WE151 Waterborne Epoxy Mica Iron Oxide Intermediate Paint

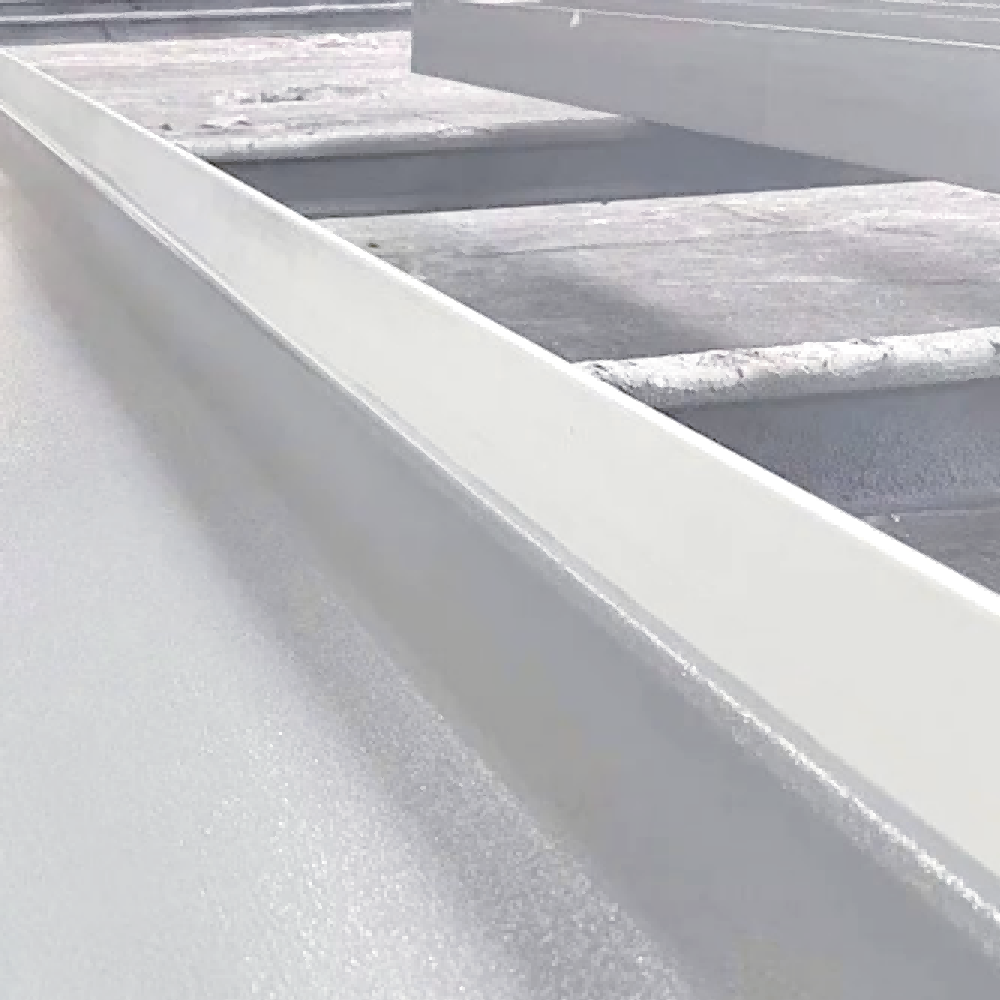

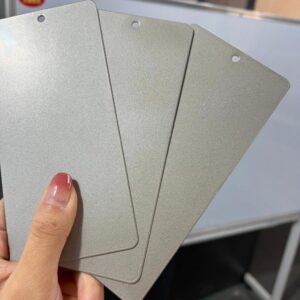

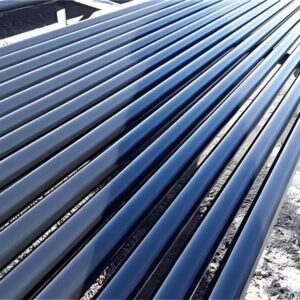

WH-WE151 Waterborne Epoxy Mica Iron Oxide Intermediate Paint is formulated with waterborne epoxy resin as the base material, combined with pigments, fillers, and additives through a specific technological process. Using water as the diluent, this environmentally friendly epoxy resin paint features low VOC content, excellent salt spray resistance, and strong adhesion to primer coatings.

SKU:

WE151 Waterborne Epoxy Mica Iron Oxide Intermediate Paint

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

General Description

WANHUA WH-WE151 Waterborne Epoxy Mica Iron Oxide Intermediate Paint is formulated with waterborne epoxy resin as the base material, combined with pigments, fillers, and additives through a specific technological process. Using water as the diluent, this environmentally friendly epoxy resin paint features low VOC content, excellent salt spray resistance, and strong adhesion to primer coatings.

Product Characteristics

- Non-flammable and non-explosive, ensuring safe transportation.

- Dilutable with tap water, and construction tools/equipment/containers can be cleaned with water, significantly reducing painting costs.

- Forms a tough anti-rust paint film.

- Excellent repaintability and inter-layer adhesion, facilitating convenient construction.

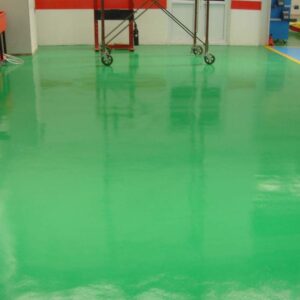

Recommended Applications

Suitable for industries such as steel structures, 网架 (space frames), containers, railways, bridges, boilers, and steel structures.

Technical Parameters

| Item | Value |

|---|---|

| Film Thickness (μm) | 60–100 |

| Coverage (㎡/L) | Theoretical: 8 ㎡/L/80μm Practical: Varies with surface treatment, spraying environment, construction method, and structure of the coated object. |

| Specific Gravity | Approximately 1.6 kg/L |

| Volume Solids Content (%) | ≥65 |

| Surface Dry (≤) | 2h (23℃) |

| Through Dry (≤) | 24h (23℃) |

| Bend Test (mm) | ≤3 |

| Cross-cut Test (Grade) | ≤1 |

| Gloss (60° Angle) | ≤10 |

| Flash Rust Inhibition | Normal |

| Water Resistance | ≥24h |

| Salt Water Resistance (3% NaCl Solution) | ≥96h |

Construction Guidelines

Surface Preparation

- Sandblast steel surfaces to Sa2.5 grade with a surface roughness of 30–75μm.

- Mechanically remove rust to St3 grade using electric tools.

Coating Compatibility

- Primer: Waterborne epoxy zinc-rich primer or waterborne epoxy iron red primer.

- Topcoat: Waterborne steel structure finish, waterborne alkyd finish, waterborne acrylic finish, waterborne polyurethane finish, or waterborne epoxy finish.

Application Notes

- Strictly avoid contact with oily substances. Stir thoroughly before use. Dilute with water as needed, preferably adding 0–10% water. Do not exceed 30% water addition to prevent reduced hiding power and film performance.

- Store at ≥0℃ in a cool, dry place, protected from freezing and direct sunlight. Shelf life: 6 months.

Construction Parameters

| Item | Requirement |

|---|---|

| Application Temperature | 5–40℃ |

| Relative Humidity | ≤80%RH |

| Application Methods | Brush, air spray, or roller application. |

| Diluent | Deionized water |

Precautions

- In high-temperature seasons, dry spraying may occur. Adjust with diluent to prevent dry spraying.

- This product must be applied by professional painters following the instructions on the packaging or in this manual.

- All coating and usage operations must comply with relevant national health, safety, and environmental regulations. For usage inquiries, contact our technical service department.

Transportation and Storage

- Store in a cool, ventilated place away from direct sunlight, at 0–40℃.

- During transportation, protect from rain, sunlight, and impact, in compliance with transportation authority regulations.

Safety Measures

- Warning: May irritate eyes and skin. Vapors may cause respiratory allergies in sensitive individuals. Possible skin allergic reactions. Avoid inhaling vapors. Keep away from eyes and skin. Use protective gear for eyes, skin, and respiratory system. Use appropriate respiratory protection to prevent potential irritation. Thoroughly wash skin after use. Wash contaminated clothing before reuse. In case of respiratory arrest, perform mouth-to-mouth resuscitation and seek medical help immediately.

- First Aid: If contact with eyes occurs, flush with clean water for at least 15 minutes. Remove contaminated clothing and shoes, and wash affected skin with soap.

Statement

The information herein is reliable. Each listed value is a theoretical data calculated from the product formula. Internal testing methods for the data can be provided upon request. Since the use conditions are beyond the manufacturer’s control, this information is not guaranteed as a warranty. The product is for professional use only. For any questions, contact us. Our technical support and customer service center are ready to provide product consultation and application technical services. Welcome to inquire via letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Subtitle text example

Title text example

Text after title text example

Additional information

| Weight | 25 kg |

|---|