WANSHIELD®63121 Antistatic Water – based Polyurethane Mortar Flooring System

WANSHIELD®63121 Antistatic Waterborne Polyurethane Mortar is a three-component, self-leveling flooring system combining the advantages of organic polymers and inorganic concrete. It is mainly developed as a thin – type anti – static polyurethane mortar self – leveling floor for light industrial workshops and other places with high requirements for anti – static properties, chemical resistance, anti – slip performance, and cleanliness.

1. Product Overview

Product Applications

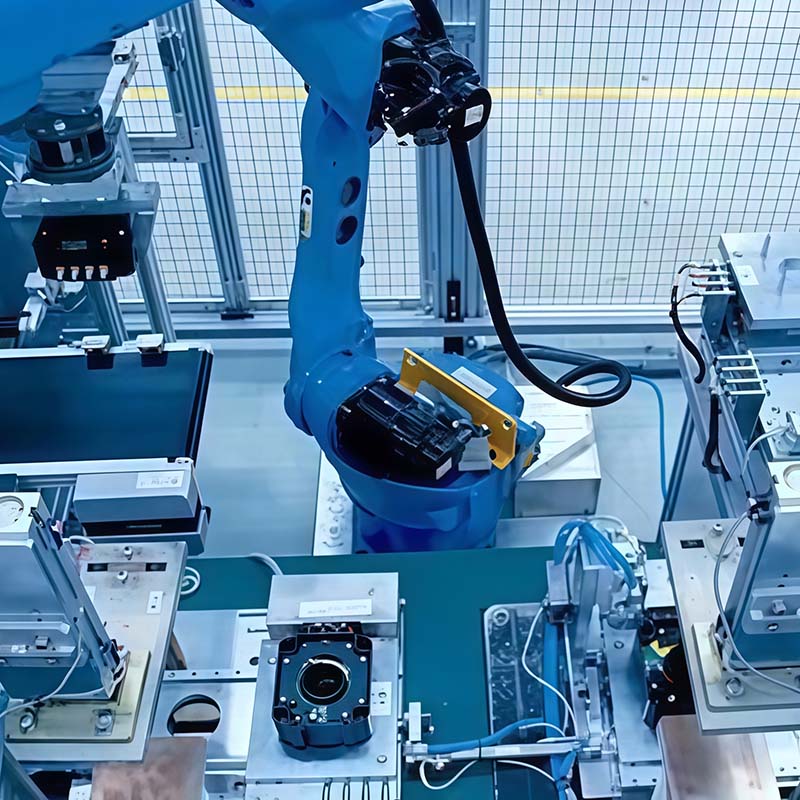

- In the electronics industry, such as computer rooms, data processing centers, and laboratories.

- In AGV factories.

- In areas with anti – static requirements.

2. Technical Specifications

| Project | Value | Test Standard |

| Condition in Container | Uniform state after stirring, without hard lumps | Visual inspection |

| Compressive Strength (7d) / MPa | ≥40 | GB/T 22374 – 2018 |

| Flexural Strength (7d) / MPa | ≥10 | GB/T 22374 – 2018 |

| Abrasion Resistance (500g/100r) / g | ≤0.15 | GB/T 22374 – 2018 |

| Slip resistance (dry COF) | ≥0.6 | GB/T 22374 – 2018 |

| Tensile Bond Strength / MPa | ≥2.0 | GB/T 22374 – 2018 |

| Impact Resistance (1000g Steel Ball) | No cracks or peeling on the surface | GB/T 22374 – 2018 |

| Water Resistance (168h) | No blistering, peeling, cracking, or discoloration | GB/T 22374 – 2018 |

| Alkali Resistance (20% NaOH, 24h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Acid Resistance (10% H₂SO₄, 48h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Oil Resistance (120# Solvent Oil, 72h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

| Salt – Water Resistance (3% NaCl, 168h) | No blistering, peeling, or cracking; slight discoloration is allowed | GB/T 22374 – 2018 |

The values provided in this document are typical test values. The specific data may vary slightly due to different environmental conditions. For our company’s products, the listed data have no binding force in legal terms.

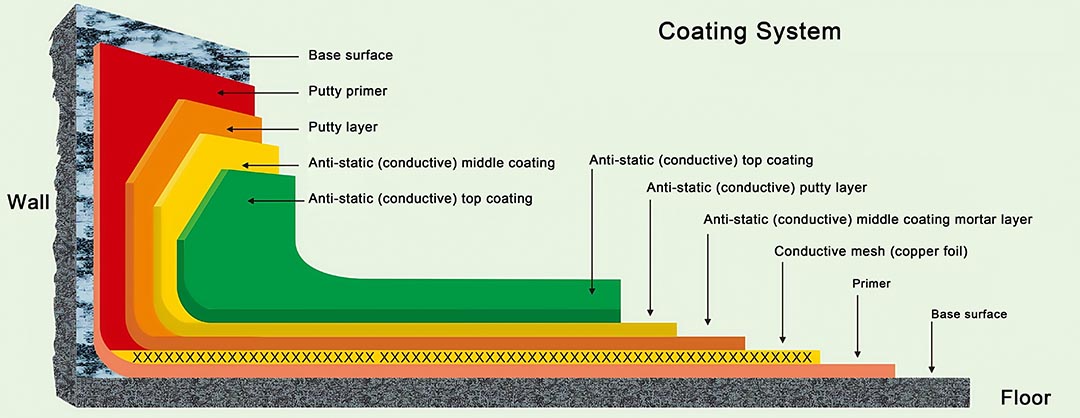

3. Surface Treatment Application Guidelines

Construction Conditions

Mixing Protocol:

| Step | Component | Ratio | Mixing Parameters |

|---|---|---|---|

| 1 | A+B+D | 3.01:3.07:var | 300rpm/2min @15-35°C |

| 2 | Add C | 10 parts | 800rpm/4min |

| 3 | Add E | 0.031 parts | 300rpm/1.5min |

- After determining the stirring time, it should be kept consistent throughout the construction process. Inconsistent stirring time for each group may cause differences in surface color and texture.

- During the mixing process, use a straight – edge trowel to scrape the raw materials adhering to the sides and bottom of the container. This operation should be carried out at least once to ensure complete mixing.

- Only the raw materials in the factory – packed containers need to be fully mixed. Temperature will affect the construction time and product curing time.

- Different mixing machines may lead to differences in fluidity. It is recommended to use the recommended mixing head for mixing.

Installation:

Base coat: 1-1.5kg/m², cure 24h @20°C. The lower the temperature, the longer the curing time.

If the primer coating has been applied for more than 72 hours or is contaminated, it is necessary to sand and vacuum the surface again before constructing the surface coating.

Top coat: 2.5-3kg/m², trowel-applied with 4kg/m² minimum for flatness.

Walkability: 24h, full cure 7 days.

Note: The drying time is measured under standard conditions (25°C, 60% humidity) and is for reference only. The drying speed varies greatly under different temperatures and humidities, and is also affected by factors such as film thickness, ventilation conditions, and underlying coatings. Generally, the drying time shortens as the temperature rises and lengthens as the temperature drops.

Before formal project construction, the buyer must conduct tests in an environment consistent with the construction conditions to ensure the reliability of the coating system for the specific project. Formal construction is regarded as the buyer’s recognition of the product’s performance inspection. If the above operations are not followed, all responsibilities shall be borne by the buyer.

4. Packaging & Storage

| Component | Package | Qty | Shelf Life |

|---|---|---|---|

| A | Plastic pail | 3.01kg | 12 months |

| B | Plastic pail | 3.07kg | 12 months |

| C | Composite bag | 10kg | 6 months |

| D/E | Pouched | 0.2-1kg | 12 months |

Storage: 5-35°C in dry, ventilated area. Away from high temperatures and fire sources.

Shelf Life: Starting from the production date, under the required storage conditions, the shelf life of Component A and Component B in their original packaging is 12 months, and that of Component C is 6 months.

5. Safety & Compliance

PPE Requirements:

NIOSH-approved respirator (OV cartridges)

Chemical goggles + face shield

Butyl gloves + Tyvek suits

First Aid:

Skin: Soap/water → polyethylene glycol if polymerized

Eyes: 15-min flush → immediate medical attention

Fire Rating:

NFPA 704: 0-1-0

Extinguishing: CO₂/dry chemical (no water jets)

Leakage and Spillage Treatment

Disclaimer

Specifications are based on current technical knowledge. Users must verify suitability for intended applications. We assume no liability for indirect losses from downstream processing.

For full SDS or technical support, contact our customer service.

Technical Support:

Wanhua Energy Conservation Technology (Yantai) Co., Ltd.

Address: No.56 Taiyuan Road, Yantai, Shandong 264006, China

Tel: +86-400-059-1116 | Fax: +86-17761309662

| Weight | 301307 kg |

|---|