Polyurea Waterproof Coating For Environmental Engineering

Polyurea waterproof coating for environmental engineering effectively addresses waterproofing, anti-seepage, and anti-corrosion issues in substrates such as concrete and steel structures, thereby prolonging service life.

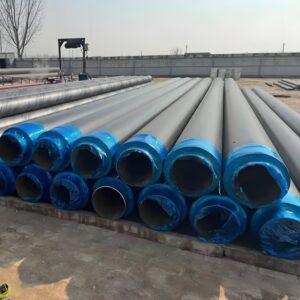

Wanefoam®7000 Pouring-Type Polyurethane Rigid Foam Insulation Pipe Composite Material (141B) For Pipes

WANEFOAM®7000 series is a polyurethane rigid foam insulation pipe composite material for casting. Its foaming agent is HCFC-141b. The foam obtained by using WANEFOAM®7000 series composite materials in combination with WANNATE®2208 has fine pores, strong adhesion, uniform density distribution, good fluidity and mold filling properties.

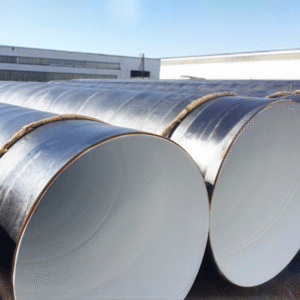

Wanefoam®7020 Spray-Coiled Polyurethane Rigid Foam Insulation Pipe Composite Material For Pipes

The foaming system of spray-coiled polyurethane rigid foam insulation pipe composite material utilizes water + physical blowing agents. When combined with WANNATE®2208, the resulting foam exhibits fine foam cell structure, excellent bonding strength with steel pipes, uniform density distribution, and good dimensional stability.

Wanefoam®7010 Pouring-Type Polyurethane Rigid Foam Insulation Pipe Composite Material (Water-Blown) For Pipes

Pouring-type polyurethane rigid foam insulation pipe composite material (water-blown) uses water as the sole blowing agent without other auxiliary foaming agents. When combined with WANNATE®2208, the resulting foam exhibits fine cell structure, strong adhesion, uniform density distribution, along with excellent flowability and mold-filling properties.

Pouring-Type Polyurethane Rigid Foam Insulation Pipe Composite Material (141B)

Pouring-type polyurethane rigid foam insulation pipe composite material (141B) is designed for pouring applications. It utilizes the ultra-low thermal conductivity and environmentally friendly blowing agent. When combined with WANNATE®2208, the resulting foam exhibits fine cell structure, strong adhesion, uniform density distribution, along with excellent flowability and mold-filling properties.

Polyurea Waterproof Coating For Urban Utility Tunnels

Polyurea waterproof coating for urban utility tunnels effectively addresses waterproofing, anti-seepage, and anti-corrosion issues in substrates such as concrete and steel structures, thereby prolonging service life.

WANSHIELD®62238 Solvent-Free Epoxy Self-Leveling Topcoat for Floor Coating

WANSHIELD®62238 is a high-performance, two-component, solvent-free epoxy self-leveling floor coating. Component A consists of epoxy resin, eco-friendly additives, and pigments, while Component B is a yellowing-resistant amine curing agent. The coating delivers an exceptionally smooth, glossy, and mirror-like finish with outstanding resistance to chemicals (acids, alkalis, salts, oils), abrasion, compression, and impact. Ideal for environments demanding superior cleanliness, aesthetics, and hygiene.

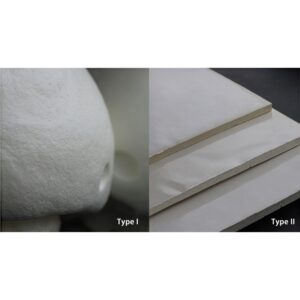

High Temperature Resistant Sealing Gel Material (Fire Resistant) Type 2

High temperature resistant sealing gel material (fire prevention and extinguishing) type 2 is a filling fire extinguishing material for coal mines. It contains components A and B. The two components are mixed in a volume ratio of 1:1 and then foamed and sprayed. The reaction process does not release heat. The foam formed has a high water content and good flame retardancy. It can be used in the fields of filling and sealing of coal mines, prevention of fire and spontaneous combustion, etc.

High Temperature Resistant Sealing Gel (Fire Resistant) Material Type 1

The silicate-modified polyurethane material used for spraying to plug air leaks in coal mines has excellent adhesion, flame retardancy, water resistance, corrosion resistance, and a certain toughness. It can still plug air leaks and seal when deformed along with the rock layer and wall, and also has a certain reinforcement effect.

Phenolic Resin Foaming Material For Coal Mine Filling And Sealing

Phenolic resin foam material for coal mine filling and sealing has excellent flame retardant properties, high expansion ratio and low reaction temperature, and is particularly suitable for large volume filling.

Polyurethane Material For Water Shutoff At Coal Mine

The polyurethane material used for coal mine water plugging has extremely high strength, excellent bonding force and solvent corrosion resistance. In a water environment, the mixed resin can expand at a high rate and densely fill all gaps. It also has a certain toughness and can deform with the rock layer while maintaining the plugging effect.