SZ111 Inorganic Zinc Silicate Primer

SZ111 is a two-component solvent-based inorganic zinc silicate primer, composed of high-quality ethyl silicate, zinc powder, high-temperature resistant anti-rust pigments, etc. It can be used as both a shop protection primer and a permanent anti-rust primer.

SKU:

SZ111 Inorganic Zinc Silicate Primer

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Overview

WH-SZ111 is a two-component solvent-based inorganic zinc silicate primer, composed of high-quality ethyl silicate, zinc powder, high-temperature resistant anti-rust pigments, etc. It can be used as both a shop protection primer and a permanent anti-rust primer.

Product Features

- Fast-drying

- Excellent cutting and welding performance

- Outstanding resistance to seawater, conductive static, high temperature (400℃), and rust

- Good compatibility, compatible with epoxy, perchloroethylene, chlorinated rubber, etc.

Recommended Applications

Steel structure products, shipyards, and other places requiring anti-rust and high-temperature resistance.

Technical Parameters

| Item | Specification |

|---|---|

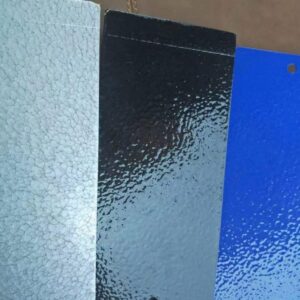

| Color | Gray; red-gray |

| Surface Finish | Matt |

| Mixing Ratio (by weight) | 2 (base material) : 1 (liquid curing agent) |

| Curing Agent | CSZ1110 |

| Specific Gravity | 1.14 kg/L |

| Volume Solids Content | 30% |

| Flash Point | 5℃ |

| Pot Life | 4 hours / 23℃ |

| Theoretical Coverage | 15 m²/L at 20μm dry film thickness |

| Application Method | Conventional spraying or airless spraying |

| Thinner/Cleaner | TH006 |

| Drying Time | Touch dry: 4 minutes @23℃; Hard dry: 7 days @20℃ |

| Recoating Interval | Minimum: 12 hours / 23℃; Maximum: 6 months. Longer intervals are allowed if the primer is intact. |

| Substrate Temperature | 0-40℃, at least 4℃ above dew point |

| Packaging | Two-component, 30 kg combined packaging |

| Storage & Shelf Life | Must comply with local regulations. Store in a cool, well-ventilated place away from excessive heat. Tightly seal containers. Shelf life: 1 year. |

Application Guidelines

Surface Preparation

- Remove oil and grease with appropriate cleaners.

- At least blast clean to Sa 2.5 standard, with surface roughness equivalent to Rugotest No.3 standard, minimum N9a or Keane-Tator comparison panel 50μm area roughness, or ISO medium roughness (G,S). Coarse-grain blasting may be used if necessary.

Mixing and Thinning

- Before use, stir the base material until uniform, then slowly add the liquid curing agent and mix thoroughly. Reverse operation is prohibited.

- Filter the mixed paint through a 60-80 mesh sieve. Only thin the mixed paint.

- For airless spraying and conventional spraying, maximum thinning ratio is 30%. For brush repair, maximum thinning ratio is 15%.

- In automatic painting lines, adjust the mixed paint viscosity to 15-18 seconds (DIN #4 cup).

Application Conditions

- Substrate temperature during application and curing must be above 4℃ and at least 3℃ above dew point.

- Maximum relative humidity during application and curing: 85%.

Safety Measures

- Pay attention to the warning labels on packaging containers.

- Use in well-ventilated conditions.

- Avoid swallowing or inhaling paint mist.

- Avoid skin contact. If paint splashes on skin, immediately clean with suitable cleaners and soapy water. If splashed into eyes, rinse thoroughly with water and seek medical attention immediately.

Declaration

The information listed in this document is reliable. Each value provided is a theoretical data calculated from the product formula. If needed, our company can inform the internal common measurement and determination methods for any of the above data. Since the use conditions are beyond the control of the manufacturer, this information is not provided as a guarantee. The product is for professional use only. For any questions, please contact our company.

Our Technical Support and Customer Service Center is willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|