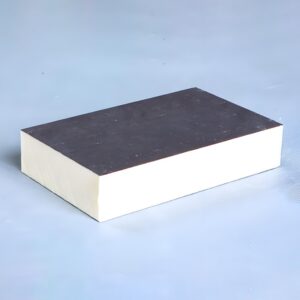

All-water-based Polyurethane Rigid Foam Spraying Compound for Coaches (A0 / OI25 / OI28)

The all – water – based polyurethane rigid foam spraying compound (A0) is a low-density formulation utilizing water as the sole blowing agent, free from auxiliary chemical blowing agents. It is a white, tasteless, light porous foam like solid.

Ultra-low formaldehyde content.

Minimal odor emission.

Zero ozone depletion potential (ODP).

1. Product Overview

2. Product Application

3. Operational Guidelines

Critical Pre-Use Notice:

Product may exhibit ingredient sedimentation during storage. Mix thoroughly until homogeneous white/yellow emulsion is achieved before application. Before construction, carefully check and calibrate the conveying ratio of the black and white materials and the mixing pressure in the high – pressure spraying machine.

Spray Parameters:

| Parameter | Specification |

|---|---|

| Equipment | High-pressure spray machine (calibrated 1:1 ratio) |

| Ambient Temperature | 5–40°C (heating required if <5°C) |

| Wind Speed | ≤5 m/s (Beaufort 3) |

| Material Temperature | >40°C at nozzle |

| Layer Thickness | Single-pass application to target thickness |

Safety Compliance:

Designate “No Open Flame” zones per GB 50404-2017 or local regulations.

Implement hot work permit system for adjacent operations.

4. Packaging & Storage

Packaging: 200L steel drums (200kg net weight).

Storage Conditions:

- Temperature: 5–30°C (avoid >40°C).

- Protection: Moisture-proof, UV-shielded.

- Shelf Life: 2 months (After 2 months, it can still be used after passing the inspection.)

Sedimentation Note:

Slight stratification after ≥7 days is normal. Re-mix thoroughly without quality impact. It should be stored in a low – temperature, well – ventilated and cool environment, sealed, avoiding direct sunlight and long – term storage in an environment above 40°C. If it is left standing for one week or more, slight stratification may occur, which is a normal physical phenomenon. Just stir it evenly to eliminate the stratification, and it will not affect the normal use of the product.

5. Safety Protocols

During the operation, be extremely careful to avoid direct contact between the compound and the skin and prevent it from splashing into the eyes. Direct contact with the all – water – based polyurethane rigid foam spraying compound (A0) for buses may cause moderate eye irritation, mild skin irritation, and may also cause skin allergies. Repeated inhalation of high – concentration vapors can lead to respiratory allergies. In case of the above situations, seek medical advice immediately and take symptomatic treatment measures such as anti – inflammation and anti – allergy.

PPE Requirements:

Chemical-resistant gloves (Butyl/Nitrile).

ANSI-approved goggles.

Protective coveralls.

First Aid Measures:

Eye Contact: Flush with water ≥15 mins → medical attention.

Skin Contact: Wash with soap/water → anti-inflammatory treatment if needed.

Inhalation: Move to fresh air → oxygen supply if distressed.

Fire Safety:

This product does not belong to the categories of flammable liquids, explosives, oxidizers, corrosives, poisons, or radioactive dangerous goods, and is not a dangerous product.

NFPA Classification: Non-flammable (storage/transport).

Extinguishing Media: CO₂/dry powder for small fires; fine water spray for large-scale incidents.

6. Spill Management

| Spill Scale | Procedure |

|---|---|

| Minor (<1L) | Dilute with water → drain to treatment system |

| Major (≥1L) | Contain with absorbents → professional recovery |

| Surface Decon | Scrub with 5% ammonia solution → pH-neutral rinse |

Disposal must comply with local hazardous waste regulations (e.g., China GB 5085.3-2007).

7. Disclaimer

Performance data represent typical values under controlled conditions. End-users must:

Conduct application tests

Verify compliance with intended use

Assume all post-delivery processing risks

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the provisions in the quality guarantee letter or supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and applications and can achieve the expected goals. Our company cannot control the further application and processing of the products. Therefore, our company’s liability for the products is limited to the delivered and used parts. Our company does not assume liability for indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are dedicated to providing you with product consultation and application technical services. You are welcome to contact us by letter or phone.

Technical Support:

Wanhua Energy Conservation Technology (Yantai) Co., Ltd.

Address: No.56 Taiyuan Road, Yantai, Shandong 264006, China

Tel: +86-400-059-1116 | Fax: +86-17761309662

| Weight | 200 kg |

|---|