – Add water first and then the powder, and stir it into a uniform paste. It is recommended to use the prepared product within 30 minutes, and mix it as you use. The set paste shall not be added with water and stirred for use again.

- Substrate treatment – The moisture content of the substrate should be ≤20%. For concrete structures and loose substrates, an interface agent is required for treatment.

Performance Indicators

| Test Items | National Standard Requirements | Test Data |

| Film State – Initial Setting Time | ≥1h | 1h30min |

| Final Setting Time | ≤8h | 2h08min |

| Flexural Strength /MPa | ≥1.0 | ≥1.5 |

| Compressive Strength /MPa | ≥2.5 | ≥2.8 |

| Tensile Bond Strength /MPa | ≥0.3 | ≥0.5 |

| Bulk Density /kg/m³ | ≤1000 | 800 |

The values provided in this document are typical test values, and the specific data may vary slightly due to environmental conditions. For our company’s products, the listed data has no legal binding force.

Precautions

- It is recommended to construct when the construction temperature is between 5 – 35°C and the relative air humidity is ≤85%.

- Changes in temperature and humidity affect the available time, drying time, and drying speed.

- In case of continuous rainy or low – temperature weather, appropriately extend the maintenance time of the gypsum layer. When the moisture content is lower than 20%, the next – step surface putty construction can be carried out to avoid blistering of the surface putty caused by excessive water content in the bottom layer and yellowing of the gypsum in the later stage.

- When constructing in windy weather, it is recommended to close doors and windows to avoid rapid water loss on the surface of the gypsum due to excessive air circulation, which may cause cracking and affect the strength.

- If the wall base loses water too quickly, it is necessary to apply an interface agent for priming first to prevent the gypsum from cracking after being applied to the wall.

The buyer must conduct tests in an environment consistent with the construction conditions before the formal project construction to ensure the reliability of the material used in this specific project. During formal construction, it is regarded that the buyer has recognized the qualified performance inspection of the product. If the above operations are not followed, all responsibilities shall be borne by the buyer.

Packaging Specification

25±0.5kg/bag.

Storage Precautions

This product should be placed on a wooden pallet in a dry place, and moisture – proof and waterproof measures should be taken.

Shelf Life

From the date of production, under the specified storage conditions, the shelf life is 6 months.

Safety Precautions

Direct contact may cause moderate eye irritation and mild skin irritation, and may cause skin allergies. Seek medical attention immediately and take symptomatic treatment measures.

Once it gets into the eyes, rinse immediately with clean water and seek medical attention if necessary. In case of ingestion, seek medical attention immediately for symptomatic treatment.

Once it gets into the eyes, rinse immediately with clean water and seek medical attention if necessary. In case of ingestion, seek medical attention immediately for symptomatic treatment.

Fire and Explosion Hazards

This product is not a flammable liquid, explosive, oxidizer, corrosive, toxic, or radioactive hazardous material during storage and transportation, and it is not a hazardous product.

Fire – fighting Media: Carbon dioxide, foam, or chemical dry powder fire extinguishers can be used for fire – fighting. When there is no other fire – fighting agent available, a large amount of atomized water can be sprayed. Once the fire is extinguished, the spilled materials should be cleaned up (see Leakage and Spillage Handling).

Fire – fighting Procedure: Normal protection.

Fire – fighting Media: Carbon dioxide, foam, or chemical dry powder fire extinguishers can be used for fire – fighting. When there is no other fire – fighting agent available, a large amount of atomized water can be sprayed. Once the fire is extinguished, the spilled materials should be cleaned up (see Leakage and Spillage Handling).

Fire – fighting Procedure: Normal protection.

Leakage and Spillage Handling

Small amounts of leaked and spilled materials can be washed away with water. In case of a large – scale leak, collect and recycle the materials, and wash the contaminated ground with water or detergent. The disposal of waste composite materials must comply with local government environmental protection regulations.

For more information, please refer to our company’s product safety technical specification or contact our company’s customer service center.

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. The user has the responsibility to test the products purchased from our company to verify whether they are suitable for their intended processes and uses and to achieve the desired purpose. Our company cannot control the further application and processing of our products. Therefore, our liability for the products provided is limited to the part we deliver and that the buyer uses. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product – related consultation and application technical services. Welcome to contact us by letter or phone.

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. The user has the responsibility to test the products purchased from our company to verify whether they are suitable for their intended processes and uses and to achieve the desired purpose. Our company cannot control the further application and processing of our products. Therefore, our liability for the products provided is limited to the part we deliver and that the buyer uses. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product – related consultation and application technical services. Welcome to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 5485.71 kg |

|---|