Polyurea Waterproof Coating For Urban Utility Tunnels

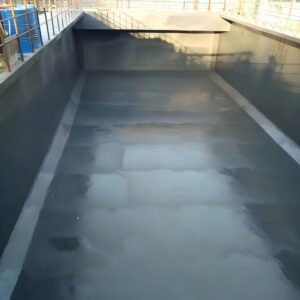

Polyurea waterproof coating for urban utility tunnels effectively addresses waterproofing, anti-seepage, and anti-corrosion issues in substrates such as concrete and steel structures, thereby prolonging service life.

Product Introduction

Polyurea waterproof coating for urban utility tunnels effectively addresses waterproofing, anti-seepage, and anti-corrosion issues in substrates such as concrete and steel structures, thereby prolonging service life.

Performance Characteristics

1.Rapid gelation and curing: Can be sprayed and formed on any curved, inclined, or vertical surfaces.

- High solid content with zero VOC emissions, environmentally friendly

- Achieves desired thickness in a single application: Eliminates need for multiple layers and associated defects.

- Exceptional physical properties and chemical resistance.

- Seamless, monolithic coating,skin-tight protective layer with no joints

Product Usage

Primarily used in public facilities and urban utility tunnels.

Technical Specifications

Item | Specification | Unit | Test Method |

Appearance | Component A: Light yellow viscous liquid | – | GB/T 23446-2009 |

Solid content | 100 | % | GB/T 23446-2009 |

Gel time | 13 | s | GB/T 23446-2009 |

Surface drying time | 28 | s | GB/T 23446-2009 |

Density | 1.05 | g/cm3 | GB/T 23446-2009 |

Tensile strength | 17 | MPa | GB/T 23446-2009 |

Elongation at break | 480 | % | GB/T 23446-2009 |

Tear strength | 70 | N/mm | GB/T 23446-2009 |

Impact resistance | 1.5 | kg·m | GB/T 23446-2009 |

Impermeability | 0.4MPa,2h | – | GB/T 23446-2009 |

Low-temperature flexibility | -40 | ℃ | GB/T 23446-2009 |

Substrate Preparation

Base materials shall be treated by grinding, sandblasting, or shot blasting.

Concrete substrates: Remove loose surface layers to expose the solid base. Ensure the surface is dry and free of standing water. Fill pores with specialized repair putty and apply compatible primer.

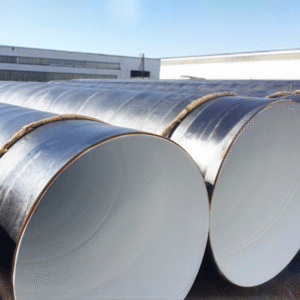

Steel substrates: Sandblast or shot blast to Sa2.5 grade. Remove dust and apply appropriate primer.

For other substrates, consult Wanhua EnergySav Technology Department.

Construction Conditions

Ambient temperature range: 5-35℃, with substrate temperature ≥3℃ above the dew point of ambient air.

Environmental humidity: ≤80% RH, and concrete substrate moisture content <6%.

Ventilation: Ensure no strong airflow in the construction area to avoid dust contamination compromising coating integrity

Construction Method

Special high-pressure airless spraying equipment

Packing Details

Component A: Net weight 220 Kg/drum

Component B: Net weight 200 Kg/drum

Mixing ratio: A:B = 1:1 (volume ratio)

Storage (Usage) Precautions

Store in a cool, ventilated, and dry warehouse, protected from rain and direct sunlight. Keep away from ignition sources and heat sources. storage temperature is 10-35℃.

Shelf life is 12 months from production date in unopened original packaging. After expiration, the product can still be used if it passes the technical specifications.

Classified as non-hazardous goods (contains no organic solvents). Protect from rain and sunlight during transit; comply with transportation regulations.

Smoking and open flames are strictly prohibited in storage, transportation, and construction sites

Expiration Date

The shelf life of polyurea waterproof coating for urban utility tunnels is 12 months from the date of production when stored under specified conditions.

For more information, please refer to the Safety Data Sheet (SDS) of our products or contact our Customer Service Center.

The indicators and data provided in this document are based on our current level of technical knowledge and practical experience, and are for reference only. Specific guaranteed indicators are subject to the quality assurance certificate or supply contract. The user is responsible for testing the products purchased from our company to verify their suitability for their intended processes and applications, and to achieve the desired objectives. Further application and processing of our products are beyond our control. Therefore, our liability for the products provided is limited to the portion delivered by us and used by you. We do not assume responsibility for indirect losses incurred during the production process using our products as raw materials. Our technical support and customer service center are available to provide consultation and technical services related to our products. We welcome your inquiries and communication via mail or phone.

Contact Information

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

| Weight | 5485.71 kg |

|---|