Inorganic Flame-Retardant Fireproof Coating AquaTop 910

AquaTop 910 water-based inorganic flame-retardant coating uses inorganic minerals as the primary binder. It chemically reacts with the mineral matrix of the substrate to form a water-and acid-resistant silicate layer. Through silicification with the mineral substrate, it generates insoluble silicate compounds, permanently bonding with the base layer. This results in excellent water resistance, acid/alkali resistance, dust resistance, and fire-retardant properties.

Product Overview

AquaTop 910 is a water-based inorganic fireproof coating formulated with mineral binders that chemically react with substrates to form insoluble silicate compounds. This creates a permanent, monolithic layer with exceptional resistance to fire (A-grade), water, acids, alkalis, and microbial growth.

Key Features

- A-Grade Fire Resistance: Non-combustible at 1000°C.

- Superior Adhesion: No peeling, blistering, or fading. and maintains long-term integrity.

- Breathable & Hydrophobic: Water-repellent yet vapor-permeable; preventing static dust accumulation. anti-static.

- Eco-Friendly: Ultra-low VOC, odorless, and antimicrobial.

- Antimicrobial & Moisture-Proof: Resists mold, mildew, and condensation in humid environments.

- Universal Compatibility: Bonds permanently to mineral substrates without primer. offering decorative versatility

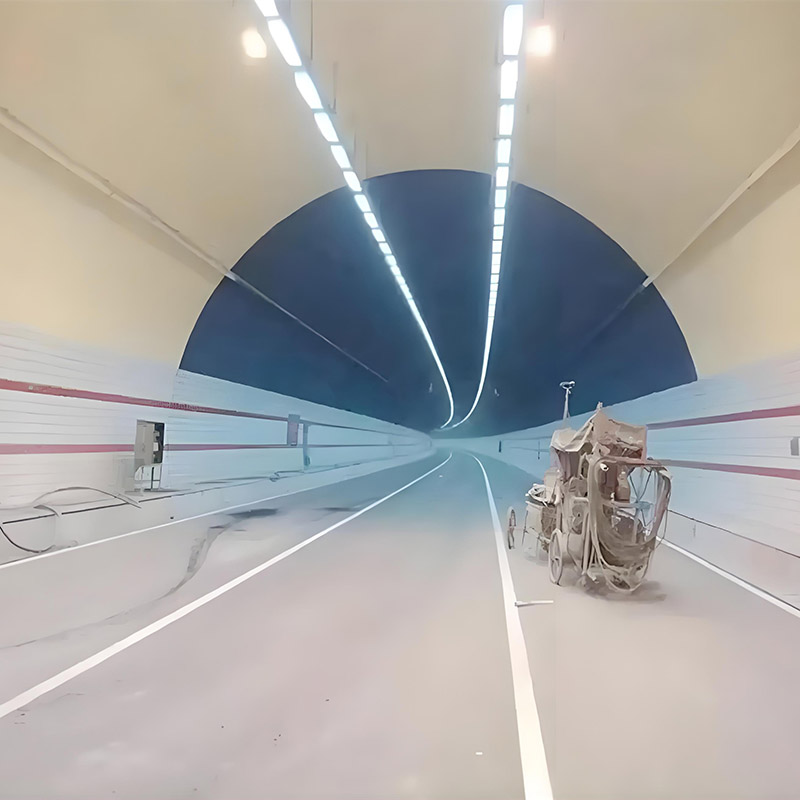

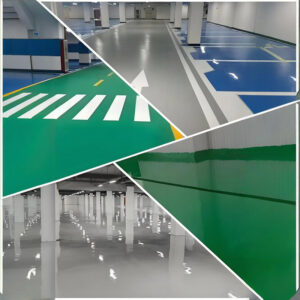

Applications

Technical Specifications

| Parameter | Specification |

|---|---|

| Color | White & custom colors |

| Finish | Matte |

| Mixing Ratio | Single-component |

| Density | ~1.4 kg/L |

| Volume Solids | 43±2% (theoretical) |

| Coverage | 8 m²/L (50μm dry film) |

| Application Methods | Brush, airless/air spray |

| Thinner | Water (0–5% dilution) |

| Drying Time (23°C, 50% RH) | Touch dry: 0.5 hours |

| Recoat Interval | 5 hours (30°C; varies with conditions) |

| Ambient Temperature | 5–50°C (avoid >85% RH) |

| Substrate Temperature | ≥3°C above dew point |

| Packaging | 25 kg/drum |

| Shelf Life | 12 months (cool, ventilated storage) |

Application Guide

- Remove oil, dust, and loose particles. For old coatings, remove loose layers and clean thoroughly.

- Substrate Condition: Avoid loose, blistered, or cracked bases.

- Repair: Fill cracks and holes with anti-crack mortar or elastic putty, allow 8-12 hours to dry, then sand and remove dust. For porous substrates, apply inorganic consolidating primer.

- Airless Spray: Nozzle 0.33–0.58mm; pressure 15–20 MPa.

- Air Spray: Nozzle 1.0–1.5mm; pressure 0.3–0.4 MPa.

- Brush/Roller: Achieves 30–50μm dry film per coat.

Safety & Storage

Although water-based, avoid inhalation of paint mist. Use protective gear (gloves, goggles) to avoid skin/eye contact and inhalation of paint mist.

Disclaimer

Contact:

| Weight | 25 kg |

|---|