Dome Roof Insulation System

Wanhua Dome Roof Insulation System

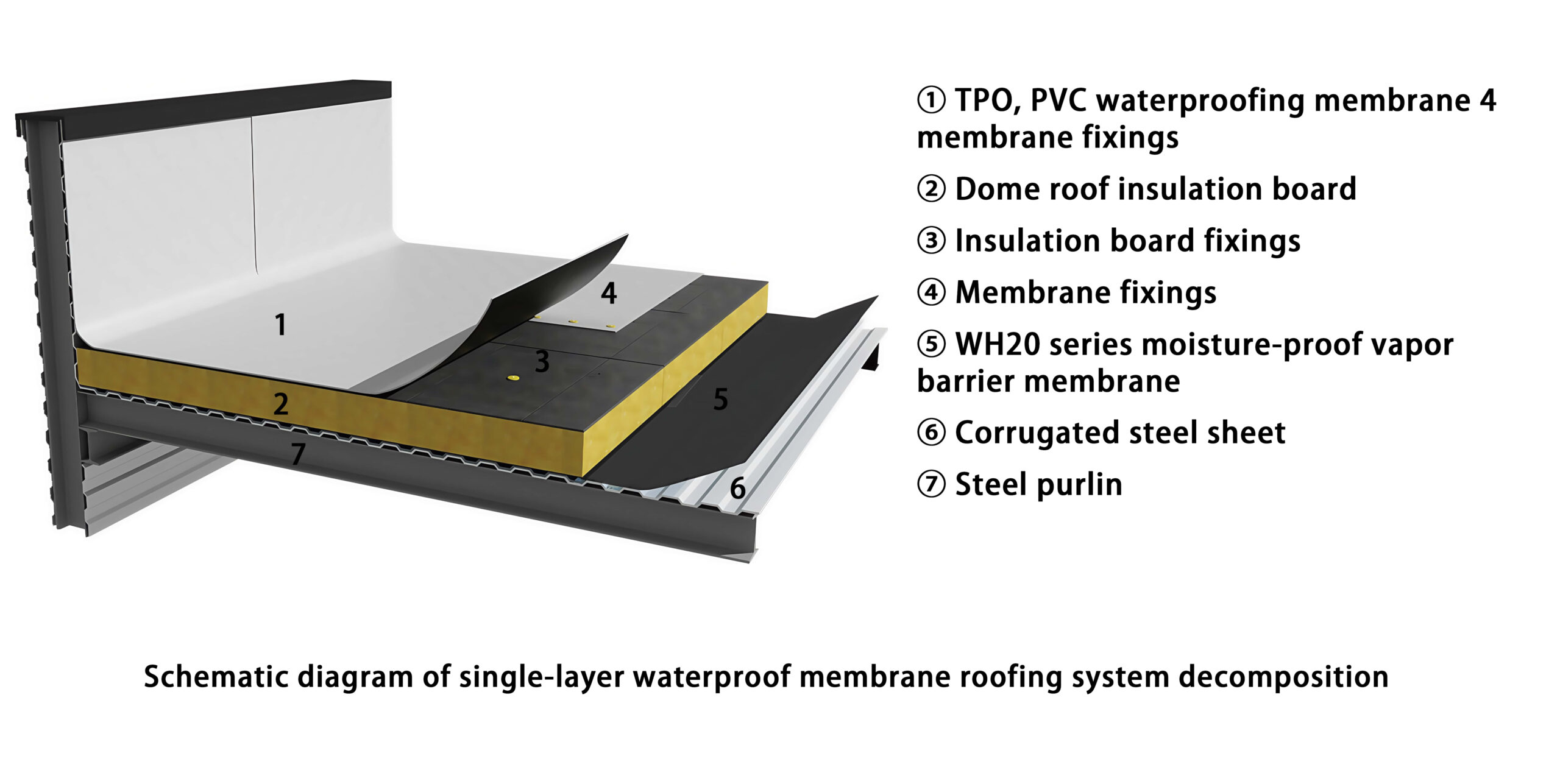

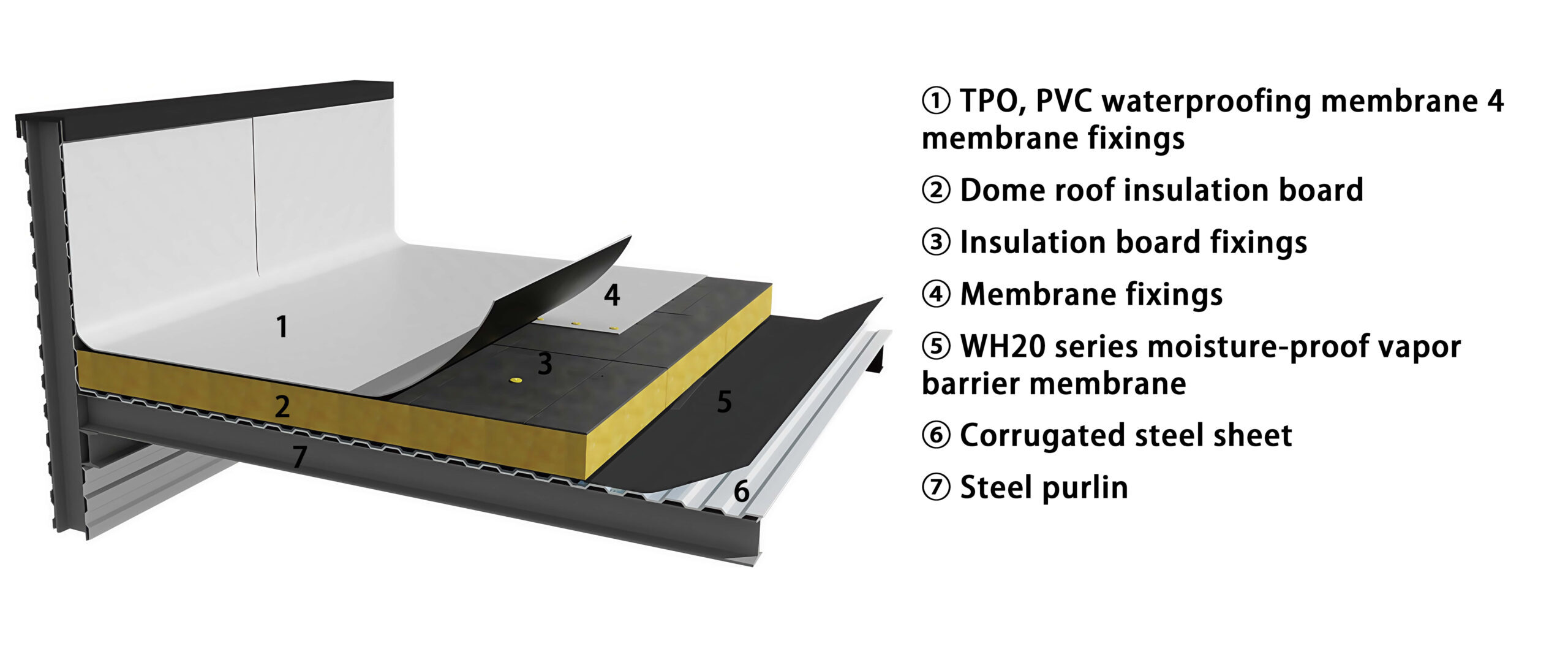

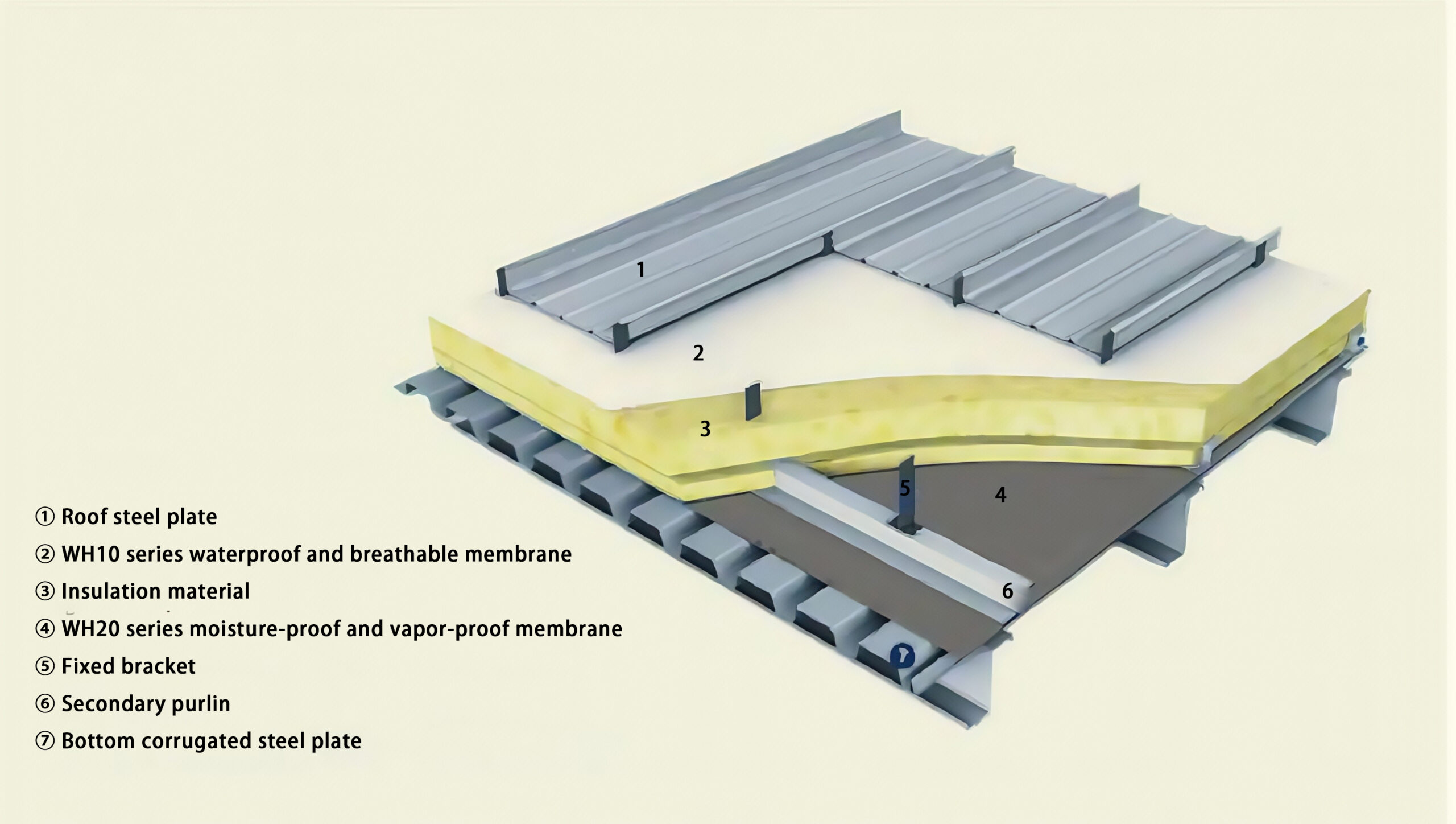

Wanhua dome roof insulation system is composed of WH20 series moisture-proof vapor barrier, dome roof insulation board, waterproof membrane layer, fixing materials (adhesives, anchors, etc.), and is mechanically connected with the roof enclosure structure to form a unified insulation system structure.

This system is a thermal insulation solution specially designed for flexible waterproof roof buildings. It has excellent thermal insulation, fireproof, waterproof, anti-seepage and pressure resistance, anti-cracking, and high flatness performance.

Application areas

Large public buildings:

Airport terminals, high-speed rail stations, convention and exhibition centers, stadiums, etc.

Large industrial buildings:

Precision industrial plants, warehouses, etc.

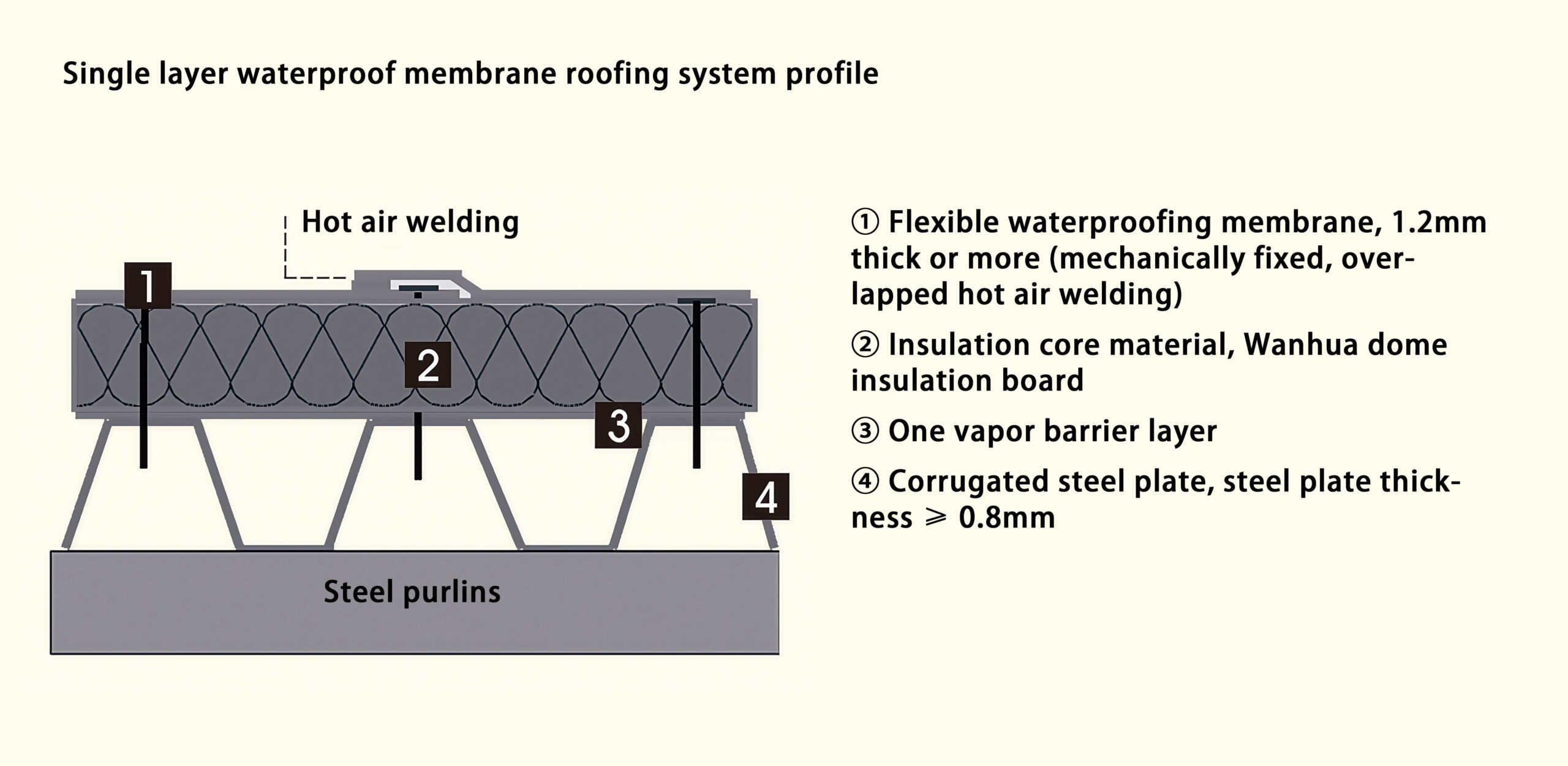

Single layer waterproof membrane roofing system

This system is widely used in metal roof insulation systems for newly built, rebuilt and expanded steel structure systems.

System material composition

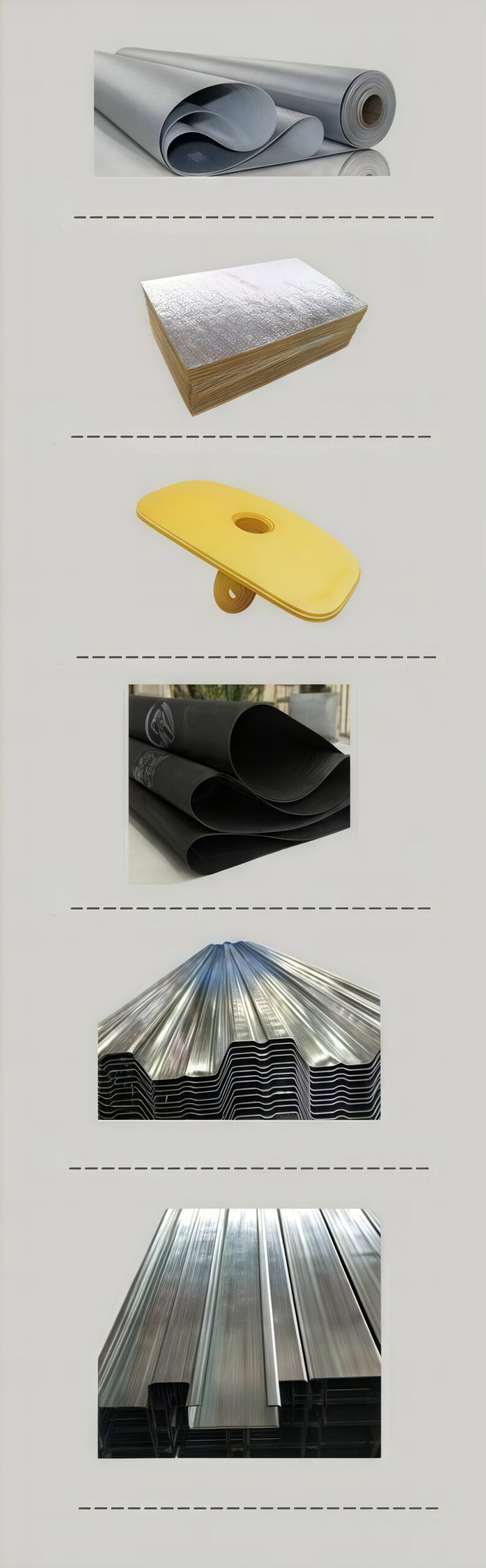

① Polymer waterproofing membrane:

Currently, commonly used polymer waterproofing membranes include TPO waterproofing membranes and PVC waterproofing membranes, which have excellent flexibility and stretchability, dimensional stability, weather resistance and UV resistance.

② Dome insulation board:

A new type of roof insulation board used for waterproofing and insulation of building roof structures, which plays a role in fire prevention, moisture resistance and insulation.

Fixers:

Mechanical fasteners used to fix waterproofing membranes and insulation boards of roof insulation systems, which play a fixing role.

Vapor barrier:

A layer of airtight and watertight protective material laid between the structural layer and the insulation layer.

It plays a role in preventing indoor water vapor from penetrating into the insulation layer.

Corrugated steel sheet:

≥0.8MM thick corrugated steel sheet.

⑥ Steel purlin:

Steel structure material of metal roofing system.

System Features

1. Long service life:

Light weight, aging resistance, wide operating temperature range, and can meet the service life of no less than 50 years under various climate conditions simulated in the laboratory.

2. High safety performance:

It has high compression strength and tensile strength. Safe and effective fasteners are used during installation to ensure the firmness and reliability of the system.

3. Excellent thermal insulation performance:

Wanhua’s “dome” roof insulation board has small size deviation and is laid densely, which can effectively avoid the “cold bridge” phenomenon and improve the thermal environment. And the thermal conductivity is low and the thermal insulation performance is good.

4. Reliable system waterproof and sound insulation performance:

It can completely solve the problems of water leakage, cold bridge condensation, noise, and multi-curved surface structure of traditional steel structure roof systems.

5. High construction efficiency:

The insulation board has large size specifications, good flatness, and light weight per unit area. Construction

Environmentally friendly, quick and easy operation, and short construction period.

Construction technology

Construction method: Mechanical fixing method

Construction precautions: Construction should be carried out under good weather conditions and should not be carried out in rain, snow, or strong winds of level 5 or above.

① Clean the base layer

② Lay the vapor barrier

③ Lay the insulation board

④ Lay the insulation board

⑤ Place the non-perforating nail kit

⑥ Fix with nails

⑦ Lay the coil

⑧ Weld the coil

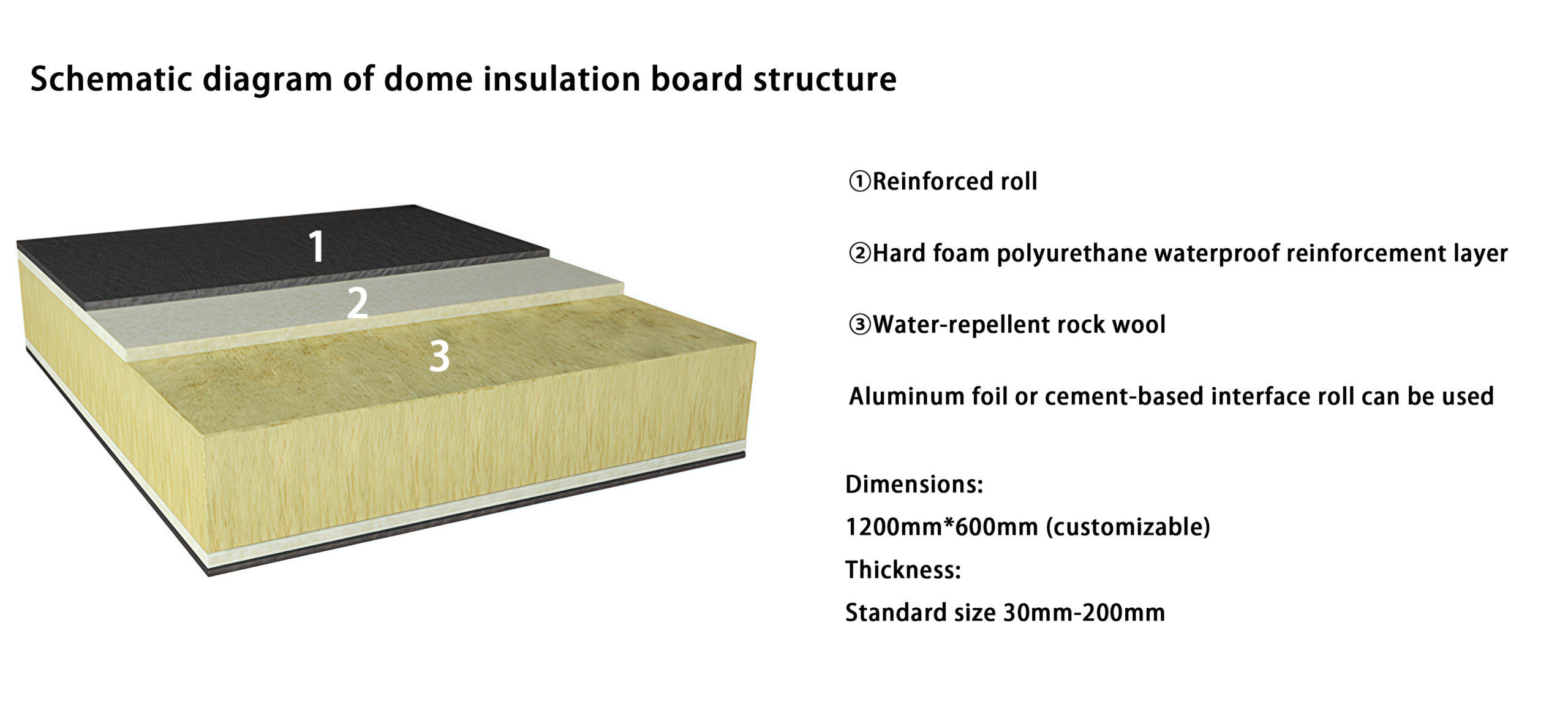

Wanhua Dome Roof Insulation Board

Wanhua Dome Roof Insulation Board is a new type of thermal insulation material that uses vertical fiber rock wool as the core material and uses polyurethane foam to form a composite of the reinforced coil and the rock wool core material in one step through a continuous production line. (hereinafter referred to as “Dome Insulation Board”)

Dome Insulation Board is a new type of roof insulation board specially designed and developed for various single-layer roof insulation systems, integrating fireproof insulation, moisture resistance and waterproofing, structural stability, and sound absorption and noise reduction.

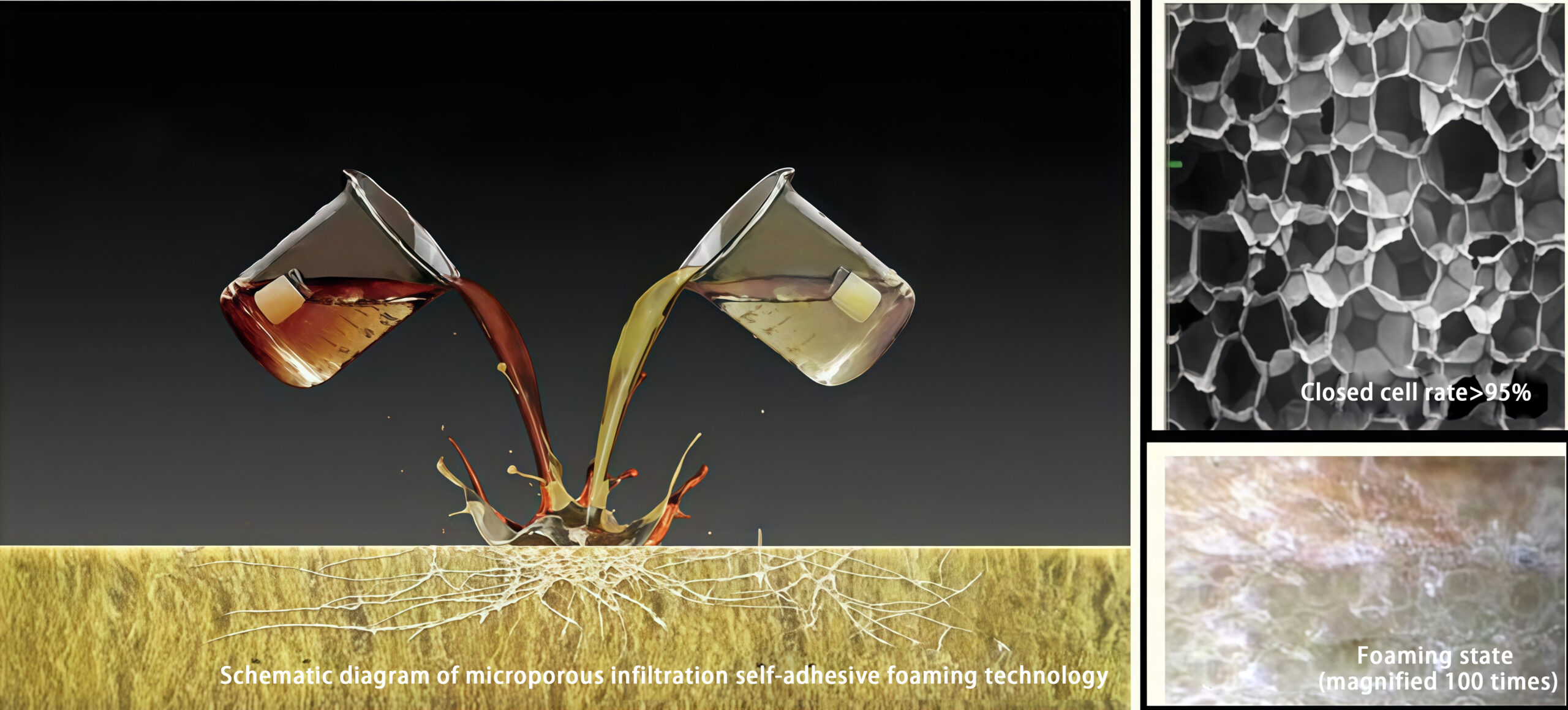

Core technology: Microporous infiltration self-adhesive foaming technology

Microporous infiltration self-adhesive foaming technology, that is, using the excellent self-adhesive properties of polyurethane, uses a spray gun to infiltrate the flowing polyurethane raw materials into the vertical fiber rock wool in molecular form under a pressure of one hundred tons, and quickly expands and solidifies at a thirty-fold expansion ratio. After the foam is completely solidified, a closed insulation layer, waterproof layer, and bonding layer are formed.

Performance Indicators

| Product Performance | unit | Dome insulation board | |

| size | Length | mm | ±2.0 |

| Width | mm | ±2.0 | |

| Thickness | mm | 0~2.0 | |

| Density | kg/m³ | 100~120 | |

| Compression strength (10% deformation) | kPa | ≥80 | |

| Point load (compression deformation 5mm) | N | ≥1000 | |

| Water repellency | % | ≥99.8 | |

| Short-term water absorption (partial immersion in water for 24h) | kg/m² | ≤0.40 | |

| Acidity coefficient | – | ≥1.8 | |

| Thermal conductivity (23±2℃) | w/(m ·K) | ≤0.040 | |

| Combustion performance | – | Class A non-flammable | |

| Tensile strength perpendicular to the board surface | MPa | ≥0.10 | |

| Dimensional stability (70℃, 48h) | % | ≤0.2 | |

| Noise reduction coefficient NRC | – | ≥0.5 | |

Features

● Class A fireproof performance

The dome insulation board uses rock wool as the insulation core material, and its combustion performance is Class A after being tested by Tianjin Fire Department. It can avoid fire hazards during construction and after delivery.

● High wind resistance and pressure resistance

The dome insulation board uses the excellent self-adhesive properties of polyurethane to continuously foam in the laminator. The flowing liquid polyurethane penetrates into the rock wool in the form of molecules, forming an infiltration-type physical bite, and 100% cavity-free connection. The small vertical rock wool strips are connected into a whole through polyurethane and high-strength interface coils, which expands the material size specifications and enhances the physical and mechanical properties of the board such as point load and compressive strength.

| National Center of Quality Supervision and Testingfor Building Energy Conservation | |||||

| Report No.:NBEC-2018CX-0072 | |||||

| NO. | Test items | Requirementof standard | Test results | Item conclusion | |

| 1 | “Dome” roof insulation board | Compression strength | ≥80kPa | 99kPa | Conforms to |

| 2 | Point load | ≥1000N | 1013N | Conforms to | |

| 3 | Core Material | Density | 100kg/m³~120kg/m³ | 115kg/m³ | Conforms to |

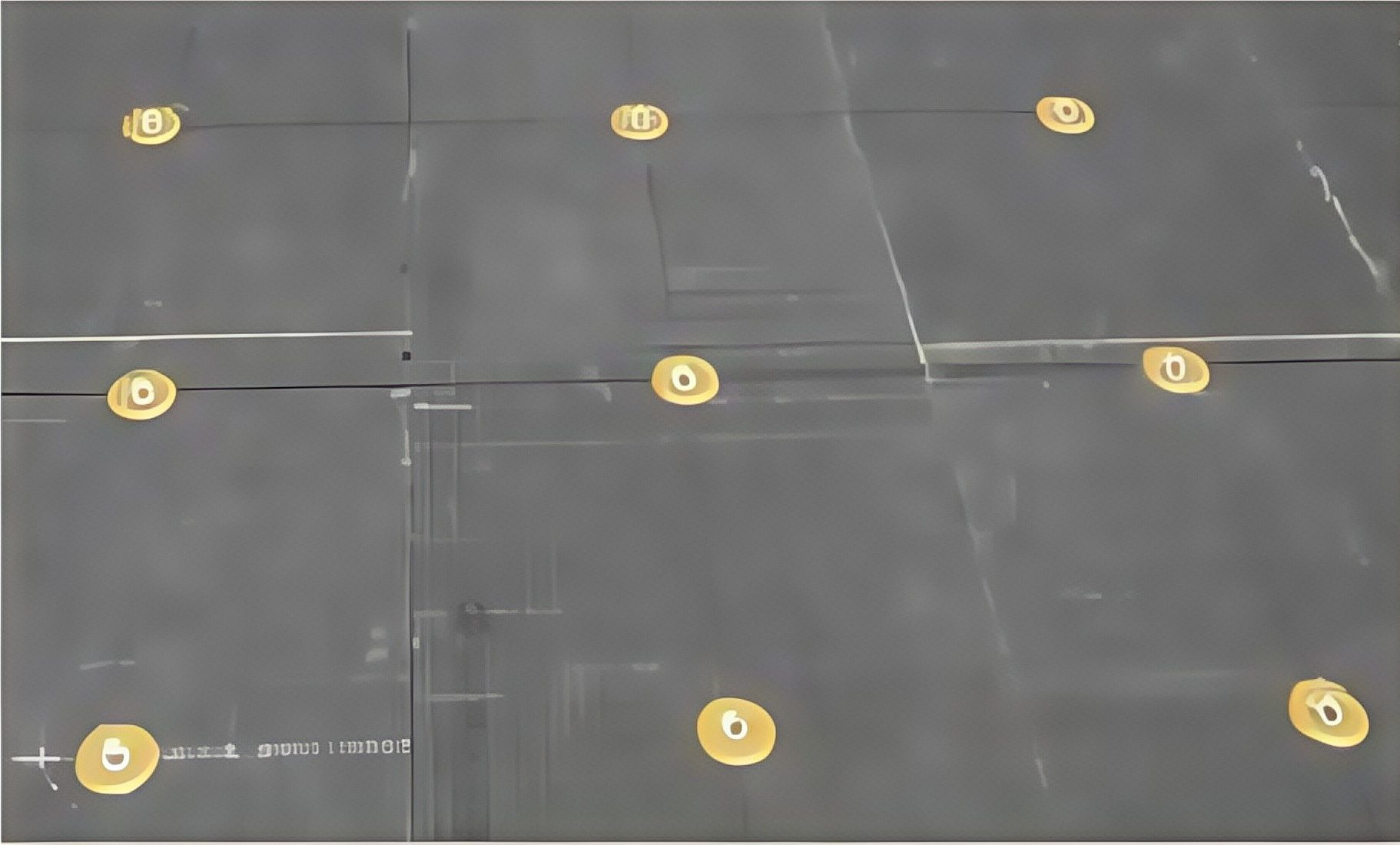

●Good dimensional stability and high flatness

The upper and lower surfaces of the dome insulation board are compounded with interface reinforcement coils, and are processed and formed in a fixed-length laminator at one time, with less dimensional deviation and high flatness, reducing the amount of auxiliary materials and construction difficulty.

The factory-measured flatness of the dome insulation board is ≤2.0mm, with high flatness, high pressure resistance, and not easy to accumulate water; while the flatness of ordinary rock wool board is ≤6.0mm, with poor flatness, difficulty in laying the waterproof layer, and easy to accumulate water

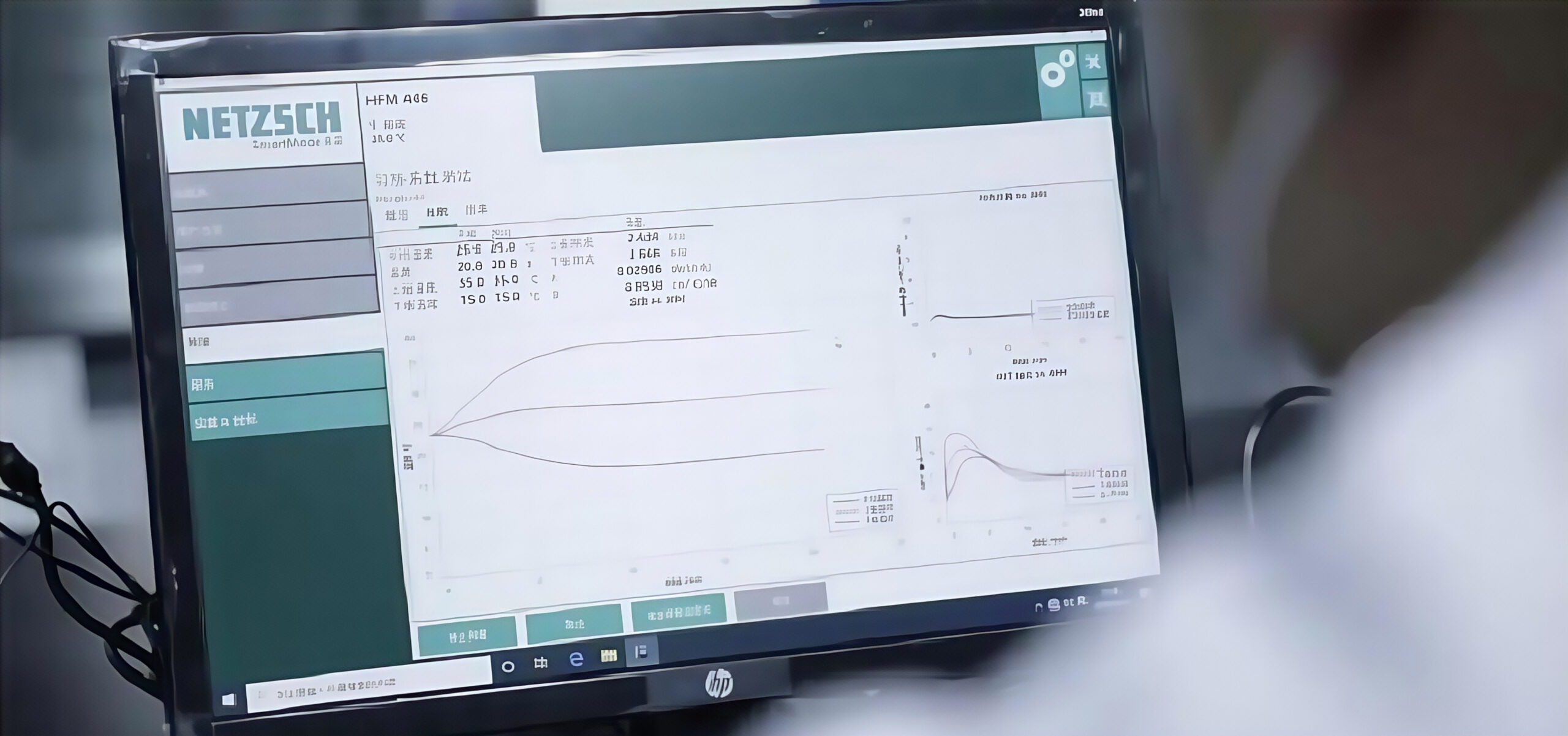

● Low thermal conductivity, good energy-saving benefits

The dome insulation board is produced by microporous infiltration self-adhesive foaming technology, the spray gun evenly distributes the material, and 100% cavity-free bonding.

The thermal conductivity of polyurethane is 0.018~0.024W/(m·k), which is evenly distributed on the upper and lower surfaces of the insulation board. Polyurethane fills the gaps in the rock wool to prevent air convection, forming a closed and complete insulation layer with excellent insulation effect.

●Unique repair function

Liquid polyurethane penetrates into the gaps in the rock wool, repairs the broken wires caused by the cutting and collision of the rock wool, and ensures the strength of the rock wool itself. Good impact resistance prevents damage due to collision during transportation, storage, and use.

Experimental comparison

● Product index comparison

| Items | unit | Ordinary rock wool board | Dome insulation board | Standard basis |

| Density | kg/m3 | 160 | 100~120 | GB/T 19686 Rockwool for building insulation products |

| Thermal conductivity (23±2℃) | w/(m ·K) | ≤0.040 | ≤0.040 | |

| Compressive strength (10% deformation) | kPa | 40 | ≥80 | |

| Point load | N | 500 | ≥1000 | |

| Water repellency | % | ≥98% | ≥99.8% | |

| Short-term water absorption (partial immersion in water for 24h) | kg/m² | ≤0.5 | ≤0.4 | |

| Tensile strength perpendicular to the board surface | MPa | 0 | ≥0.10 |

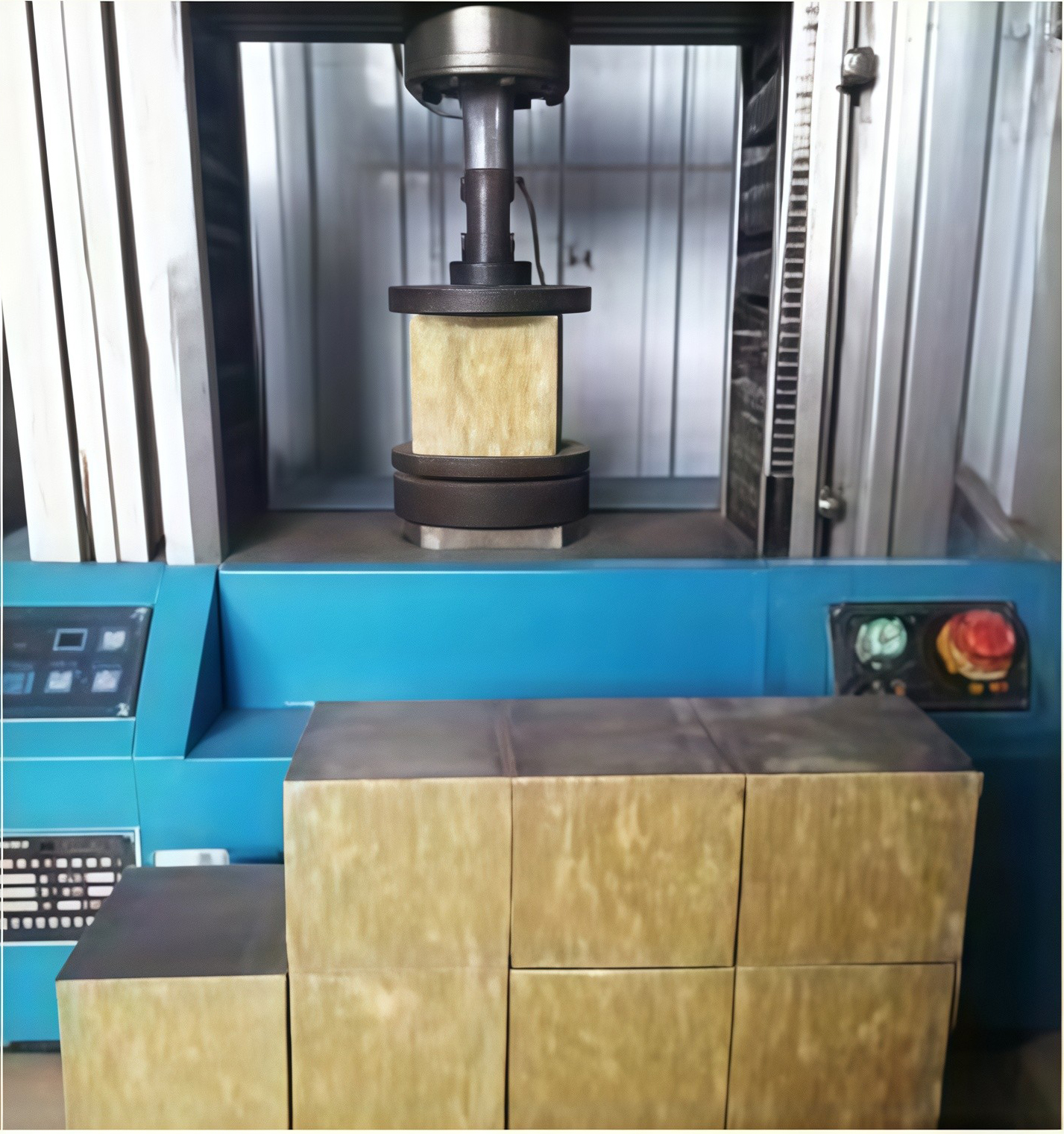

Experimental scene diagram

● Comparison of compression strength test of roof rock wool board

| Project | Serial number | Compression strength of horizontal rock wool board (deformation within 10%, KPa) | Dome insulation board compression strength (deformation within 10%, KPa) | |||

| Bulk weight 120kg/m³ | Bulk density 140kg/m3 | Bulk weight 180kg/m³ | Bulk density 100~120kg/m3 | Bulk density 140kg/m3 | ||

| Experimental data | 1 | 22 | 51 | 100 | 100 | 210 |

| 2 | 23 | 41 | 95 | 110 | 190 | |

| 3 | 24 | 49 | 100 | 130 | 190 | |

| 4 | 19 | 53 | 100 | 110 | 170 | |

| 5 | 20 | 49 | 97 | 110 | 200 | |

| 6 | 26 | 34 | 100 | 120 | 210 | |

| Data average | 22.33 | 46.17 | 98.67 | 113.33 | 195 | |

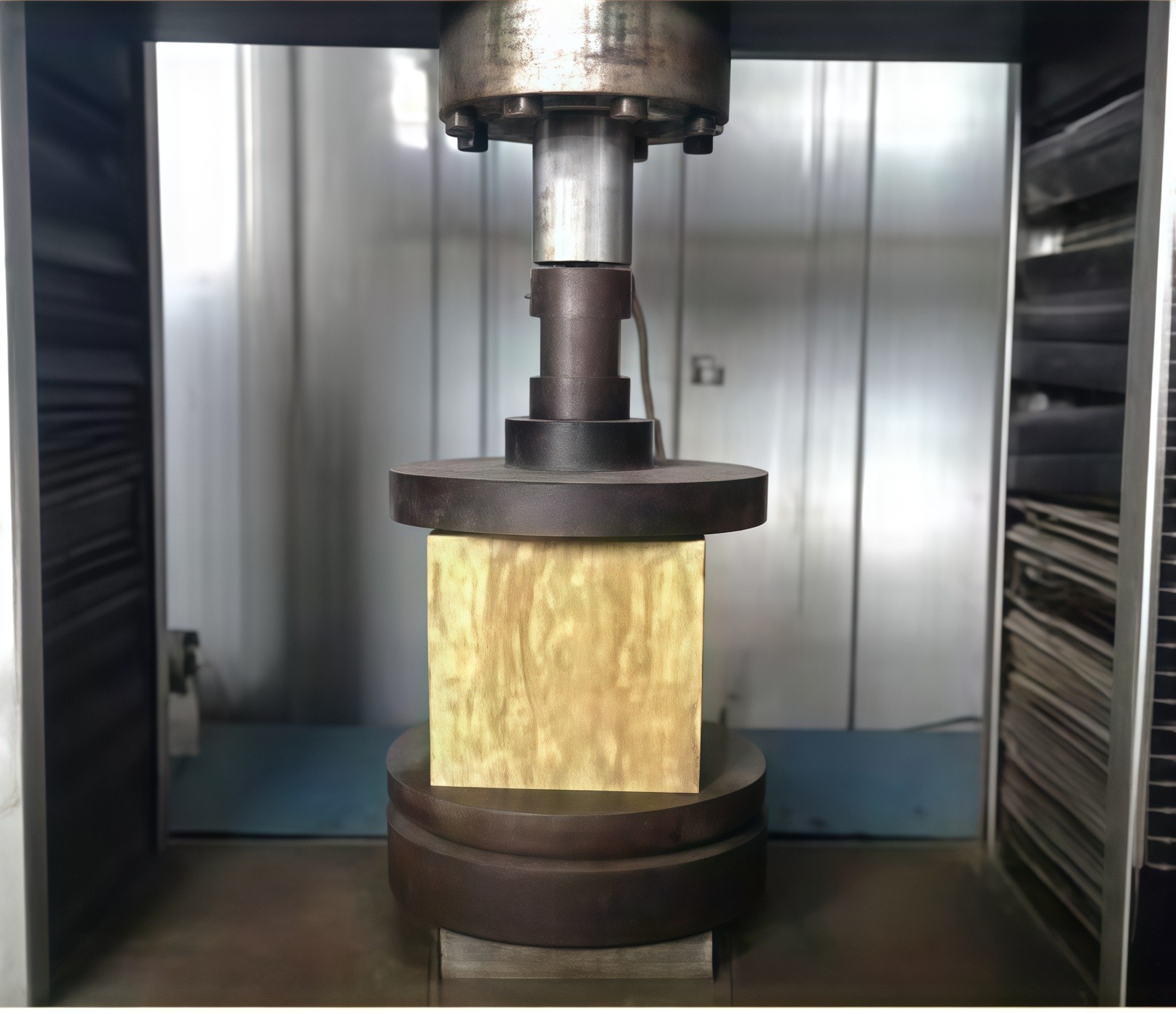

● Roof panel point load strength test comparison

Deformation occurs after force is applied No obvious change after force is applied

WH20 Series Moisture and Vapor Barrier Membrane

Product Introduction

Wanhua WH20 series moisture-proof vapor barrier film is specially designed for air tightness and condensation control of building envelope systems. It can provide excellent water vapor isolation function, protect the thermal insulation layer and building structure from the influence of moisture from the warm indoor environment, block water vapor from entering the thermal insulation layer, ensure the dryness of thermal insulation materials, and achieve long-term energy-saving effects.

●Product Features

·Airtightness and excellent vapor barrier performance ensure building air tightness.

·Watertightness and excellent waterproof performance, can be used as the second waterproof layer of the enclosure structure under special circumstances.

·Durability and excellent durability ensure the stable airtightness and watertightness of the material, making the building energy saving more lasting. ·Safety and non-slip surface, safe construction, excellent physical properties and ultra-long construction period.

●Product application

The excellent physical properties and excellent vapor barrier performance of the WH20 series products are very suitable for the vapor barrier layer in the single-layer flexible roof system. They are placed under the insulation layer to isolate the invasion of water vapor inside the building on the insulation material and ensure the long-term and effective thermal performance of the insulation material. For special application areas such as cold storage, the WH20 series products should be installed on the high temperature side.

Typical application scenarios

WH10 Series Waterproof Breathable Membrane

●Product Introduction

WH10 series waterproof and breathable membrane covers the insulation layer of the building envelope structure, which can block the invasion of wind and rain on the building, reduce air convection, enhance the water tightness and air tightness of the envelope structure, and at the same time, the excellent air permeability can quickly discharge the retained water vapor in the envelope structure, thereby maintaining the durability of the envelope structure and ensuring the comfort of the building.

●Product Features

·Air tightness Excellent windproof performance ensures the air tightness of the building, which can reduce heat convection and improve the energy-saving efficiency of the building.

·Water tightness Excellent waterproof performance can be used as the second waterproof layer of the building envelope structure. ·Breathability helps the water vapor in the envelope structure to diffuse, which is the insulation renovation to keep it naturally dry.

·Durability Excellent durability ensures the stable performance of the material’s airtightness, watertightness, and air permeability, making the building energy-saving more lasting.

●Product Application

WH10 series waterproof and breathable membrane can be widely used in steel structure workshops and public building curtain wall systems to effectively avoid insulation failure and condensation.

Typical application scenarios

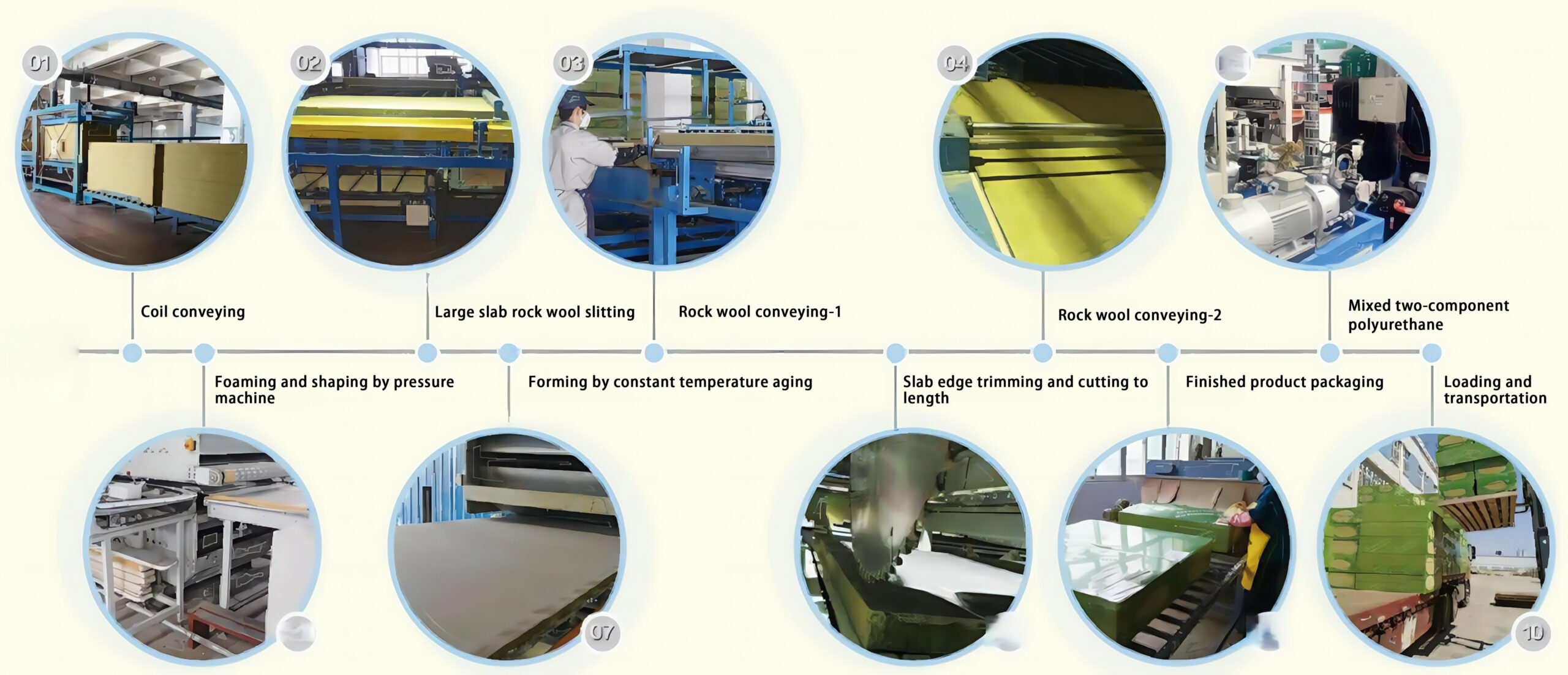

Production and workmanship

●Advanced technology

Adopting advanced continuous production technology, compared with traditional mold method and bonding method, continuous method is easier to achieve 100% cavity-free bonding between rock wool layer and interface layer. The whole production process is monitored dynamically in real time, product quality is stable and controllable, and production efficiency is 10 times higher than traditional production process.

●Production capacity

After independent technical transformation and upgrading, the production equipment in the factory area has realized the continuous production of polyurethane rock wool insulation board for the first time in China. Both production capacity and quality have made a qualitative leap. The maximum production speed of the transformed production line is 10m/min, the single-shift single-line 8-hour production capacity is 4000m², and the annual production capacity can reach 5 million m².