EP001 Epoxy Sealing Paint

As a sealing primer for anti-corrosion or floor paint construction, it provides excellent adhesion for subsequent coatings. Features outstanding permeability and easy application.

SKU:

EP001 Epoxy Sealing Paint

Category: Corrosion Protection Coatings

Tags: Coating, Corrosion Protection Coatings

Description

Product Characteristics

As a sealing primer for anti-corrosion or floor paint construction, it provides excellent adhesion for subsequent coatings. Features outstanding permeability and easy application.

Recommended Applications

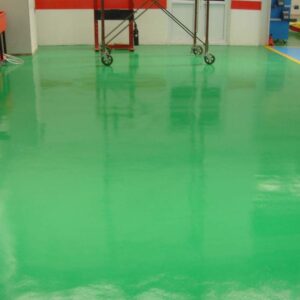

Suitable for sealing clean concrete surfaces before topcoat application, especially in high-performance paint systems and chemical-resistant coating systems.

Technical Parameters

| Item | Details |

|---|---|

| Binder/Pigment Type | Epoxy resin / polyamide curing agent |

| Color | Transparent |

| Surface Finish | High gloss |

| Mixing Ratio | 4 (binder) : 1 (curing agent) by weight |

| Specific Gravity | Approx. 1.0 kg/L |

| Volume Solids Content | 50% |

| Flash Point | 25°C |

| Pot Life | 6 hours @ 23°C |

| Theoretical Coverage | Dependent on substrate surface conditions |

| Application Method | Conventional spraying or airless spraying |

| VOC Content | 513 g/L |

| Drying Time | Touch dry: approx. 4 hours @ 20°C; Hard dry: 7 days @ 20°C |

| Recoating Interval | Minimum: 4 hours @ 23°C (73.4°F) |

| Recommended Primer | None |

| Substrate Temperature | At least 4°C (7°F) above dew point |

| Packaging & Storage | Two-component, 20 kg combined packaging. Store in cool, ventilated areas, away from excessive heat. Keep containers tightly sealed. Shelf life: 1 year. |

Application Guidelines

Surface Preparation

- Remove all release agents, oils, and other contaminants via sandblasting, volatilization burning cleaning, or appropriate cleaning agents.

- For concrete surfaces, depending on structure and usage, adopt sandblasting, high-pressure freshwater jetting, or power tool treatment to remove residues and contaminants, achieving a rough and solid surface.

- Eliminate dust and loose materials. If mechanical treatment is unavailable, use acid pickling: clean with 5% (by weight) nitric or phosphoric acid solution. Note: Take necessary protective measures for strong acids and follow safety rules. Pre-soak concrete with freshwater before pickling to prevent acid corrosion of steel reinforcement. Let the acid soak for 3–4 minutes, then rinse with freshwater—first with 5% (by weight) NaOH solution, then thoroughly with freshwater.

- After treatment and uniform drying, the surface should be smooth, rough, and free of loose materials, with a pH range of 6.5–8.0. Allow at least 2 days of ventilation drying (65% relative humidity, 20°C).

- Quality control for pretreatment: Scratch the surface with a hard blade—the treated surface must be solid, allowing only a clear single scratch. Concrete must be fully cured (approximately 28 days for ordinary Portland cement), with surface moisture below 4% after thorough drying. Control capillary action or foundation moisture. Apply and cure only at temperatures above 10°C.

Mixing and Dilution

- EP001 is a two-component product requiring correct component ratio. Mix all material in each barrel thoroughly before use. Add curing agent and stir for 3 minutes.

- Use a variable-speed power mixer. Avoid over-stirring to prevent accelerated curing and shortened pot life. High temperatures shorten pot life; low temperatures extend it.

- Dilution is generally unnecessary. If required, add a small amount of diluent (5% or less) per local VOC and air quality regulations.

Safety Precautions

- Warning: Irritating to eyes and skin. Vapors may cause respiratory allergies in sensitive individuals. May cause skin allergic reactions. Avoid inhaling vapors. Keep away from eyes and skin. Use protective gear for eyes, ears, and skin. Use a suitable respirator to avoid potential respiratory irritation. Thoroughly wash skin after use. Wash contaminated clothing before reuse. In case of respiratory arrest, perform mouth-to-mouth resuscitation and seek medical help immediately.

- First Aid: In case of eye contact, flush with clean water for at least 15 minutes. Remove contaminated clothing and shoes, and wash affected skin with soap.

Declaration

The information herein is reliable. Each value is a theoretical data calculated from the product formula. Upon request, our company can provide internal standard test methods for the data above. Since usage conditions are beyond the manufacturer’s control, this information is not a guarantee. The product is for professional use only. For any questions, contact our company.

Our Technical Support and Customer Service Center is ready to provide product consultation and application technical services. Welcome to contact us via letter or phone.

Contact:

Wanhua Energysav Science & technology Group Co.,Ltd

Address: No. 56 Taiyuan Road, Yantai, Shandong, China

Fax: 400-059-1116 | Tel: +86-17761309662 | Postal Code: 264006

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|