Two-Component Spray Polyurea Waterproof Coating for Water Conservancy

Two-component spray polyurea waterproof coatings are widely used in water conservancy, transportation, construction, chemical industry, electric power, metallurgy, ocean and other fields. They can effectively solve the waterproofing, anti-seepage and anti-corrosion problems of substrates such as concrete and steel structures, and improve their service life.

Spray Polyurea Waterproof Coating for Water Conservancy

Spray polyurea waterproof coating is a new generation of polyurea elastomer material which is formed by spraying and curing on-site with semi-prepolymer, resin, amine chain extender, additives, pigment and other raw materials.

WANSHIELD®63120 Waterborne Polyurethane Mortar Floor Coating

The WANSHIELD®63120 water – based polyurethane mortar series includes four models: MD1, MD2, MD3, and MD4. These are four – component water – based polyurethane mortar floor materials. Their composites possess almost all the advantages of organic polymers and inorganic concrete. Each model is designed for specific application scenarios and has unique features, such as chemical resistance, corrosion resistance, load – bearing capacity, and wear resistance.

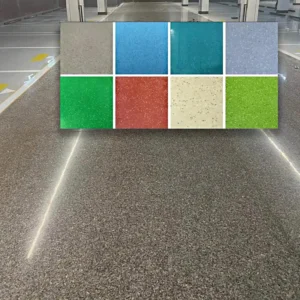

WANSHIELD®63122 Colored – Sand Water – based Polyurethane Mortar Flooring System

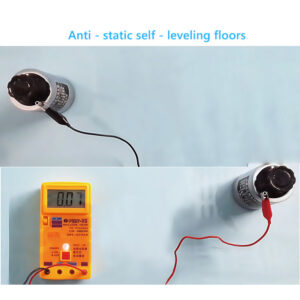

WANSHIELD®63121 Antistatic Water – based Polyurethane Mortar Flooring System

WANSHIELD®63121 Antistatic Waterborne Polyurethane Mortar is a three-component, self-leveling flooring system combining the advantages of organic polymers and inorganic concrete. It is mainly developed as a thin – type anti – static polyurethane mortar self – leveling floor for light industrial workshops and other places with high requirements for anti – static properties, chemical resistance, anti – slip performance, and cleanliness.

WANSHIELD®63238 Floor Coating Ultra-Wear-Resistant Polyurethane Topcoats

WANSHIELD®63238 Polyurethane Topcoats are solvent-free, high-solids, multi-component coatings available in two formulations:

63238-V: Clear coat

63238-P: Colored coat

Performance Features:

Exceptional wear resistance (≤0.03g/500r) and impact resistance.

UV stability (non-yellowing).

Chemical resistance (acids, alkalis, oils).

Slip-resistant texture (dry coefficient ≥0.50).

High solid content and low viscosity.

Good anti-slip performance, and the ability to reduce tire noise.

Permeable pavement glue Two-Component Solvent-Free Polyurethane Adhesive

Polyurethane Adhesive (Non-Yellowing) as a key material, playing an important role in bonding crushed stones and forming the structure of the permeable pavement, which helps to improve the rainwater infiltration and drainage capacity of cities and realize the relevant functions of sponge cities.

B1 Grade Polyurethane Rigid Foam Spray Composite Material For Water Conservancy Water Level Fluctuation Area

The foaming agent of B1 grade polyurethane rigid foam spray combination material for water conservancy water level fluctuation area is an environmentally friendly foaming agent with ultra-low thermal conductivity. It can be constructed on cement surface, brick surface, wood surface and other substrates, with strong bonding force and good product dimensional stability.

Water-Based B1-Grade Polyurethane Rigid Foam Spray Combination for Water Conservancy

The foaming agent of the water-based B1-grade polyurethane rigid foam spray combination is an environmentally friendly foaming agent with ultra-low thermal conductivity. It can be constructed on cement surfaces, brick surfaces, wood surfaces and other substrates. It has strong bonding strength and good product dimensional stability.