Anti – static Epoxy Self – leveling Topcoat for Floor Coating

This solvent-free, two-component epoxy floor coating incorporates uniformly dispersed high-performance conductive fibers, ensuring stable and durable anti-static properties (surface resistance: 10⁴–10⁹ Ω). Customizable to project requirements, it effectively prevents electrostatic discharge (ESD) and electromagnetic interference (EMI).

Product Overview

This solvent-free, two-component epoxy floor coating incorporates uniformly dispersed high-performance conductive fibers, ensuring stable and durable anti-static properties (surface resistance: 10⁴–10⁹ Ω). Customizable to project requirements, it effectively prevents electrostatic discharge (ESD) and electromagnetic interference (EMI).

Key Features

- Durability: High mechanical strength, abrasion/compression resistance, suitable for heavy-duty areas.

- Chemical & ESD Resistance: Stable anti-static performance under exposure to acids, alkalis, oils, and salts.

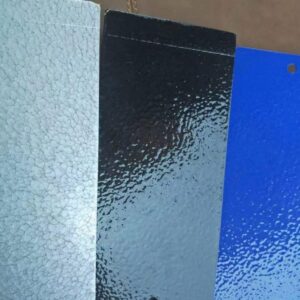

- Aesthetic Appeal: Smooth, glossy finish with vibrant color options.

- Eco-Friendly: Solvent-free epoxy system compliant with environmental standards.

Applications

Ideal for ESD-sensitive environments:

Electronics manufacturing

Communication facilities

Hospital operating rooms

Military facilities

Chemical storage areas

Physical & Chemical Properties

| Property | Specification | Test Standard |

|---|---|---|

| Condition in container | Homogeneous, no lumps after mixing | Visual inspection |

| Film appearance | Smooth, glossy | Visual inspection |

| Surface drying time (h) | ≤8 | GB/T 22374-2018 |

| Full curing time (h) | ≤48 | GB/T 22374-2018 |

| Initial fluidity (mm) | ≥140 | GB/T 22374-2018 |

| Pencil hardness (H) | ≥3H | GB/T 6739-2006 |

| Abrasion resistance (750g/500r, g) | ≤0.03 | GB/T 22374-2018 |

| Tensile bond strength (MPa) | ≥2.0 (standard) / ≥2.0 (post-immersion) | GB/T 16777-2008 |

| Impact resistance (500g/1000g steel ball) | No cracks/delamination | GB/T 22374-2018 |

| Slip resistance (dry) | ≥0.5 | GB/T 22374-2018 |

| Chemical resistance* | No blistering/delamination; slight discoloration allowed | GB/T 22374-2018 |

*Includes water (168h), oil (120# solvent, 72h), alkali (20% NaOH, 72h), acid (10% H₂SO₄, 48h).

Note: Data are typical values; actual performance may vary with conditions. Specifications are non-binding.

Construction Requirements

- Concrete strength ≥C25; the flatness should meet the requirement of a 2m alignment ruler with an error within 3mm.

- 28-day curing period required before application to achieve the best results.

- Ambient temperature: 5–35°C (avoid application below 5°C). as it may affect the project quality and the strength of the cured paint film.

- Substrate moisture ≤5%; ambient humidity ≤80%. Otherwise, problems such as blistering may occur, affecting the appearance.

- Ensure dust-free and ventilated environment (avoid strong airflow).

2. Surface Treatment:

- Grind the substrate to remove contaminants, loose layers, and create a rough surface for enhanced adhesion. For any concrete damaged, loosened, or contaminated by substances due to exposure to chemicals, it should be removed until the solid concrete is reached. Grinding treatment can remove the floating dust, stains, and loose layers on the surface of the construction substrate, and at the same time roughen the substrate surface, which is beneficial for improving the adhesion between the substrate and the epoxy floor coating.

3. Primer Application:

- Select a solvent – free epoxy primer or a universal leveling epoxy primer.

Apply it with a trowel for spreading or a roller for painting. The construction dosage is approximately 0.15 – 0.25 kg/m².

- Ensure no missed coating areas and avoid over – coating. If necessary, apply a second coat of primer or repair the missed coating areas.

4.Intermediate Layers:

5. Topcoat Application:

Construction Parameters

Mixing ratio (by weight): A:B = 5:1. use a high – speed mixer to stir thoroughly.

Pot life (25°C): 1.5 hours after mixing (1 hour after pouring). The higher the temperature, the shorter the pot life. Construction is generally not recommended when the ambient temperature during construction is higher than 35°C.

Diluent: Not allowed.

Recoat interval: The next construction process can be carried out only after confirming that the coating is completely dry. Usually, 24 hours under standard conditions (25°C, 60% humidity).

Note: Drying time varies with temperature, humidity, film thickness, and ventilation. Higher temperatures shorten drying time.

Before formal project construction, the buyer must conduct tests in an environment consistent with the construction conditions to ensure the reliability of the coating system for the specific project. Formal construction is regarded as the buyer’s recognition of the product’s performance inspection. If the above operations are not followed, all responsibilities shall be borne by the buyer.

Packaging & Storage

Packaging:

Component A: 20kg iron drum

Component B: 4kg iron drum

Storage & Transport:

- Store in a dry, ventilated area at 5–35°C. Avoid heat and open flames.

- Shelf life: 12 months in original packaging.

Safety Precautions

Under normal construction conditions, the dried coating is non – toxic. Please use it with confidence. For detailed information on toxicity, safety, and first aid, please refer to the Material Safety Data Sheet (MSDS) of this product.

Skin: Soap/water → seek medical help if irritation persists.

Eyes: 15-min flush → immediate ophthalmologist visit.

Fire Rating:

This product is not classified as a flammable liquid, explosive, oxidizer, corrosive, toxicant, or radioactive hazardous material during storage and transportation, and is not a hazardous product.

Fire: Use CO₂, foam, or dry chemical extinguishers.

- In the absence of other fire-fighting agents, a large amount of fog-like water can also be used for spraying. After the fire is extinguished, the spilled materials should be cleaned up (refer to the leakage and spillage treatment section).

Leakage and Spillage Treatment

Disclaimer

Contact:

| Weight | 20 kg |

|---|