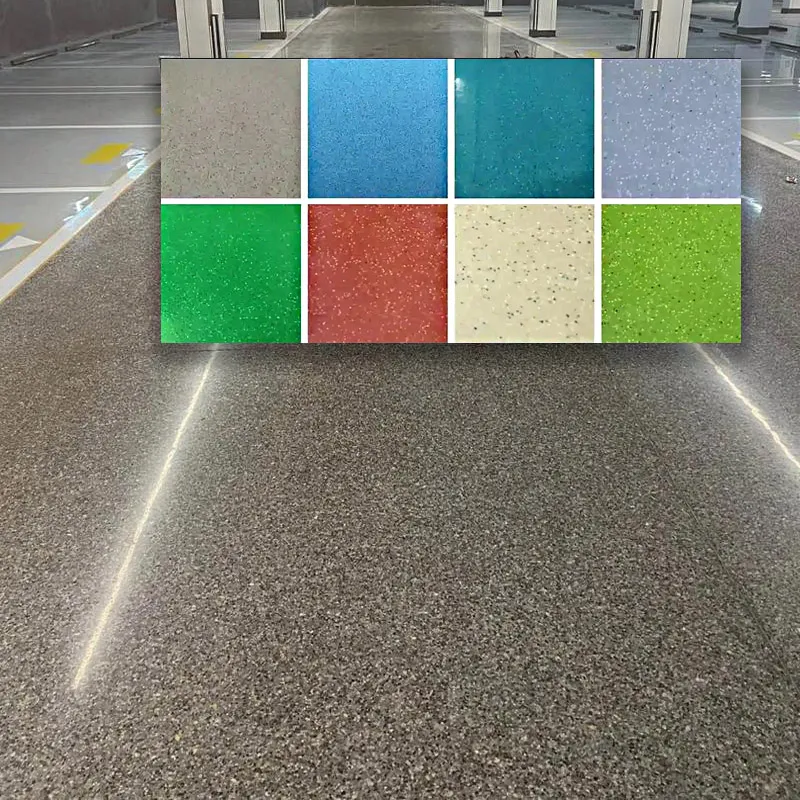

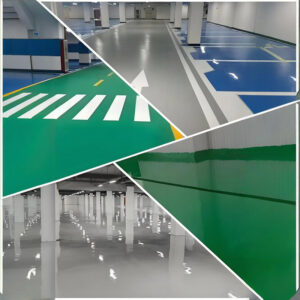

WANSHIELD®63122 Colored – Sand Water – based Polyurethane Mortar Flooring System

1. Product Overview

Wide – Range Temperature Adaptability: -20°C to +75°C

Vicat softening point ≥140°C

Abrasion resistance ≤0.15g/100r

Slip resistance (dry COF ≥0.6)

Applications

- In food processing factories, dairies, breweries, and distillation workshops, where the floor needs to withstand the impact of food production processes, including exposure to various ingredients, cleaning agents, and changes in temperature and humidity.

- In pharmaceutical intermediate production workshops and laboratories, where a clean, durable, and chemically resistant floor is required to meet strict hygiene and safety standards.

- In both wet and dry processing areas, as well as refrigerated and frozen zones, due to its ability to adapt to different temperature and humidity conditions and its resistance to water and cold.

- In chemical processing plants, pulp and paper mills, large – scale clean warehouses, and storage areas, where the floor is constantly exposed to chemicals, heavy loads, and the need for easy cleaning and maintenance.

| Project | Value | Testing Standard |

| Condition in Container | Uniform state after stirring, without hard lumps | Visual inspection |

| Vicat Softening Point / °C | ≥ 140 | GB/T 22374 – 2018 |

| Compressive Strength (7d) / MPa | ≥ 40 | GB/T 22374 – 2018 |

| Flexural Strength (7d) / MPa | ≥ 10 | GB/T 22374 – 2018 |

| Abrasion Resistance (500g/100r) / g | ≤ 0.15 | GB/T 22374 – 2018 |

| Anti – slip Property (Dry Friction Coefficient) | ≥ 0.6 | GB/T 22374 – 2018 |

| Tensile Bond Strength / MPa | ≥ 2.0 | GB/T 22374 – 2018 |

| Impact Resistance (1000g Steel Ball) | No cracks or peeling on the surface | GB/T 22374 – 2018 |

| Water Resistance (168h) | No blistering, peeling, cracking, or discoloration | GB/T 22374 – 2018 |

| Alkali Resistance (20% NaOH, 24h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Acid Resistance (10% H₂SO₄, 48h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Oil Resistance (120# Solvent Oil, 72h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Salt – water Resistance (3% NaCl, 168h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

3. Application Guidelines

Surface Treatment Before Construction

Concrete substrate ≥C25 with ≥1.5MPa pull-off strength

Moisture content <10%

Surface profile: ICRI CSP 3 (50-100μm) via mechanical abrasion

- For All New and Old Concrete Floors: The concrete strength must reach C25 or above, and the pull-out strength should not be lower than 1.5MPa. Thoroughly remove surface stains and loose soil until reaching the solid concrete layer. For any concrete damaged, loosened, or contaminated by substances due to exposure to chemicals, it should be removed until the solid concrete is exposed.

- For Painted Old Floors: Completely sand off the loose or incompatible old paint coatings. If the underlying concrete surface or a clean, dry, and intact compatible coating is exposed, it can be left without further removal.

- For Oil-Stained Floors: When the oil stains seriously affect the adhesion of the floor coating to the base surface, the oil-stained floors should be thoroughly cleaned and sanded.

- For New Concrete Floors: Ensure that the floor has passed the curing period and the moisture content is less than 10%. It is crucial to use mobile sandblasting tools and grinding equipment to treat the concrete surface to achieve the appropriate surface roughness.

- For other surfaces: If the product is to be used on other substrates, please consult the Technical Department of Yantai Wanhua.

For detailed instructions on base surface treatment, please consult us to obtain relevant materials.

Construction Conditions

Coating Environment Temperature: 15 – 30°C. The base surface temperature should be at least 3°C higher than the air dew-point temperature.

Coating Environment Humidity: <80%, and the moisture content of the concrete base surface should be less than 10%.

Ventilation Conditions: Ensure that the construction site is well-ventilated and dust-free. However, there should be no strong wind to avoid bringing in dust and affecting the appearance.

Mixing Methods:

| Step | Components | Ratio | Mixing Parameters |

|---|---|---|---|

| 1 | A+B+D | 5.48:5.71:var | 300rpm/1min @>35°C |

| 2 | Add C | 20 parts | 800rpm/2min @15-35°C |

After determining the stirring time, it should be kept consistent throughout the construction process. Inconsistent stirring time for each group may cause differences in surface color and texture.

- During the mixing process, use a straight-edge trowel to scrape the raw materials adhering to the sides and bottom of the container. This operation should be carried out at least once to ensure complete mixing.

- Only the raw materials in the factory-packed containers need to be fully mixed. Temperature will affect the construction time and product curing time.

- Different mixing machines may lead to differences in fluidity. It is recommended to use the recommended mixing head for mixing.

Primer Coating

- After applying the primer coating, allow it to dry for 24 hours (when the ground temperature is 20°C; the lower the temperature, the longer the curing time). Then, proceed with the surface coating construction.

- If the primer coating has been applied for more than 72 hours or is contaminated, it is necessary to sand and vacuum the surface again before constructing the surface coating.

Surface Coating

Installation:

Base coat: 1mm (0.9kg/m²), cure 24h @20°C

Top coat: 3-5mm (6-10kg/m²), trowel-applied

Walkability: 24h, full cure 7 days

4. Packaging & Storage

| Component | Package | Qty | Shelf Life |

|---|---|---|---|

| A | Plastic pail | 5.48kg | 6 months |

| B | Plastic pail | 5.71kg | 6 months |

| C | Composite bag | 20kg | 6 months |

| D | Pouched | 0.2-1kg | 6 months |

Storage: 5-30°C in dry, ventilated area.

- Storage and Transportation Conditions: The paint should be stored in a sealed, dry, cool, and well-ventilated environment at 5 – 30°C, away from high temperatures and fire sources. During transportation, the materials should be stacked steadily, and the carriage environment should be kept dry, enclosed, and protected from moisture and frost.

- Shelf Life: Starting from the production date, under the required storage conditions, the shelf life of the product in its original packaging is 6 months.

5. Safety & Compliance

Before use, carefully read the construction instructions and warning labels on the packaging container. When constructing, wear a gas mask and other protective equipment. Avoid inhaling paint mist and skin contact with the paint.

PPE Requirements:

NIOSH-approved respirator

Chemical goggles + nitrile gloves

First Aid:

Skin: Soap/water → seek medical help if irritation persists.

Eyes: 15-min flush → immediate ophthalmologist visit.

Fire Rating:

This product is not classified as a flammable liquid, explosive, oxidizer, corrosive, toxicant, or radioactive hazardous material during storage and transportation, and is not a hazardous product.

NFPA 704: 0-1-0

Extinguishing: CO₂/dry chemical

- In the absence of other fire-fighting agents, a large amount of fog-like water can also be used for spraying. After the fire is extinguished, the spilled materials should be cleaned up (refer to the leakage and spillage treatment section).

Leakage and Spillage Treatment

6. Technical Support

Applications:

Food processing plants (FDA compliance)

Pharmaceutical facilities (GMP grade C/D)

Chemical processing areas

7.Disclaimer

Contact:

| Weight | 5485.71 kg |

|---|