Wanefoam®7000 Pouring-Type Polyurethane Rigid Foam Insulation Pipe Composite Material (141B) For Pipes

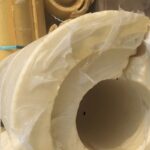

WANEFOAM®7000 series is a polyurethane rigid foam insulation pipe composite material for casting. Its foaming agent is HCFC-141b. The foam obtained by using WANEFOAM®7000 series composite materials in combination with WANNATE®2208 has fine pores, strong adhesion, uniform density distribution, good fluidity and mold filling properties.

Product Introduction

WANEFOAM®7000 series is a polyurethane rigid foam insulation pipe composite material for pouring. Its foaming agent is HCFC-141b. The foam obtained by using WANEFOAM®7000 series composite materials in combination with WANNATE®2208 has fine pores, strong adhesion, uniform density distribution, good fluidity and mold filling.

WANEFOAM®7000 series composite materials can adjust the reaction time and flame retardant performance according to customer process requirements, and the products meet the requirements of standard CJ/T 114-2000.

Product Use

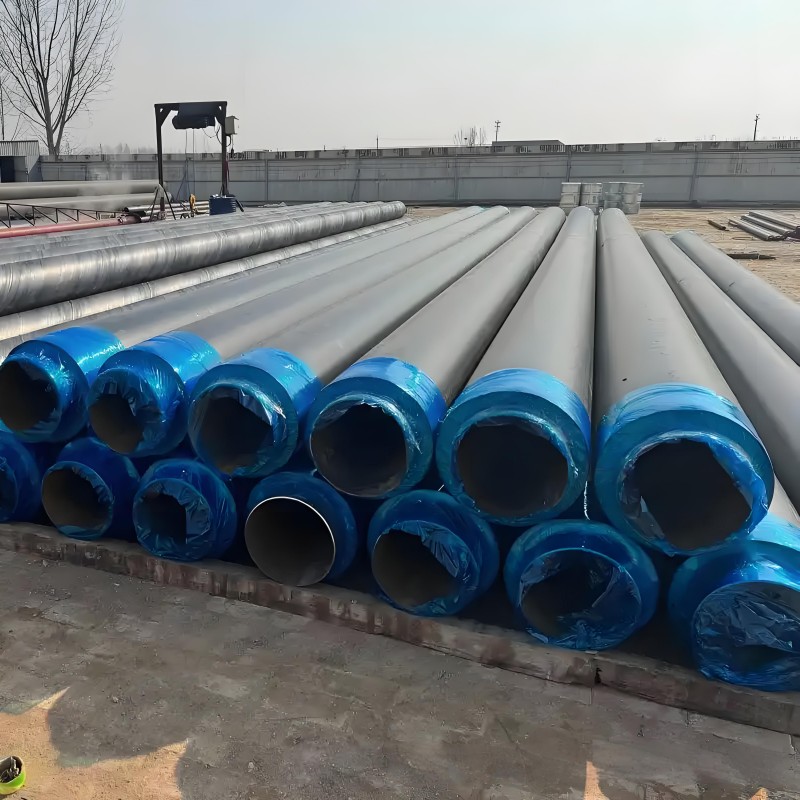

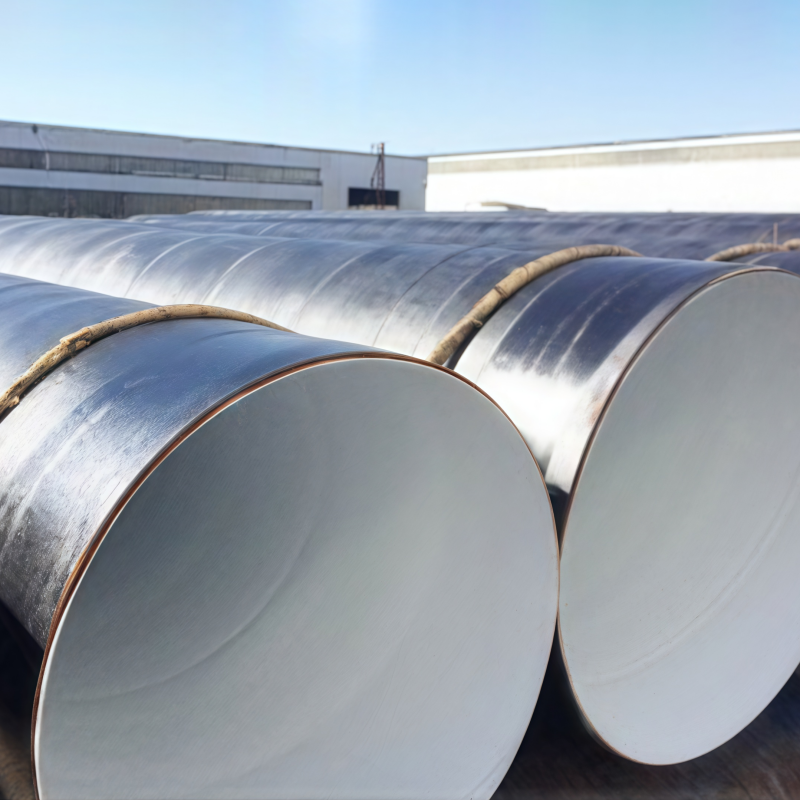

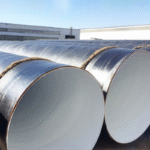

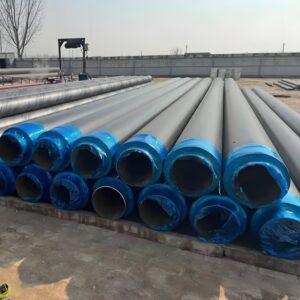

WANEFOAM®7000 series composite materials are suitable for the production of insulation pipes of various diameters and lengths. The products are suitable for conveying various fluids and high-temperature liquids. Different grades of WANEFOAM@7000 series composite materials are respectively suitable for one-step and two-step production processes, and the material reaction time and free foaming density can be adjusted according to customer process requirements.

Before using WANEFOAM®7000 series composite materials, tests must be done to ensure the reliability of the composite material system for use in this specific process.

Physical and Chemical Properties

Item | Specification |

Viscosity 25°C, mPa•s | 100-800 |

Density,g/cm3 | 1.10±0.10 |

Color | Light yellow or yellow |

Free Foaming Parameters

Item | Specification |

Cream Time,s | 15-35 |

Gel Time,s | 60-150 |

Tack-Free Time,s | 100-300 |

Free-Rise Density,Kg/m3 | 22-32 |

Product Physical Properties

Item | Specification | |

Density,kg/m3 | ≥60 | |

Thermal Conductivity,W/(m.k) | ≤0.033 | |

Radial Compressive Strength,Mpa | ≥0.3 | |

Water Absorption,% | ≤10 | |

Closed Cell Content,% | ≥88 | |

Heat Resistance | Dimensional Change Rate,% | ≤3 |

Weight Change Rate,% | ≤2 | |

Strength Change Rate,% | ≥5 | |

(1) WANEFOAM®7000 series and WANNATE 2208 are foamed together, material temperature: 22℃, material weight ratio 1:1-1.2, and mixed manually with electric stirring (2500r/min).

(2) The values provided in this article are typical test values, and the specific data may vary slightly due to environmental conditions. For our company’s products, the listed data are not legally binding.

Precautions for use

Before using WANEFOAM®7000 series casting materials, please check and calibrate the black and white material temperature and the casting equipment delivery ratio and mixing pressure.

Before production, please ensure that the core tube and the tube shell are dry and clean. If you want to achieve the ideal bonding effect, it is recommended to preheat the tube core to above 35 degrees. If the filling amount is too small or a large amount of foam leaks out of the tube shell during the casting operation, it may cause the product to shrink. Please increase the filling amount or pay attention to the sealing of the tube shell. If the production process is multiple castings, pay attention to controlling the length of each casting.

The production site should be a fire-free zone with good ventilation and should be away from fire sources. Smoking is strictly prohibited. When there is a fire operation nearby, the fire approval system must be strictly implemented, and corresponding safety measures and special personnel supervision must be taken.

Before the formal production of the product, the buyer must first conduct a test in an environment consistent with the production conditions to ensure the reliability of the combined material system for use in this specific product process. During the formal production, it is deemed that the buyer has recognized that the performance inspection of the product has passed. If the above operation is not performed, the buyer shall bear all the responsibilities.

The combined material should be stored in a sealed container to avoid absorbing water vapor. Therefore, during storage and transportation, the container must be kept dry and sealed.

WANEFOAM®7000 series castables should be stored in a sealed and ventilated cool place at room temperature between 5-35℃, avoiding direct sunlight or long-term storage above 40℃ to avoid large-scale volatilization of the foaming agent, affecting storage and product performance.

Shelf life

Under appropriate storage conditions, the storage period of WANEFOAM®7000 series casting materials is 3 months. After more than 3 months, it can continue to be used after passing the inspection.

Safety precautions

Direct contact with WANEFOAM®7000 can cause moderate eye irritation and mild skin irritation, and can cause skin allergies. Repeated inhalation of high concentrations of vapor can cause respiratory allergies. See a doctor immediately and take symptomatic treatment measures such as anti-inflammatory and anti-allergic treatment.

Be careful when operating to prevent direct contact with the skin and splashing into the eyes. Please wear necessary protective equipment (gloves, protective glasses, work clothes, etc.).

Once splashed on the skin or in the eyes, rinse with clean water for at least 15 minutes, wash the skin with soapy water, and seek medical attention if necessary. In case of accidental ingestion, please seek medical attention immediately for symptomatic treatment.

Combustion and explosion hazards

This product is not a flammable liquid, explosive, oxidant, corrosive, toxic or radioactive hazardous material during storage and transportation, and is not a dangerous item.

Fire extinguishing media: Carbon dioxide, foam, or chemical dry powder fire extinguishers can be used to extinguish fires. When there is no other fire extinguishing agent, a large amount of mist water spray can be used. Once the fire is extinguished, the spilled materials should be cleaned up (see leakage and spillage treatment).

Firefighting procedures: Normal protection

Leakage and spillage treatment

A small amount of leaked and spilled materials can be washed away with water. If a large amount of leakage occurs, contain and recycle it, and wash the contaminated ground with water or detergent. The disposal of waste composite materials must be carried out in accordance with the environmental protection regulations of the local government.

Version information

First release date: June 1, 2021 Version number: V1.0

Contact Information

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

| Weight | 5485.71 kg |

|---|