PRF Rock Wool Composite Polyurethane Fireproof Insulation Board

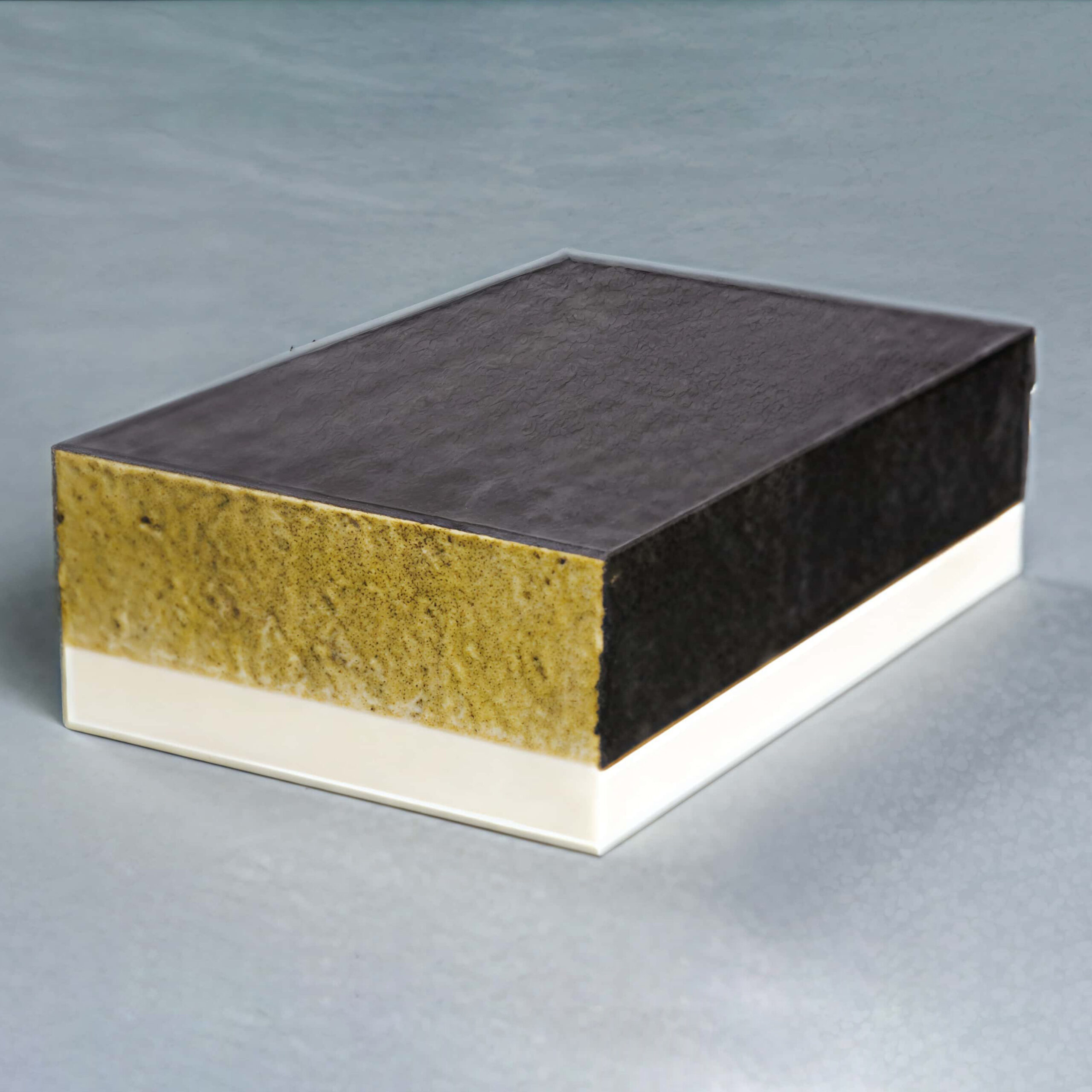

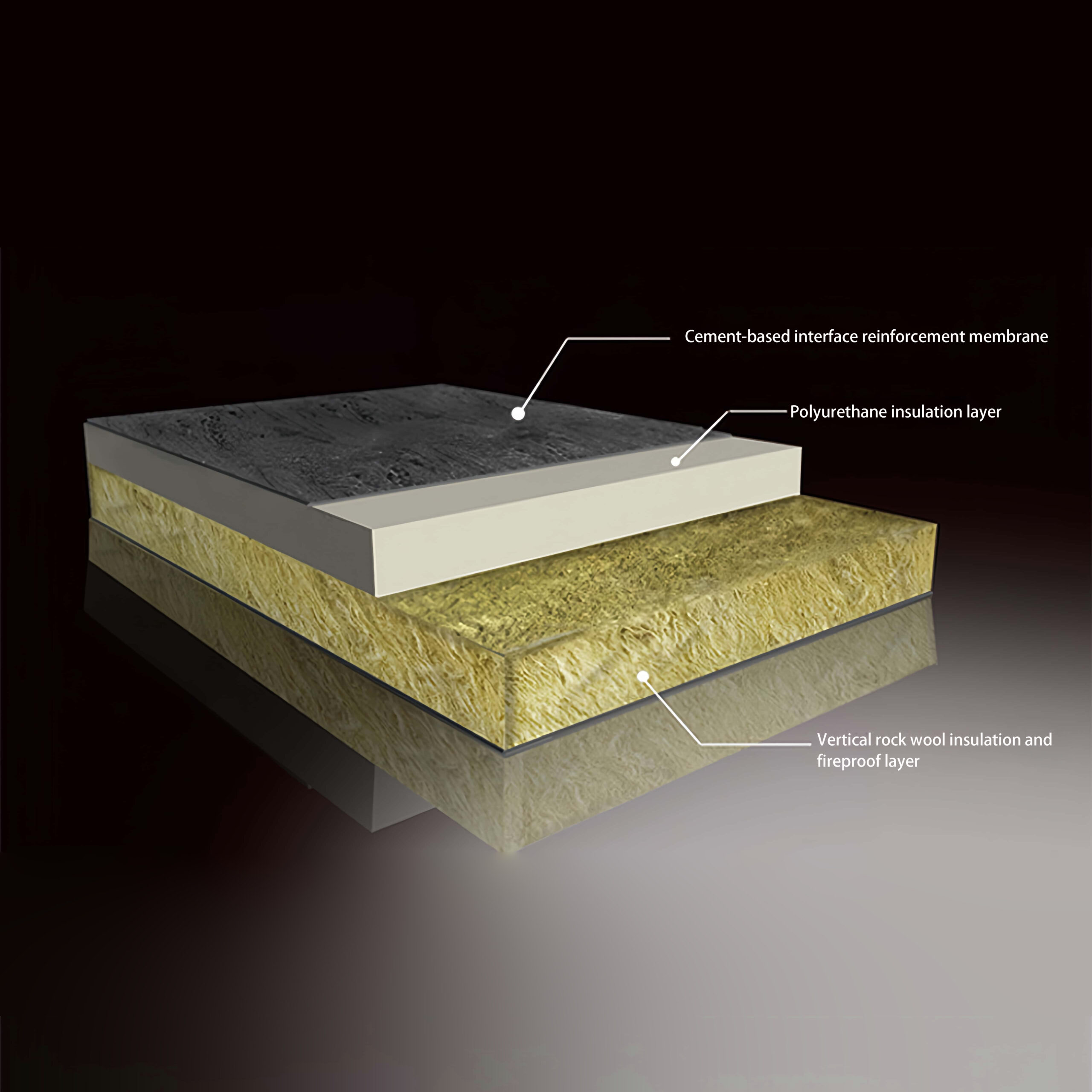

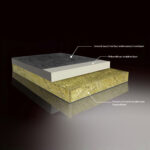

PRF rock wool composite polyurethane fireproof insulation board is a new generation of insulation product that integrates heat preservation and fire prevention. It is made by foaming rigid polyurethane between vertical filament rock wool and reinforcing coiled material through continuous foaming technology and prefabricated by using the permeability and self-adhesiveness of polyurethane.

SKU:

PRF rock wool composite polyurethane fireproof insulation board

Categories: Panels, Insulation Panels

Tags: Panels, Insulation Panels, Thermal Insulation of Facades

Description

Product Introduction

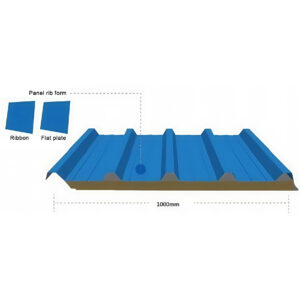

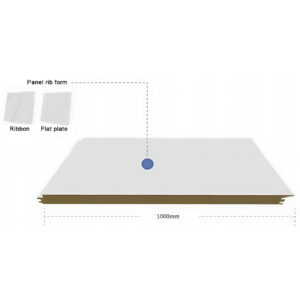

The PRF Rock Wool Composite Polyurethane Fireproof and Heat-insulating Board is prefabricated by the continuous foaming technology. The rigid polyurethane foam is foamed between the vertical filament rock wool and the reinforced coil. Utilizing the permeability and self-bonding property of polyurethane, it is a new-generation heat-insulating product integrating heat insulation and fire protection (abbreviated as: PRF Board). The thickness of the vertical filament rock wool board is not less than 45mm, and the thickness of the polyurethane can be calculated according to the heat transfer coefficient requirements of the wall.

- Advantages: No need to set fireproof doors and windows or fire barriers. The heat insulation system is equivalent to Class A, and there are no restrictions on application height and places.

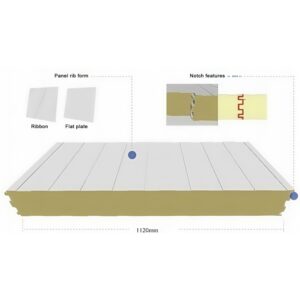

- Standard Dimensions: 1200mm * 600mm (customizable). Thickness: 50mm – 150mm.

- Application Scope: Exterior wall insulation of buildings with Class A fire protection requirements; severe cold and cold regions with high energy-saving requirements; ultra-low energy consumption buildings.

Product Features

- The structural fire protection is equivalent to Class A.

- Excellent mechanical properties.

- Excellent waterproof effect.

- Low heat transfer coefficient with no thermal bridge effect.

- High interface strength.

- Simple construction process, short construction period, and low overall system cost.

Performance Indicators

| Rock Wool Board (mm) | Rock Wool Embedded Polyurethane Structural Fireproof Insulation Board (mm) | Polyurethane + Rock Wool | |

| PU | RF | ||

| 85 | 60 | 15 | 45 |

| 100 | 70 | 25 | 45 |

| 150 | 95 | 40 | 45 |

The ultra-low thermal conductivity and excellent heat-insulating properties of rigid polyurethane foam make up for the defects of single rock wool board, such as high thermal conductivity and poor heat-insulating performance. Thus, it reduces the thickness of the exterior wall insulation system and the building’s plot ratio.

- Thermal parameters of the rock wool composite polyurethane fireproof and heat-insulating board:

- The thermal conductivity of rigid polyurethane foam is 0.018 – 0.024W/(m·K), and the correction coefficient is 1.10.

- The thermal conductivity of rock wool strips is 0.045W/(m·K), and the correction coefficient is 1.10.

- For others, refer to Appendix – B of GB50176.

Production Process

Wanhua’s PRF Board adopts the advanced domestic continuous production process. Compared with the traditional mold method and bonding method production processes, the continuous method is more conducive to achieving cavity-free bonding between the rock wool layer and the interface layer. The entire production process is under real-time dynamic monitoring, ensuring stable and controllable product quality. The production efficiency is 10 times higher than that of traditional production processes.

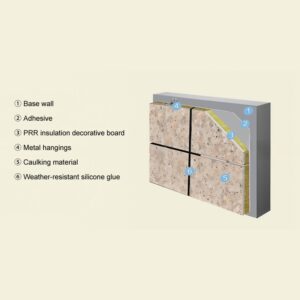

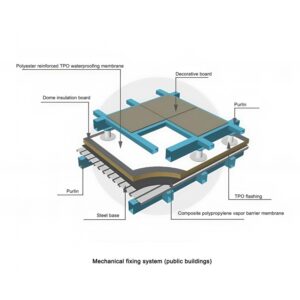

System Process

The PRF external insulation system adopts the construction process of “adhesion + anchoring”, providing double insurance.

For more information, please refer to the safety technical specification of our company’s products or contact our company’s customer service center.

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their respective intended processes and applications and to achieve the desired goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

The indicators and data provided in this material are based on our current technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify their suitability for their respective intended processes and applications and to achieve the desired goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part delivered by us and used by you. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are willing to provide you with product consultation and application technical services. Welcome to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 5485.71 kg |

|---|