Water System Products Application Manual

Background

Solve the problem at the source Remediate problems promptly

Prevention first, combined with prevention and treatment

In the process of consolidation and hardening of large-volume concrete, new concrete dams will generate tensile stress inside or on the surface due to the sudden drop in external ambient temperature, which may lead to large cracks in severe cases.

Existing concrete dams are inevitably damaged and leaked during use, especially in high-cold areas. Concrete dams are easily affected by sudden drops in temperature, ice pull, ice push, and leakage during use in winter, thus affecting the safe operation of the dam.

Wanhua’s thermal insulation and anti-seepage system provides thermal insulation, anti-seepage and anti-ice pull protection for new concrete dams, repairs and reinforces various leaks and cracks for existing concrete dams, and provides a full set of solutions such as plain concrete and anti-abrasion for various related supporting projects.

Wind and rain erosion stress

Long-term wind and rain erosion has caused continuous damage to the dam body. Complex stress changes have aggravated the generation of dam cracks. Water seepage from dam cracks is still a global problem. Various objective factors have greatly reduced the service life of the dam, so auxiliary anti-seepage and long-term thermal insulation of the dam are particularly important.

Cracks Water seepage

Spray rigid polyurethane foam

Polyurethane (PU) is a general term for high molecular polymers containing urethane segments (—NHCOO—) in their molecular structure, which are generated by the reaction of polyisocyanates (MDI, TDI,

ADI) with polyols and various additives.

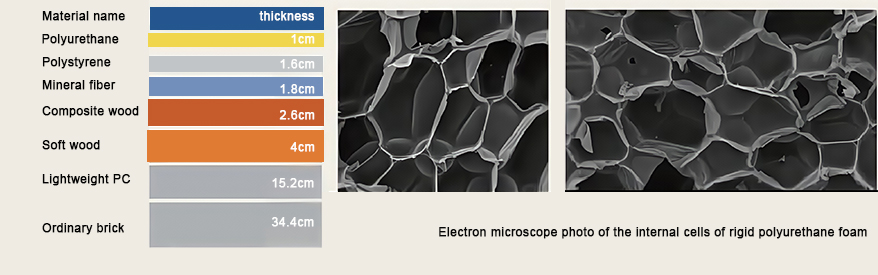

Good thermal insulation performance

The thermal conductivity is more than 35% lower than that of polystyrene board, achieving the same energy-saving effect, and the thickness is 1/2 thinner than EPS and 1/3 thinner than XPS

High bonding strength

Microporous infiltration self-adhesion can be constructed and formed on any complex curved surface, and can be fully bonded with concrete, wood, steel, cement board, ceramic tile (reverse), ceramic tile (front), and glass.

High compressive strength

Wanhua has developed a special polyurethane insulation material for reservoirs and dams for water conservancy projects. The compression strength and tensile strength can meet the design requirements of various high water pressures of 0.1~1.5MPa. The high strength performance can effectively solve the hazards caused by compression creep.

Good waterproof effect

According to experiments, after 28 days of submersion in water, the water absorption rate of 60mm polyurethane is only 0.013v/v, without any water seepage.

Polyurea waterproof coating

Spray polyurea waterproof coating

Spray Polyurea Elastomer (SPUA) is a new type of solvent-free, pollution-free green construction technology, known as the greatest discovery and technological revolution in the field of coatings and coatings. Spray Polyurea technology has completely broken through the limitations of traditional environmentally friendly coating technology, combining new technologies, new materials and new processes, and is a revolutionary leap in traditional construction technology.

Performance characteristics

Fast curing, one-time molding

Gel in 10 seconds, reach traffic strength in 10 minutes.

High temperature and high pressure professional spraying, can be constructed and molded on any complex curved surface in one time.

Quick drying bonding of wet substrates

Developed bonding materials matching wet substrates, fast curing, high bonding strength.

High elongation and good waterproofness

Under low temperature environment of -20℃, crack tracking can still reach more than 5mm.

Skin-like waterproofing: no water absorption, no water leakage, no leakage. Tensile strength: >16MPa, elongation at break:>450%.

Wear resistance

The wear resistance is 2 times that of 610 nylon, 3 times that of high-density polyethylene, and 18 times that of rubber.

| Material name | Wear amount/mg |

| Spray polyurea | 8 |

| Nylon 610 | 16 |

| High-density polyethylene | 28 |

| PTFE | 44 |

| Nitrile rubber | 48 |

| Material name | Wear amount/mg |

| Natural rubber | 146 |

| PVC | 161 |

| Styrene-butadiene rubber | 179 |

| ABS | 270 |

| Chloroprene rubber | 285 |

Note: Use CS17 grinding wheel, with a mass of 1000g/wheel and a rotation speed of 5000r/min. Single-component polyurea coating can be used for water surface protection with a flow rate of less than 30m/s.

Polyaspartic acid polyurea

It is constructed by reacting polyisocyanate prepolymers with highly hindered amino compounds such as secondary amino groups, and is applied by brushing, rolling, scraping or spraying. The gel speed is controllable and it will not react and cure instantly. After the reaction, a high-molecular polymer elastic coating with all cross-linking points being urea bonds is formed.

Performance characteristics

Weather resistance

It has anti-ultraviolet performance, suitable for sun exposure environment, and improves the decorative performance of the surface.

Low temperature flexibility

It has low temperature flexibility of -40℃, and can be used in low temperature environment (-35~40℃) in high-cold areas, especially resisting concrete cracking and deformation at low temperature without leakage.

Abrasion resistance

It is suitable for water-facing surface anti-seepage of hydraulic concrete buildings, surface anti-seepage of cracks and expansion joints, water surface protection with flow rate less than 20m/s, and surface durability protection.

| Project | Performance requirements | ||

| TypeI | TypeI | Type Ⅲ | |

| Surface drying time (h) | ≤3 | ||

| Leveling (%) | ≥20 | ||

| Solid content (%) | ≥95 | ≥90 | |

| Tensile strength (MPa) | ≥10 | ≥15 | ≥20 |

| Elongation at break (%) | ≥300 | ≥200 | ≥150 |

| Water absorption | ≤3.0 | ||

One-component polyurea

Mix the polyisocyanate prepolymer with the chemically blocked amino compound in liquid form, and apply it by brushing, rolling, scraping or spraying. Under the action of moisture in the air, the blocked amino compound hydrolyzes to produce terminal amino groups and generate cross-linking points with the prepolymer, forming a high-molecular polymer elastic coating with all cross-linking points being urea bonds.

Reaction principle

The terminal amino group in the R component is chemically blocked. The blocked intermediate will not react chemically with the -NCO-containing component under the condition of isolating air and moisture, and can coexist in the same system.

Once the mixture comes into contact with air, the blocked polyamine is unblocked under the action of moisture, releasing the terminal amino group -NH2 or -NH-, which quickly reacts with -NCO to form a urea bond.

Performance characteristics

Convenient construction

No power or equipment is required, and the batching process is omitted. It can be used immediately after opening the barrel, which greatly improves the convenience and flexibility of construction.

Low temperature flexibility

It has -40℃ low temperature flexibility and can be used in low temperature environments in high-cold areas (-35~40℃), especially resisting cracking and deformation of concrete at low temperatures without leakage.

Abrasion resistance

It is suitable for water-facing surface anti-seepage of hydraulic concrete buildings, surface anti-seepage of cracks and expansion joints, protection of water-passing surfaces with a flow rate of less than 30m/s, and surface durability protection.

| Project | Performance requirements | |

| TypeI | TypeⅡ | |

| Surface drying time (h) | ≤3 | |

| Solid content (%) | ≥80 | |

| Tensile strength (MPa) | ≥15 | ≥20 |

| Elongation at break (%) | ≥300 | ≥200 |

| Water absorption | ≤5 | |

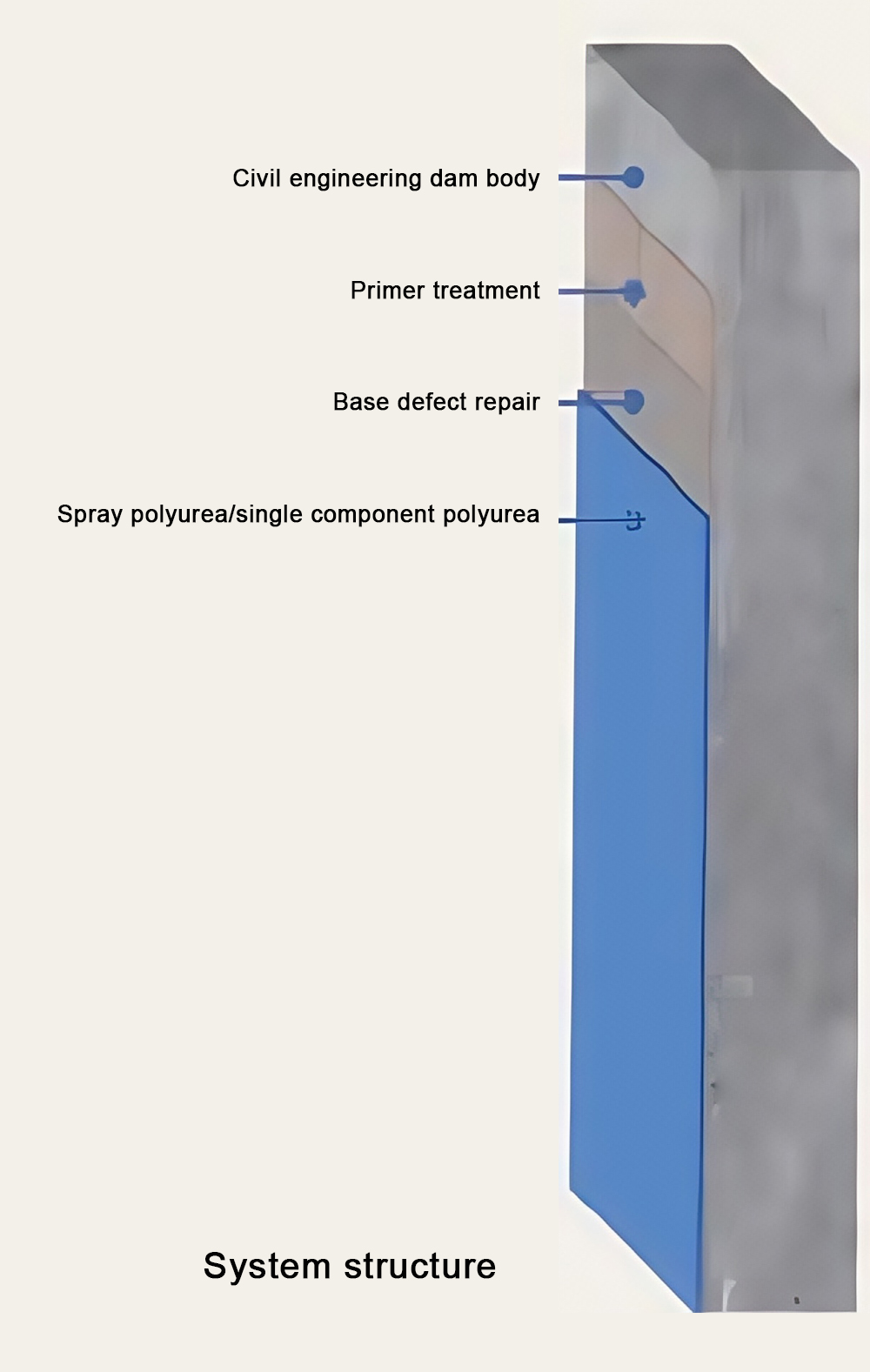

Water system insulation and anti-seepage

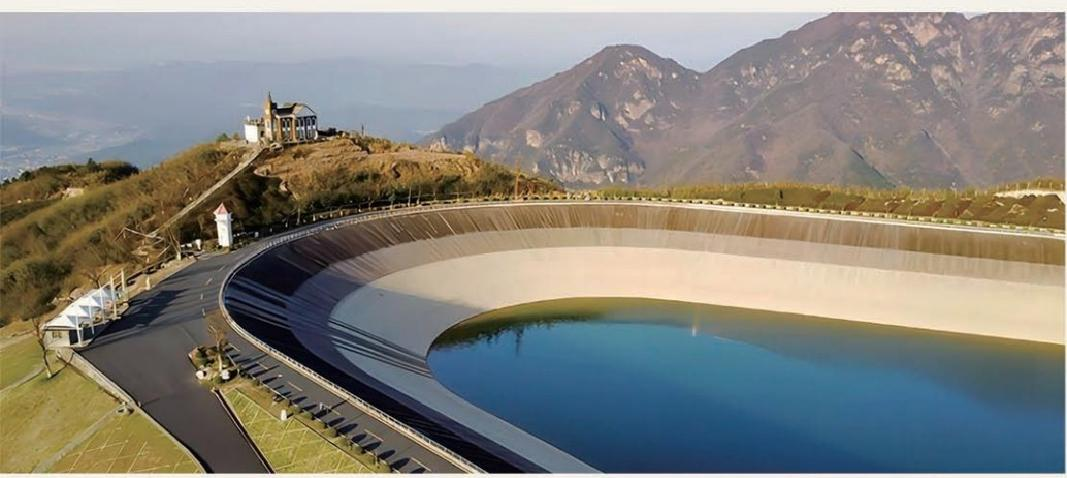

Pumped storage anti-seepage system

Scope of application

Pumped storage dam, reservoir anti-seepage area, diversion tunnel and other fluid scouring areas

Method: Spraying polyurea/single component polyurea

System characteristics

Good waterproof effect, high elongation, bridging cracks, abrasion resistance is much higher than epoxy coatings

High bonding strength to wet base surface

Quick curing and molding, vertical spraying without flowing

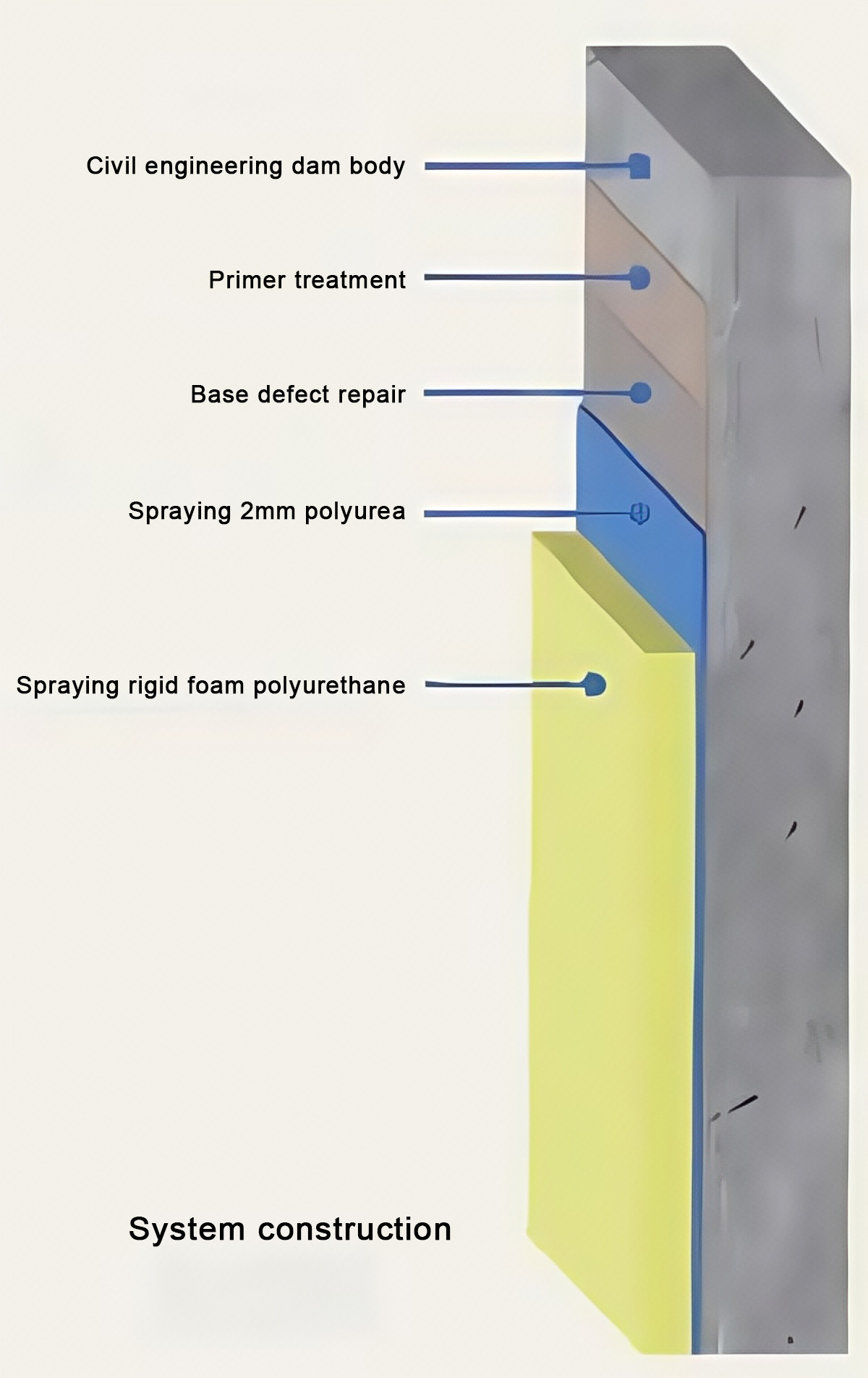

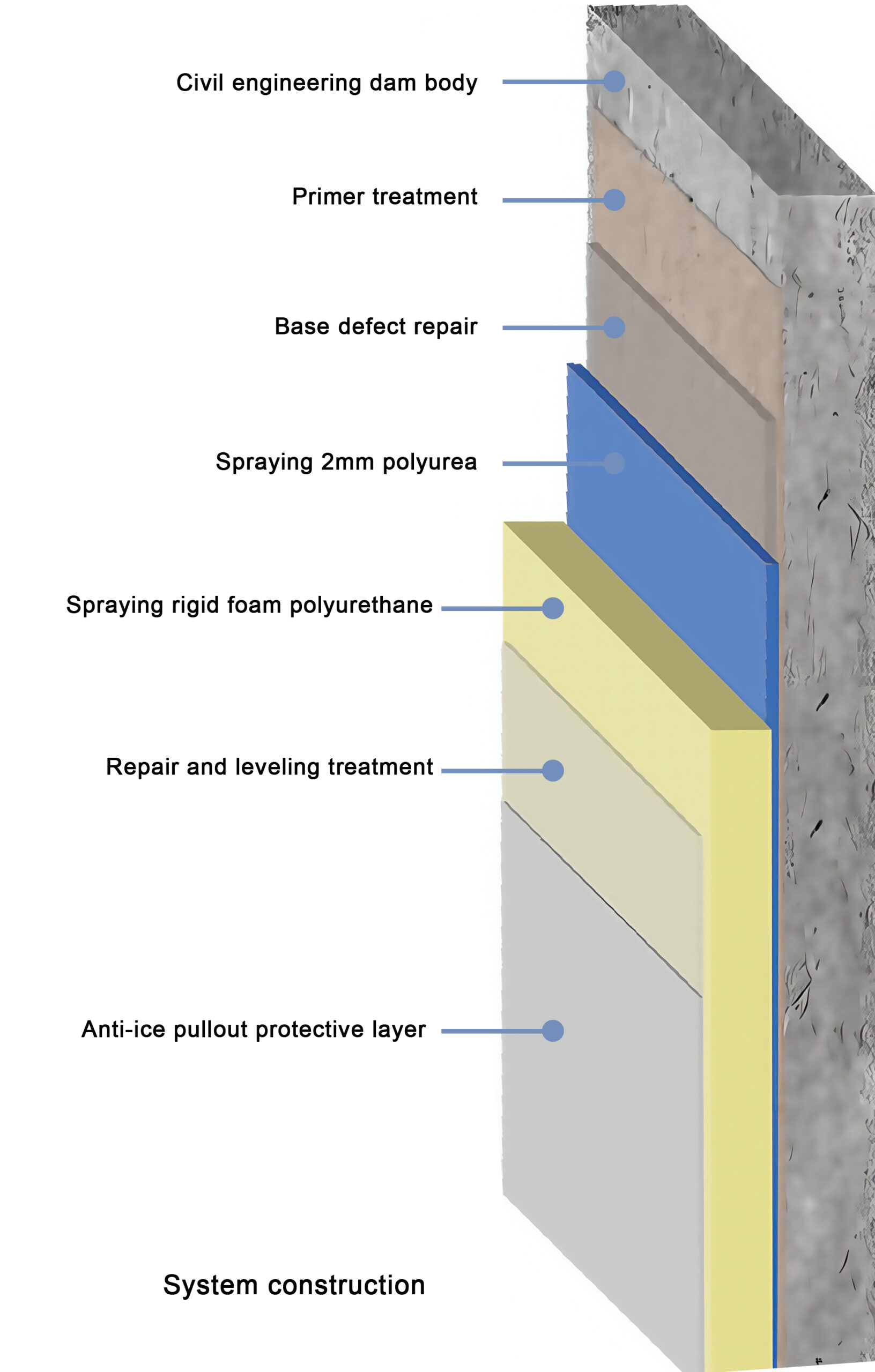

Thermal insulation and anti-seepage system

Scope of application

The following parts of the water level change area upstream of the dam

Method: auxiliary anti-seepage + external thermal insulation

System characteristics

Good thermal insulation effect, the temperature change of the dam body is only 3℃, avoiding frost damage High compressive and shear strength, high water pressure does not produce compression deformation Excellent tensile performance, bridging cracks, and preventing water from penetrating into the dam body Spraying construction on the vertical dam body is more efficient and the overall construction effect is good

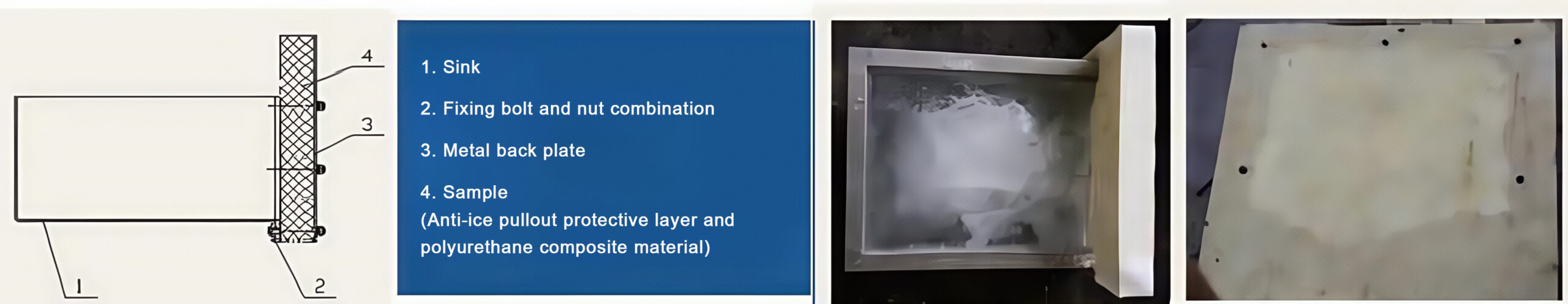

Anti-ice pull system

Applicable scope

Water level fluctuation area upstream of the dam

Method: auxiliary anti-seepage + external insulation + surface protection

System features

Good insulation effect, the dam body temperature changes by only 3°C, avoiding frost damage High hydrophobicity, low adhesion to ice, excellent anti-ice pull performance No compression deformation and shear failure under the action of ice thrust

Excellent tensile performance, bridging cracks, preventing moisture from penetrating into the dam body

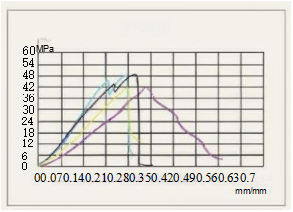

Ice pull resistance test research The test condition is -20℃, the mold is removed after freezing for 72 hours, and the verification is repeated six times.

Ice pullout test under actual dam icing conditions

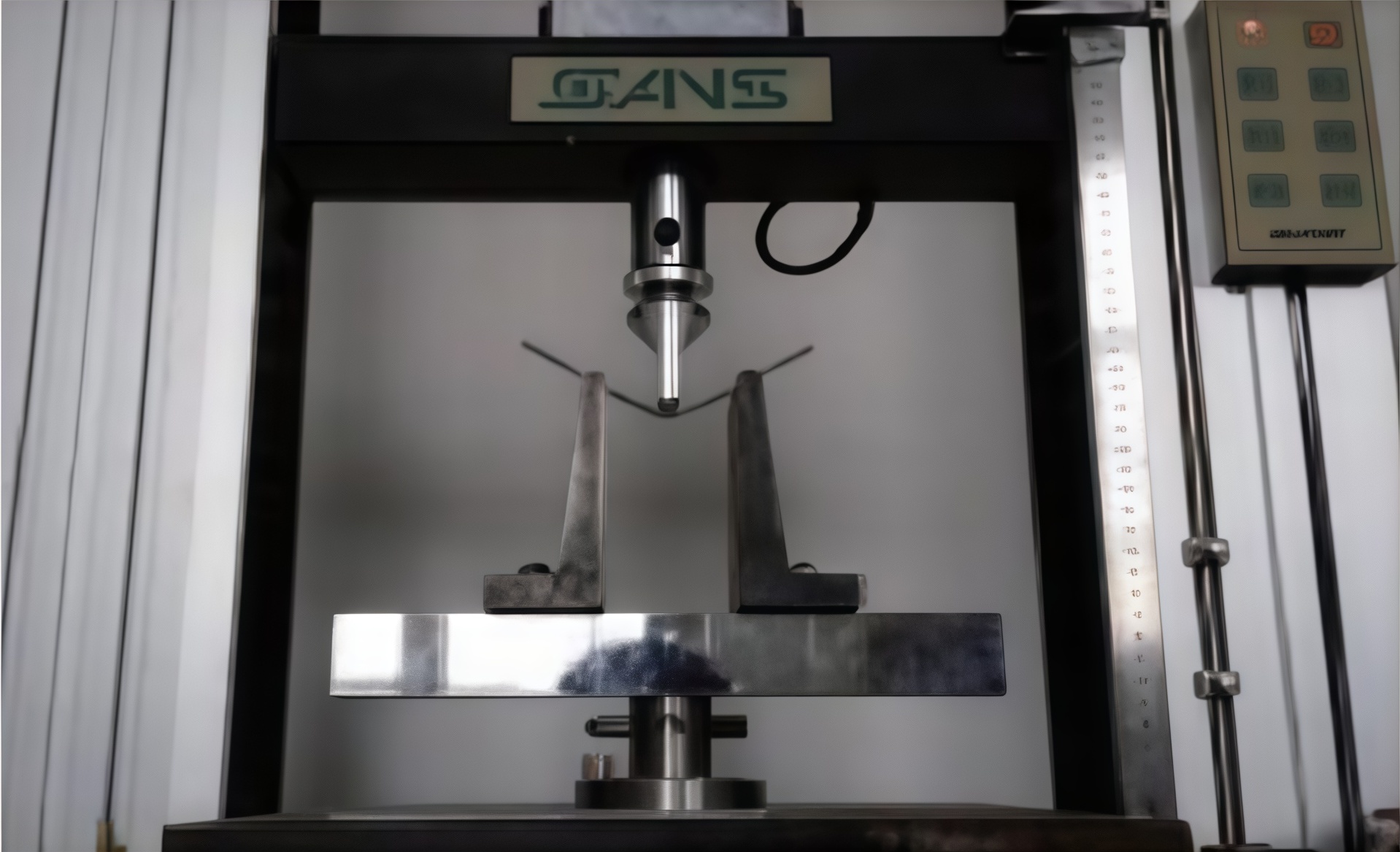

Stress-strain testing

| No. | Specimen length (1) | Sample thickness (h) | Sample span (L) | Sample width (b) | Flexural modulus (Ef) | Bending strength (ofM) |

| Unit | mm | mm | mm | mm | MPa | MPa |

| 1 | 16.5 | 3.82 | 60 | 15.14 | 1809.2 | 48.64 |

| 2 | 15.5 | 2.98 | 60 | 15.73 | 2010.6 | 42.33 |

| 3 | 15.3 | 2.99 | 60 | 15.24 | 1985.2 | 42.21 |

| 4 | 16.5 | 3.62 | 60 | 15.17 | 2256.8 | 49.11 |

| Average | 2015.45 | 45.5725 |

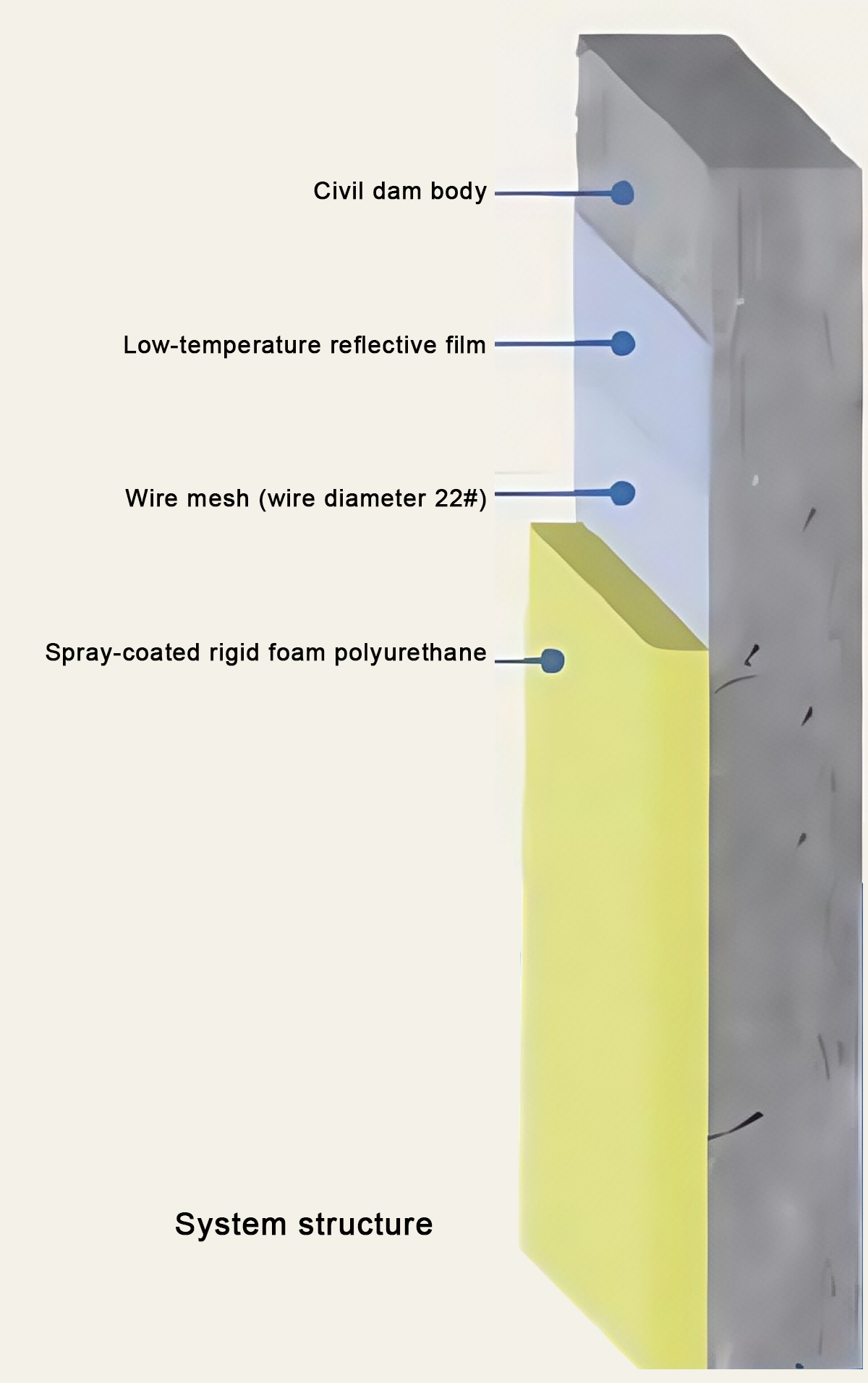

Temporary winter insulation system

Scope of application

Temporary winter protection of concrete dams in high-cold areas

Method: External insulation

System features

Good insulation effect, the temperature change of the dam body is only 3℃, avoiding frost damage and reducing the occurrence of temperature cracks

Quick construction and easy removal

Water conservancy system construction technology

1. Base surface treatment

Use an angle grinder to grind the construction dam surface, clean the dam surface floating slurry, dust, dirt, release agent, and loose surface layer, ensure that the base surface is clean and dry, and thoroughly clean the dust from grinding.

2. Primer treatment

Precisely mix and mix evenly, use a wheel to repeatedly roll and brush, fully cover, fully penetrate, and achieve uniform coating, no missing coating, and no accumulation. It can seal the moisture, pores, and minor defects on the surface of the concrete base.

3. Base material defect repair (for polyurea anti-seepage)

Precisely mix the repair material, stir evenly, repair all the base defects such as holes and cracks, and manually fill the remaining small pinholes. The base surface is sealed for the second time, which enhances the bonding strength with the base surface and provides guarantee for the construction quality of the subsequent polyurea spray coating.

4. Lay low-temperature reflective film and fix wire mesh (for temporary insulation during winter)

Lay out and position according to the on-site construction conditions, cut and lay in parallel, use transparent tape to bond between the membranes, press the steel wire mesh panels on the surface, anchor the steel wire mesh firmly from top to bottom with anchor nails, and connect the grid panels with self-adhesive tape (or 22# binding wire). The number of anchor nails per square meter should not be less than 3~4.

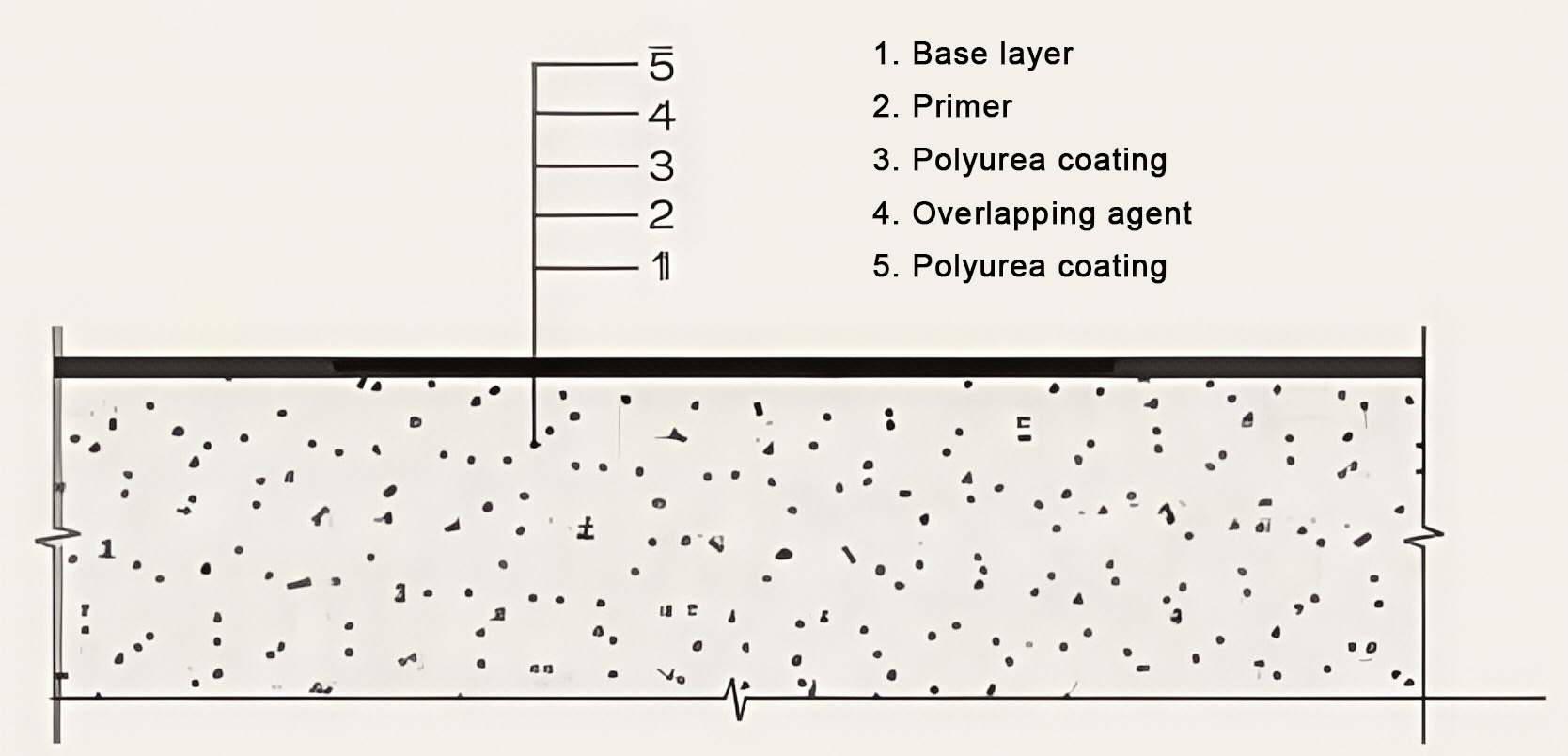

5. Spray polyurea

Protect the parts outside the spraying area, check the moisture level of the base surface and the ambient temperature and humidity, debug and test the sprayer before spraying, and spray the parts according to the principle of difficult first and easy later, up first and down later, multiple times at a time, and cross-spray to the thickness required by the design.

6. Spraying rigid foam polyurethane

Ensure that the base surface is dry, check the ambient temperature, humidity and wind force, and construct the details first and then the large surface. Check the foam quality at any time during the spraying process to ensure the smoothness of the appearance. Spray multiple times at a time to the thickness required by the design.

7. Anti-ice pull-out protective layer

Precisely proportion the anti-aging topcoat, spray evenly, without missing or accumulating, to achieve the purpose of sealing, thereby improving the durability of the insulation layer.

Node processing example

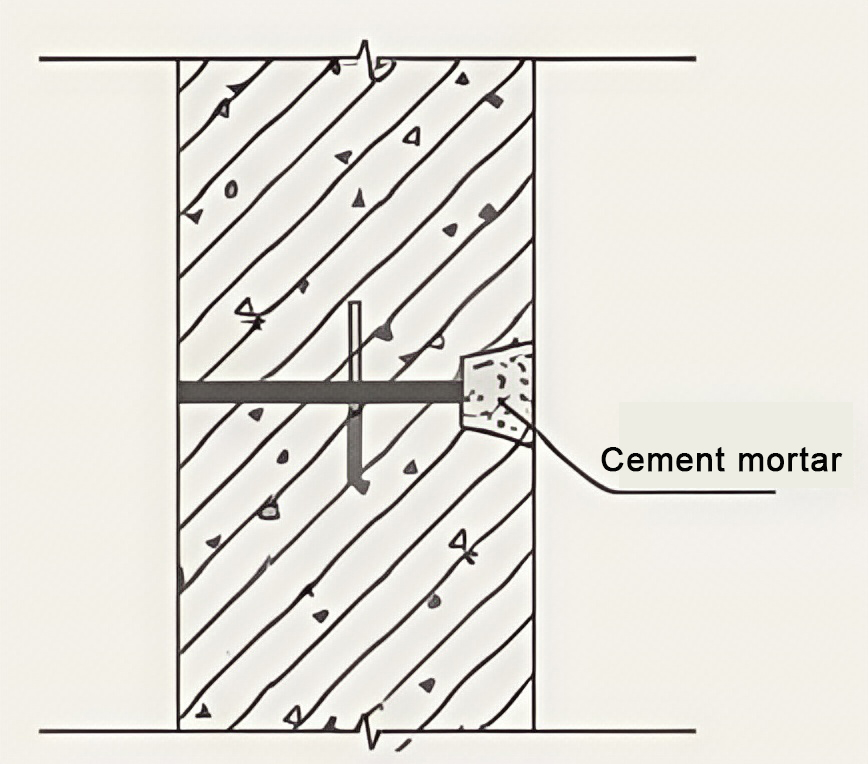

Bolt holes and other base holes

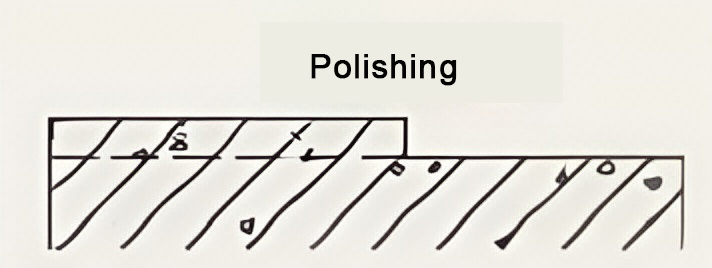

Wrong platform

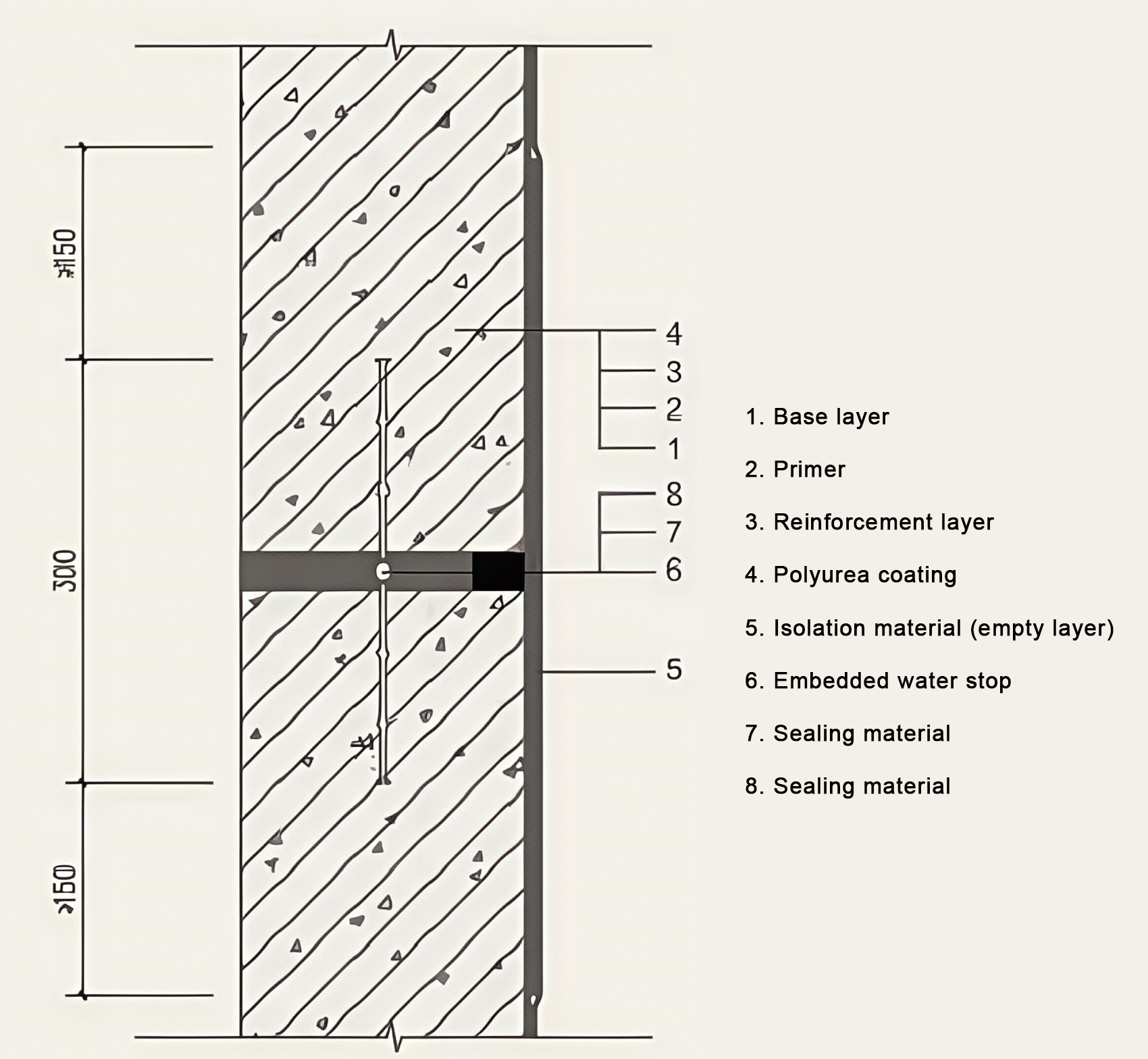

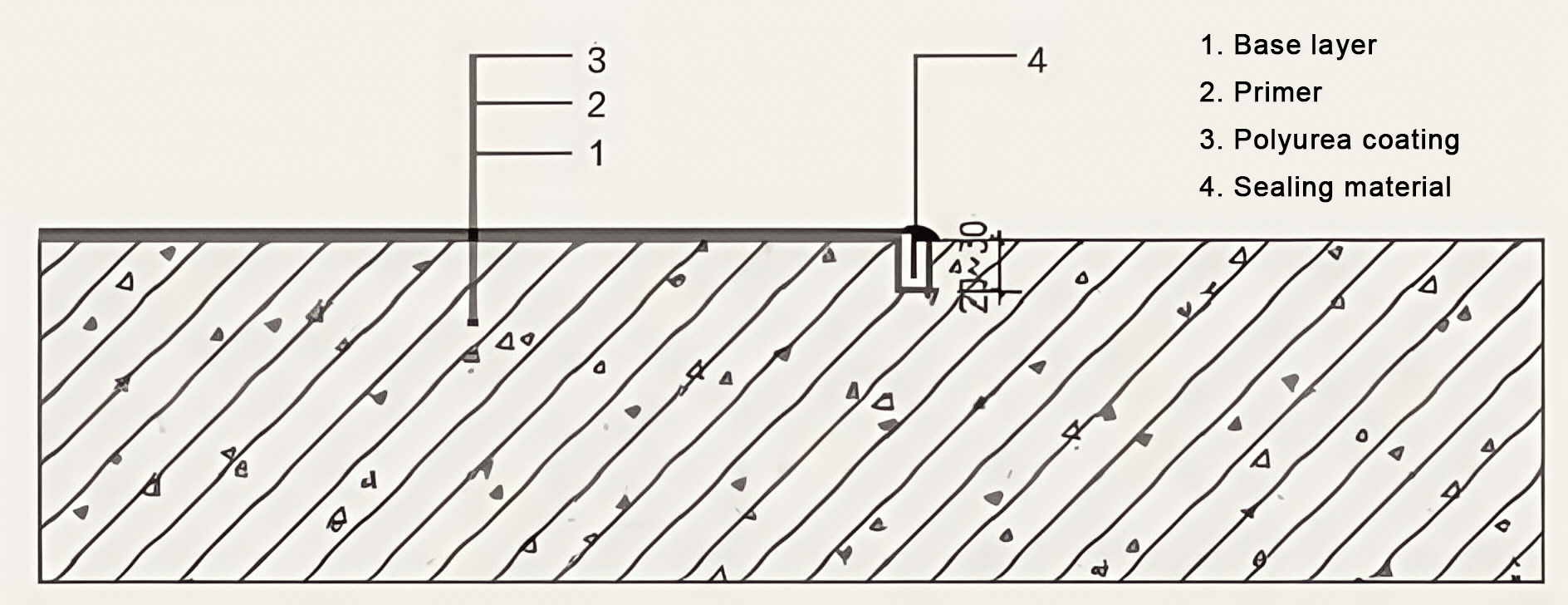

Deformation seam

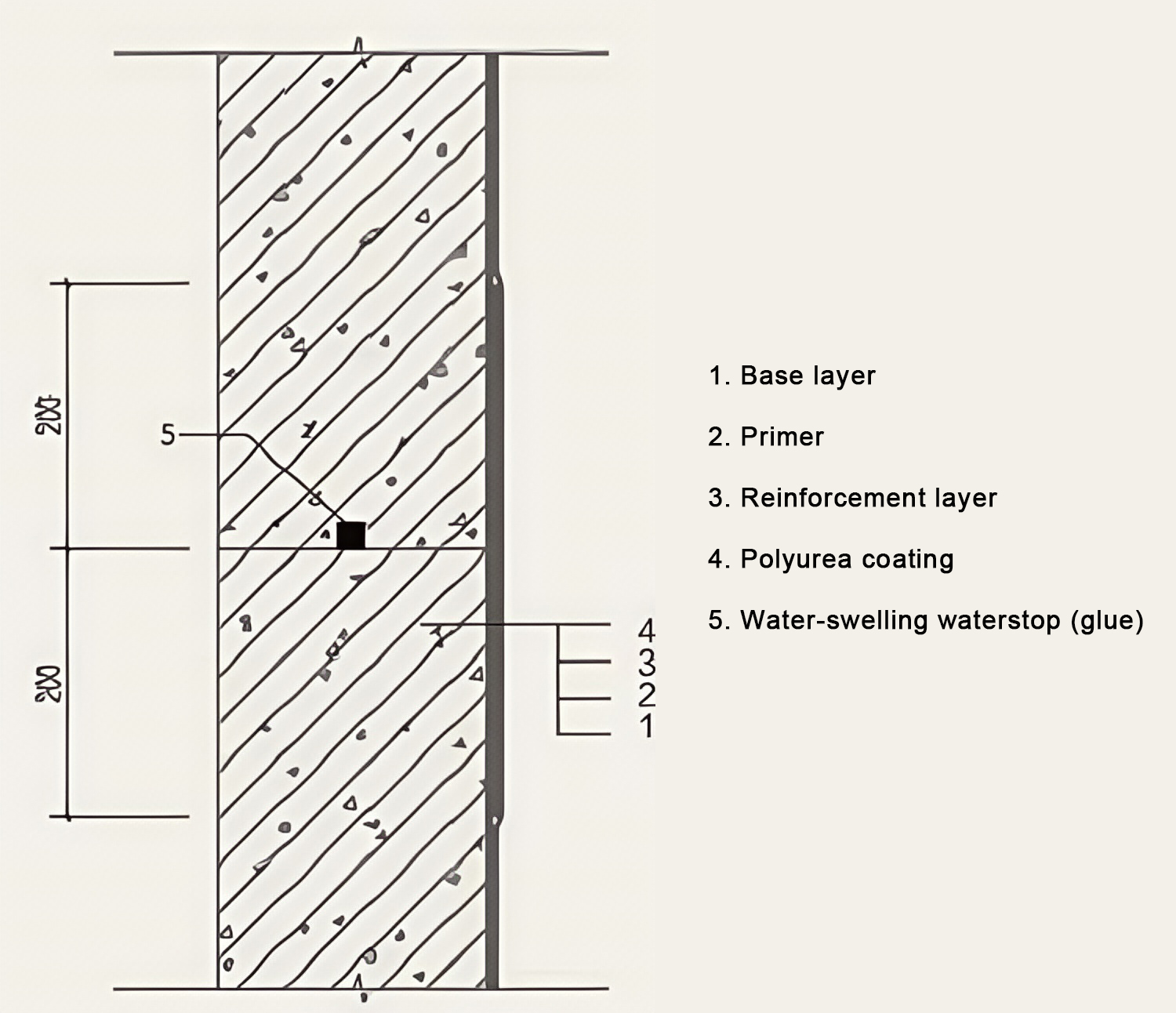

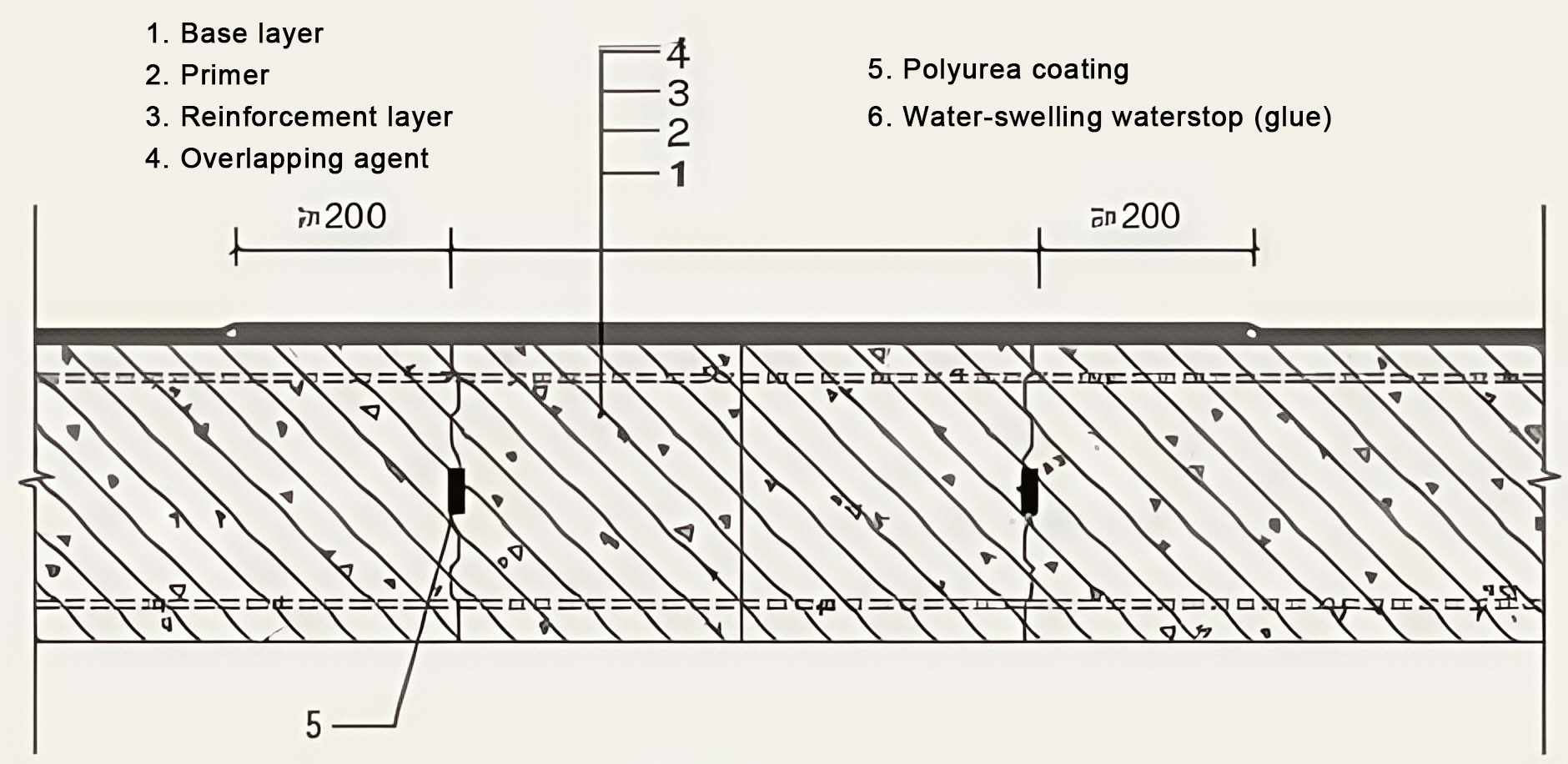

Construction seam

Polyurea lap joint

Polyurea sealing

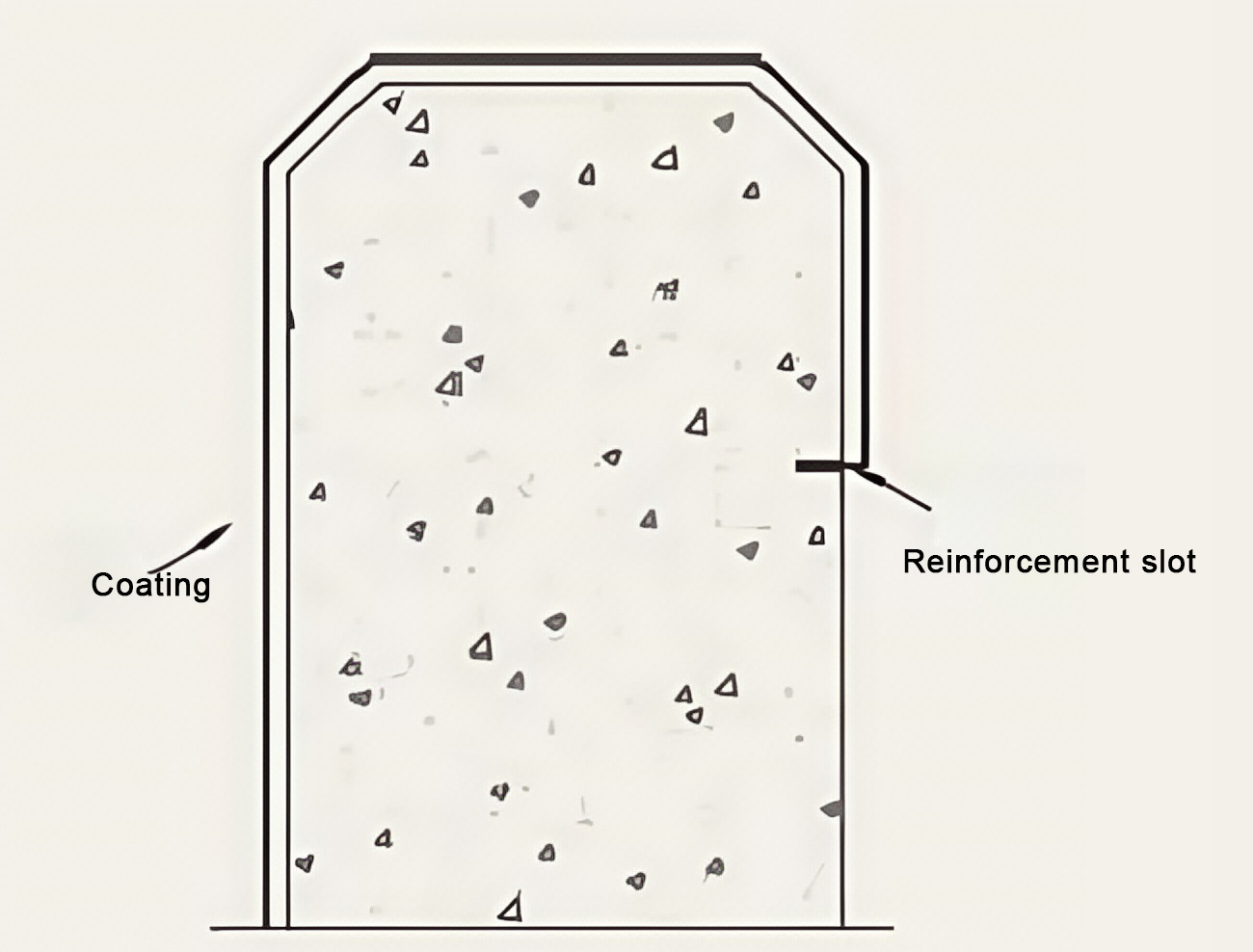

Diversion hole edge finishing

Post-casting strip

Polymer grouting plugging system

Polymer grouting plugging material is a low-ratio foaming grouting plugging material. It reacts chemically when it comes into contact with water to form an elastic gel-like solid body, thereby achieving a good water-stopping purpose. It is a new generation of waterproof plugging reinforcement material.

Product Features

Low-ratio foaming, no expansion of cracks, high safety factor; low viscosity and good permeability after mixing with water;

Excellent density, capable of secondary penetration;

Good hydrophilicity and pourability, and the viscosity and curing speed of the slurry can be adjusted as needed.

Performance indicators

| Item | Technical Parameters |

| Density, g/cm² | ≥1.05 |

| Viscosity, mPa.s | ≤1.0×1.03 |

| Setting time, s | ≤800 |

| Non-volatile content, % | ≥78 |

| Compressive strength, MPa | ≥6 |

Scope of application

Grouting of dam body

Sealing and anti-seepage of cracks in water supply tunnels

Anti-seepage reinforcement of cracks in dam body concrete

Reinforcement of deformed buildings, soil improvement, protection and stabilization of soil surface.

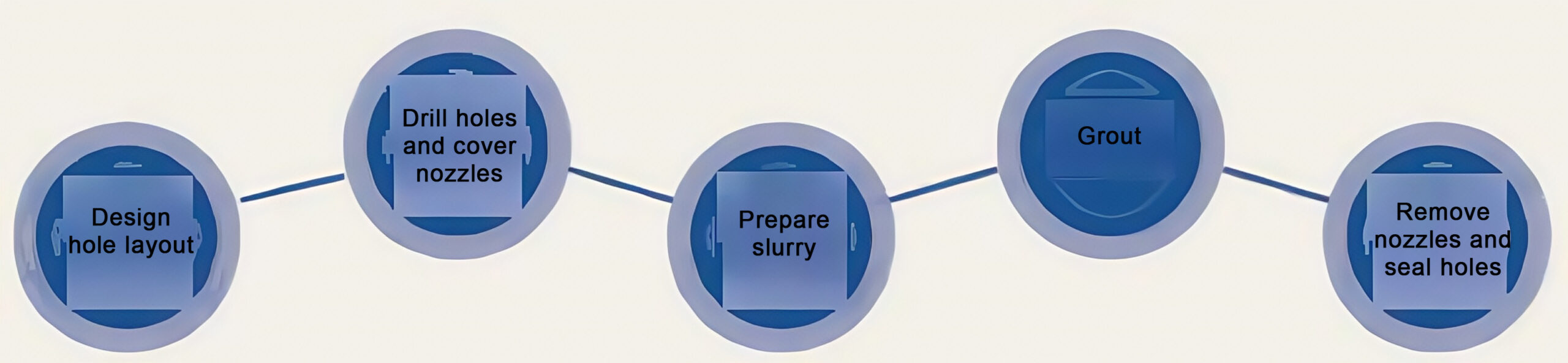

Construction process examples

Construction points

Carefully check the leaking part and clean the dirt near the leaking part in preparation for grouting;

Drill grouting holes at the leaking part. For deep cracks, drill inclined holes through the crack surface, bury the grouting nozzle, and seal it with quick-drying cement;

Determine the grouting pressure and grouting volume according to the specific situation of the leaking part. Use a plugging grouting pump to inject this product into the crack. When pure slurry appears in all adjacent holes, move to the adjacent hole and grout at the specified pressure until it can no longer be pressed in, then close the valve;

After 72 hours, check whether there is water seepage at the leaking part. If there is no water seepage, break the grouting nozzle and seal and smooth the base surface with quick-drying cement.

Fair faced concrete system

Wanhua Energy-saving Clear Water Concrete Protective Paint is divided into primer and topcoat. Through professional construction technology, it can make up for the many inevitable appearance defects of concrete during the on-site pouring process.

By applying high-performance clear water concrete protective paint, a transparent protective layer is formed on its surface, which can prevent rainwater from penetrating and resist sunlight exposure, and play a comprehensive protective role on concrete, which can effectively extend the service life of concrete.

Product Features

It has excellent permeability and density, and is breathable and impermeable;

It has the characteristics of mildew and algae resistance, anti-fouling function, excellent water resistance and washability, and water-based environmental protection and pollution-free.

Performance indicators

| Item | Technical parameters |

| Surface drying time | ≤2h |

| Resistance to artificial aging | 1000h no blistering, no peeling, no cracks Powdering: ≤1 Discoloration: ≤2 |

| Resistance to scrubbing | ≥95 |

| Resistance to staining | ≤3% |

| Waterproofness | 0.3MPa, 0.5h, water permeability |

| Low temperature flexibility (wrap around φ10mm rod) | -15℃, no cracks |

Scope of application

Applicable to the outer surface of plain concrete of various buildings such as dams.

Construction Preparation – Base treatment – Material matching/color matching – Painting Construction – Finished product Protection

Technical Solution

| Process name | Scope of application |

| Pure transparent protection method | 1. The quality of clear water pouring is very good |

| 2. The clear water texture is completely retained and defects are allowed | |

| Transparent local repair method | 1. The quality of clear water pouring is very good |

| 2. Keep the clear water texture and small area defects, and only repair the large area defects | |

| Full coloring repair method | 1. The quality of clear water pouring is average |

| 2. The base surface color difference is serious and there are many honeycomb surfaces | |

| Imitation of clear water method | 1. The quality of clear water pouring is poor |

| 2. The leakage of mortar and sand is serious. There are large areas of honeycomb surfaces or construction on non-clear water concrete surfaces |