Rigid Foam Spraying Compound, WANEFOAM®325

The WANEFOAM®325 (Type I) polyurethane rigid foam spraying coating is a fast – curing system. After molding, it can bear loads immediately, which can meet the requirements of most spraying and insulation construction projects.

This technical manual applies to WANEFOAM® 325 Type I, II, and III formulations. For product differentiation, please refer to the comparison table below.

1. Product Overview

WANEFOAM® 325 (Type I) is a high-performance rigid polyurethane foam spray system formulated with an ultra-low thermal conductivity, environmentally friendly blowing agent. When combined with WANNATE® 2208 isocyanate component, it produces foam products with exceptional flame retardancy.

Key Features:

Versatile Substrate Compatibility: Bonds strongly to concrete, brick, wood, and other substrates.

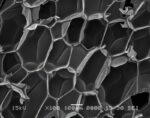

Superior Stability: Excellent dimensional stability (≤1.5% at 70°C/48h) and closed-cell structure (≥90%).

Flame Retardancy: Class B2 fire rating (GB 8624-2012) with an oxygen index ≥26% (GB/T 2406.2-2009).

2. Applications

3. Physicochemical Properties

| Parameter | Type I | Type II | Type III |

| Viscosity (25°C, mPa·s) | 40–450 | 40–450 | 50-600 |

| Density (g/cm³) | 1.10 ± 0.10 | 1.10 ± 0.10 | 1.10 ± 0.10 |

| Appearance | Colorless to pale yellow | Colorless to pale yellow | Colorless to pale yellow |

Free-Foaming Parameters:

| Parameter | Type I | Type II | Type III |

| Cream Time (s) | 2–3 | 2–3 | 2–3 |

| Gel Time (s) | 9–10 | 9–10 | 9–10 |

| Tack-Free Time (s) | 10–13 | 10–13 | 10–17 |

| Free-Foam Density (kg/m³) | 35–41 | 35–41 | 45-50 |

Physical Properties

| Property | Type I | Type II | Type III |

| Density (kg/m³) | ≥35 | ≥45 | ≥55 |

| Thermal Conductivity (W/(m·k)) | ≤0.024 | ≤0.024 | ≤0.024 |

| Compressive Property (10% Deformation, kPa) | ≥150 | ≥200 | ≥300 |

| Water Impermeability (Without Skin, 0.2Mpa, 30min) | – | impermeable | impermeable |

| Dimensional Stability (70℃, 48h) (%) | ≤1.5 | ≤1.5 | ≤1.0 |

| Closed – Cell Content (%) | ≥90 | ≥92 | ≥95 |

| Water Absorption (%) | ≤3 | ≤2 | ≤1 |

| Oxygen Index (%) | ≥26 | B2 | B2 |

Testing Conditions:

Material temperature: 25°C

Mixing ratio (A:B): 1:1 by volume

Stirring speed: 2500 rpm (electric mixer)

5. Operational Guidelines

6. Packaging & Storage

7. Safety & Emergency Procedures

8.Disclaimer

Contact:

| Weight | 200 kg |

|---|