XPS High Compressive Cold Storage

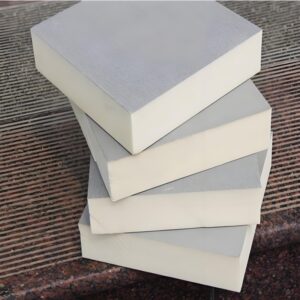

XPS high compressive cold storage panel is a high-performance thermal insulation panel developed for cold storage environments, manufactured by advanced Extruded Polystyrene (XPS) technology.

SKU:

XPS High Compressive Cold Storage

Categories: Panels, XPS Board/Crack-Resistant Panel

Tags: Panels, XPS Board/Crack-Resistant Panel

Description

1. Product Overview

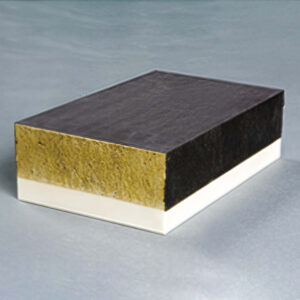

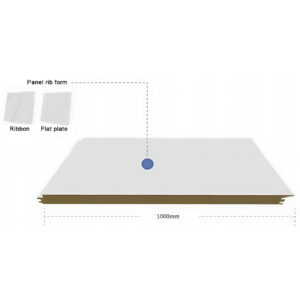

XPS high compressive cold storage panel is a high-performance thermal insulation panel developed for cold storage environments, manufactured by advanced Extruded Polystyrene (XPS) technology. Using high-quality polystyrene resin as the base material, added with special formula additives, it is formed by high-temperature and high-pressure extrusion foaming to create a unique closed-cell honeycomb structure. This structure endows the product with excellent thermal insulation, high compressive strength, and outstanding moisture-proof and waterproof properties, effectively maintaining the low-temperature environment of cold storage, reducing energy consumption, and serving as an indispensable core thermal insulation material for cold storage construction and maintenance.

2. Application Scenarios

- Food Cold Storage: Widely used in various food freezers and refrigerators, such as storage and preservation of meat, seafood, fruits, and vegetables. It effectively blocks external heat, maintains stable internal temperature, and extends the shelf life of food.

- Medical Cold Storage: Suitable for cold storage of temperature-sensitive medical products such as vaccines, drugs, and biological products, providing precise and stable low-temperature protection to meet strict medical storage standards.

- Industrial Cold Storage: Plays an important role in low-temperature storage of industrial products such as chemical raw materials and electronic components, effectively preventing product deterioration and damage caused by temperature changes, and ensuring the quality of raw materials and finished products in industrial production.

- Logistics Cold Chain: Used in cold chain logistics transfer cold storage, refrigerated containers, and other facilities to provide continuous and stable low-temperature environments for goods during transportation and warehousing, ensuring the efficient operation of the cold chain.

3. Performance Indicators

| Item | Parameters |

|---|---|

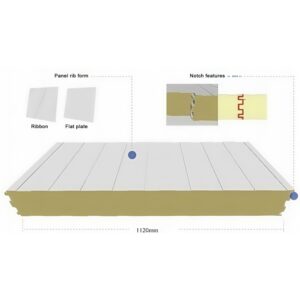

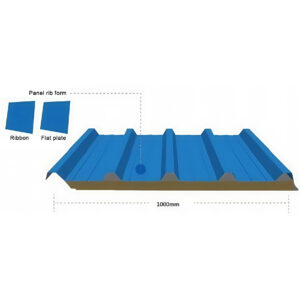

| Dimensions | 2400×600×50mm, 2400×1200×50mm, suitable for different cold storage structures, facilitating construction and splicing. |

| Color Options | Standard color is yellow (eye-catching and easy to identify); customized colors are supported to adapt to decoration and identification requirements. |

| Compressive Strength | 250~1200kPa, capable of withstanding pressures from cargo stacking, equipment operation, and personnel operation to prevent panel deformation. |

| Thermal Conductivity | ≤0.030W/(m·K), extremely low thermal conductivity, minimizing heat exchange between inside and outside of cold storage, reducing energy consumption of refrigeration equipment. |

| Water Absorption | ≤1.0%, excellent moisture-proof and waterproof performance, resisting the humid environment in cold storage, and avoiding the decline of thermal insulation performance and panel mildew. |

| Low-temperature Resistance | Stable performance within the temperature range of -40℃~80℃, no embrittlement or deformation, and long-term adaptation to the extreme low-temperature environment of cold storage. |

| Environmental Protection Index | Complies with national environmental protection standards, stable chemical properties, no harmful substance release, and no pollution to stored items and the environment during production and use, ensuring food safety and environmental health. |

4. Usage Notes

1. Before Installation

- Clean and inspect the installation surface (wall/ground) to ensure it is flat, dry, free of oil and sharp protrusions. Level the uneven surface if necessary.

- The construction environment temperature is recommended to be ≥5℃ to avoid panel embrittlement caused by low temperature, which affects installation quality and splicing effect.

2. During Installation

- Operate strictly in accordance with the design plan and construction specifications. Ensure tight splicing of panels, use special sealing strips/sealants to fill gaps, and prevent thermal bridge generation.

- Fix the panels firmly with special anchor bolts or adhesives; avoid collision and scratch of panels, and replace damaged panels in time.

3. During Use

- Open flame or high-temperature equipment are strictly prohibited in the cold storage to prevent panel damage caused by high temperature.

- Regularly inspect the sealing strips and sealants, and replace or repair them in time if aging or cracking is found; avoid impact and scratch on panels when handling goods.

5. Packaging Specifications

- Packaging Materials: The whole panel is wrapped with high-strength moisture-proof plastic film, and the outer layer can be fixed and packed with wooden pallets to prevent moisture and collision, facilitating forklift loading and unloading.

- Packaging Quantity: 6 pieces per pack for 2400×600×50mm specification, and 5 pieces per pack for 2400×1200×50mm specification.

6. Storage (Usage) Notes

- Storage Environment: Store in a dry, ventilated, and cool indoor environment, avoiding open-air stacking and direct sunlight; storage temperature is -10℃~28℃ to prevent deformation due to high temperature or freezing damage due to low temperature.

- Stacking Requirements: The stacking height shall not exceed 2 meters, and stack evenly; store products of different specifications, colors, and batches separately, and strictly prohibit heavy pressure; inspect regularly and handle moisture and deformation in time.

- Service Life: Under proper storage conditions, it is recommended to use within 6 months from the production date; if used beyond the period, the performance shall be tested, and use only after passing the test.

7. Warranty Period

The warranty period is 1 year, calculated from the date of product delivery. During the warranty period, if the product is damaged or fails to meet the performance standards due to its own quality problems, our company will provide free maintenance or replacement; problems caused by improper use, human damage, or force majeure (such as earthquakes, floods, etc.) are not covered by the warranty.

8. Safety Precautions

1. Construction Safety

- Construction personnel must wear safety protection equipment such as safety helmets, gloves, and safety belts; operate electric tools in accordance with regulations to prevent mechanical injury and electric shock.

- Set up obvious safety warning signs at the construction site to prohibit irrelevant personnel from entering.

2. Fire Safety

- Although XPS cold storage panels have certain flame retardancy, they should be kept away from open flames and high-temperature heat sources during storage and use, and smoking and open-fire operations are strictly prohibited on site.

- The cold storage should be equipped with qualified fire-fighting equipment (fire extinguishers, fire hydrants, etc.), keep the fire passage unobstructed, and carry out regular fire drills to improve fire response capabilities.

3. Health Safety

- If the panel is found to be damaged or deformed, replace it in time to avoid increased energy consumption and harmful substance release affecting air quality and stored items.

- When replacing damaged panels, construction personnel should wear protective masks and gloves to avoid contact with dust and debris.

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 25 kg |

|---|