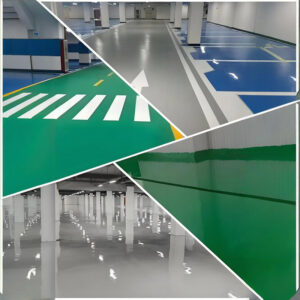

WANSHIELD®63238 Floor Coating Ultra-Wear-Resistant Polyurethane Topcoats

WANSHIELD®63238 Polyurethane Topcoats are solvent-free, high-solids, multi-component coatings available in two formulations:

63238-V: Clear coat

63238-P: Colored coat

Performance Features:

Exceptional wear resistance (≤0.03g/500r) and impact resistance.

UV stability (non-yellowing).

Chemical resistance (acids, alkalis, oils).

Slip-resistant texture (dry coefficient ≥0.50).

High solid content and low viscosity.

Good anti-slip performance, and the ability to reduce tire noise.

1. Product Overview

Product Applications

2. Key Differences Physical and Chemical Properties

| Parameter | 63238-V (Clear) | 63238-P (Colored) |

|---|---|---|

| Primary Use | Transparent protective layer | Decorative colored finish |

| Packaging | Plastic buckets | Steel drums |

| Pot Life (25°C) | 30 minutes | 90 minutes |

| Shelf Life | 6 months | 12 months |

| Mixing Ratio (A:B:C) | 5:2:3 (fixed) | 5:2:3 (adjustable for 4-component systems) |

| Application Flexibility | Limited to clear finishes | Custom color options available |

3. Technical Specifications

Common Performance Data:

| Property | Value | Test Standard |

| Condition in Container | Uniform state after stirring, without hard lumps | Visual inspection |

| Drying Time (h) – Surface Drying | ≤8 | GB/T 22374 – 2018 |

| Drying Time (h) – Through Drying | ≤48 | GB/T 22374-2018 |

| Hardness (pencil) | ≥6H | GB/T 22374-2018 |

| Abrasion Resistance (750g/500r) / g | ≤0.03 | GB/T 22374 – 2018 |

| Anti-slip Property (Dry Friction Coefficient) | ≥0.50 | GB/T 22374 – 2018 |

| Water Resistance (168h) | No blistering, peeling, cracking, or discoloration | GB/T 22374 – 2018 |

| Adhesion strength | ≥2.0 MPa | GB/T 22374-2018 |

| Impact resistance | No cracking (1kg ball) | GB/T 22374-2018 |

| Chemical resistance | Passes 72h exposure | GB/T 22374-2018 |

4. Application Guidelines

Surface Preparation:

- For all new and old concrete floors: The concrete strength must reach C25 or above. Thoroughly remove surface stains and loose soil until reaching the solid concrete layer. For any concrete damaged, loosened, or contaminated by substances due to exposure to chemicals, it should be removed until the solid concrete is exposed.

- For painted old floors: Completely sand off the loose or incompatible old paint coatings. If the underlying concrete surface or a clean, dry, and intact compatible coating is exposed, it can be left without further removal.

- For oil-stained floors: When the oil stains seriously affect the adhesion of the floor coating to the base surface, the oil-stained floors should be thoroughly cleaned and sanded.

- For new concrete floors: Ensure that the floor has passed the curing period and the moisture content is less than 6%. It is crucial to use mobile sandblasting tools and grinding equipment to treat the concrete surface to achieve the correct surface roughness.

- For other surfaces: If the product is to be used on other substrates, please consult the Technical Department of Yantai Wanhua Energy Conservation and Environmental Protection New Material Co., Ltd.

Concrete strength ≥C25, moisture <6%.

Remove oil/contaminants (sandblasting recommended for new concrete).

Application Conditions:

| Factor | Requirement |

|---|---|

| Ambient temperature | 5-35°C (substrate 3°C above dew point) |

| Humidity | <80% RH |

| Ventilation | Dust-free, moderate airflow |

Coating Process:

Mix components per specified ratio

Apply via squeegee + cross-roller technique

Allow 24h recoat interval at 25°C/60% RH

| Parameter | WANSHIELD®63238-P | WANSHIELD®63238-V |

|---|---|---|

| Mixing Ratio (by Weight) | Generally, Component A: Component B: Component C = 5:2:3. For four-component systems, after fully mixing Components A, B, and C, add Component D and stir thoroughly. Adjust according to actual situations. | Component A: Component B: Component C = 5:2:3. Fully mix Components A and B, then add Component C and stir thoroughly. |

| Pot Life (25°C) | 1h30min (1h when poured on the ground). The higher the temperature, the shorter the pot life. Construction is generally not recommended when the ambient temperature is higher than 35°C. | 30 minutes. The higher the temperature, the shorter the pot life. Construction is generally not recommended when the ambient temperature is higher than 35°C. |

| Diluent | No diluent is allowed to be added to the paint. | No diluent is allowed to be added to the paint. |

| Recoating Interval | The next construction process can be carried out only after confirming that the coating is completely dry. Usually, the interval under standard environmental conditions is 24 h. | The next construction process can be carried out only after confirming that the coating is completely dry. Usually, the interval under standard environmental conditions is 24 h. |

Note: The drying time is measured under standard conditions (25°C, 60% humidity) and is for reference only. The drying speed varies greatly under different temperatures and humidities, and is also affected by factors such as film thickness, ventilation conditions, and underlying coatings. Generally, the drying time shortens as the temperature rises and lengthens as the temperature drops.

Before formal project construction, the buyer must conduct tests in an environment consistent with the construction conditions to ensure the reliability of the coating system for the specific project. Formal construction is regarded as the buyer’s recognition of the product’s performance inspection. If the above operations are not followed, all responsibilities shall be borne by the buyer.

5. Packaging & Storage

| Formulation | Component | Package Size | Material |

|---|---|---|---|

| 63238-V | A | 5kg | Plastic |

| B | 2kg | Plastic | |

| C | 3kg | Plastic | |

| 63238-P | A | 5kg | Steel |

| B | 2kg | Steel | |

| C | 3kg | Steel |

Storage: 5-35°C, dry/ventilated, away from ignition sources and high temperatures.

6. Safety & Compliance

PPE Requirements:

Respirator (organic vapor cartridge)

Chemical goggles (ANSI Z87.1)

Nitrile gloves + coveralls

First Aid:

Skin contact: Soap/water wash → seek medical help if irritated

Eye exposure: 15-min flush → immediate ophthalmologist visit

Fire Safety:

This product is not classified as a flammable liquid, explosive, oxidizer, corrosive, toxicant, or radioactive hazardous material during storage and transportation, and is not a hazardous product.

Non-flammable per NFPA 30

Extinguishing media: CO₂/dry chemical

Leakage and Spillage Treatment

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the provisions in the quality guarantee letter or supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and applications and can achieve the expected goals. Our company cannot control the further application and processing of the products. Therefore, our company’s liability for the products is limited to the delivered and used parts. Our company does not assume liability for indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are dedicated to providing you with product consultation and application technical services. You are welcome to contact us by letter or phone.

Technical Support:

Wanhua Energy Conservation Technology (Yantai) Co., Ltd.

Address: No.56 Taiyuan Road, Yantai, Shandong 264006, China

Tel: +86-400-059-1116 | Fax: +86-17761309662

| Weight | 523 kg |

|---|