Classification and application of Wanhua Energy Saving’s main floor products

Contents

01 Waterborne polyurethane mortar

02 Solvent-free polyurethane

03 Epoxy floor & corundum curing agent floor

04 Comprehensive analysis

Wanhua energy-saving floor coating product series

High-end - waterborne polyurethane mortar

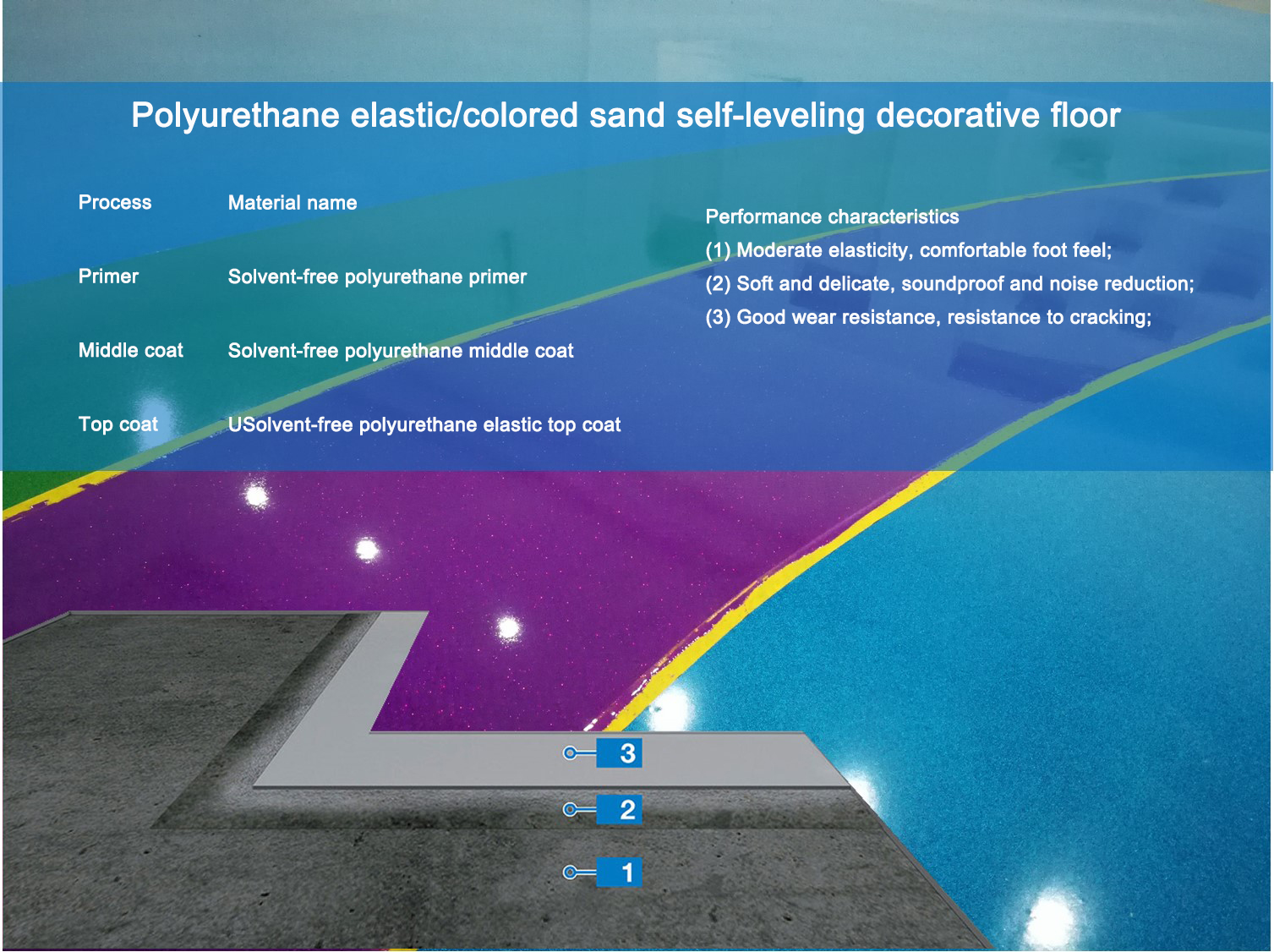

Mid-high end - solvent-free polyurethane super wear-resistant, elastic polyurethane

Mid-low end - epoxy self-leveling, solvent-free epoxy, epoxy anti-static self-leveling, epoxy floating colored sand self-leveling, water-based epoxy

Low end - corundum, sealing curing agent, high solid epoxy

Waterborne polyurethane mortar

Product introduction

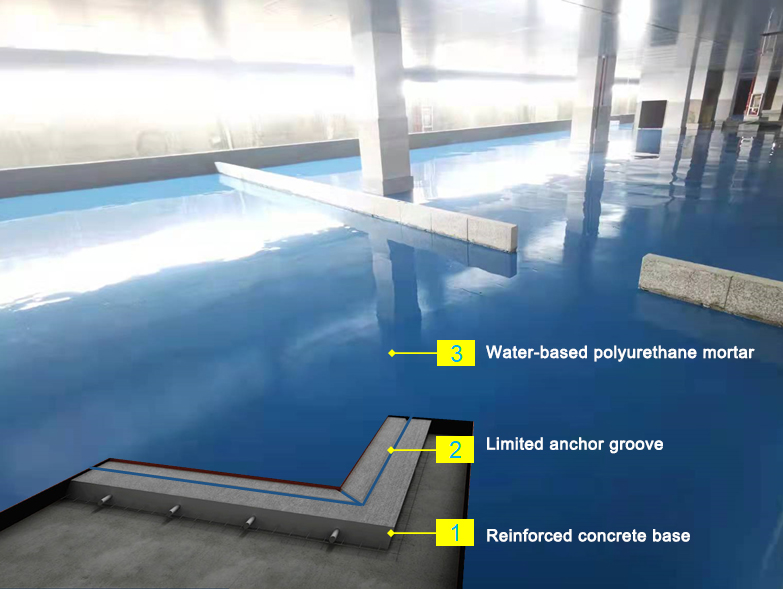

Waterborne polyurethane mortar floor system

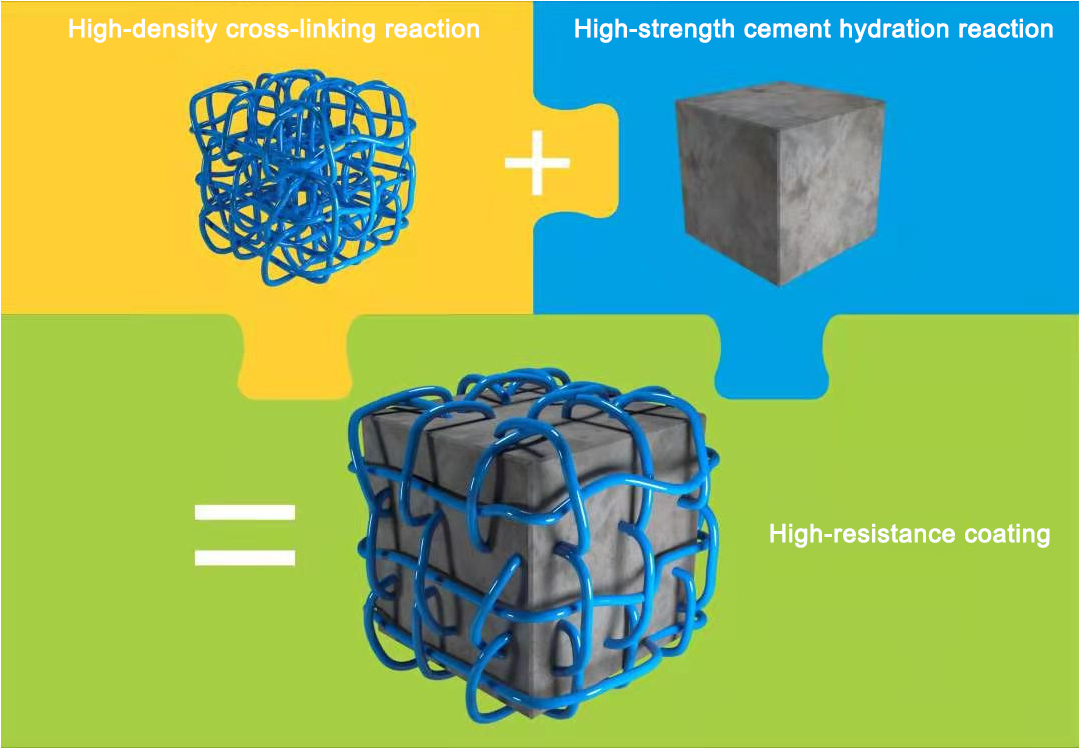

●Waterborne polyurethane mortar floor material is a combination of polyurethane resin, silicate cement and aggregate, formed by organic cross-linking reaction.

●The polyurethane resin component provides corrosion resistance, wear resistance and toughness, and the inorganic component provides excellent mechanical impact resistance and high temperature resistance.

●Therefore, this product has all the advantages of organic polymers and inorganic cement materials.

Performance characteristics

- High and low temperature resistance

The long-term service temperature range is -40~120℃, and can withstand short-term thermal shock of 150℃

- Impact resistance

The unique anchor reinforcement effect can disperse mechanical stress and thermal stress to ensure no delamination

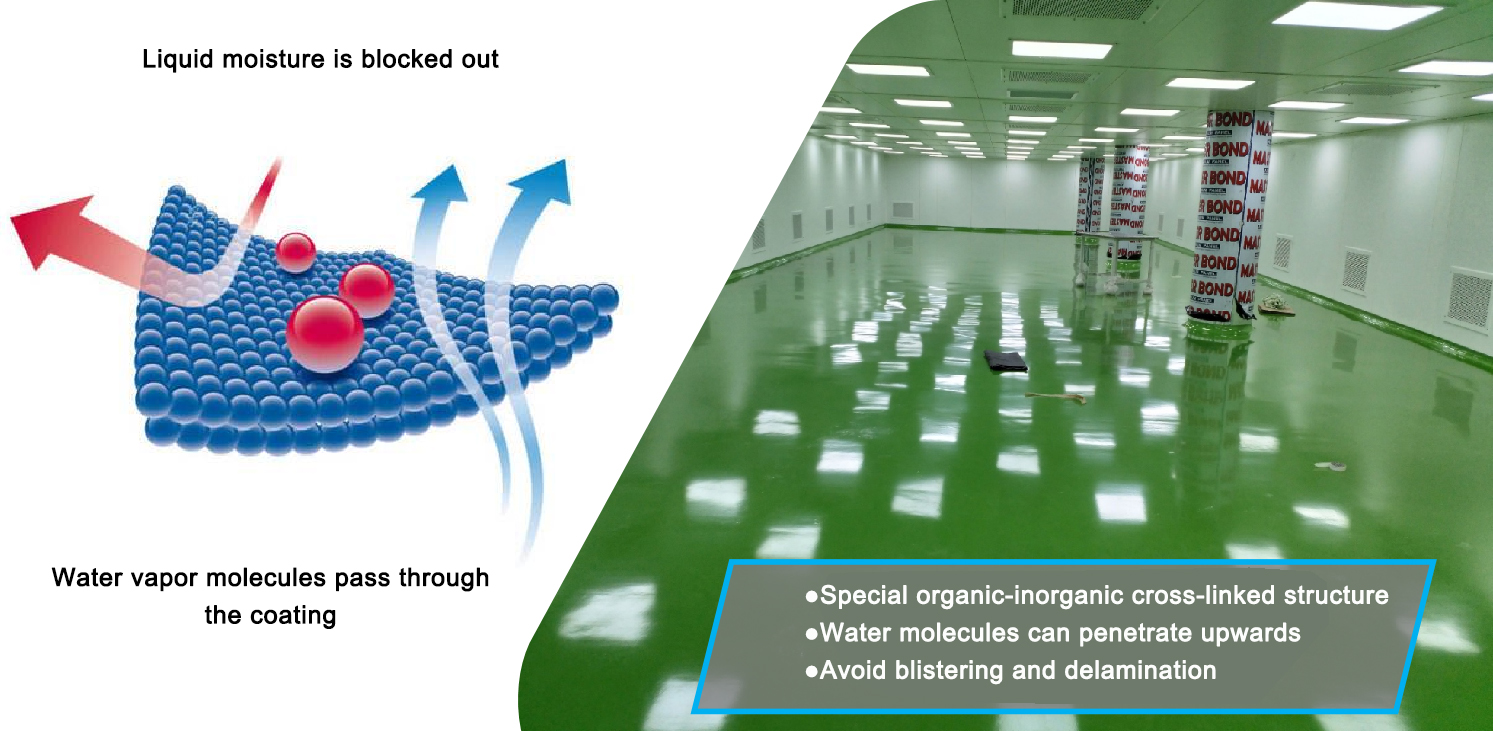

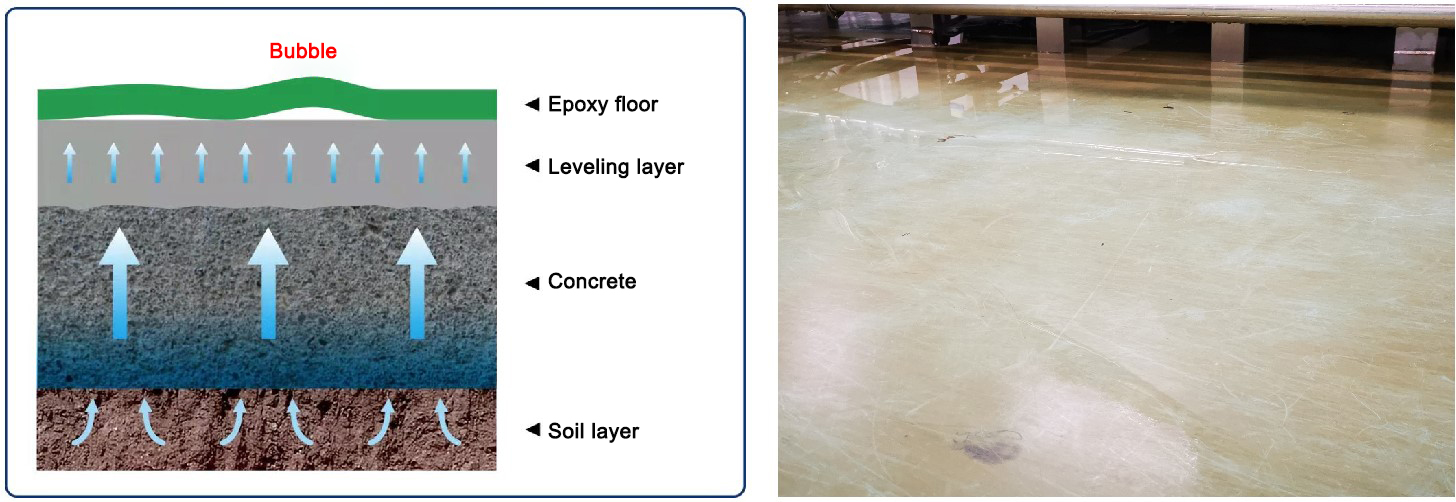

- Breathable coating

It is dense and impermeable, and allows water vapor to vent upward, effectively avoiding blistering of the coating

- Anti-slip coating

It has high anti-slip properties against moisture or grease, eliminating the safety hazards of personnel slipping and vehicle skidding

- Chemical resistance

It can withstand the corrosion of various harsh chemicals and resist more than 50% concentrated sulfuric acid

Mechanical properties

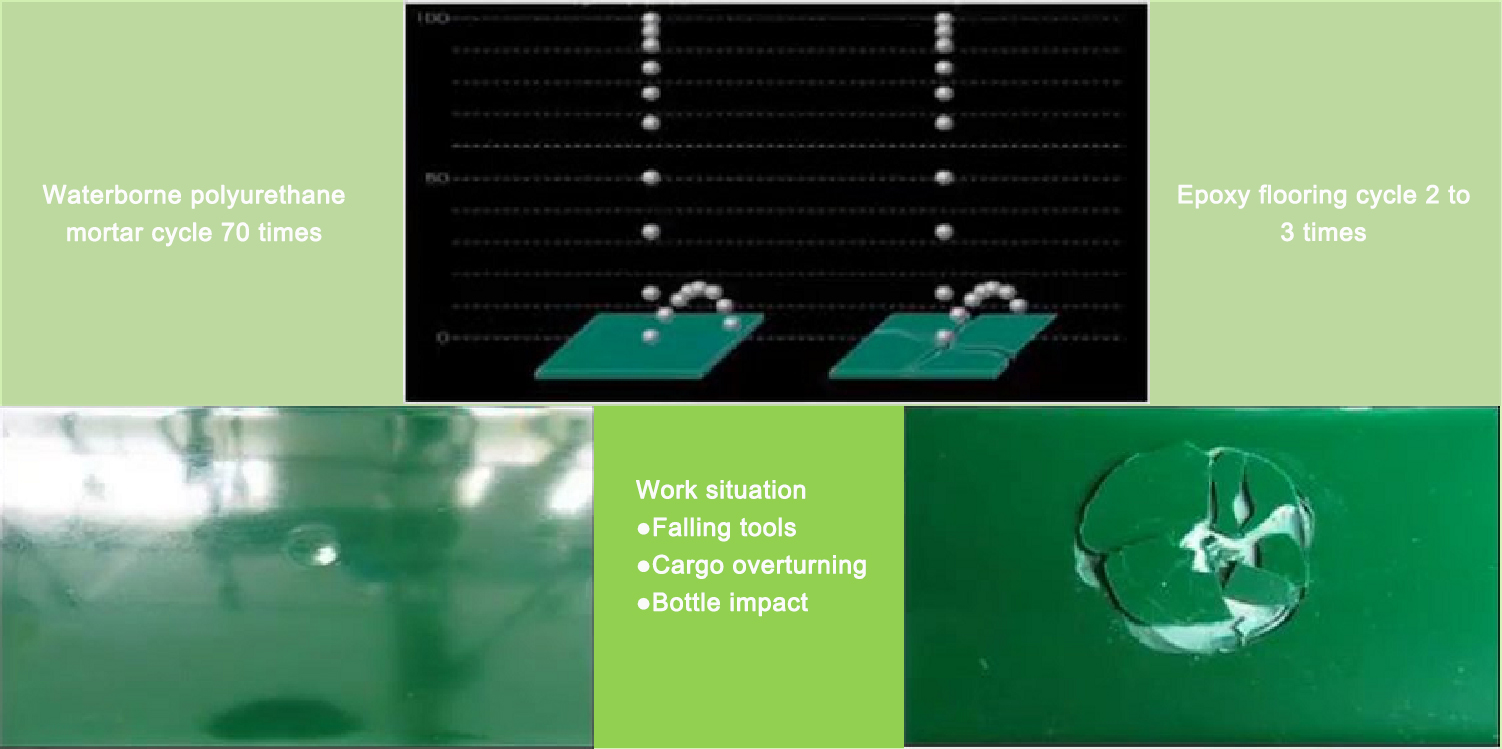

Impact resistance

Dropping a 1KG iron ball from a height of 1 meter is one cycle

Hardness & Wear Resistance

Waterproof & Breathable

Temperature resistance

Shenhua Beihai Power Plant Main Building

4mm waterborne polyurethane mortar floor

Wanhua Energy Saving Plant 5#

6mm colored sand water-based polyurethane mortar

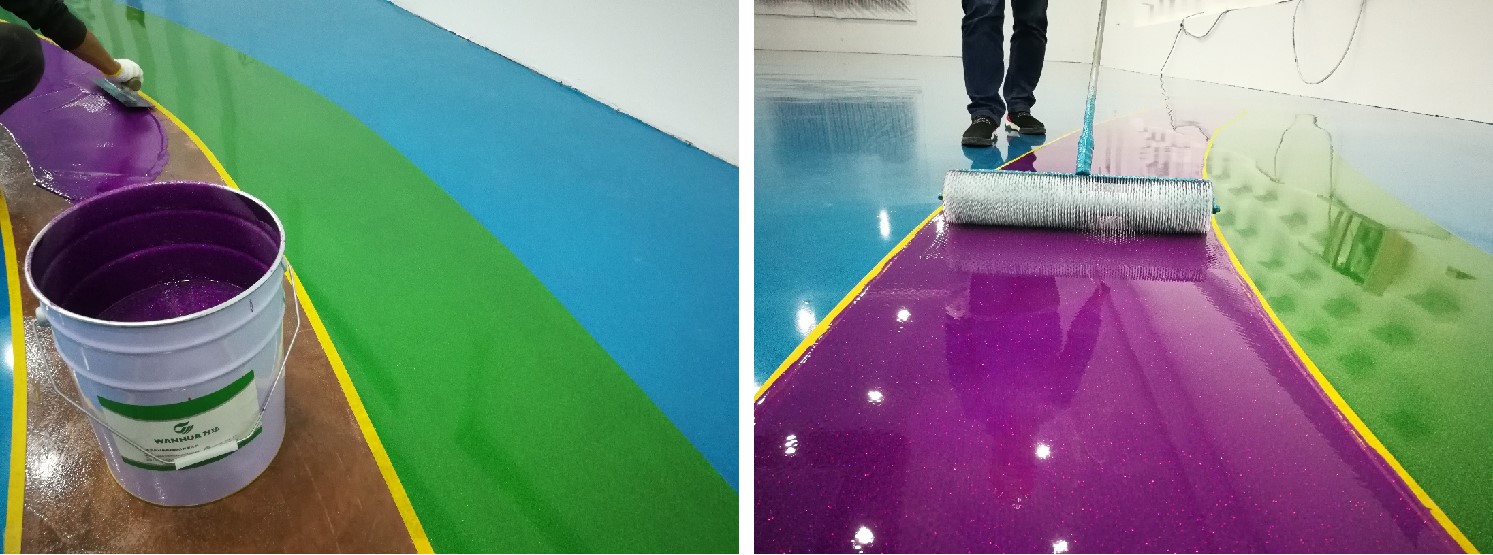

Solvent-free polyurethane flooring

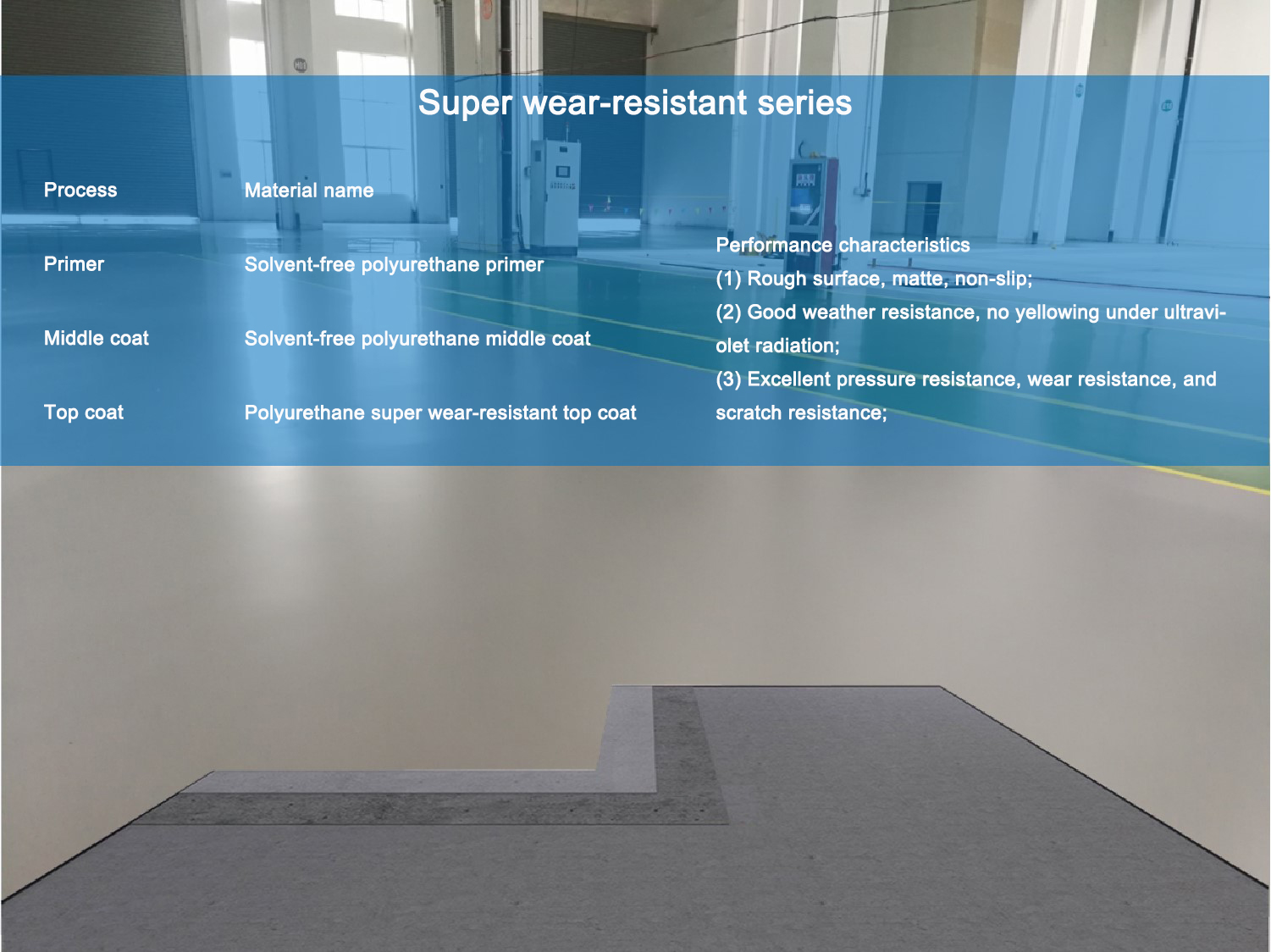

Solvent-free polyurethane super wear-resistant floor

Unique crack bridging ability, excellent noise reduction and wear resistance;

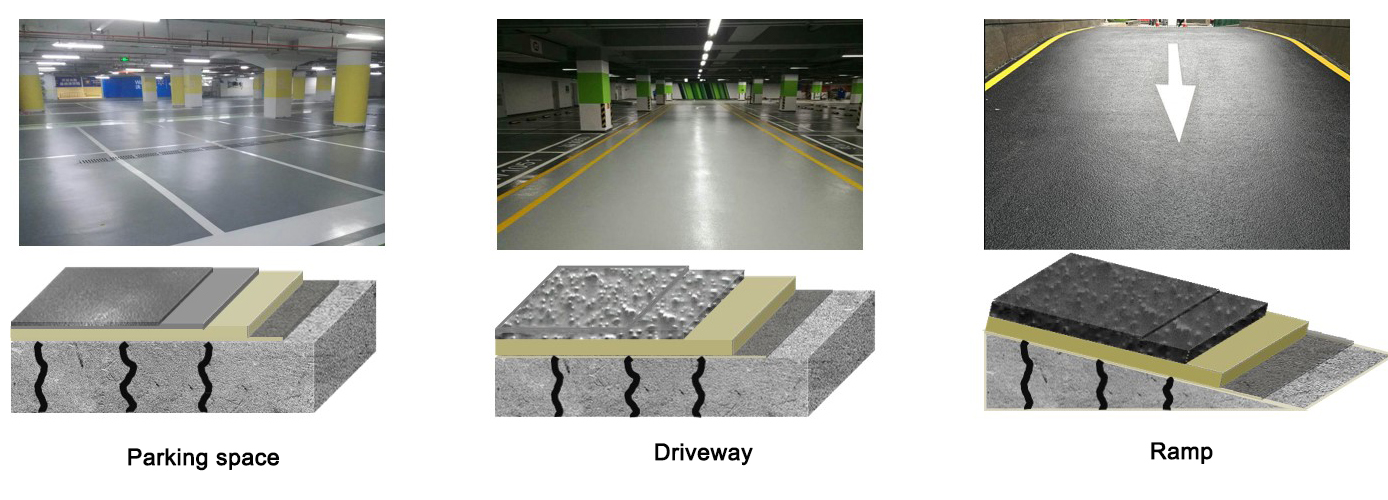

Mainly used in various indoor, outdoor, semi-outdoor, rooftop, ramp, etc.;

Indoor and outdoor, rooftop helicopter landing pad and various rapid repair passage occasions.

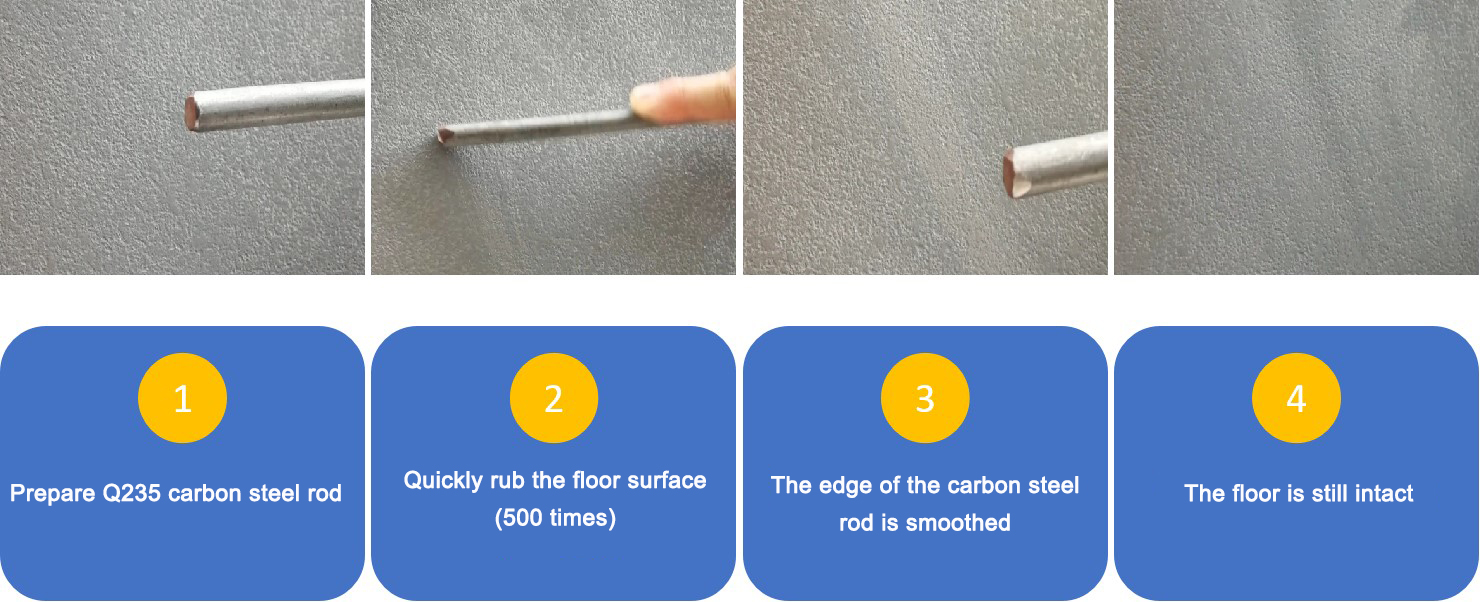

Excellent metal scratch resistance

Noise reduction, no light pollution

Development Zone Helipad

Development Zone Helipad

Jiangxi Yunmo Exhibition Hall

Epoxy floor & diamond hardener floor

Advantages: good decorative effect, high adhesion

| Primer | Solvent-free epoxy primer | Water-based epoxy primer | Antistatic epoxy primer |

| Mid-coat | Solvent-free epoxy midcoat | Water-based epoxy midcoat | Universal flow-spreading epoxy midcoat |

| Topcoat | Solvent-free epoxy topcoat | Solvent-free epoxy self-leveling flat paint | Solvent-free epoxy self-leveling colored sand |

| Solvent-free epoxy antistatic self-leveling flat paint | Epoxy super wear-resistant non-slip topcoat | Epoxy textured non-slip topcoat |

Application scenarios

Qingdao New Oriental Guobin Mansion underground garage

limitation

Easy to bubble in humid environment

Easy to turn yellow, not wear-resistant, not water-resistant

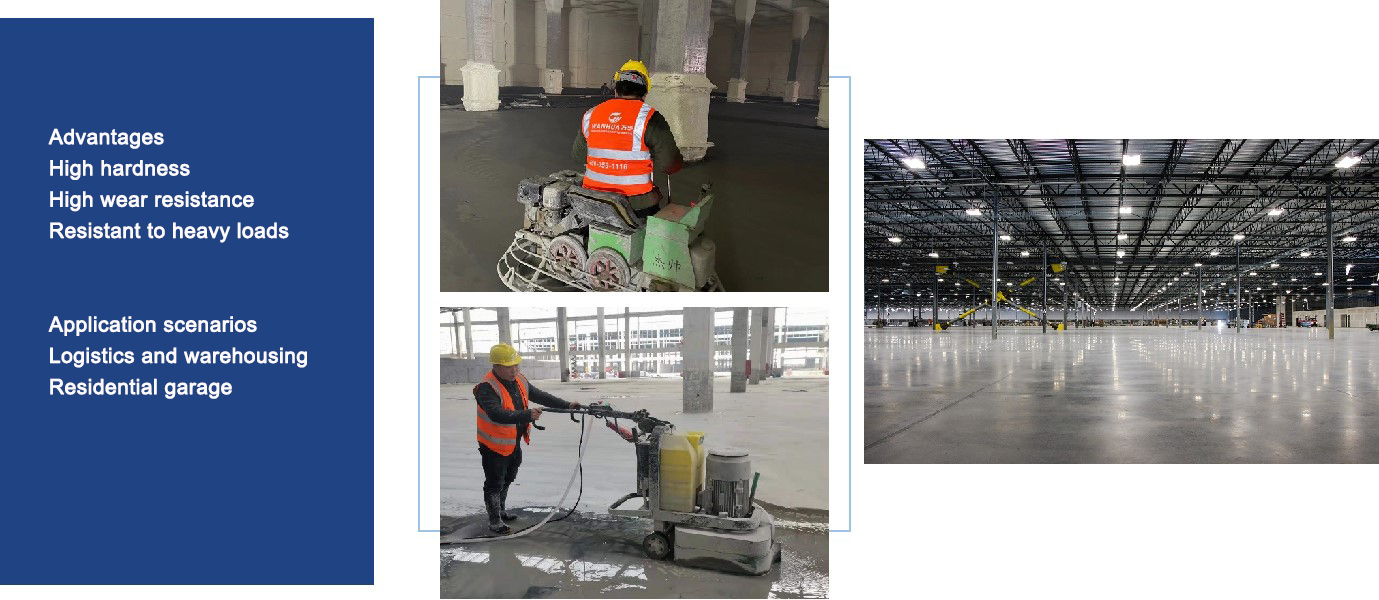

Emery + curing agent floor

Guangdong Qingyuan Jinbang 250,000 square meters logistics park

limitation

Uneven color, low decorative effect

Unavoidable cracking and dust

Comprehensive analysis

Performance comparison

| Serial number | Item | Waterborne polyurethane mortar | Solvent-free epoxy/polyurethane flooring | Emery Hardener Floor | |||

| Performance characteristics | Evaluation | Performance indicators | Evaluation | Performance indicators | Evaluation | ||

| 1 | Moisture resistance | The moisture content of the base layer is required to be ≤15%, the coating is breathable, and even if it is affected by moisture, it will not cause bubbling | Excellent | The moisture content of the base layer is required to be ≤8%, and the coating is not breathable. For underground garages excavated from deep foundation pits, blistering due to moisture is a common problem | Poor | Porous structure, breathable | Excellent |

| 2 | Fire rating | Class A non-flammable | Excellent | B2 grade flammable | Poor | Class A non-flammable | Excellent |

| 3 | Scratch resistance | The coating is made of the same material from bottom to top, and the protective surface layer is thick and cannot be scratched | Excellent | The middle coating is filled with a large amount of quartz sand to increase the thickness, and only a thin topcoat is used to provide surface protection, which is easily scratched to form obvious scratches | Poor | Scratch resistant (no marks left by scratching with a coin) | Excellent |

| 4 | Crack resistance | Tough material, which can resist cracks in the concrete base layer | Excellent | Rigid material, general crack resistance | Average | Rigid material, poor crack resistance | Poor |

| 5 | Hot tire mark resistance | Tire rubber molecules are not easy to remain and tire marks are not easy to form | Excellent | Tire rubber molecules are easily left to form black tire marks | Average | Residual rubber molecules in the tire form a lot of black tire marks | Poor |

| 6 | Surface hardness | Mohs hardness 6H | Excellent | Mohs hardness 2H | Average | Mohs hardness 6H | Excellent |

| 7 | Impact resistance | 24J, equivalent to a 1KG steel ball hitting from a height of one meter without cracks | Excellent | 12J, can only withstand a 1KG steel ball impact from a height of 0.5 meters | Average | 24J, equivalent to a 1KG steel ball hitting from a height of one meter without cracks | Excellent |

Performance comparison

| Serial number | Project | Waterborne polyurethane mortar | Solvent-free epoxy/polyurethane flooring | Emery Hardener Floor | ||||

| Performance characteristics | Evaluation | Performance indicators | Evaluation | Performance indicators | Evaluation | |||

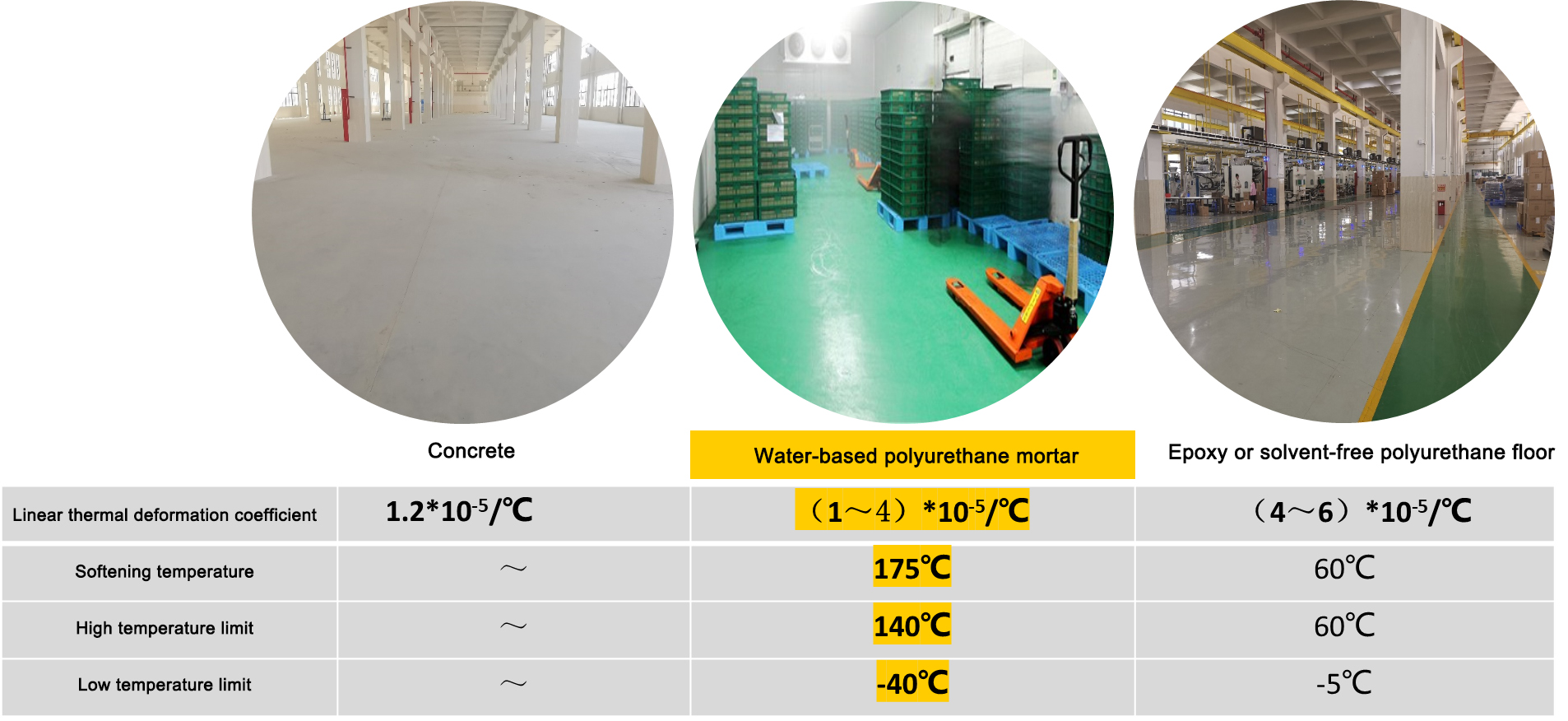

| 8 | Deformation coefficient | 1.2*10-5/℃, deformation coefficient is consistent with concrete, and it moves synchronously with concrete during thermal expansion and contraction | Excellent | 4~6*10-5/℃, deformation coefficient is much larger than concrete, thermal expansion and contraction are not synchronized, easy to delaminate | Poor | Deformation coefficient is consistent with concrete, and it moves synchronously with concrete during thermal expansion and contraction | Excellent | |

| 9 | Environmental protection | Water-based environmentally friendly materials, TVOC≤10, no odor is generated during construction and use | Excellent | Oil-based materials, TVOC≤20, there will be a certain odor during the construction process | Medium | Inorganic environmentally friendly materials, TVOC≤10, no odor is generated during construction and use | Excellent | |

| 10 | Anti-slip properties | BPN≥70, whether in dry or humid environment, it can maintain excellent anti-slip effect | Excellent | BPN is about 50~55, the anti-slip effect is low in humid environments, and the noise is loud (squeaking) | Medium | BPN is less than 50, and the anti-slip effect is poor in humid environments | Poor | |

| 11 | Resistance to temperature changes | Normal temperature 23℃ (18h) → low temperature -40℃ (3h) → high temperature 120℃ (3h), no change after 5 temperature change cycles | Excellent | Limited to use within the range of 0℃~60℃, prone to cracking in severe cold climates | Poor | Under low temperatures, the cracks are frozen and expanded, expanding the growth of cracks | Medium | |

| 12 | Resistance to wet and dry conditions | No change | Excellent | Under long-term dry and wet alternation, it is easy to turn white | Medium | Under long-term dry and wet alternation, it is easy to turn white | Medium | |

| 13 | Decorative effect | The surface effect is generally semi-gloss or matte | Medium | The surface effect can be semi-gloss or matte, and can also be high-gloss | Excellent | The color is extremely uneven and the decorative effect is poor | Poor | |

| 14 | Comprehensive cost of the whole life cycle | Single life cycle | Generally 10 to 15 years, up to the same life as concrete floor | Excellent | The renovation cycle is generally 3~5 years | Medium | The renovation cycle is generally 5 to 8 years | Medium |

| Single cost | ☆☆☆ | ☆☆ | ☆ | |||||

| Comprehensive cost (taking 15 years as an example) | ★★ | ★★★ | ★★ | |||||

| No renovation is required during this period, and there is no need to consider the issue of occupying the site | Every renovation involves the issue of occupying the site | No renovation is required during this period, but dust and cracking are becoming more and more obvious | ||||||

Performance Analysis

1. Waterborne polyurethane mortar flooring has both excellent polyurethane polymer materials and inorganic mortar materials in the system, so the system has all the advantages of organic polymers and inorganic concrete materials, and has excellent resistance to heavy impact, temperature changes and cold and hot shock. Except for the decorative performance that cannot achieve high gloss effect, other performances are better than solvent-free epoxy types.

2. The outstanding advantage of solvent-free epoxy flooring is that it is relatively high in decorativeness, but there are also significant disadvantages that it is easy to bubble when affected by moisture, easy to produce scratches during use, and easy to crack at low temperatures; although the cost of a single construction is low, due to the short service life, it needs to be completely removed during renovation, and the comprehensive cost in the entire life cycle requires a higher cost.

3. The performance characteristics of solvent-free polyurethane flooring and solvent-free epoxy flooring are roughly the same, but it has more advantages than epoxy in terms of wear resistance, weather resistance and crack resistance.

4. Although the diamond abrasive and curing agent floor has achieved excellent results in many indicators, it cannot avoid problems such as cracking and dust separation. It does not have decorative properties and it is difficult to improve the environmental quality.

Scene comparison

Water-based polyurethane mortar

Commercial high-end garage

A-class office building garage

Food processing workshop (acid and alkali resistant)

Heavy industrial plant (corrosion resistant, impact resistant)

Pharmaceutical industry

Polyurethane flooring

Commercial mid-range garage (super wear-resistant)

Hospitals, schools (elastic)

Office space (elastic)

Epoxy flooring

Residential low-end garages

Light industrial plants

Electronic cleanrooms

Emery hardener

Residential low-end garage

Logistics warehousing

Price Comparison

| Not less than 2 years | Thickness | Reference comprehensive unit price | Reference service life |

| Water-based polyurethane mortar | 3mm-6mm | 280~350元/㎡ | Not less than 8 years |

| Ultra-wear-resistant polyurethane | 2mm-super wear-resistant | 80~100元/㎡ | Not less than 3 years |

| 2mm-elastic | 100~150元/㎡ | ||

| Epoxy flooring | 2mm-anti-slip | 60~80元/㎡ | Not less than 2 years |

| 2mm-glossy | 60~80元/㎡ | ||

| Carborundum wear-resistant aggregate | —— | 15~35元/㎡ | Not less than 3 years |

| Sealing curing agent | —— | 12~20元/㎡ |

Recommended floor selection

Wanhua Chemical Industrial Park Staff Dormitory and Supporting Facilities Project

Emery sand curing agent floor is a relatively cost-effective process, but it is only applicable to low-end markets such as residential garages or warehouses, and is not recommended for the Tianshan Road project.

Apart from the quality risk of bubbling caused by moisture, the epoxy process may not have too many criticisms in the early stage of use, but after 3-5 years of use, the site may need to be vacated for renovation.

The performance characteristics of solvent-free polyurethane flooring are roughly the same as those of solvent-free epoxy flooring, but it has more advantages than epoxy in terms of wear resistance, weather resistance and crack resistance.

In the Tianshan Road project, it is recommended to use high-end water-based polyurethane mortar. In terms of performance characteristics, appearance, durability and other aspects, water-based polyurethane mortar has more comprehensive cost-effective advantages.