Wanhua Energy-Saving WANPANEL®Series

Color coated steel sheet

Color-coated steel sheets are products made on a continuous unit using cold-rolled steel strips, galvanized steel strips (electro-galvanized, hot-dip galvanized, etc.) as substrates, after surface pretreatment (degreasing, cleaning, chemical treatment, etc.), coating with liquid coating by roller coating, and then baking and cooling. Color-coated steel sheets have the advantages of good corrosion resistance, bright colors, beautiful appearance, easy processing and forming, and the original strength of steel sheets, and low cost.

Types of color-coated substrates for construction

Alu-zinc substrate

Excellent corrosion resistance, suitable for making building exterior panels, can be processed at various levels such as general forming, mechanical biting, etc.

Hot-dip galvanized aluminum-zinc substrate

The coating composition is roughly 55% aluminum, 1.5% silicon, and the rest is zinc. This substrate has excellent corrosion resistance and is suitable for making building exterior panels. It can be processed at various levels such as general forming, stamping, and deep stamping.

Hot-dip galvanized aluminum substrate

The coating composition is 5% aluminum, 0.1% mixed rare earth elements, and the rest is zinc. The substrate has excellent corrosion resistance, good plating forming properties, and good coating and welding properties.

Electroplated zinc substrate

The coating has high purity, good corrosion resistance, thin zinc layer, and good processing performance. It is suitable for making home appliances, steel windows or indoor partitions, etc.

Types of coatings

Primer

Primers are divided into polyester primers, polyurethane primers, epoxy primers, etc. according to different film-forming resins. Commonly used are epoxy primers and polyurethane primers, which are processed and manufactured with anti-rust pigments such as zinc chrome yellow and strontium chrome yellow.

Topcoat

Generally, polyester resin (PE), high-durability polyester resin (HDP),

silicon-modified polyester resin (SMP), polyvinylidene fluoride resin (PVDF), acrylic resin, polyurethane are used. Thermosetting cross-linking curing system uses methyl ether amino resin or blocked isocyanate resin, and pigments with good high temperature resistance and weather resistance are selected.

Backcoat

Currently, it can be divided into 2/1, 2/2, and 2/1M systems in China.

2/1 system: The back can be coated with a layer of primer or only a layer of back paint. It is mainly used for sandwich panels and requires the coating to have good bonding and foaming properties.

2/2 system: A two-coat system of primer and back paint is used. Foaming properties are generally not required. It is used as a single board.

2/1M system: Generally, 3 microns of primer and 6 microns of back paint are applied. It can replace 2/1 and requires the back to be able to foam.

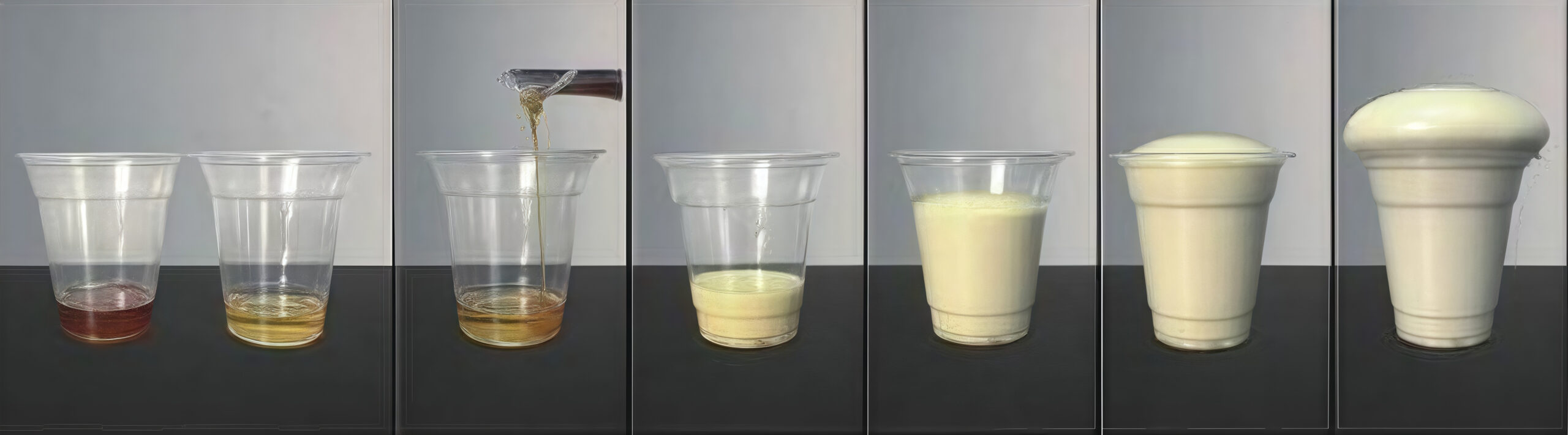

Introduction to PIR

PIR(Polyisoeyanurate Foam)is the abbreviation of polyurethane modified isocyanurate foam, which is a kind of Foam with typical carbon and nitrogen hexagonal rigid heterocyclic structure.

PIR is an ideal organic low temperature heatinsulation material with low thermal conductivity,light weight and strong adaptability,which is widely used in the fieldof thermal insulation in cold storage, construction,oil refinery,chemical plant.

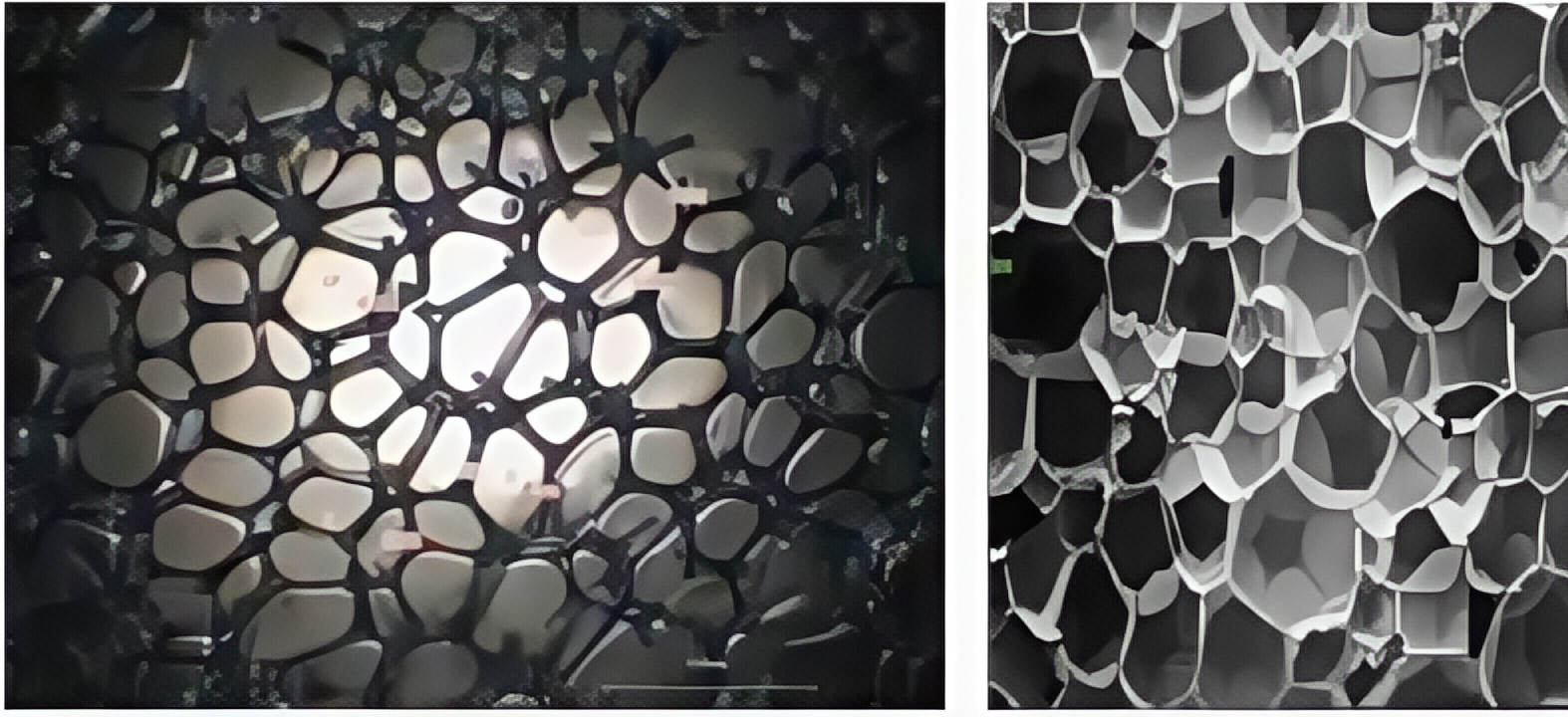

The molecular structure

Microscope photo of foam macrostructure

Characteristics of polyurethane modified isocyanurate foam

Good resistance tolow temperature and heat

PIR foam can be used at-196℃~+160℃ for a long time,and can withstand temperatureup to 200℃ in a short timewith the size change rate<1%.

Good flame penetration resistance

The thickness of 2.5cm PIR foam board can be burmed through by propane flame for 30min,while the same thickness of polyurethane sheet will be bumed through with a few minutes.

Low smoke when burning,good flame-retardant performance

Compared with polyurethane foam, polyurethane modified isocyanate foam has better ignition resistance, flame spread resistance and burnout resistance.When burning,a solid carbonized surface with less smoke will be formed quickly.

Low water absorption

PIR foam has higher closed cell rate and lower water absorption than polyurethane foam.

High stability

Due to the different molecular structures, PIR foam contains more polyisocyanurate chains, which are more stable to heat and most chemical reagents. And the isocyanurate chains have excellent temperature resistance and dimensional stability.

Product

●Cold storage board

01 Single slot type

02 Double slot type

03 Hook lock box type

04 Hook lock box frame type

●Building roof

1.PIR roof board

●Clean board

01 PIR clean board

●Building wall board

01 PIR seamed wall board

02 PIR seamless wall board

03 PIR internal partition board

●Rock wool and PIR double sandwich board

01 1+1 rock wool and PIR double sandwich board

02 2+1 rock wool and PIR double sandwich board

Rock wool (glass wool) sandwich board

●Building wall board

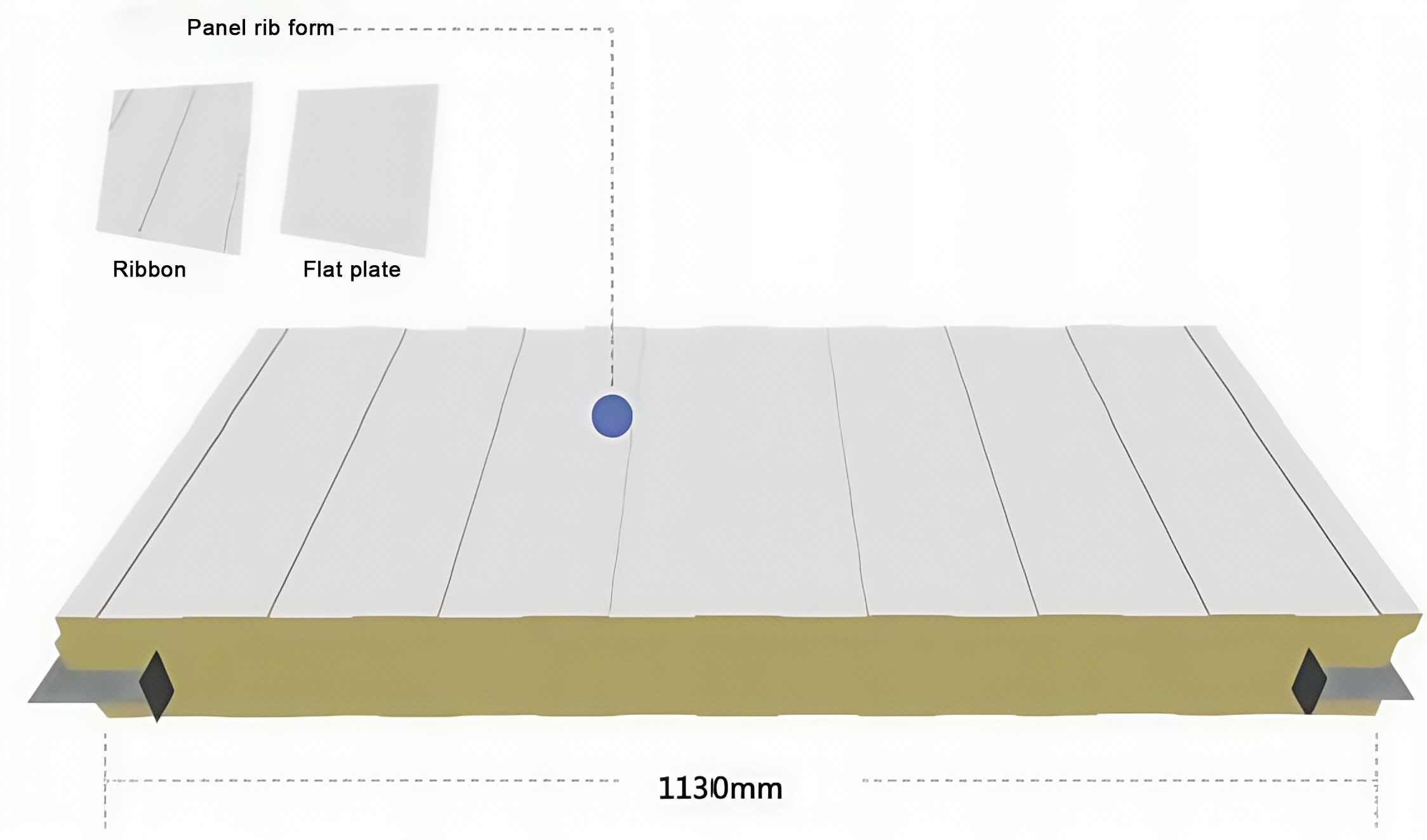

01 Rock wool (glass wool) seamed exterior wall board

02 Rock wool (glass wool) seamless exterior wall board

03 Rock wool (glass wool) internal partition board

●Building roof board

01 Rock wool (glass wool) roof board

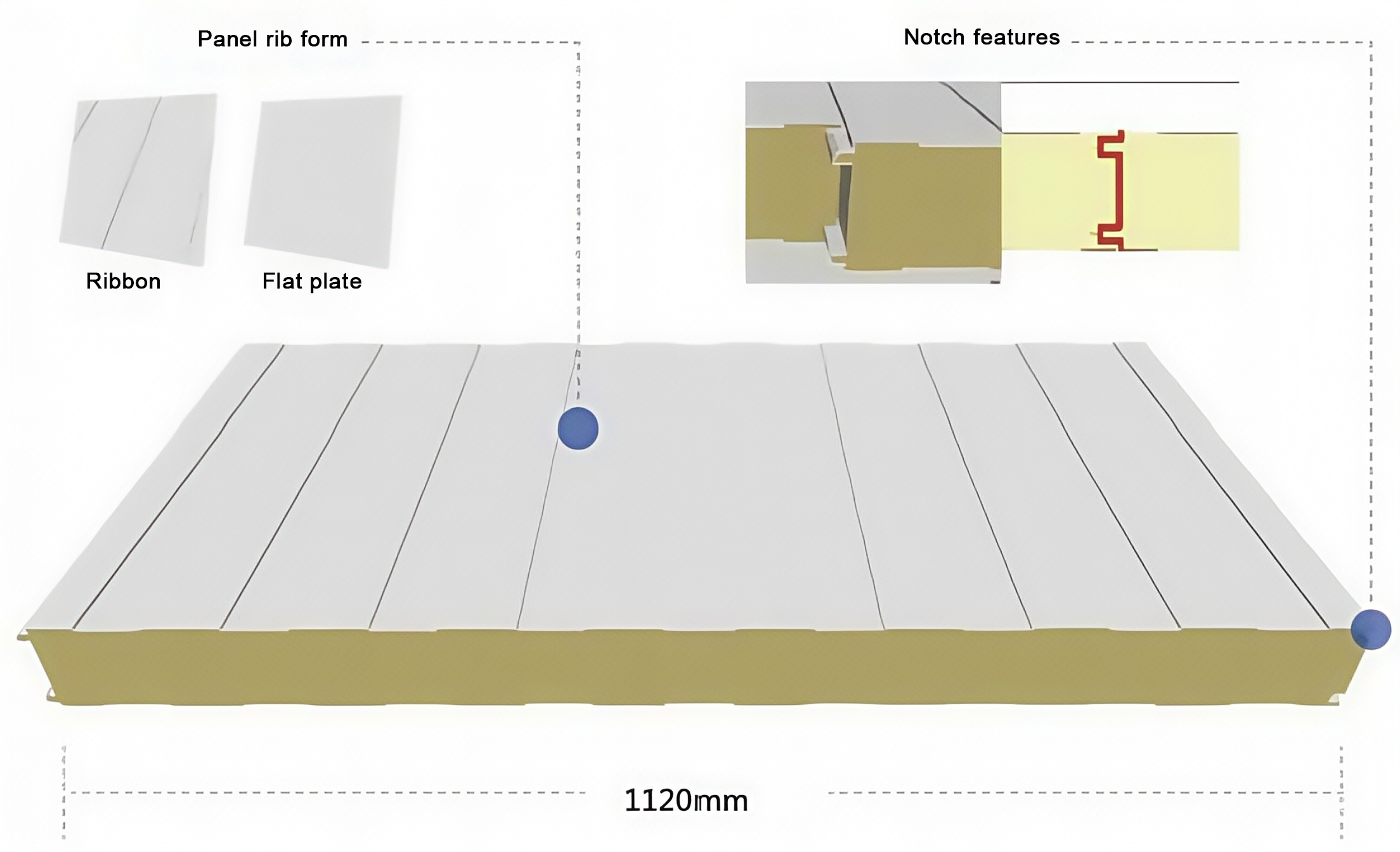

Single slot cold storage panel

Concaveand convex groove structure design improvesthe insulation andair tightness of the plate joints,which isspecially designed for the refrigerated room and warchouse.The steel plate wraps the groove sothat the groove is noteasy to be damaged,deformed anddetached,and thebending strength is increased at the same time.

Product Technical Parameters

| Sandwich panel thickness (mm) 50, 100, 150, 200 |

Temperature difference between inside and outside the warehouse (℃) 20, 30, 40, 55 |

Wall panel simply supported height (m) 3, 3.8, 4.2, 5 |

| Top plate simple support height (m) 2.5, 3, 3.6, 4.2 |

Plate weight (kg/m2) 10, 12.5, 15, 17.5 |

Flame retardant grade B1, B2 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

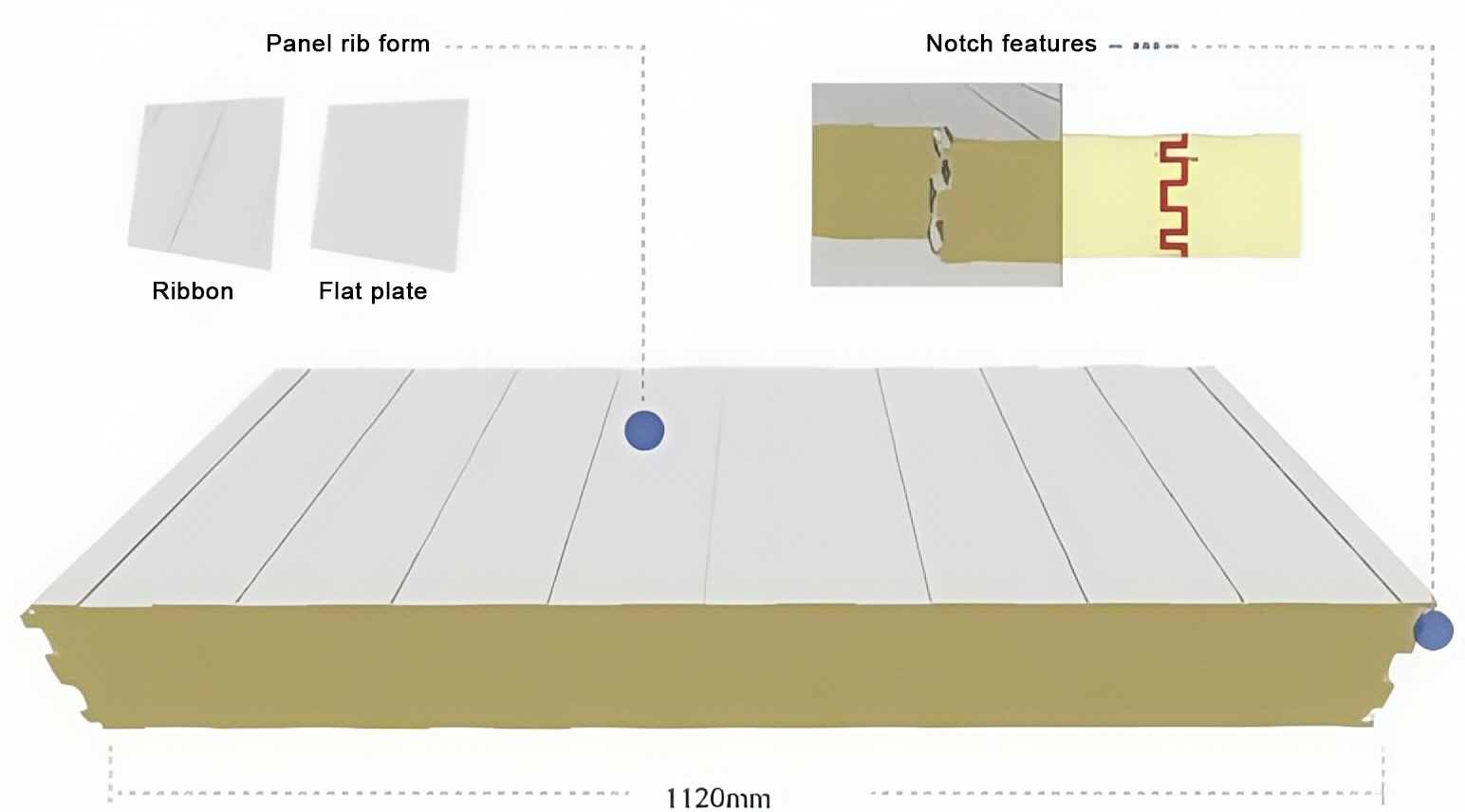

Double slot cold storage panel

Double notch makes theplate uniformand stable,with better hea insulationperformance,waterproof performance,which islight andexquisite and able tosolve the temperature difference of coldstorage industry effectively.

Product Technical Parameters

| Sandwich panel thickness (mm) 150, 200,250 |

Temperature difference between inside and outside the warehouse (℃) 40, 55,70 |

Wall panel simply supported height (m) 3.8, 4.2, 5 |

| Top plate simple support height (m) 3.6, 4.2,5 |

Plate weight (kg/m2) 15, 17.5,20 |

Flame retardant grade B1, B2 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

Hook lock box cold storage panel

The hook lock box cold storage plate iseccentrichookplate,which isdesigned for assembling small and medium-sized cold storageand heat insulation room,boxbody.Each precast boardis surrounded by ahigh strength lock,which is very convenient toassemble.

Product Technical Parameters

| Sandwich panel thickness (mm) 50, 100, 150, 200 |

Temperature difference between inside and outside the warehouse (℃) 20, 30, 40, 55 |

Wall panel simply supported height (m) 3, 3.8, 4.2, 5 |

| Top plate simple support height (m) 2.5, 3, 3.6, 4.2 |

Plate weight (kg/m2) 10.6 、13.1 、15.6 、18.1 |

Flame retardant grade B1, B2 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

Hook lock box frame cold storage panel

Linkedby hook lock tightly,the boardhas good insulationperformance and high strength.Within a certain module,the cold storage can be freely changed in three directionsof length,width and height,andcan be expanded or reduced according to the need.The assembled plate canalso be disassembledandreasembled in different places.

Product Technical Parameters

| Sandwich panel thickness (mm) 50, 100, 150, 200 |

Temperature difference between inside and outside the warehouse (℃) 20, 30, 40, 55 |

Wall panel simply supported height (m) 3, 3.8, 4.2, 5 |

| Top plate simple support height (m) 2.5, 3, 3.6, 4.2 |

Plate weight (kg/m2) 10.6 、13.1 、15.6 、18.1 |

Flame retardant grade B1, B2 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

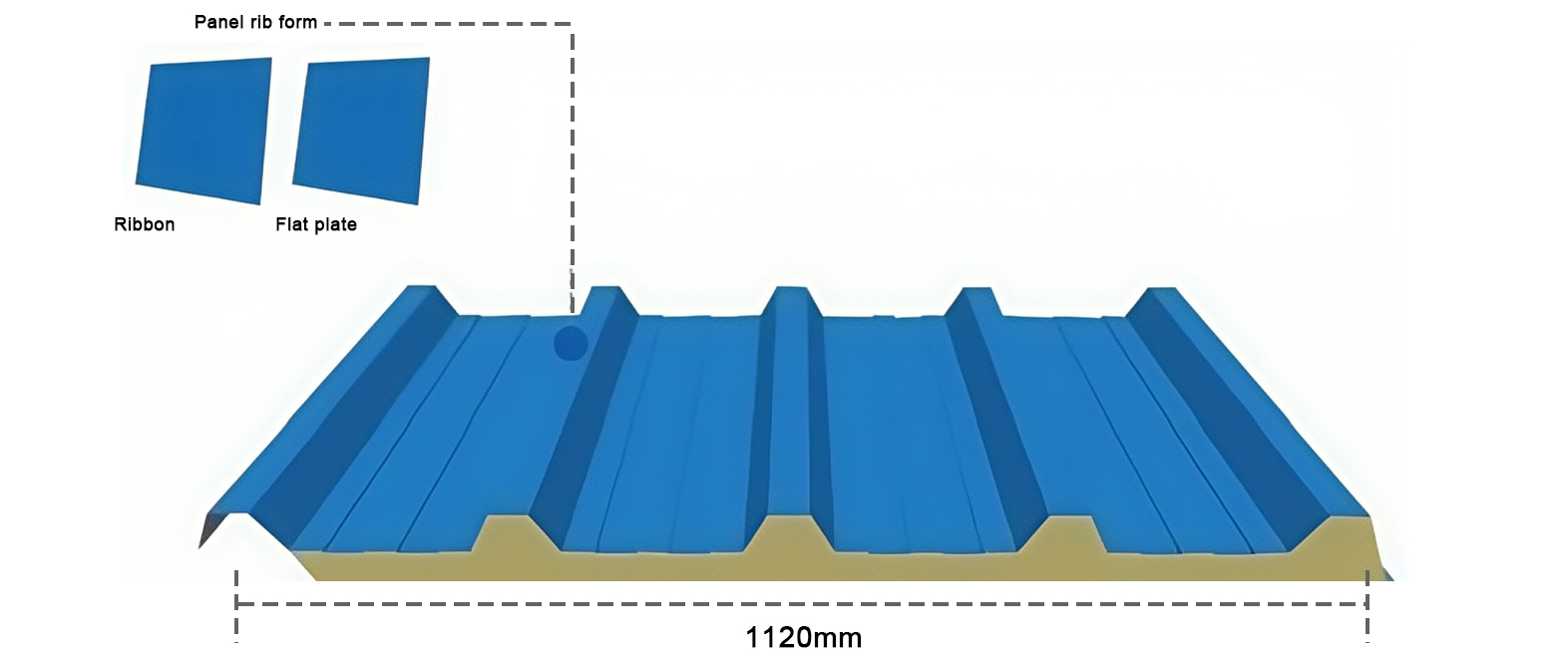

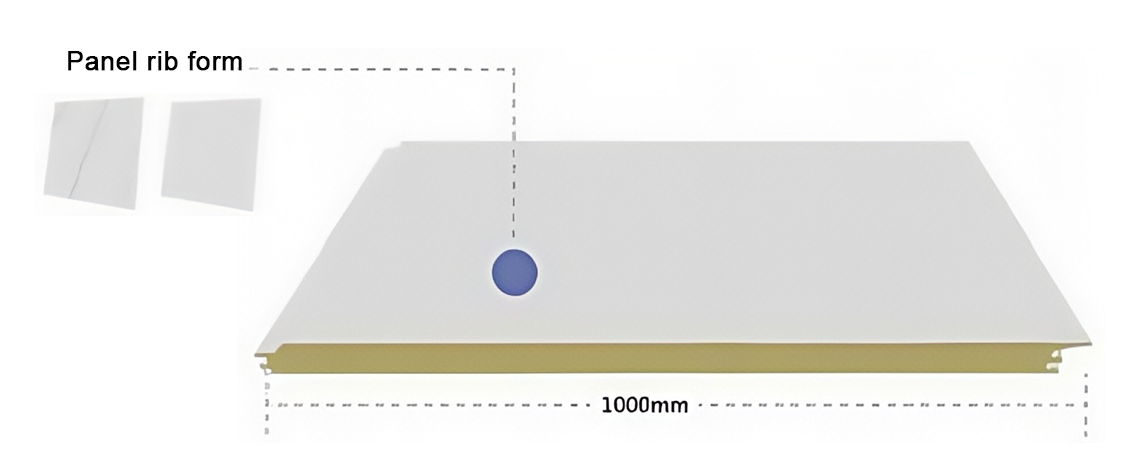

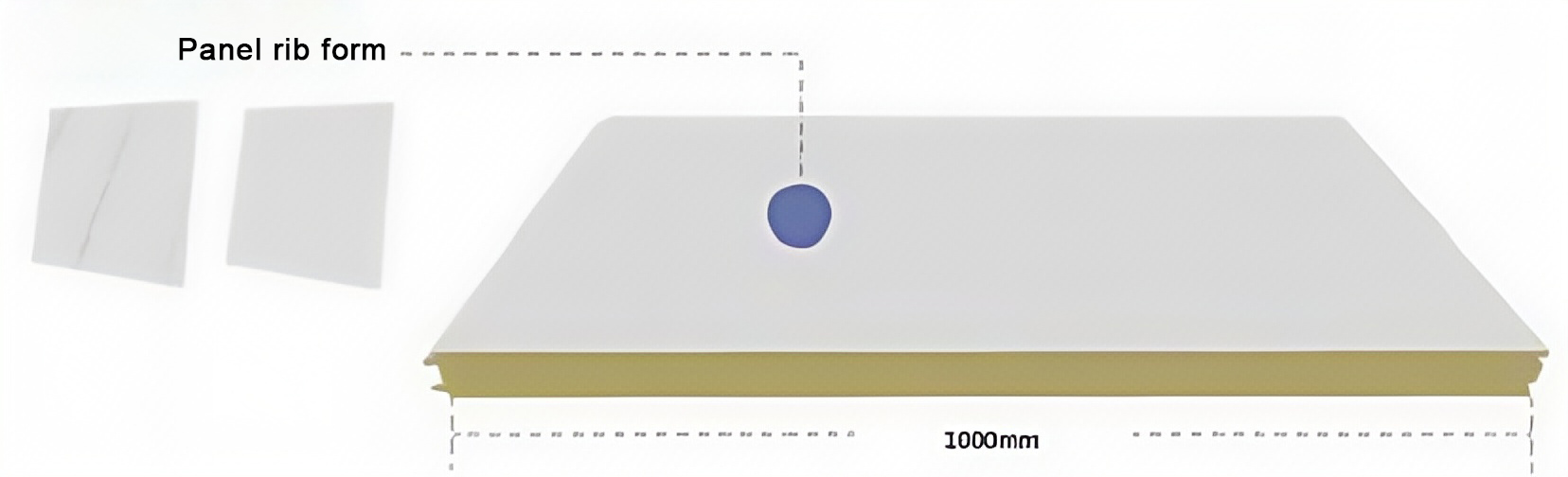

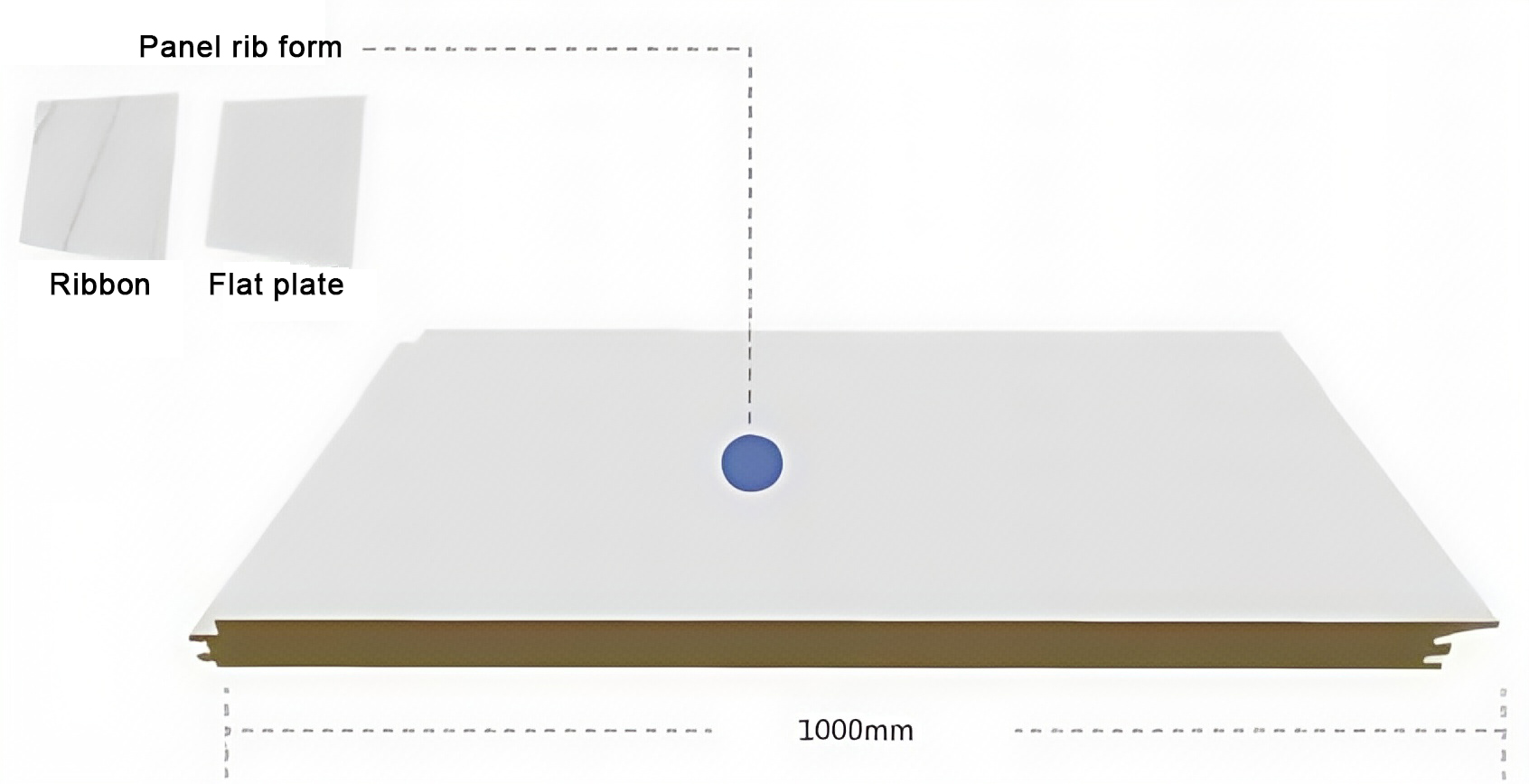

PIR roof board

Unique water-proof design can effectivelyprevent rainwaterleakageand avoid the phenomenon of cold bridge.

The peak heightof40mm can greatly improve the drainage effeet and bearing capacity of the roof,and effectively reduce the construction cost while cnsuring thethermal insulation effect of the building.The roofslope can reach 3%.

Product Specifications

| External steel plate | Thickness (mm): 0.4-0.8 |

| Coating: HDP/SMP/PE | |

| Titanium steel plate thickness (mm): 0.4/0.5/0.6 Coating: SMP/PE | |

| Plate thickness: 50, 100, 150 Plate width (mm): 1000 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

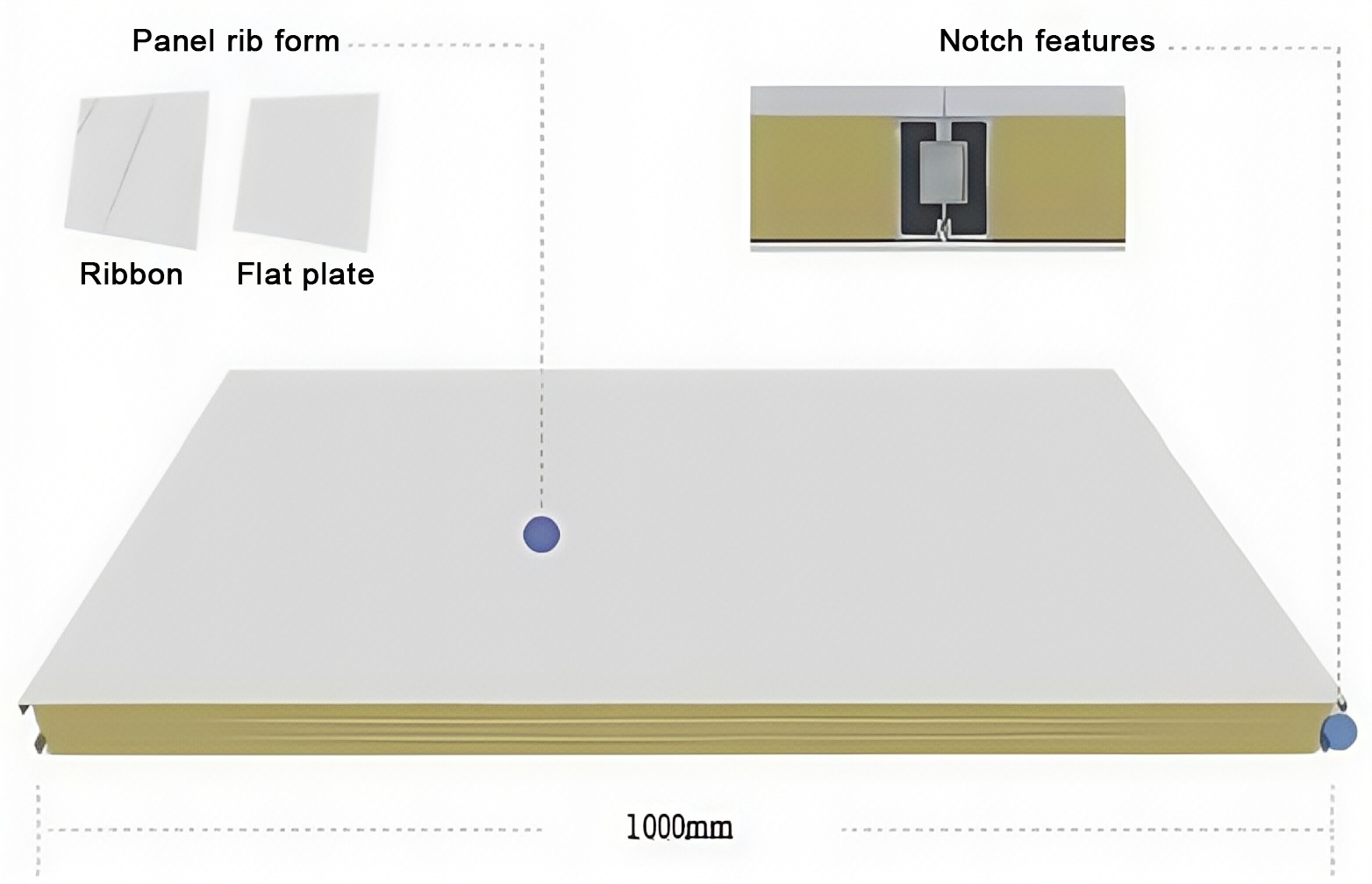

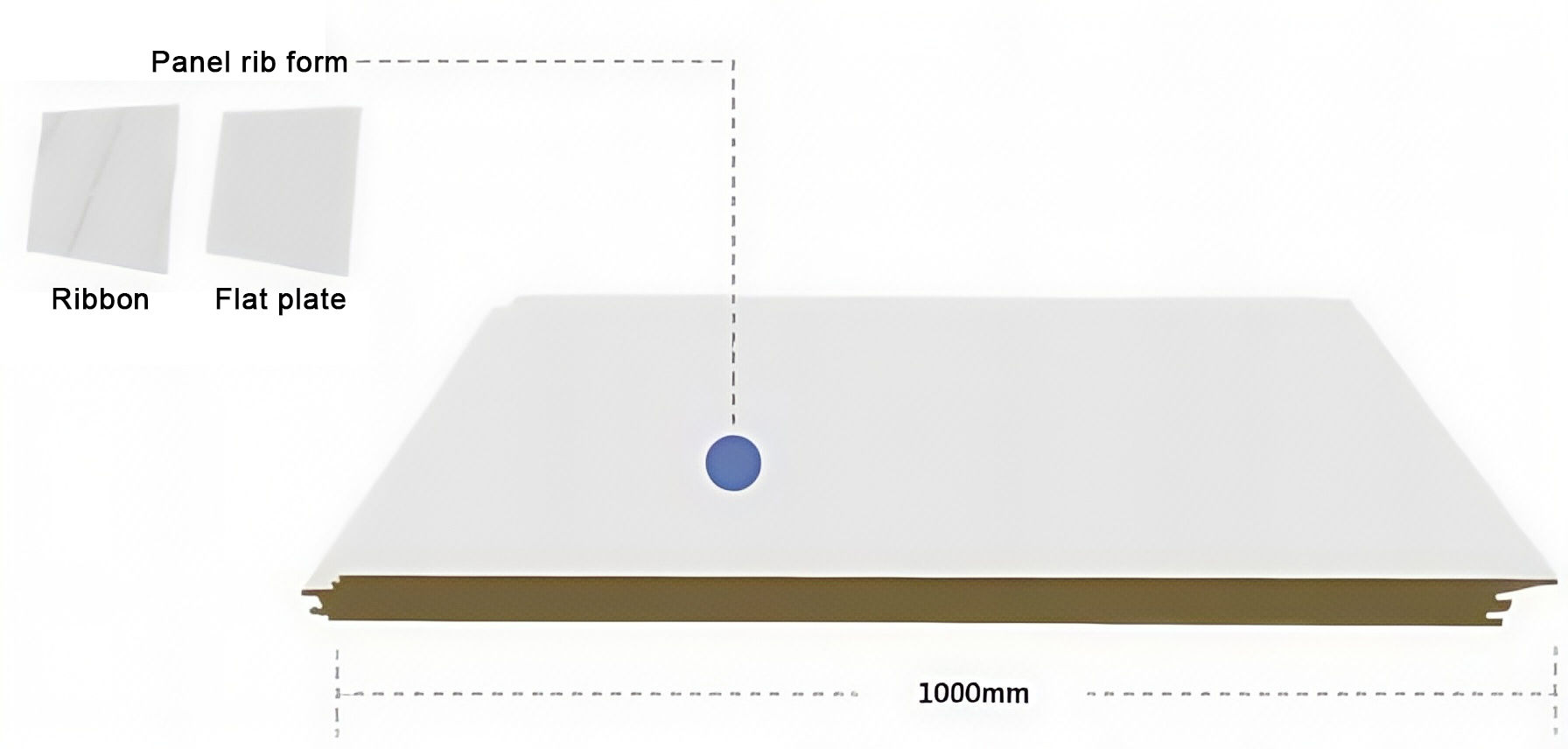

PIR Clean Board

Purification board has unique dustproof,anti-static,antibacterial and other effects,can be widely used in electronics, pharmaceutical,food,biological and other clean engineering fields

Product Specifications

| External steel plate | Thickness (mm): 0.4-0.8 |

| Coating: HDP/SMP/PE | |

| Titanium steel plate thickness (mm): 0.4/0.5/0.6 Coating: SMP/PE | |

| Plate thickness: 50, 100, 150 Plate width (mm): 1000 |

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

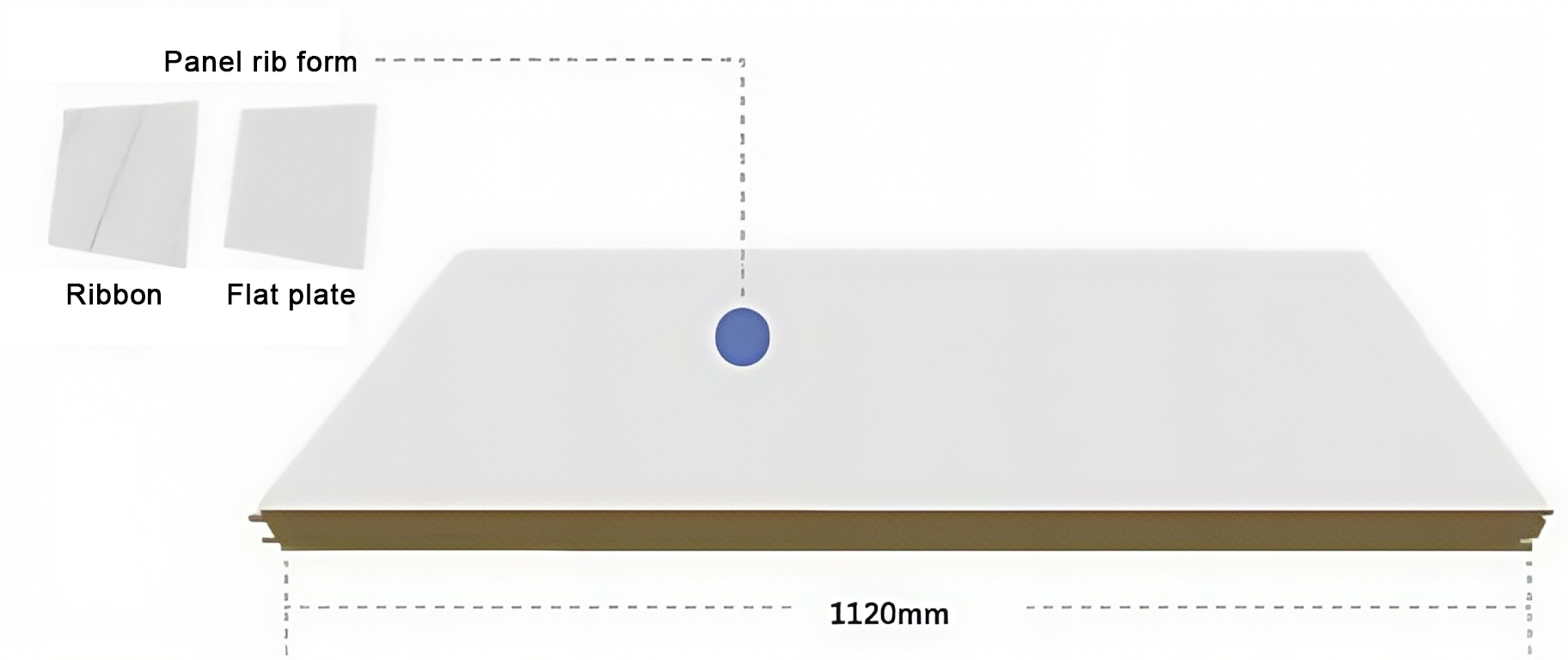

PIR Seamed External Wall Panel

Using polyurethane side sealing technology and the board has excellentfire and moistureresistance performance.

Curtain wall effect can be presented with the technology of enterprise mouth.

Light board,high steel,saving external wall keel.Curtain wall effect canbe presentedwith the technology of enterprise mouth.

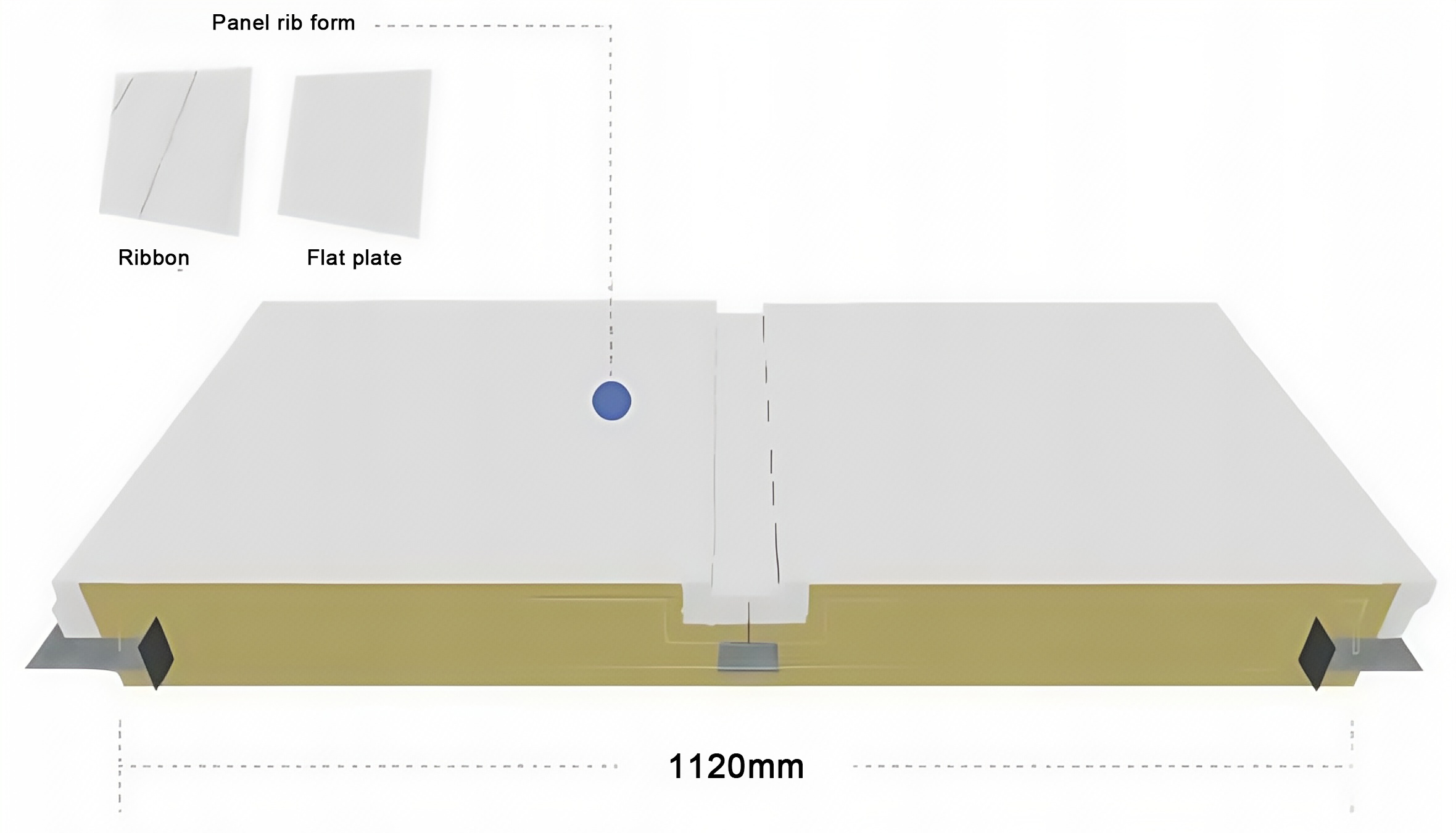

PIR seamless exterior–wall panels

The polyurethane wall panel is fixedon the strip by tapping screw and connected by hidden nailtype plug.

Used for extermal wall transverse fiting and longitudinal fiting.

Unique water-proof design can effectively prevent rainwater leakage of longitudinal-fitted plate.

PIR Interior Partition Panels

Used for indoor partition or ceiling ,Lightboard,high steel,saving external wallkeel.

Meethe cument bulding design fire protecion codeGB/50016-2014poburethane surface non emptygunAdassfie materialetemal protection requrements

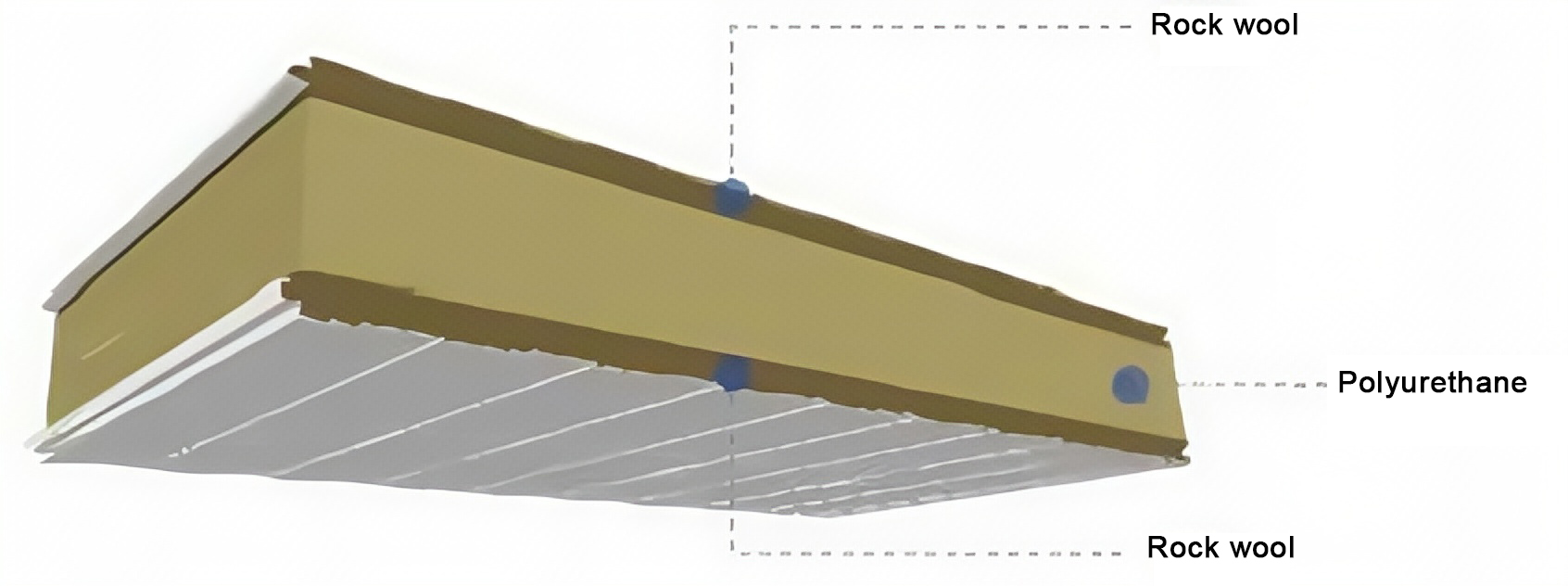

1+1 rock wool PIR double sandwich panel

Excellent fireandmoisture resistance of sheetmetal.

Combining thermal insulation of polyurethane with non-flammability of rock wool can effectively isolate heat and smoke fromfire and prevent fire spreading.

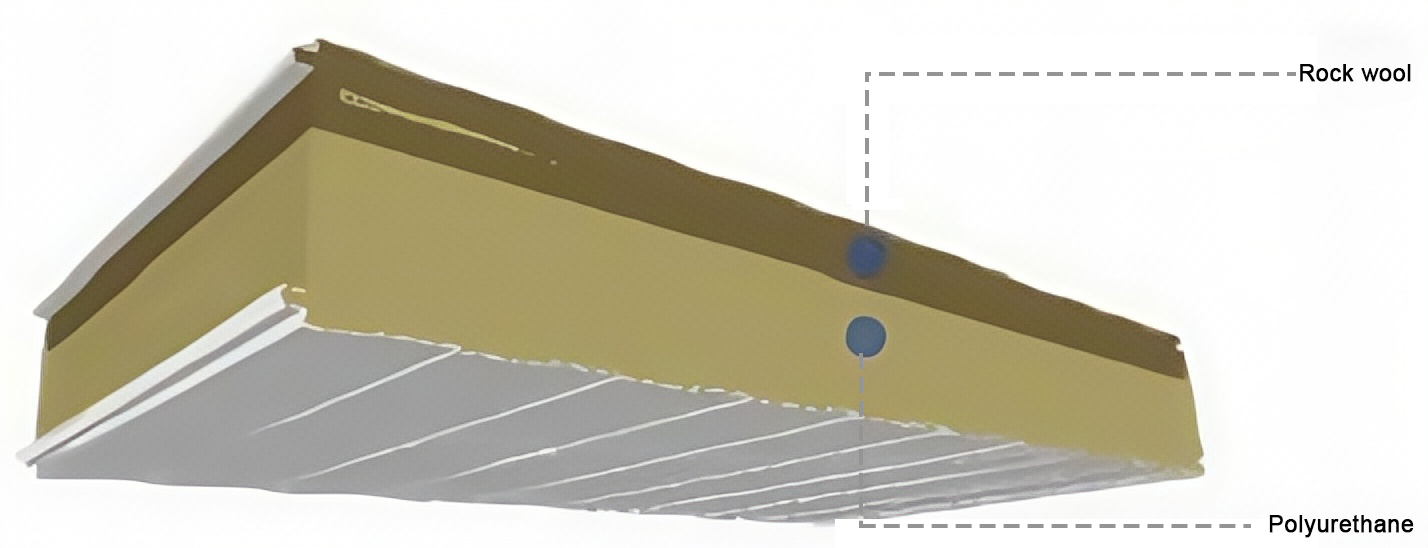

2+1 rock wool and PIR double sandwich board

Excellent fire andmoistureresistance of sheetmetal.

The upper and lowerlayersof non-combustible,high-temperature resistant rock woolare filled with heat-insulating polyurethane,which caneffectively isolateheatand smokefrom fireand prevent firespreading.

Rock wool (glass wool)seamed exterior–wall panel

Using polyurethane side sealingtechnology and the boardhas excellent fire andmoistureresistance performance.

Used for externalwall transverse fiting,adjustable plate seam.

Curtain wall effect can be presented with the technology of enterprise mouth.

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

Rock wool(glass wool)seamless exterior–wall panel

Using polyurethane side sealing technology,theboard has excellent fireand moisture resistanceperformance.

Used for extermal wall transverse fitting and longitudinal fiting.

Unique water-proof designcan effectively prevent rainwater leakage of longitudinal-fited plate.

*Specific colors such as pure white, white gray, silver gray, blue, red, orange, etc. are subject to the actual product

Rock wool(glass wool)parition wall board

Non-combustible,fire gradeA.

Used for indoor partition or ceiling.

Excellent hydrophobic performance,agingresistance.

Excellent insulation performance.

Sound absorption and noise reduction.

Biodegradable,environmental protection.

High acidity coefficicnt,greatly reduce the corrosion of metal.

Rock wool (glass wool)roof board

Non-combustible,fire grade A1.

The peak heightof 40mm can greatly improve the drainage effect andbearing capacity of the roof,and effectively reduce the construction cost while ensuring the thermal insulation effect of the building.The roof slope can reach 3%.