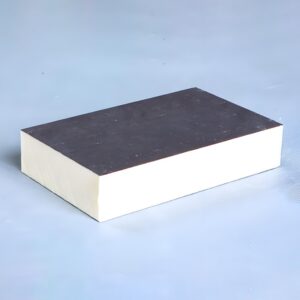

Water-Based B1-Grade Polyurethane Rigid Foam Spray Combination for Water Conservancy

The foaming agent of the water-based B1-grade polyurethane rigid foam spray combination is an environmentally friendly foaming agent with ultra-low thermal conductivity. It can be constructed on cement surfaces, brick surfaces, wood surfaces and other substrates. It has strong bonding strength and good product dimensional stability.

SKU:

Water-based B1-grade polyurethane rigid foam spray combination

Categories: Foam, Polyether Polyols for Rigid Foam

Tags: Foam, rigid foam, Foam for Water Conservancy, Foam for Dam

Description

Product Introduction

The foaming agent of the water-use B1-grade sprayed polyurethane rigid foam blending material is an environmentally friendly foaming agent with an ultra-low thermal conductivity. When used in combination with WANNATE®2208, it can produce foam products with excellent flame retardancy, achieving a combustion performance of B1 grade (GB 8624 – 2012).

The water-use B1-grade polyurethane foam can be applied to cement surfaces, brick surfaces, wood surfaces, and other substrates. It has strong adhesion and good product dimensional stability.

Product Usage

The water-use B1-grade sprayed polyurethane rigid foam blending material is a fast-curing system that can bear loads immediately and meets the construction requirements of most spray insulation applications. Before using this material, it is necessary to conduct tests first to ensure the reliability of the blending material system for use in specific projects.

Physical and Chemical Properties

| Item | Index |

| Viscosity at 25°C, mPa•s | 40 – 250 |

| Density, g/cm³ | 1.10 ± 0.10 |

| Color | Light yellow or yellow |

Free Foaming Parameters

| Item | Index |

| Cream Time, s | 2-3 |

| Gel Time, s | 9-10 |

| Tack-Free Time, s | 11-18 |

| Free Foaming Density, Kg/m³ | 32-45 |

Physical Properties

| Item | Index |

| Mechanism Foam Density, kg/m³ | ≥50 |

| Thermal Conductivity, W/(m·k) | ≤0.024 |

| Compressive Property (10% Deformation), kPa | ≥300 |

| Dimensional Stability (70°C, 48h), % | ≤1.5 |

| Tensile Bond Strength (with Cement Mortar, at Room Temperature), Mpa | ≥0.10 |

| Water Absorption Rate, % | ≤3 |

Foaming Requirements

(1) For the foaming of the water-use B1-grade sprayed polyurethane rigid foam blending material, the material temperature should be 25°C, the volume ratio of materials is 1:1, and it should be mixed manually using an electric stirrer (2500 r/min).

(2) Operate in accordance with the precautions in this document. The overall density of the foam product obtained by the high-pressure spraying machine is greater than 45 kg/m³.

(3) The values provided in this document are typical test values. Specific data may vary slightly depending on environmental conditions. For our company’s products, the listed data have no legal binding force.

(2) Operate in accordance with the precautions in this document. The overall density of the foam product obtained by the high-pressure spraying machine is greater than 45 kg/m³.

(3) The values provided in this document are typical test values. Specific data may vary slightly depending on environmental conditions. For our company’s products, the listed data have no legal binding force.

Precautions for Use

The construction equipment for the water-use B1-grade sprayed polyurethane rigid foam blending material is a high-pressure spraying machine. Before construction, please check and calibrate the conveying ratio of the black and white materials and the mixing pressure of the high-pressure spraying machine.

The suitable temperature for spray operation is 10 – 40°C, the wind speed should not exceed 5 m/s (grade 3 wind), the relative humidity should be less than 75%, and construction is not allowed in rainy days. When the construction environment temperature is lower than 10°C, reliable technical measures should be taken to ensure the spraying quality.

During spray operation, control the temperature of the black and white materials entering the spray gun to be higher than 30°C, and ensure that the substrate is dry and clean. Control the thickness of each spray of foam within the range of 1 – 1.5 cm (excluding the primer layer). During construction, the next layer can only be sprayed after the surface of the previously sprayed polyurethane rigid foam is no longer sticky. Other relevant standards shall be implemented in accordance with national standards. If the above conditions are not met, the buyer shall bear all responsibilities.

Spray operations shall be carried out in accordance with GB 50404 – 2017 “Technical Code for Rigid Polyurethane Foam Insulation and Waterproof Engineering”.

The construction site should be a fire – prohibited area with good ventilation, away from fire sources, and smoking is strictly prohibited. When there is hot work nearby, the hot work approval system must be strictly implemented, and corresponding safety measures and special supervision should be carried out.

Before formal construction of the project, the buyer must conduct tests in an environment consistent with the construction conditions to ensure the reliability of the blending material system for use in specific projects. Formal construction is regarded as the buyer’s recognition of the qualified performance inspection of the product. If the above operations are not followed, the buyer shall bear all responsibilities.

Packaging Specifications

200L green iron drums.

Storage (Use) Precautions

The blending material should be stored in a sealed container to avoid absorbing water vapor. Therefore, during storage and transportation, it is necessary to ensure that the container is dry and sealed.

The water-use B1-grade sprayed polyurethane rigid foam blending material should be stored in a sealed manner in a cool and ventilated place at a room temperature between 5 – 35°C, avoiding direct sunlight or long-term storage above 40°C to prevent the massive volatilization of the foaming agent, which may affect storage and product performance.

Shelf Life

Under suitable storage conditions, the storage period of the water-use B1-grade sprayed polyurethane rigid foam blending material is 3 months. After 3 months, it can be used continuously after passing the inspection.

Safety Precautions

Direct contact with the water-use B1-grade sprayed polyurethane rigid foam blending material can cause moderate eye irritation and mild skin irritation, and may cause skin allergies. Repeated inhalation of high-concentration vapors can cause respiratory allergies. Seek medical advice immediately and take anti-inflammatory, anti-allergic and other symptomatic treatment measures.

When operating, be careful to prevent direct contact with the skin and splashing into the eyes. Wear necessary protective equipment (gloves, safety glasses, work clothes, etc.).

Once splashed on the skin or into the eyes, rinse immediately with clean water for at least 15 minutes, wash the skin with soapy water, and seek medical advice if necessary. In case of ingestion, seek medical advice immediately for symptomatic treatment.

Fire and Explosion Hazards

This product is not a flammable liquid, explosive, oxidizer, corrosive, toxic, or radioactive hazardous material during storage and transportation, and it is not a hazardous product.

Fire – fighting Media: Carbon dioxide, foam, or chemical dry powder fire extinguishers can be used for fire – fighting. When there is no other fire – fighting agent available, a large amount of water mist can be sprayed. Once the fire is extinguished, the spilled materials should be cleaned up (see Leak and Spill Treatment).

Fire – fighting Procedures: Normal protection.

Leak and Spill Treatment

Small amounts of leaked and spilled materials can be washed away with water. In case of a large leak, collect and recycle the materials, and wash the contaminated ground with water or detergents. The disposal of waste blending materials must comply with local government environmental protection regulations.

For more information, please refer to the safety technical specifications of our company’s products or contact our company’s customer service center.

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. Specific guaranteed indicators shall be subject to the quality guarantee letter or supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and uses and to achieve the desired goals. Further applications and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 250 kg |

|---|