Polymer Facing Mortar

Polymer plastering mortar has certain flexibility and crack resistance, water repellency, good air permeability and durability, and is easy to construct, safe and reliable, and green and environmentally friendly.

SKU:

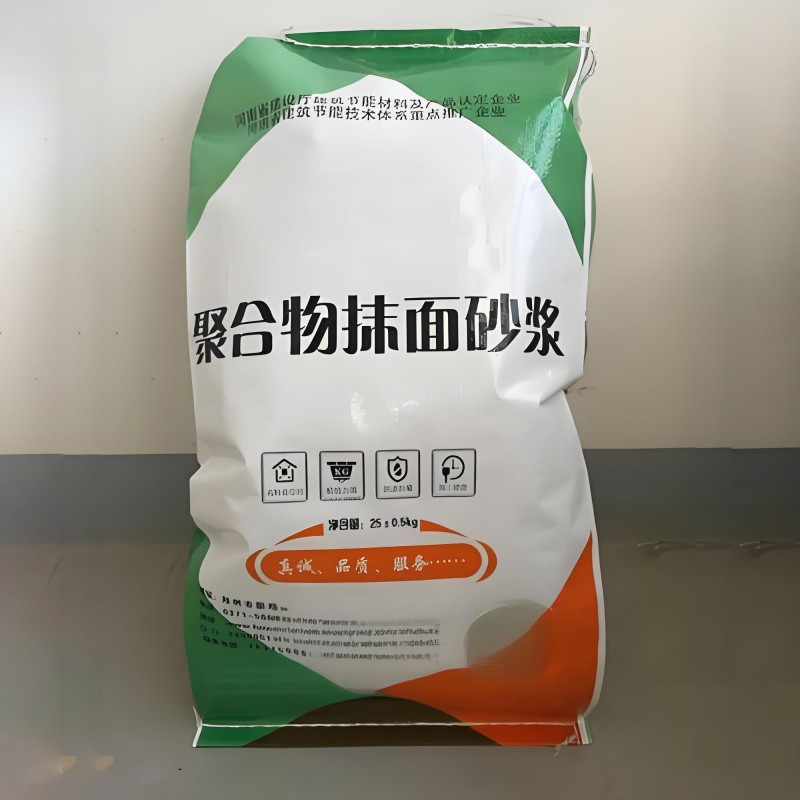

Polymer Facing Mortar

Categories: Mortar, Facade Material, Polymer Mortar

Tags: Mortar, Facade Material, Polymer Mortar

Description

Product Introduction

The polymer rendering mortar is compounded from high – quality Portland cement, selected mineral fillers, multiple water – based polymer materials and various additives. It has certain flexibility and crack resistance, water repellency, good air permeability, durability. It is easy to construct, safe and reliable, and environmentally friendly.

Construction Method

- Remove dust, oil stains, sundries from the wall to make the surface clean.

- The surface of the pasted insulation board should be as flat, clean and firm as possible. If necessary, it can be sanded with coarse – grained sandpaper. The insulation boards should be pressed tightly together. For possible board joints, if the surface needs to be insulated, it is also necessary to use the rubber powder polystyrene particle mortar for leveling.

- First, add an appropriate amount of clean water into the container, and then pour the rendering mortar into it in proportion and stir thoroughly until it becomes a thick paste – like slurry without lumps.

- The stirred mortar should be used up within 2 hours. If it hardens during the process, it should be discarded and not re – added with water for use.

- First, apply the first layer of rendering mortar, then paste the fiberglass mesh, and finally apply the second layer of rendering mortar for leveling.

Performance Indicators

| Rendering Mortar | Original Strength | Water – Resistance | Freeze – Thaw Resistance |

|---|---|---|---|

| Tensile Bond Strength /Mpa (with Cement Mortar) | ≥0.10MPa, failure interface on polystyrene board | ≥0.10MPa, failure interface on polystyrene board | ≥0.10MPa, failure interface on polystyrene board |

| Tensile Bond Strength /Mpa (with Expanded Polystyrene Board) | – | – | – |

| Compressive Strength / Flexural Strength (Cement – based) | ≤3.0 | – | – |

| Cracking Strain (Cement – based) % | ≥1.5 | – | – |

| Operability Time h | 2 | – | – |

Precautions

- No additives should be added during the on – site construction of the rendering mortar. Strictly control the water – cement ratio and plastering time.

- During transportation, pay attention to moisture – proof, rain – proof and sun – proof.

- During storage, the rendering mortar should be placed in a dry and ventilated place to avoid getting damp.

- The application environment temperature is 5℃ – 35℃.

- Before the formal construction of the project, the buyer must conduct tests in an environment consistent with the construction conditions to ensure the reliability of the material used in this specific project. Formal construction is regarded as the buyer’s recognition of the qualified performance inspection of the product. If the above operations are not followed, all responsibilities shall be borne by the buyer.

Packaging Specification

(25±0.5) kg/bag

Storage Precautions

Store in a rain – proof, moisture – proof and well – ventilated place.

Shelf Life

From the date of production, under the specified storage conditions, the shelf life is 12 months.

Safety Precautions

This product contains cement components. If it accidentally splashes into the eyes, it should be rinsed thoroughly with clean water immediately or go to the hospital for treatment in a timely manner.

Fire and Explosion Hazards

This product is not a flammable liquid, explosive, oxidizer, corrosive, toxic or radioactive dangerous product during storage and transportation. It is not a dangerous product.

- Fire – fighting Medium: Carbon dioxide, foam or chemical dry powder fire extinguishers can be used for fire – fighting. When there is no other fire – fighting agent, a large amount of atomized water can be sprayed. Once the fire is extinguished, the spilled materials should be cleaned up (see Leakage and Spillage Treatment).

- Fire – fighting Procedure: Normal protection

Leakage and Spillage Treatment

A small amount of leaked or spilled materials can be washed away with water. In case of a large – scale leak, collect and recycle the materials, and wash the polluted ground with water or detergent. The disposal of waste composite materials must comply with local government environmental protection regulations.

For more information, please refer to our company’s product safety technical specification or contact our company’s customer service center. The indicators and data provided in this material are based on our existing technical knowledge and practical experience and are for reference only. The specific guaranteed indicators shall be subject to the quality guarantee letter or the supply contract. Users are responsible for testing the products purchased from our company to verify whether they are suitable for their respective intended processes and uses and to achieve the desired goals. Further application and processing of our company’s products are beyond our control. Therefore, our liability for the products provided is limited to the part we deliver and that you use. We do not assume indirect losses caused during the production process using our company’s products as raw materials. Our company’s technical support and customer service center is willing to provide you with product consultation and application technical services. You are welcome to contact us by letter or phone.

Contact Address: No. 56 Taiyuan Road, Yantai City, Shandong Province, Wanhua Energy – Saving Technology (Yantai) Co., Ltd.

Contact person: Vivin Yi

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

WhatsAPP: +86 17761309662

Email: wanhuachemical@outlook.com

Tel: +86 17761309662

Wechat: yivonnie

More Similar Items

The Largest MDI Manufacturer and Polyurethane Raw Material Supplier

Additional information

| Weight | 5485.71 kg |

|---|