WB002 Single-Component Polymer Waterproof Coating

WB002 one-component high-molecular polymer waterproof coating is based on modified acrylate multi-copolymer emulsion

A thick single-component water-based high-molecular waterproof coating film scientifically processed by adding various additives and fillers to the base material

Materials.

SKU:

WB002 Single-Component Polymer Waterproof Coating

Category: Architectural Coatings

Tags: Coating, Architectural Coatings

Description

Overview

WH-WB002 Single-Component Polymer Waterproof Coating is a high-quality water-based polymer waterproof coating material. It is made from modified acrylate multi-copolymer emulsion as the base material, blended with various additives and fillers through scientific processing.

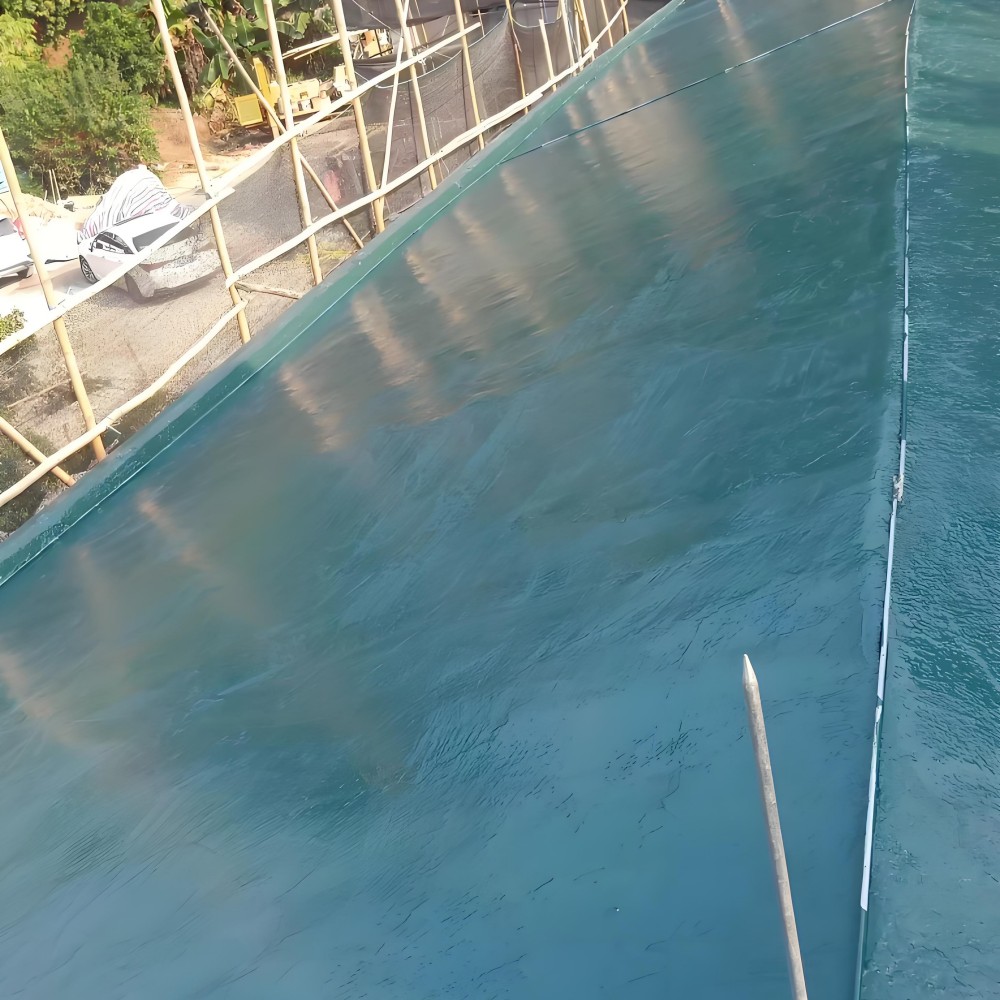

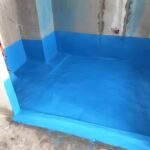

Recommended Applications

This product is suitable for waterproofing projects on roofs, walls, indoor toilet and bathroom floors, kitchen floors, etc. It can also be used for decorative protection of roof waterproof layers.

Performance Characteristics

- Environmentally Friendly: Water-based emulsion, free of any organic solvents, non-toxic and harmless, belonging to green environmental protection products.

- Moist Substrate Application: Can be constructed on damp substrates with high bonding strength, ensuring firm adhesion to both the substrate and the outer protective decorative layer.

- High Durability: Features high film strength and large elongation, showing strong adaptability to substrate shrinkage and deformation cracks.

- Weather Resistance: Resistant to ultraviolet rays, weathering, and aging.

- Convenient Construction: Cold application process, simple to construct and easy to repair.

Technical Properties

Appearance: Milky white liquid at room temperature, homogeneous without agglomeration after stirring.

Physical and Mechanical Properties:

All physical and mechanical properties of the coating exceed the standards specified in JC/T864-2008. The main technical requirements are as follows:

All physical and mechanical properties of the coating exceed the standards specified in JC/T864-2008. The main technical requirements are as follows:

| Test Item | Technical Index | |

|---|---|---|

| Ⅰ | Ⅱ | |

| Tensile Strength (MPa) ≥ | 1.0 | 1.5 |

| Elongation at Break (%) ≥ | 300 | – |

| Low-Temperature Flexibility (℃) | -20℃, No Cracks | – |

| Water Impermeability (0.3MPa, 30min) | Impermeable | – |

| Drying Time | ||

| – Surface Dry (h) ≤ | 4 | – |

| – Through Dry (h) ≤ | 8 | – |

| Solid Content (%) ≥ | 65 | – |

| Tensile Strength Retention Rate (%) | ||

| – After Heat Treatment ≥ | 80 | – |

| – After Alkali Treatment ≥ | 60 | – |

| – After Acid Treatment ≥ | 40 | – |

| Elongation at Break After Treatment (%) | ||

| – After Heat Treatment ≥ | 200 | – |

| – After Alkali Treatment ≥ | 200 | – |

| – After Acid Treatment ≥ | – | – |

| – After Artificial Weathering Treatment ≥ | – | 200 |

| Heating Expansion and Contraction Rate (%) | ||

| – Elongation ≤ | 1.0 | – |

| – Contraction ≤ | 1.0 | – |

Construction Guidelines

Substrate Preparation:

The substrate should be flat, solid, clean, free of standing water, floating dust, and oil stains. Cracks in the substrate and grooves reserved for pipe roots should be first filled with sealing materials before thorough cleaning.

The substrate should be flat, solid, clean, free of standing water, floating dust, and oil stains. Cracks in the substrate and grooves reserved for pipe roots should be first filled with sealing materials before thorough cleaning.

Detail Treatment for Additional Waterproofing:

Before applying the main waterproof layer, apply 1-2 coats of the coating (with a thickness of not less than 1 mm) as an additional waterproof layer at key points such as 阴阳角 (yin-yang corners) and pipe roots. When using a layer of reinforcing material, it should be embedded in the middle of the coating film.

Before applying the main waterproof layer, apply 1-2 coats of the coating (with a thickness of not less than 1 mm) as an additional waterproof layer at key points such as 阴阳角 (yin-yang corners) and pipe roots. When using a layer of reinforcing material, it should be embedded in the middle of the coating film.

Coating Application:

Apply the coating in 2-3 passes, with each pass applied only after the previous one is dry. The brushing direction of each subsequent pass should be perpendicular to the previous one. If reinforcing materials are used, they should be laid flat without wrinkles and fully impregnated by the coating. The coating thickness below the reinforcing material should be at least 1.0 mm, and above it should be at least 0.5 mm.

Apply the coating in 2-3 passes, with each pass applied only after the previous one is dry. The brushing direction of each subsequent pass should be perpendicular to the previous one. If reinforcing materials are used, they should be laid flat without wrinkles and fully impregnated by the coating. The coating thickness below the reinforcing material should be at least 1.0 mm, and above it should be at least 0.5 mm.

Top Coat Application:

Dilute the coating with a small amount of water (water addition should not exceed 10% of the coating volume) and roll it on once to improve the surface smoothness and finish.

Dilute the coating with a small amount of water (water addition should not exceed 10% of the coating volume) and roll it on once to improve the surface smoothness and finish.

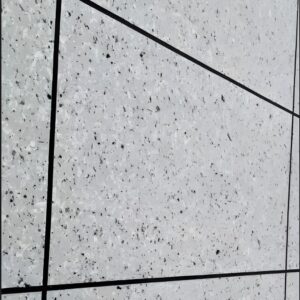

Protective and Isolation Layer:

After the coating waterproof layer is completed and accepted, construct the protective and isolation layer as per the design requirements.

After the coating waterproof layer is completed and accepted, construct the protective and isolation layer as per the design requirements.

Quality Requirements

After the waterproof layer is constructed, carefully inspect all parts of the project, especially the weak links. Any issues found should be repaired immediately. The coating should not have cracks, warping edges, blisters, delamination, or other defects.

Reference Consumption

The coating consumption is approximately 2.5 kg/㎡ per millimeter thickness of the coating film.

Precautions

- The construction temperature should be above 5℃. Construction is not recommended in rainy weather or when the substrate has standing water.

- This product is not for consumption.

- Surface decoration construction can only be carried out after the waterproof coating is completely dry.

- Full drying of the coating takes about 2-3 days, which should be appropriately extended in humid environments. Water storage testing can only be conducted after full drying.

- The coating can be diluted with water, but the water addition should not exceed 10% of the coating volume.

Declaration

The information listed in this document is reliable. Each value provided is a theoretical data calculated from the product formula. If needed, our company can provide internal common measurement and determination methods for the above data. Since the usage conditions cannot be controlled by the manufacturer, this information does not constitute a guarantee. The product is only for professional use. For any questions, please contact our company.

Our Technical Support and Customer Service Center is willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|