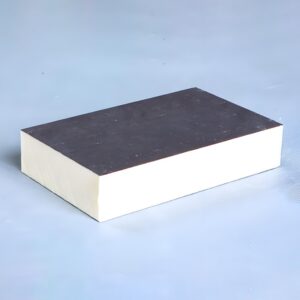

B1-Grade Spray Polyurethane Rigid Foam Composite Material for Refrigerated Fishing Boats

1. Product Overview

2. Key Applications

3. Technical Specifications

Physicochemical Properties

| Parameter | Specification | Test Method |

|---|---|---|

| Viscosity (25°C, mPa·s) | 50-200 | GB/T 12009.3 |

| Density (g/cm³) | 1.10±0.10 | ISO 845 |

| Color | Light yellow | Visual inspection |

Free-Foaming Parameters

| Parameter | Specification |

|---|---|

| Cream Time (s) | 2-3 |

| Gel Time (s) | 9-10 |

| Tack-Free Time (s) | 10-13 |

| Free-Foam Density (kg/m³) | 32-45 |

Physical Properties

| Parameter | B1 | B2 |

| Molded Foam Density (kg/m³) | ≥45 | ≥37 |

| Thermal Conductivity (W/(m·K)) | ≤0.024 | ≤0.024 |

| Compressive Strength (10% deformation, kPa) | ≥200 | ≥150 |

| Dimensional Stability (70°C, 48h, %) | ≤1.5 | ≤1.5 |

| Tensile Bond Strength (with Cement Mortar, at Room Temperature, Mpa) | ≥0.10 | ≥0.10 |

| Water Absorption (%) | ≤3 | ≤3 |

4. Processing Guidelines

Before construction, please be sure to check and calibrate the conveying ratio of the black and white materials and the mixing pressure in the high – pressure spraying machine. The suitable environmental temperature for spraying operations is 10 – 40°C, the wind speed should not exceed 5m/s (level 3 wind), the relative humidity should be less than 75%, and construction is prohibited in rainy days. When the construction environmental temperature is lower than 10°C, reliable technical measures should be taken to ensure the spraying quality.

The construction site should be designated as a fire – free area, with good ventilation, away from fire sources, and smoking is strictly prohibited. When there is hot work nearby, the hot work approval system must be strictly implemented, and corresponding safety measures should be taken, with special personnel assigned for monitoring.

Mixing Parameters:

Material temperature: 25±2°C

Mixing ratio (A:B): 1:1 by volume

Mixing method: Electric stirring at 2500 rpm

Spray Application:

Equipment: High-pressure spray machine

Ambient conditions:

Temperature: 10-40°C

Wind speed: ≤5 m/s (Beaufort 3)

Humidity: <75% RH

Layer thickness: 1-3 cm per pass

Curing: Subsequent layers may be applied only when previous layer is tack-free. Formal construction is regarded as the buyer’s recognition of the product’s performance inspection. If the above requirements are not followed, all responsibilities shall be borne by the buyer.

5. Packaging & Storage

6. Safety & Compliance

7. Environmental & Disposal

Spill Management:

Minor spills: Dilute with water → drain to treatment system

Major spills: Contain with absorbents → professional recovery

Disposal: Must comply with local hazardous waste regulations

The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators are subject to the provisions in the quality guarantee letter or supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their intended processes and applications and can achieve the expected goals. We have no control over the further application and processing of our company’s products. Therefore, our liability for the products we provide is limited to the part that we deliver and that is used by you. We do not assume liability for the indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center are dedicated to providing you with product consultation and application technical services. You are welcome to contact us by letter or by phone.

Technical Support:

Wanhua Energy Conservation Technology (Yantai) Co., Ltd.

Address: No.56 Taiyuan Road, Yantai, Shandong 264006, China

Tel: +86-400-059-1116 | Fax: +86-17761309662

| Weight | 200 kg |

|---|