Coal Mine Brochure

Wanguzhi 9100/9100-3 series

Polyurethane materials for coal mine reinforcement/silicate modified polyurethane materials

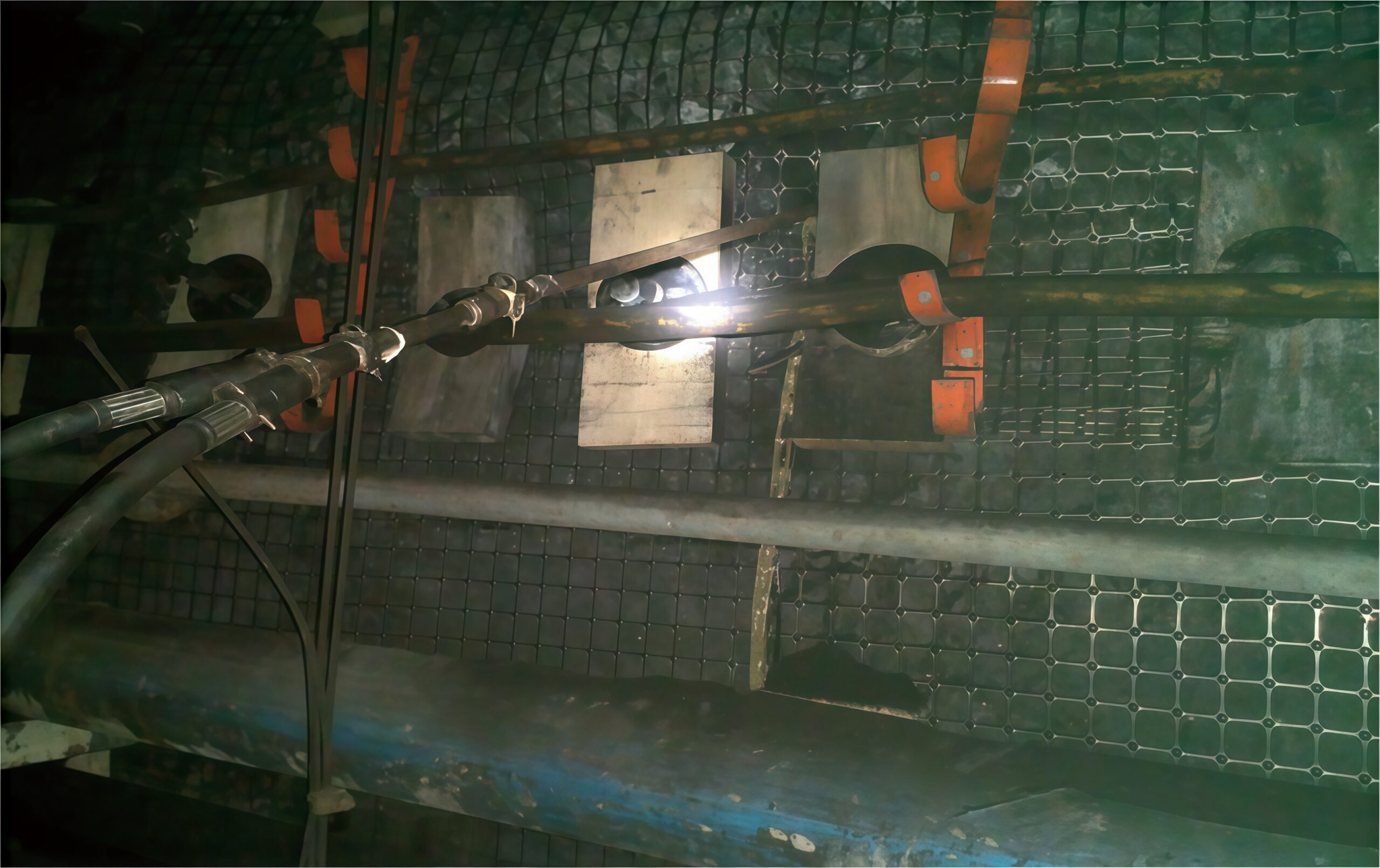

Reinforcement of mining working face, advance reinforcement of excavation working face across faults, reinforcement of spalling and coal pillars, reinforcement of working face triangle area, reinforcement of broken roof of working face, advance reinforcement of broken roof of working face, advance coal and rock solidification for coal uncovering at stone gate, prevention of roof collapse of mining working face, top support, and stabilization of various roadbeds.

Wanduzhi 9000 series

Polyurethane materials for coal mine water blocking

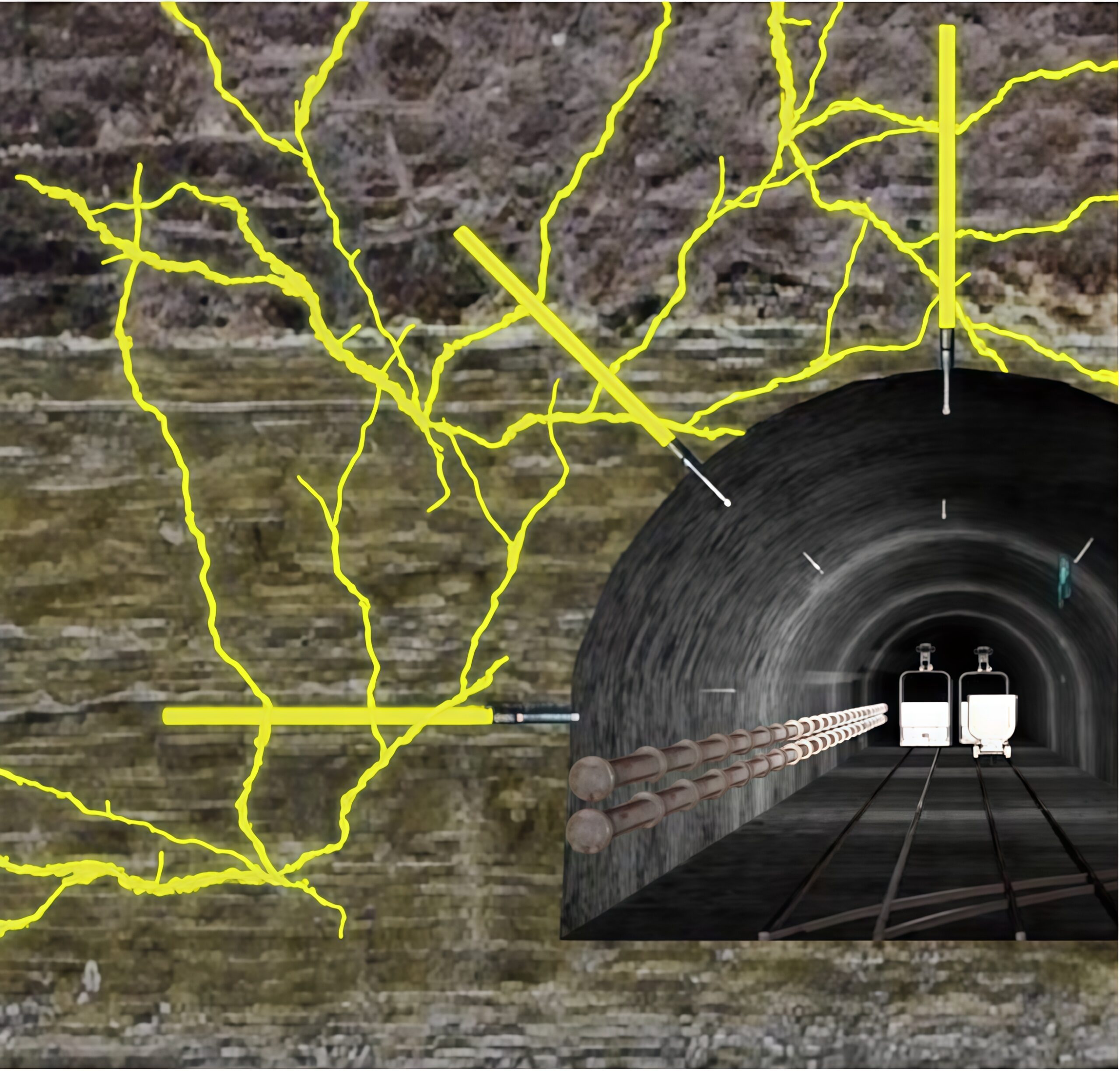

Water blocking of coal bunkers, water blocking and reinforcement of shafts, water flow closure, retaining wall construction, water seepage treatment of tunnel lining cracks, water seepage treatment and reinforcement of dam bodies.

Wanchongzhi 9500 series

Polymer foaming material for coal mine filling and sealing

Hollow filling, underground fire wall construction, filling of void areas in mining working faces, sealing of inlet and return air corners, side isolation in the case of geothermal heat, permanent sealing of goaf areas, rapid sealing of working faces (temporary sealing), and filling behind tunnel lining walls.

Wanfengzhi 9260 series

Polymer materials for spraying and plugging air leakage in coal mines

Surface protection and air leakage prevention of loose coal and rock mass in the mining tunnels of high-gas mines or flammable mines, gas leakage prevention treatment, surface protection of coal and rock mass in large tunnels and machine-borne chambers, including crack prevention, air leakage prevention and leakage prevention, rapid surface protection of expansive surrounding rock after excavation

, crack prevention and air leakage prevention control of underground closed wall surfaces.

Wananzhi 9109-1 series

Fire extinguishing foam materials for coal mines

Filling behind the wall of the support for the goaf, plugging the cracks of small coal pillars along the goaf, filling the high-risk area to prevent gas accumulation, filling the cracks and voids of coal and rock, blocking the gas in the gaps, fast construction of fire walls and closed wall filling, blocking the spread of fire, preventing the outflow of harmful gases, and ensuring the safety of workers.

Wananzhi 9109-3 series

Fire extinguishing gel foam materials for coal mines

Fire prevention of closed or scrapped tunnels and goaf areas, fire extinguishing of coal field fires, fire extinguishing of spontaneous combustion of coal piles, fire extinguishing of spontaneous combustion of underground fires, fire extinguishing of spontaneous combustion areas of coal pillars adjacent to the working face of the mining face, fire extinguishing of spontaneous combustion areas of coal pillars on both sides of the mining area preparation tunnel, gas accumulation prevention in goafs and high-risk areas, prevention of spontaneous combustion of coal in goafs and high-risk areas, and preventive fire prevention in goafs of working faces.

WANEFOAMR9100

Polyurethane material for coal mine reinforcement

Product Introduction

WANEFOAM®9100 series is a polyurethane grouting material for coal mine reinforcement. After the A component and the B component are evenly mixed in a volume ratio of 1:1, they can quickly polymerize into an infusible and insoluble polymer material. This material has extremely high strength and adhesion, excellent flame retardancy and solvent corrosion resistance, and has a certain toughness. It can deform with the rock layer while maintaining the effect of blocking and reinforcement.

Product Use

WANEFOAM®9100 series is suitable for the reinforcement of various broken coal and rock masses in mines, tunnels and other projects. The low-viscosity mixed resin can quickly penetrate into tiny gaps and polymerize and solidify into a high-strength and high-toughness polymer material. Even in a water environment, the mixed resin can expand at a high rate and maintain good strength.

Before using the WANEFOAM°9100 series products, tests must be done to ensure the reliability of the combined material system in this specific project.

Product Features

WANEFOAM®9100 series, liquid AB components and their uniformly mixed polymerized infusible polymer resin materials have the following characteristics:

1. Low material viscosity and strong penetration ability

2. Flame retardant performance meets the requirements of MT113-1995

3. Excellent solvent resistance and corrosion resistance

4. Quick and convenient construction, low or no odor between materials

5. Good material adhesion, high strength and certain toughness, can adapt to long-term ground pressure

The performance indicators of WANEFOAM®9100 series polyurethane materials for coal mine reinforcement meet the requirements of AQ/T 1089-2020. Some indicators are as follows:

Physical and chemical properties

| Item | Index | |

| Component A | Component B | |

| Appearance | Light yellow liquid, evenly distributed, no agglomeration | Brown liquid, evenly distributed, no agglomeration |

| Flash point, ℃ | Above 100℃, and 15% above the maximum reaction temperature | Above 100℃, and 15% above the maximum reaction temperature |

| Viscosity, mPa.s (20℃) | <500 | <500 |

| Density, kg/m³ | 1100±50 | 1200±50 |

Reaction parameters

| Item | Index |

| Maximum reaction temperature (℃) | ≤100 |

| Expansion multiple, times | ≥1.0 |

| Reaction start time, s | 20~120 |

| Curing end time, s | 80~240 |

Physical properties

| Item | Index | |

| / | Oxygen index, % | ≥28 |

| Strength properties | Compressive strength, MPa | ≥40 |

| Tensile strength, MPa | ≥5 | |

| Shear strength, MPa | ≥15 | |

| Adhesion strength, MPa | ≥3.0 | |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9100-3

Silicate-modified polyurethane material for coal mine reinforcement

Product Introduction

WANEFOAM®9100-3 series is a silicate-modified polyurethane grouting material for coal mine reinforcement. After the A component and the B component are evenly mixed in a volume ratio of 1:1, they can quickly polymerize into an infusible and insoluble polymer material, which can be cured smoothly and maintain good strength even in a humid environment. It has excellent bonding performance, flame retardancy, and solvent corrosion resistance, and has a certain toughness. It can deform with the rock layer while maintaining the effect of plugging and reinforcement.

Product Use

WANEFOAM®9100-3 series is suitable for the reinforcement of various broken coal and rock masses in mines, tunnels and other projects. The low-viscosity mixed resin can quickly penetrate into tiny gaps and polymerize and solidify into a high-strength and high-toughness polymer material, especially in a water environment without foaming, and can maintain a high compressive strength.

Before using the WANEFOAM®9100-3 series products, tests must be done to ensure the reliability of the combined material system in this specific project.

Product Features

WANEFOAM®9100-3 series, liquid AB components and their uniformly mixed polymerized infusible polymer resin materials have the following characteristics

1. Low material viscosity, strong penetration ability, high flash point

2. Excellent flame retardant performance, in line with MT113-1995 requirements

3. Excellent solvent resistance and corrosion resistance

4. Excellent antistatic performance

5. Quick and convenient construction, low or no odor between materials

6. High compressive strength and certain toughness, can adapt to long-term ground pressure

The performance indicators of WANEFOAM®9100-3 series of silicate-modified polyurethane materials for coal mine reinforcement meet the requirements of AQ/T 1089-2020. Some indicators are as follows:

Physical and chemical properties

| Project | Index | |

| Component A | Component B | |

| Appearance | Transparent liquid, evenly distributed, no agglomeration | Brown liquid, evenly distributed, no agglomeration |

| Flash point, ℃ | Above 100℃, and 15% above the maximum reaction temperature | Above 100℃, and 15% above the maximum reaction temperature |

| Viscosity, mPas (20℃) | <500 | <500 |

| Density, kg/m³ | 1450±50 | 1200±50 |

Reaction parameters

| Item | Index |

| Maximum reaction temperature (℃) | ≤100 |

| Expansion multiple, times | ≥1.0 |

| Reaction start time, s | 20~120 |

| Curing end time, s | 80~240 |

Physical properties

| Item | Index | |

| / | Oxygen index, % | ≥28 |

| Strength properties | Compressive strength, MPa | ≥40 |

| Tensile strength, MPa | ≥5 | |

| Shear strength, MPa | ≥15 | |

| Adhesion strength, MPa | ≥3.0 | |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9000

Polyurethane material for coal mine water blocking

Product Introduction

WANEFOAM®9000 series is a polyurethane grouting material for coal mine water plugging. Its A component and B component can be quickly polymerized into an infusible and insoluble polymer material after being evenly mixed in a volume ratio of 1:1. This material has extremely high strength and adhesion, excellent flame retardancy and solvent corrosion resistance, and has a certain toughness. In a water environment, it can achieve a rapid plugging effect through volume expansion.

Product Use

WANEFOAM®9000 series is suitable for waterproof plugging in mines, tunnels and other projects. The low-viscosity mixed resin can quickly penetrate into tiny gaps and polymerize and solidify into a high-strength and high-toughness polymer material. In a water environment, the mixed resin can quickly expand and foam, densely fill all gaps, and achieve the purpose of plugging.

Before using WANEFOAMO9000 grouting material, a test must be done to ensure the reliability of the combined material system in this specific project.

Product Features

WANEFOAM®9000 series AB components and their uniformly mixed polymerized infusible polymer resin materials have the following characteristics

1. Low material viscosity and strong permeability

2. Rapid foaming in water, with high expansion ratio

3. Still has high compressive strength after expansion

4. Excellent dimensional stability, no shrinkage

5. Quick and convenient construction, low or no odor between materials

The performance indicators of WANEFOAM®9000 series polyurethane materials for coal mine water plugging meet the requirements of AQ/T 1087-2020. Some indicators are as follows:

Physical and chemical properties

| Project | Index | |

| Component A | Component B | |

| Appearance | Light yellow liquid, evenly distributed, no lumps | Brown liquid, evenly distributed, no agglomeration |

| Flash point, ℃ | Above 100℃, and 15% above the maximum reaction temperature | Above 100℃, and 15% above the maximum reaction temperature |

| Viscosity, mPas (20℃) | <500 | <500 |

| Density, kg/m³ | 1100±50 | 1200±50 |

Reaction parameters

| Item | Index |

| Maximum reaction temperature (℃) | ≤140 |

| Expansion multiple, times | ≥1.0 |

| Reaction start time, s | 20~120 |

| Curing end time, s | 80~240 |

Physical properties

| Item | Index |

| Permeability, cm/s | ≤1×10-6 |

| Compressive strength, MPa | ≥50 |

| Tensile strength, MPa | ≥20 |

| Shear strength, MPa | ≥20 |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9500

Polymer foaming material for coal mine filling and sealing

Product Introduction

WANEFOAM°9500 series is a polymer foam material for coal mine filling and sealing. Its A component and B component can be quickly polymerized into infusible and insoluble polymer foam after being uniformly mixed in a predetermined volume ratio (4:1). This foam has excellent adhesion, flame retardancy, water resistance and corrosion resistance, and has a certain toughness, and can deform with the rock layer and wall.

Product Application

WANEFOAM®9500 series is suitable for various hollow filling, tunnel sealing and other fields in mines, tunnels and other projects, and plays a role in isolating air, sealing gas and strengthening. The low-viscosity mixed resin can quickly diffuse and penetrate into large and small gaps and quickly foam and solidify into a polymer foam with a certain elasticity, and the foaming ratio can reach 25-30 times or more.

Before using WANEFOAM®9500 series products, tests must be done to ensure the reliability of the combined material system in this specific project.

Product Features

The liquid AB components of WANEFOAM®9500 and the infusible and insoluble polymer foam material formed by uniform mixing have the following characteristics:

1. Low material viscosity and strong permeability

2. Low internal reaction heat

3. Flame retardant performance meets the requirements of MT113-1995, oxygen index ≥35%

4. Excellent solvent and corrosion resistance

5. Excellent antistatic performance

6. Quick and convenient construction

The performance indicators of WANEFOAMO9500 series polymer foam materials for coal mine filling and sealing meet the requirements of AQ/T 1090-2020. Some indicators are as follows:

Physical and chemical properties

| Project | Index | |

| Component A | Component B | |

| Appearance | Brown suspension, no lumps | Brown, no lumps |

| Flash point, ℃ | Above 100℃, and 15% above the maximum reaction temperature | Above 100℃, and 15% above the maximum reaction temperature |

| Viscosity, mPas (20℃) | <6000 | 10-30 |

| Density, kg/m³ | 1250±50 | 1450±50 |

Reaction parameters

| Item | Index |

| Maximum reaction temperature, °C | ≤95 |

| Expansion multiple, times | ≥25 |

| Reaction start time, s | 2~20 |

| Curing end time, s | 20~200 |

Physical properties

| Project | Index | |

| / | Oxygen index, % | ≥35 |

| Compressive strength, kPa | Compressive strain 10% | ≥10 |

| Compressive strain 30% | ≥12 | |

| Compressive strain 70% | ≥40 | |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9260

Polymer material for spraying and plugging air leaks in coal mines

Product Introduction

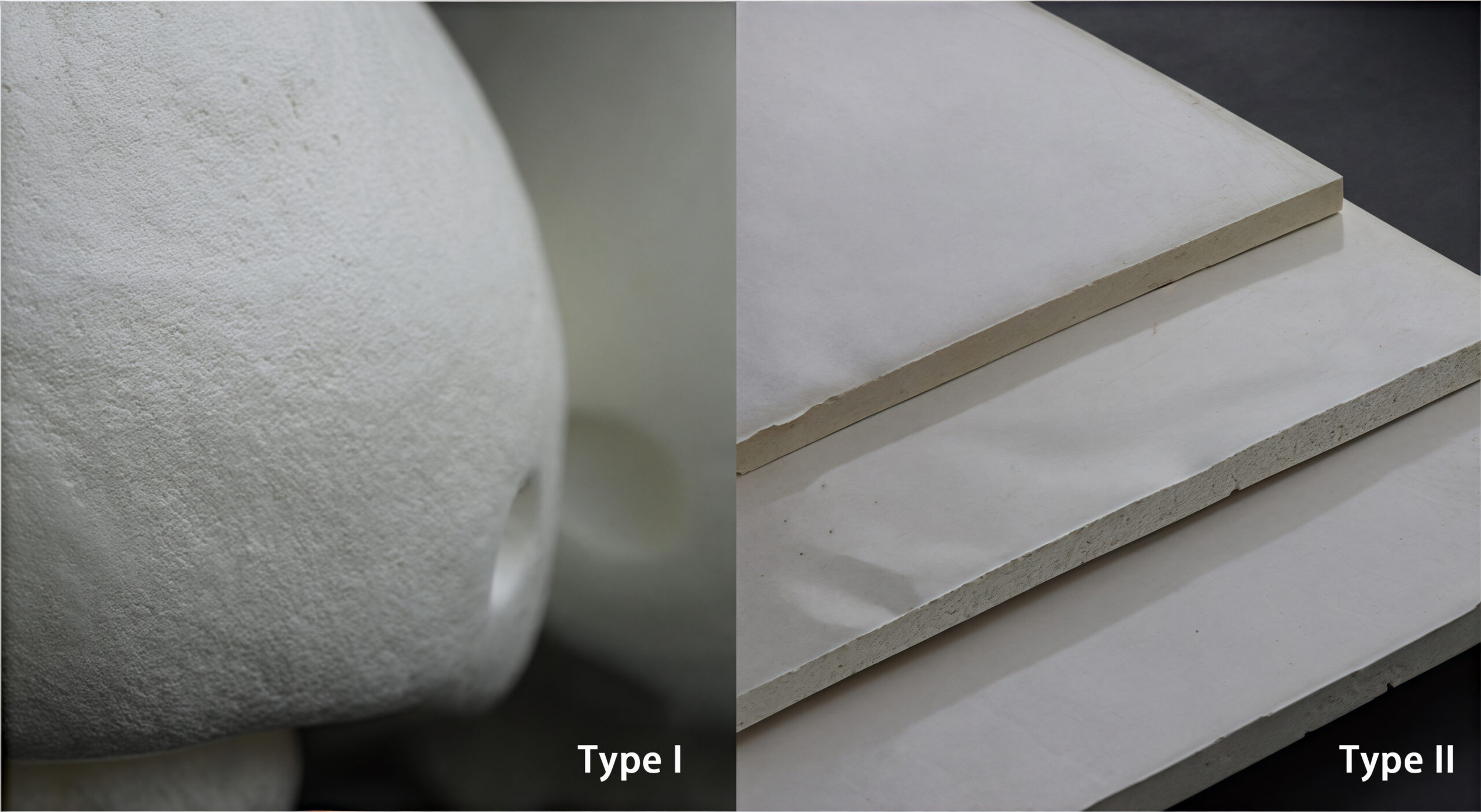

WANEFOAM®9260 series is a polymer material for coal mine spray plugging. After using a pneumatic pump to evenly mix component A and component B in a volume ratio of 1:1, they can quickly polymerize into a flexible material with excellent plugging function. According to application requirements, the material can be divided into foaming material (Type I) and non-foaming material (Type II). The material has been inorganically modified, does not contain any toxic and harmful substances, has a low reaction temperature, and is a safe spraying material. It is easy to construct, and there is no flow and sagging problem when spraying on the vertical and top surfaces. In addition, the material has strong adhesion to the coal wall, high tensile strength, large tensile deformation, and excellent airtightness.

Product Uses

1. Protection of loose rock surface and air leakage prevention in mining tunnels of high-gas mines or flammable mines;

2. Rapidly spray the tunnel surface to block gas during excavation;

3. Spray on the surface of coal pillars to prevent spontaneous combustion of coal seams caused by air leakage;

4. Prevent cracking and air leakage on the surface of coal rock in large tunnels or closed walls.

Product Features

WANEFOAM®9260 series, infusible and insoluble polymer materials formed after uniform mixing have the following characteristics:

1. Liquid components are solvent-free, with high flash point and high safety;

2. Spraying materials can solidify quickly and have high construction efficiency;

3. Excellent adhesion to coal wall, low reaction temperature and good flame retardancy;

4. The material has good flexibility and can withstand a certain degree of deformation.

Physical and chemical properties

| Project | Index | |

| Component A | Component B | |

| Appearance | Transparent or translucent liquid, evenly distributed, no lumps | Brown liquid, evenly distributed, no lumps |

| Flash point, ℃ | Above 100℃, and 15% above the maximum reaction temperature | Above 100℃, and 15% above the maximum reaction temperature |

| Viscosity, mPas (20℃) | <300 | <300 |

| Density, kg/m³ | 1300±100 | 1200±100 |

Reaction parameters

| Project | Index |

| Maximum reaction temperature, °C | ≤100 |

| Curing time, h | ≤2 |

Physical properties

| Project | Index | ||

| Tensile strength, MPa | ≥2.0 | ||

| Elongation at break, % | ≥30 | ||

| Combustion performance | Alcohol burner combustion test | Average value of burning time with flame, s | ≤3 |

| Maximum value of burning time with flame, s | ≤10 | ||

| Average value of burning time without flame, s | ≤10 | ||

| Maximum value of burning time without flame, s | ≤30 | ||

| Flame extension, mm | ≤280 | ||

| Alcohol burner combustion test | Average value of burning time with flame, s | ≤6 | |

| Maximum value of burning time with flame, s | ≤12 | ||

| Average value of burning time without flame, s | ≤20 | ||

| Maximum value of burning time without flame, s | ≤60 | ||

| Flame extension, mm | ≤250 | ||

| Surface resistance, Ω | ≤3×108 | ||

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9109-1

Fire extinguishing foam material for coal mine filling

Product Introduction

WANEFOAM®9109-1 is a foam material for filling and extinguishing fire in coal mines. It contains component A and component B. After the two components are mixed in a volume ratio of 1:1, they react quickly and form a foam. The reaction process releases low heat, and the foam formed has high water retention and good flame retardancy. It has good filling and flame retardancy.

Product Use

The foam formed by WANEFOAM®9109-1 has a high expansion ratio, good strength, and good flame retardancy. It can be used for:

1. Backfilling of the wall of the support along the goaf and plugging of small coal pillar cracks along the goaf;

2. Filling the caves in high-risk areas to prevent gas accumulation;

3. Filling coal rock cracks and caves to block gas in the gaps;

4. Used for rapid construction of fire walls and closed walls to block the spread of fire and prevent the outflow of harmful gases to ensure the safety of workers.

Product Features

When WANEFOAM®9109-1 is used, component A and component B are mixed in a volume ratio of 1:1 to quickly form a foam solid body. It has the following characteristics:

1. The heat release during the foam formation process is low, and the temperature of the surrounding environment is not changed, which fundamentally solves the problem of large heat generation during the application of traditional polyurethane/phenolic resin materials;

2. After the AB components are mixed, the initial emulsified foam has good fluidity, is conducive to diffusion, and can penetrate into the cracks of broken rock bodies;

3. Good flame retardancy, the foam does not burn or collapse under high temperature fire source;

4. Good antistatic property, the foam body retains a large amount of water and has natural antistatic properties.

Physical and chemical properties

| Item | Index | |

| Component A | Component B | |

| Appearance | Milky white liquid, evenly distributed, no lumps | Transparent liquid, evenly distributed, no lumps |

| Flash point, ℃ | No flash point | No flash point |

Reaction parameters

| Item | Index |

| Maximum reaction temperature, °C | Normal temperature |

| Foaming ratio, times | ≥10 |

| Curing time, s | ≤120 |

Physical properties

| Project | Indicators |

| Flame retardant performance | Non-flammable |

| Antistatic performance | Complies with MT/T 113-1995 |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

WANEFOAM®9109-3

Gel foam material for coal mine fire extinguishing

Product Introduction

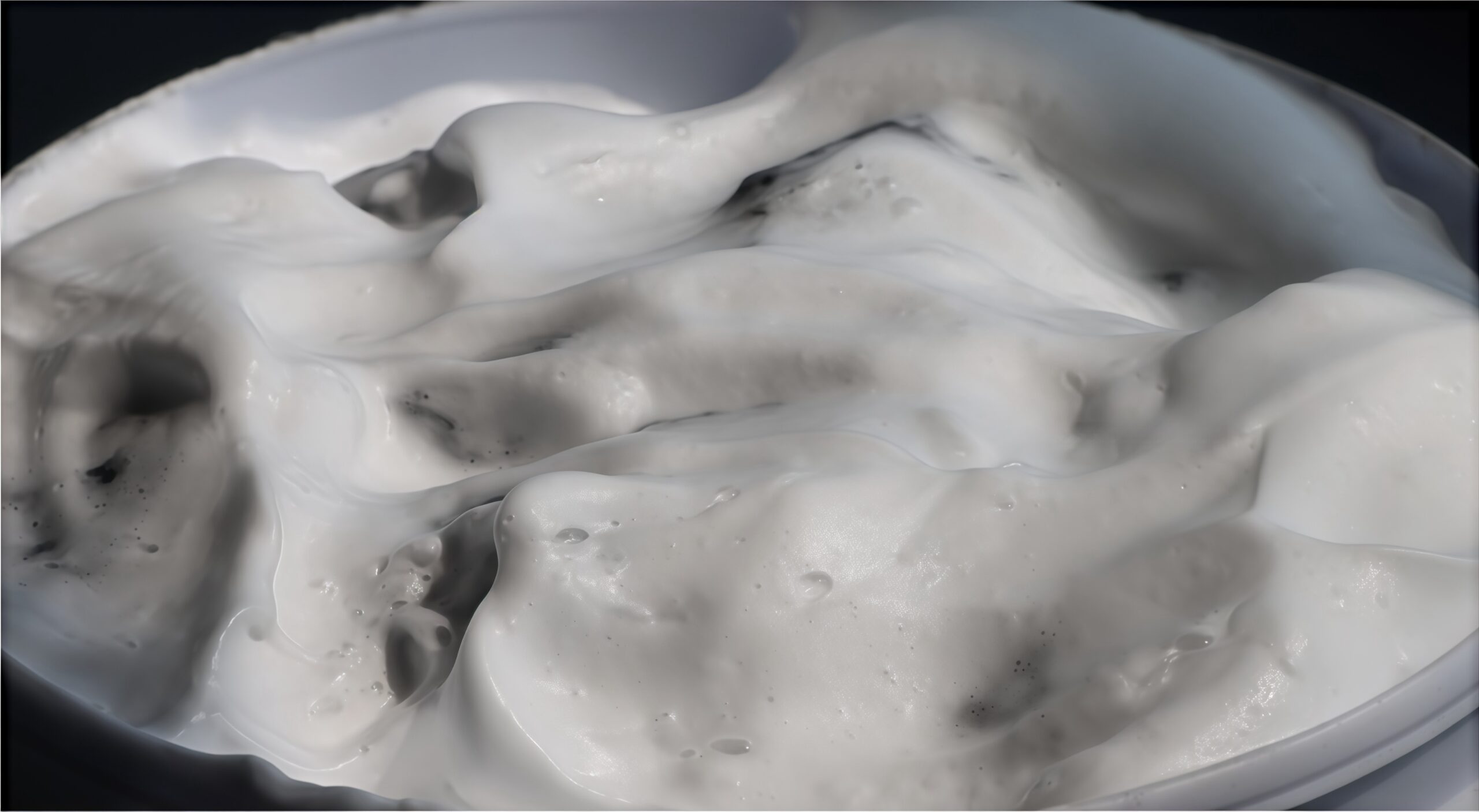

WANEFOAM®9109-3 is a gel foam material for coal mine fire extinguishing, which contains component A and component B. After the two components are mixed, they are foamed by a special foaming device and then injected (sprayed) onto the coal wall. It contains special structures and high-efficiency fire extinguishing factors, which can achieve the effect of completely preventing coal spontaneous combustion.

Product Use

WANEFOAM®9109-3 can be covered on floating coal, effectively preventing coal from contacting oxygen and preventing coal oxidation, thereby effectively preventing coal spontaneous combustion. It can be applied to: closed or scrapped tunnels and goaf areas; coalfield fires, coal pile spontaneous combustion fires, underground spontaneous combustion fires; spontaneous combustion and ignition areas of coal pillars adjacent to the working face of the mining face; spontaneous combustion and ignition areas of coal pillars on both sides of the preparation tunnel of the mining area; goaf areas and high-rise areas to prevent gas accumulation and coal spontaneous combustion; preventive fire prevention in the goaf area of the working face.

Product Features

When WANEFOAM®9109-3 is used, component A and component B are mixed and foamed by special foaming equipment to form a foam gel with a high foaming ratio.

It has the following characteristics:

1. Gel foam has good covering and stacking properties. It can be stacked up in the fire prevention area. It can cover the high, medium and low fire sources in the goaf or coalfield fire area in a large range and all-round manner, avoiding the problem of yellow mud grouting collapse;

2. Gel foam can solidify water in the gel body for a long time. The water in the gel layer can absorb heat and cool down for a long time, which can effectively prevent the fire from re-igniting and avoid the problem of large amount of water loss in other ordinary foams;

3. Gel foam can also cover and adhere to floating coal cracks, and has good performance of plugging air leakage channels while extinguishing fire;

4. Gel foam contains a large amount of inhibitors and high-efficiency fire extinguishing molecules, which can permanently inhibit and isolate the coal body from oxygen, achieving the effect of completely preventing and controlling coal spontaneous combustion.

Physical and chemical properties

| Project | Index | |

| Component A | Component B | |

| Appearance | Transparent liquid, evenly distributed, no lumps | Transparent liquid, evenly distributed, no lumps |

| Flash point, ℃ | No flash point | No flash point |

| Viscosity, mPa·s (20℃) | ≤150 | ≤150 |

Reaction parameters

| Project | Index |

| Maximum reaction temperature, °C | No heat release |

| Foaming ratio, times | ≥20 |

| Initial setting time, s | ≤90 |

| Final setting time, min | ≤10 |

Physical properties

| Item | Index |

| Water retention | ≥90 |

| Flame retardant properties | Non-flammable |

| Antistatic properties | Complies with MT/T 113-1995 |

| Toxicity | Non-toxic |

Note: The values provided in this article are typical test values. The specific data may vary slightly due to environmental conditions. For our company’s products, the data listed are not legally binding.

Wanhua mining polymer materials products safety and reliability

● Multiple cooling technologies have been independently developed, and the materials have a lower reaction temperature

After the two components of the polyurethane grouting material are mixed, a polymerization reaction occurs, releasing heat. If the reaction temperature of the grouting reinforcement material is too high, it will cause the material to accumulate too much heat too quickly in the coal mine and tunnel, which may cause serious safety accidents such as spontaneous combustion, smoke, and gas explosion.

Controlling the reaction temperature of the material is the safety red line of mining products. The company has independently developed a number of cooling technologies. The maximum reaction temperature of the mining reinforcement materials produced is lower than 100℃, and it has passed the experimental evaluation of the maximum reaction temperature of the coal safety certification simulation construction process (injection volume of 100KG).

●The product uses a combination of structural flame retardants and other solutions, which has good flame retardancy and long-lasting flame retardancy

In order to achieve the flame retardant effect, polyurethane materials need to add flame retardants to the resin. There are many types of flame retardants. According to different flame retardant elements, they can be divided into halogen, phosphorus, bromine and other flame retardants. According to different structures, they can be divided into two types: additive physical flame retardants and structural flame retardants. Different flame retardants have their own characteristics and need to be selected according to the application scenario.

Our company’s mining products use the synergistic effect of different flame retardant elements to make the materials more flame retardant than products on the market that use a single flame retardant, with a higher oxygen index. At the same time, the use of structural flame retardants does not affect the mechanical properties of the materials, and the flame retardancy is long-lasting.

In addition, we have also developed a series of halogen-free, highly flame-retardant and environmentally friendly reinforcement materials to respond to the requirements of customers who produce chemical coal for low chlorine or chlorine-free, and eliminate the problem of halogen elements poisoning heavy metal catalysts during the use of chemical coal.

● Focus on material toughness while ensuring strength, and pay attention to the balance between material strength and toughness

Our company’s mining material products optimize raw materials and formulas. On the basis of ensuring the compressive strength of the materials, we pay more attention to the toughness indicators such as tensile strength, shear strength, and elongation at break of the materials, ensuring that the materials have good toughness, and move with the coal and rock layers during the movement of the rock layers and various deformations, and play the greatest possible reinforcement and sealing role.

● Low odor during construction, no adverse effects on water quality and soil

Reactive tertiary amine catalysts are used in resin products. The catalyst molecules contain active groups, which can react with the curing agent to become part of the polymer structure. They will not escape into the air and have no pungent odor.

The raw materials are all well-known brands in the industry, and the quality inspection process for warehousing is detailed and comprehensive, and the raw materials are strictly controlled.

The heavy metal content in the product is strictly controlled. According to the national standard for drinking water, no heavy metals such as hexavalent chromium, lead, cadmium, and arsenic are detected in the product.

The specific environmental protection indicators of the three kinds of mining polymer materials are:

| Test items | Test Results | |

| Soaking water | Hexavalent chromium, mg/L | None (not detected) None (not detected) None (not detected) None (not detected) |

| Lead, mg/L | ||

| Cadmium, mg/L | ||

| Arsenic, mg/L | ||

| Copper, mg/L | ≤0.0003 | |

| Mercury, mg/L | ≤0.0003 | |

● Large production capacity, stable supply, high cost performance

Our company has advanced production equipment and perfect raw material supply channels, with an annual production capacity of 50,000 tons and stable supply. It has an advanced production management system, good product batch stability, low cost and high cost performance.