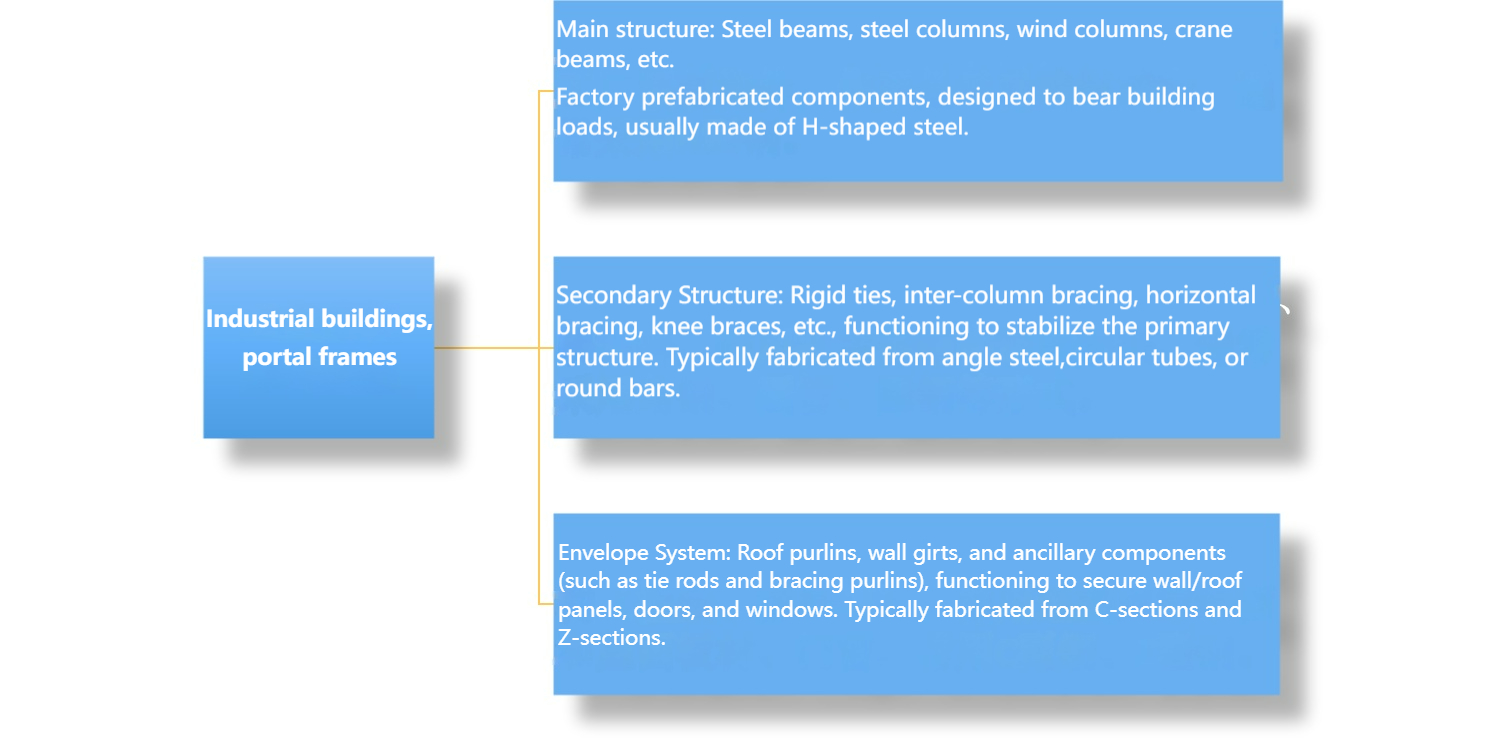

Structural Requirements for Portal Rigid Frames

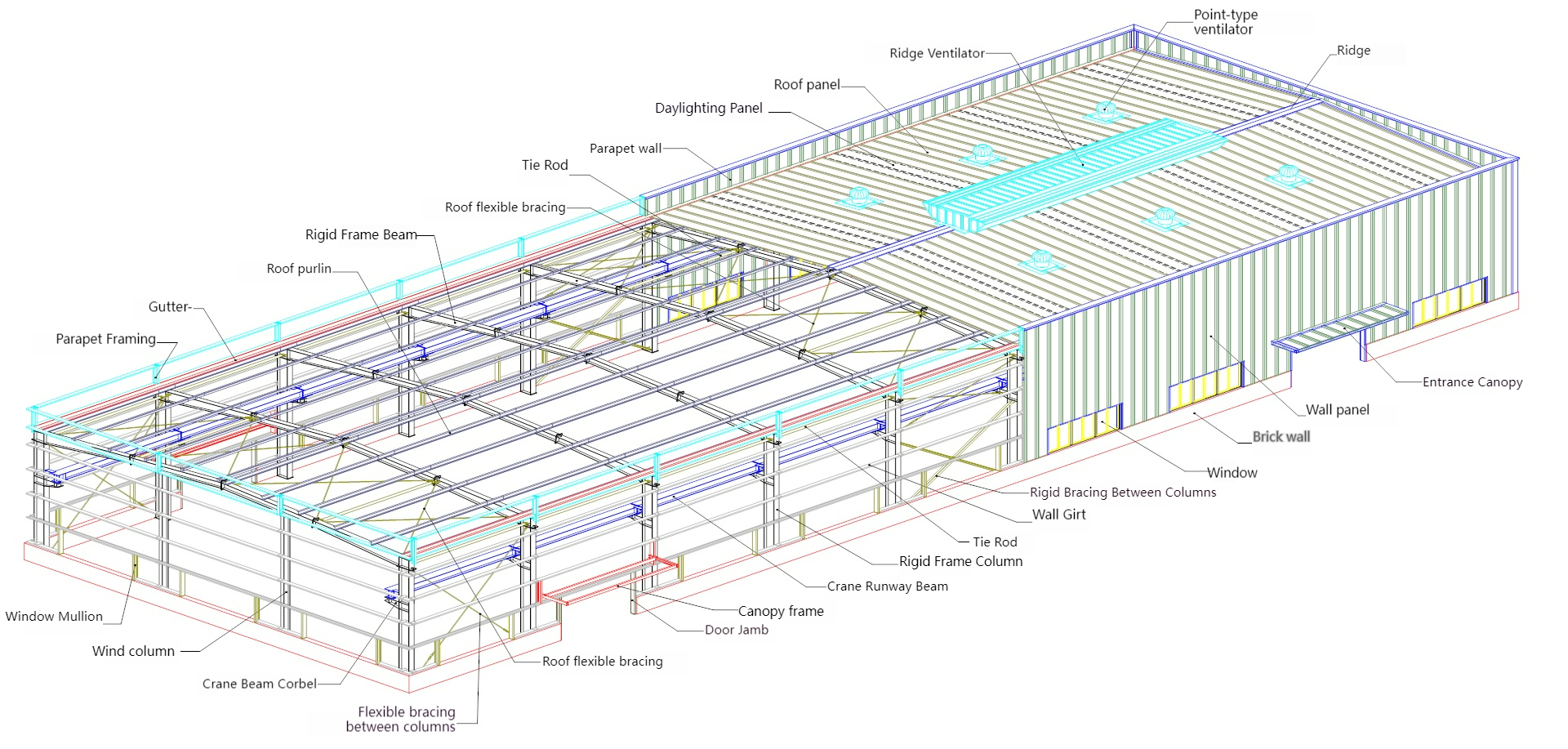

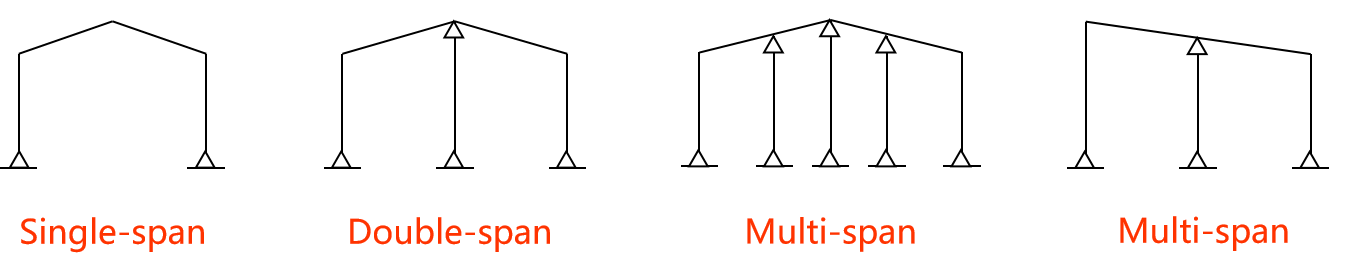

1.Span: Distance between steel column axes; 18~36m for single-span, not exceeding 48m.

2.Column Spacing: Distance between adjacent rigid frames; 6~9m, not exceeding 12m.

3.Eaves Height: Height of the top of side steel columns; 4.5~9m, not exceeding 15m.

4.Roof Slope: Inclination angle for drainage; 5%~20%.

5.Crane Capacity: For portal rigid frames, crane lifting capacity should not exceed 20 tons (medium-duty service).

1.Light Total Building Weight: Approximately half the weight of concrete buildings, reducing the cost of foundation engineering.

2.Good Plasticity and Toughness, Excellent Seismic Performance: Steel’s plasticity prevents sudden fracture due to overloading; its ductility enhances adaptability to dynamic loads. Post-earthquake investigations (Tangshan and Wenchuan) show minimal damage to all-steel structures even in high-intensity earthquake zones.

3.Strong Architectural Flexibility: Meets requirements for large spans and high clear heights; truss or grid structures enable aesthetic and comfortable designs.

4.Fast Construction Speed: All steel components are prefabricated in factories, with on-site bolting or welding and modular construction, shortening the construction period by over 1/4.

5.Good Environmental Performance: Steel is recyclable, reducing construction waste.

1.Poor Fire Resistance: The stress of carbon structural steel decreases rapidly when the temperature exceeds 300-350℃, leading to safety accidents.

2.Poor Corrosion Resistance: Steel rusts when exposed to air, water, and oxygen, reducing its service life.

3.Slightly Higher Material Cost: The per-square-meter cost of steel is 10%~20% higher than that of concrete structures, but labor and time costs need to be considered comprehensively.

4.Building Energy Efficiency Issues: Steel is a good thermal conductor (thermal conductivity: ~40~50W/(m·K)) with lower airtightness than concrete buildings, requiring extra attention to thermal insulation for residential buildings.

5.Limited Application Scope: Suitable for single-story industrial buildings, multi-story frames, and some super high-rises; not cost-effective for low-to-medium high-rises.

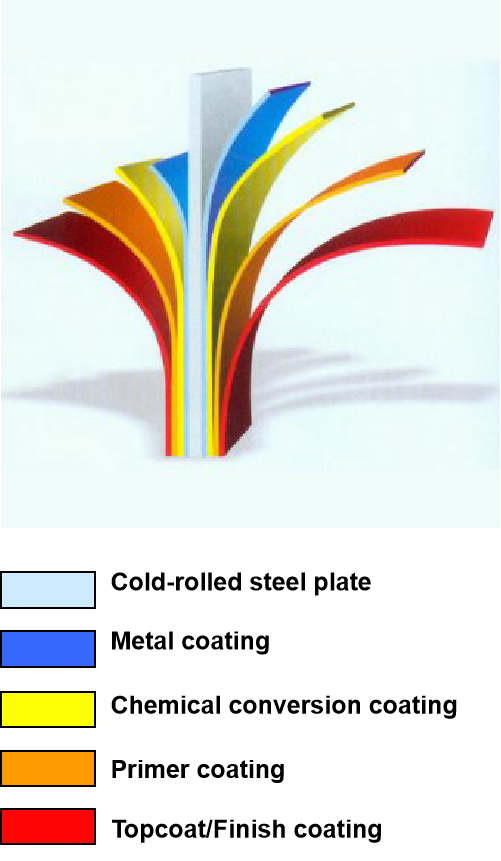

Color-coated steel sheet (also known as color plate) uses cold-rolled steel plate (surface-coated with an anti-corrosive layer) as the substrate. After surface pre-treatment (including degreasing and chemical conversion), one or more layers of differently colored organic coatings are applied via roller coating. The sheet is then formed by baking and cooling.

1、Substrate: Color-coated steel sheet substrates typically have a thickness range of 0.4mm to 0.8mm, with a yield strength of 220MPa to 550MPa.

2、Coatings: Common types include hot-dip aluminum-zinc alloy coated, hot-dip galvanized, and hot-dip zinc-aluminum-magnesium alloy coated. Hot-dip galvanized: Denoted by the letter "Z", with a typical range of 60–275 g/m² (both sides). Hot-dip aluminum-zinc: Denoted by the letter "AZ", with a typical coating weight range of 80–180 g/m² (both sides). The alloy composition comprises 55% aluminum, 43.5% zinc, and 1.6% silicon. Hot-dip zinc-aluminum-magnesium:Denoted by the letter "ZM", with a typical coating weight range of 70–180 g/m² (both sides). The alloy composition comprises zinc supplemented with 11% aluminum, 3% magnesium, and trace amounts of silicon.

3、Coating process: After chemical pre-treatment, paint is applied in two coating stages. The film thickness requirement is ≥20μm on the front side and ≥5μm on the back side. The process is categorized into: Two-coat one-bake (2/1), Two-coat two-bake (2/2). In metal sandwich panels, the 2/1 process is commonly used as the primary material.

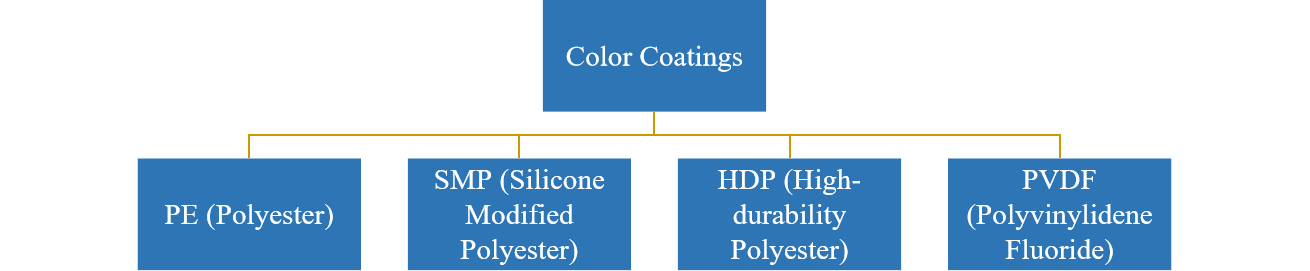

1、PE (Polyester): Offers excellent adhesion properties and ease of processing, with relatively low cost. It provides wide options for colors and gloss levels, but exhibits moderate durability, typically with a service life of 5–8 years. It is readily available in stock.

2、SMP (Silicone Modified Polyester): Compared to polyester coatings, it provides enhanced weather resistance, thermal stability, and anti-aging performance. Priced higher than PE, it typically offers a service life of 10 years and requires custom production.

3、HDP (High-durability Polyester): Enhanced with ultraviolet absorbers and hindered amine light stabilizers (HALS) to achieve exceptional long-term weatherability. Priced higher than SMP coatings, it typically offers a service life of up to 15 years and is typically custom-ordered.

4、PVDF (Polyvinylidene Fluoride): Offers superior weather resistance, melt resistance, corrosion resistance, wear resistance, and UV resistance, along with excellent processability. However, it has the highest cost and limited color options. Its typical service life reaches 20 years, but it is rarely available as stock material.

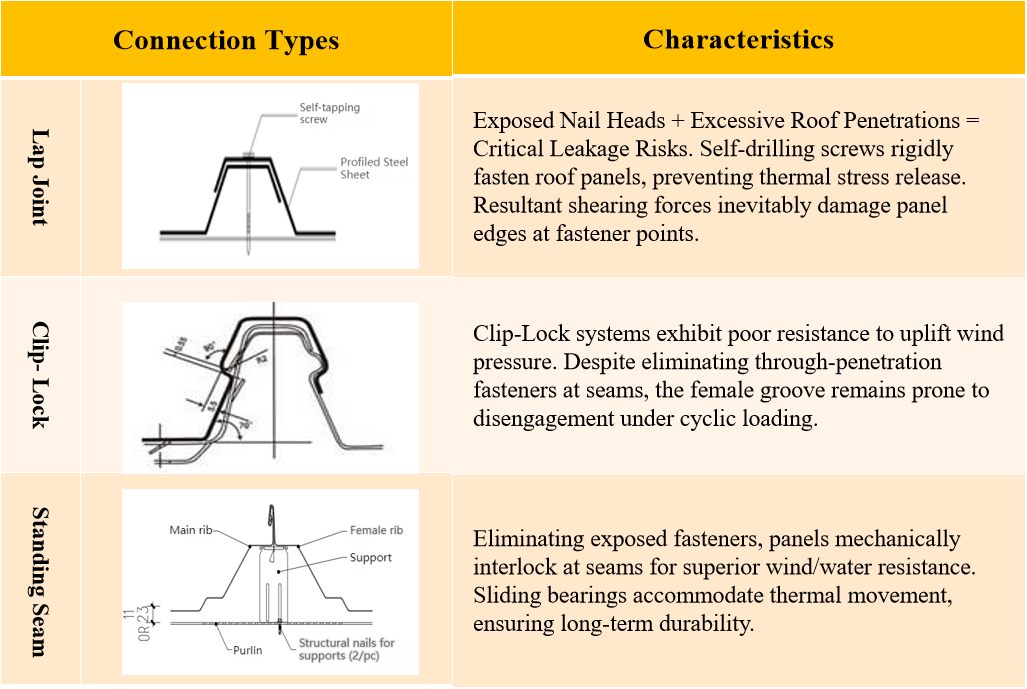

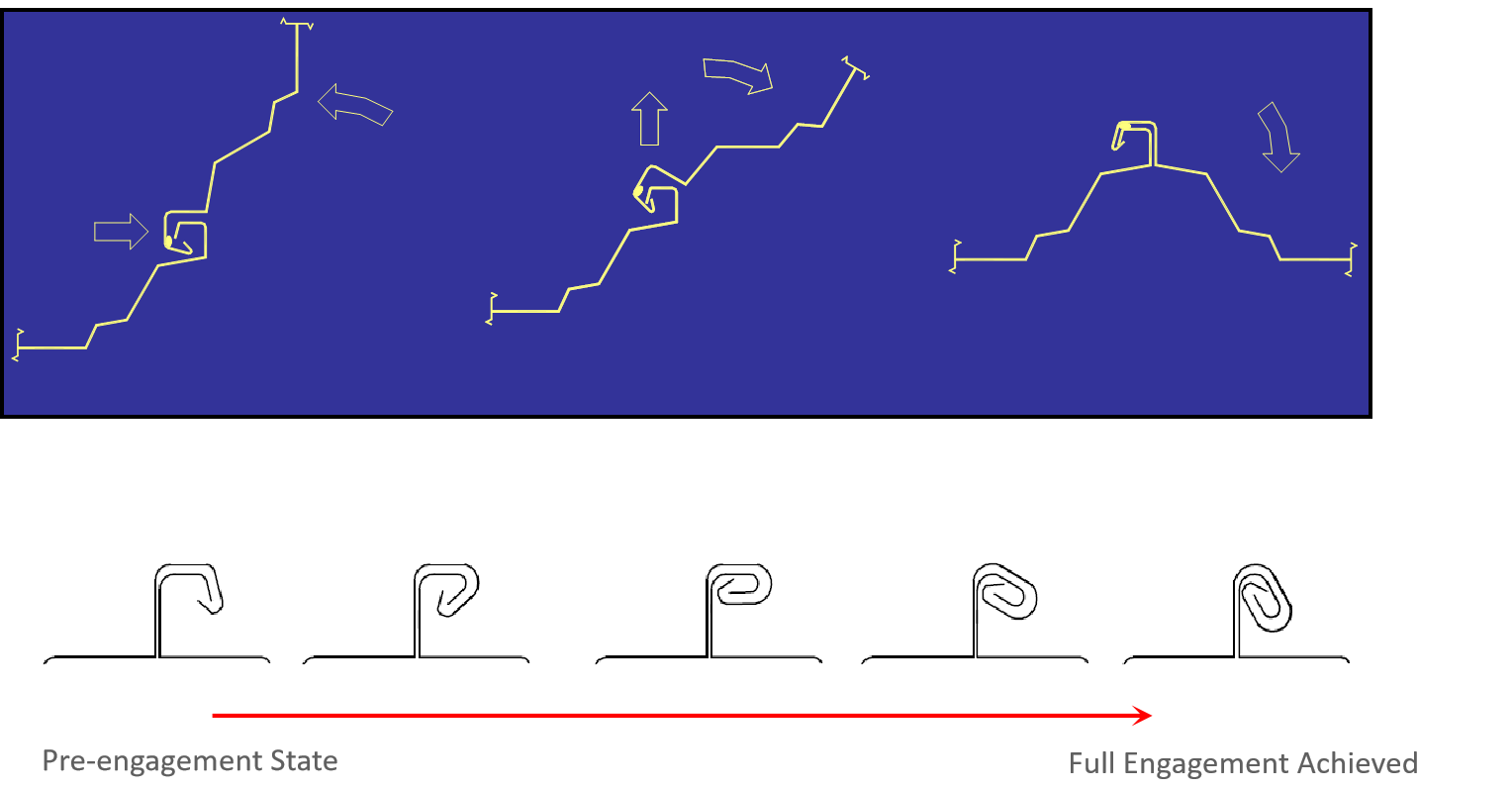

180° standing seam

360° standing seam

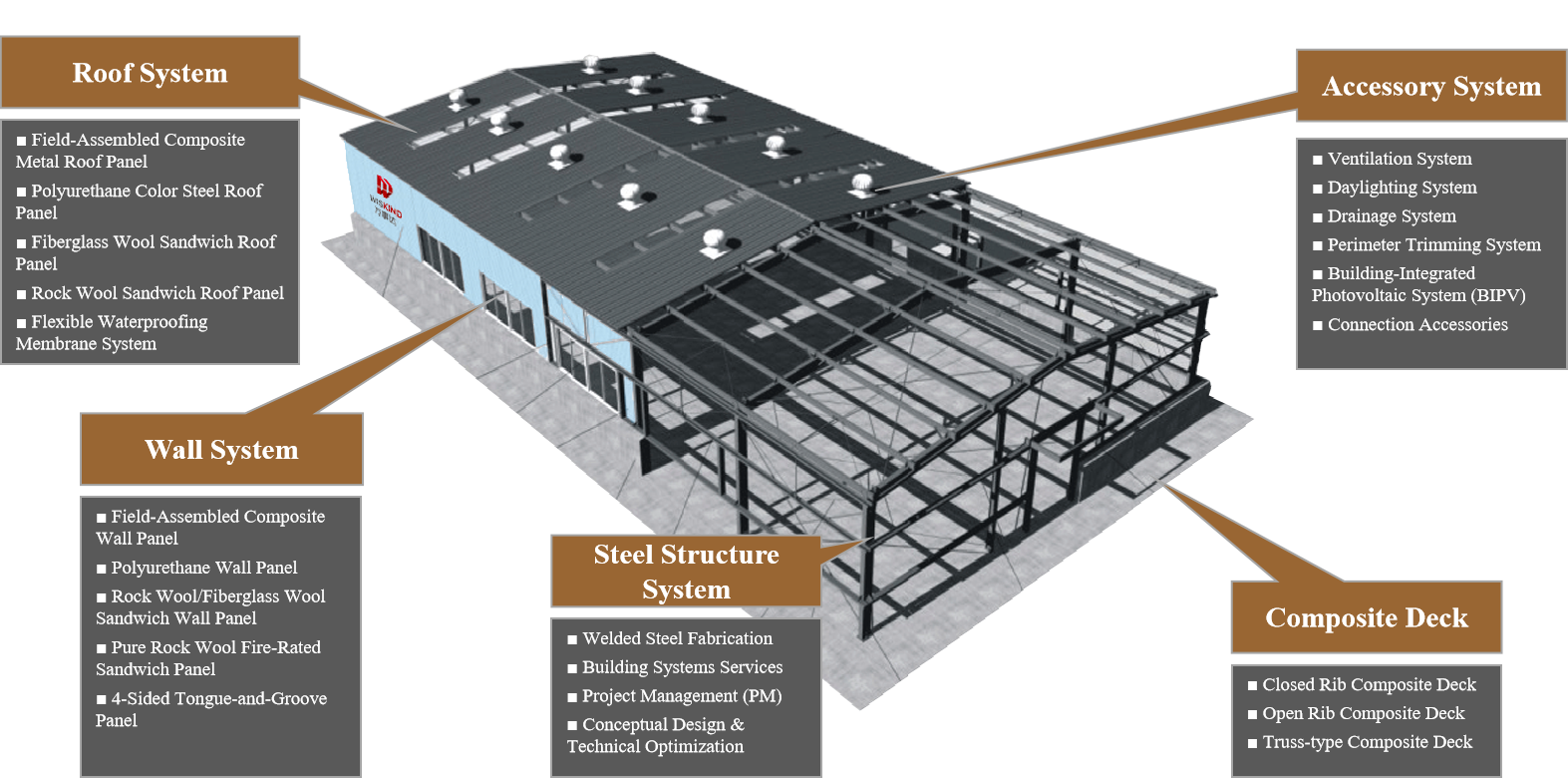

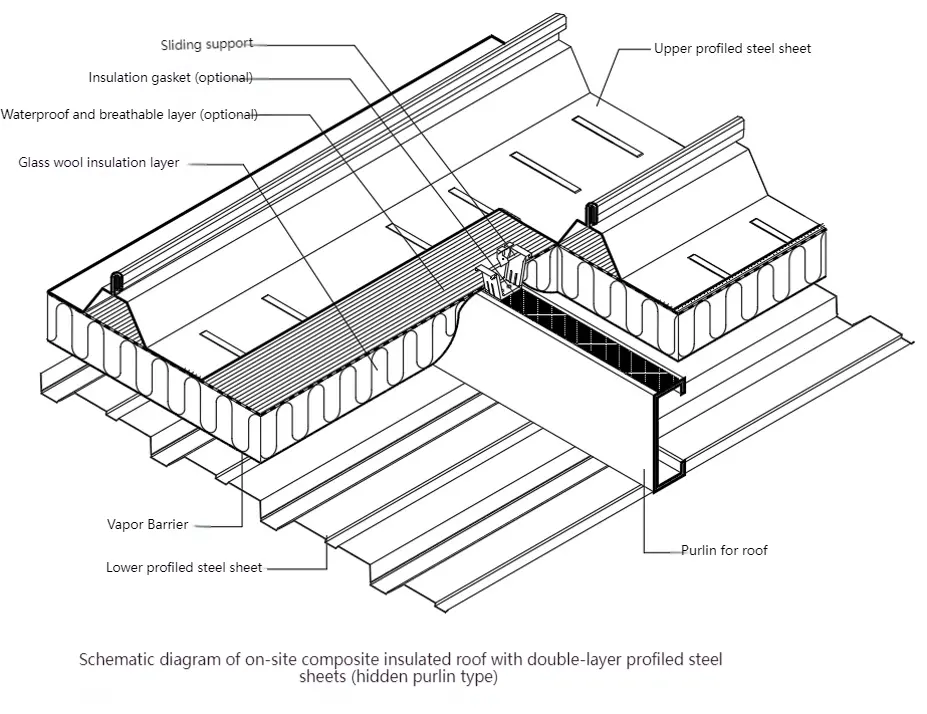

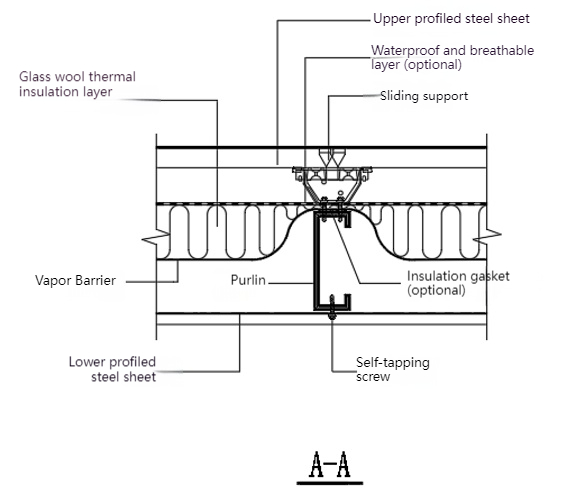

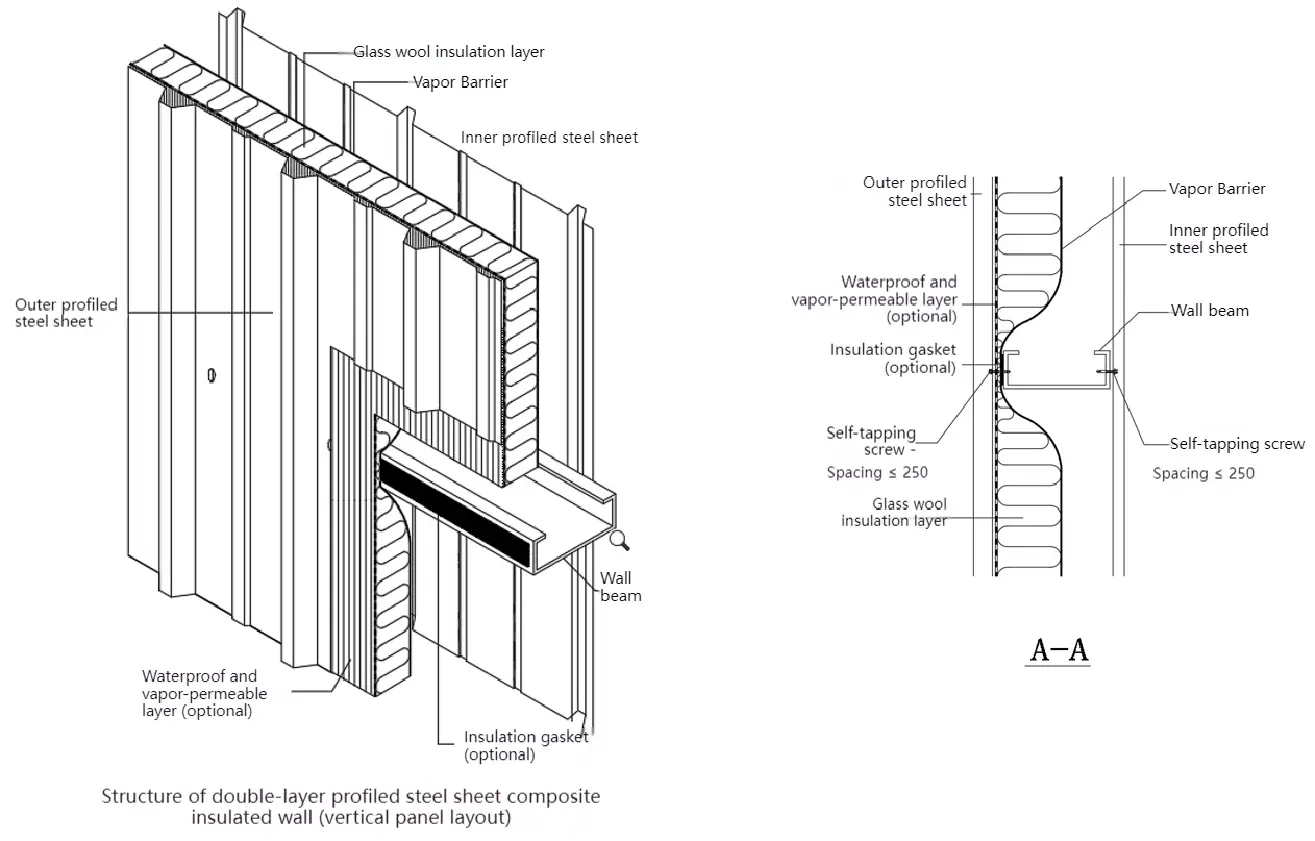

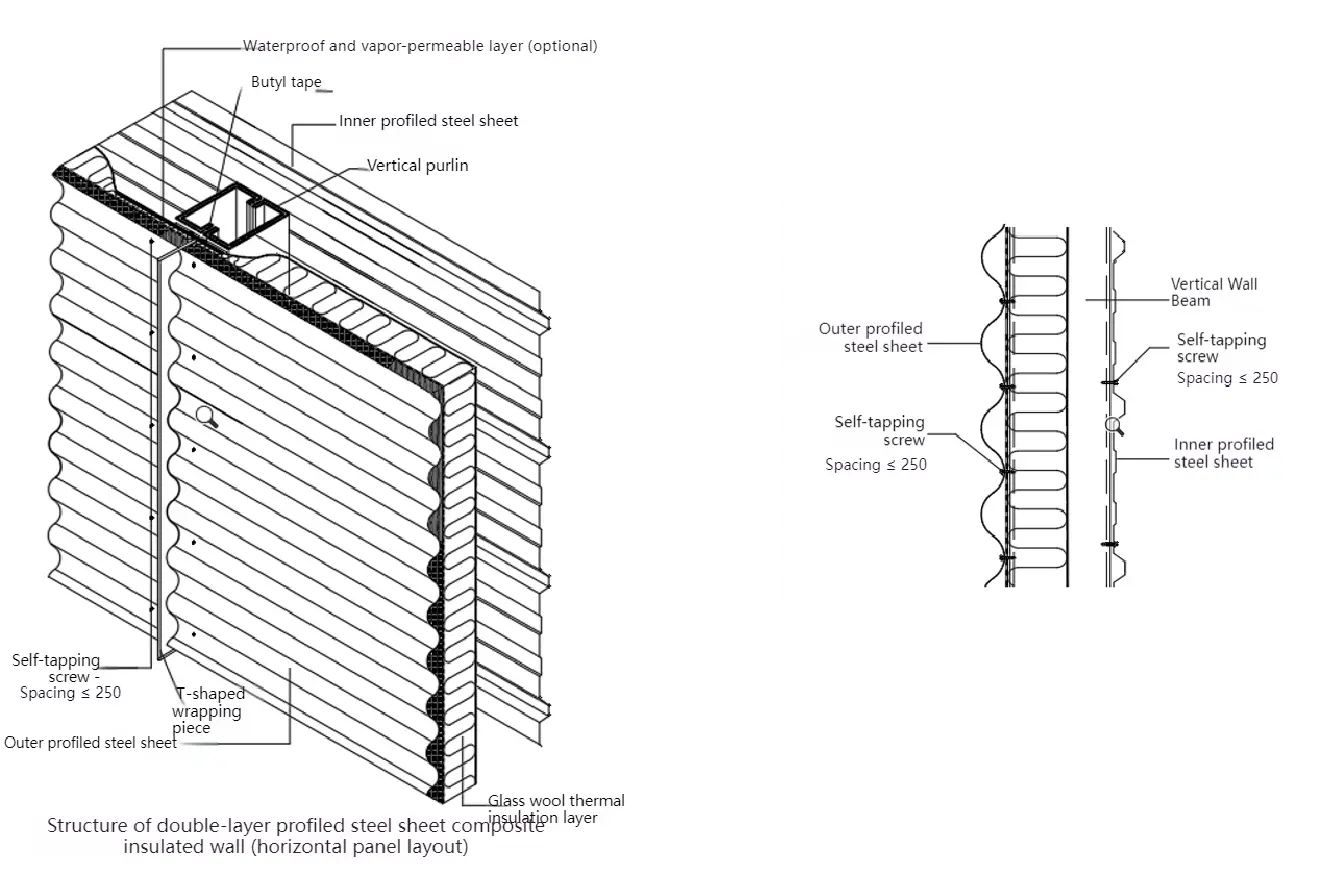

1.Multiple construction processes: At least three processes (installing outer panels, insulation layers, and inner panels) are required.

2.Roof single panels can be roll-formed on-site, allowing flexible control of panel length.

3.Most wall single panels are fixed with exposed self-tapping screws; the exterior appearance and waterproof performance are inferior to prefabricated insulation panels.

4.Glass wool rolls are compressed at purlins, reducing insulation performance.

5.The corrugated effect of single-layer wall panels has a strong industrial style, with a less integrated appearance than factory-prefabricated panels.

6.To improve the wind resistance of single-layer wall panels, additional self-tapping screws are required, leading to excessive nail holes and easy corrosion.

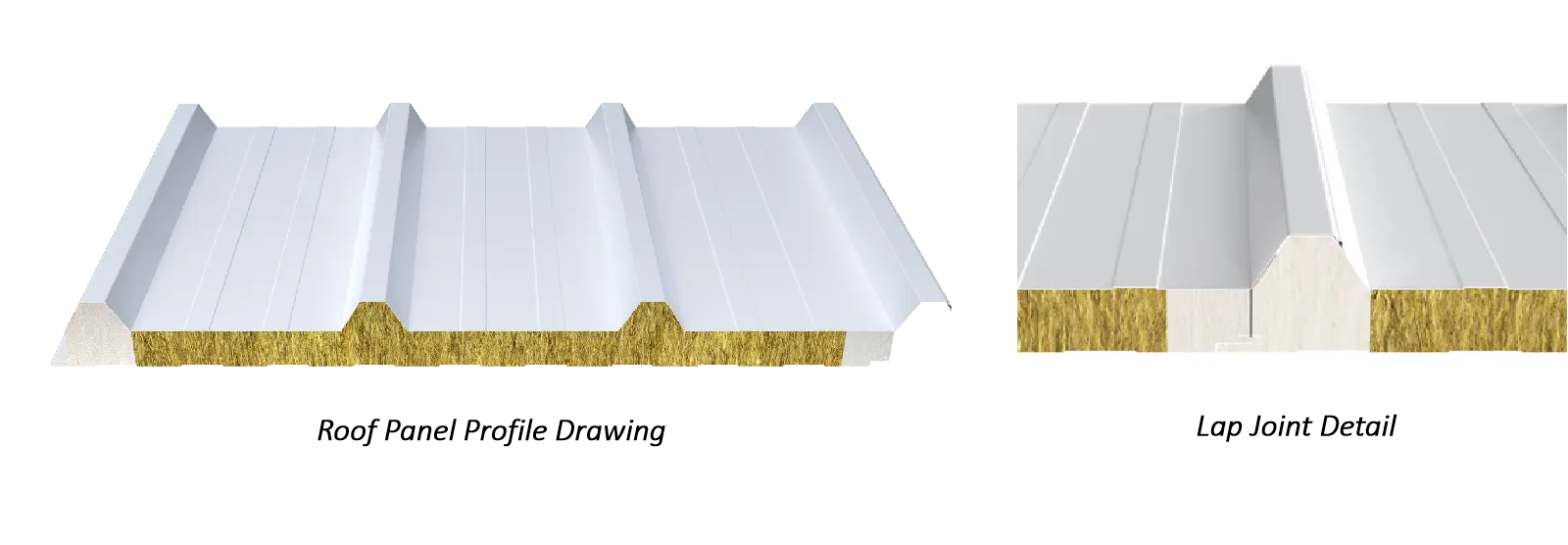

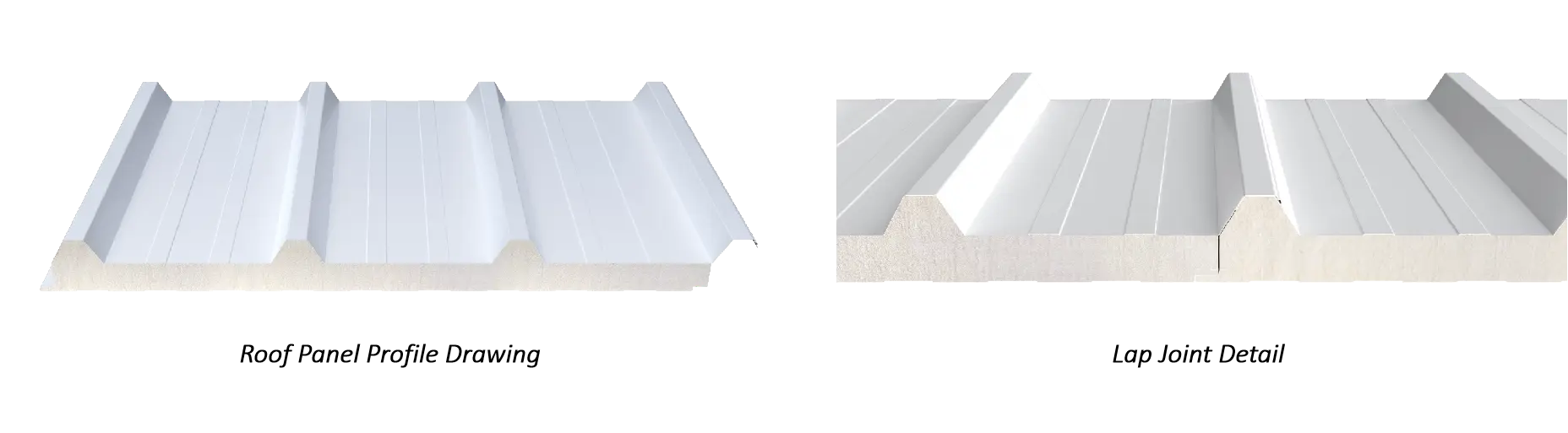

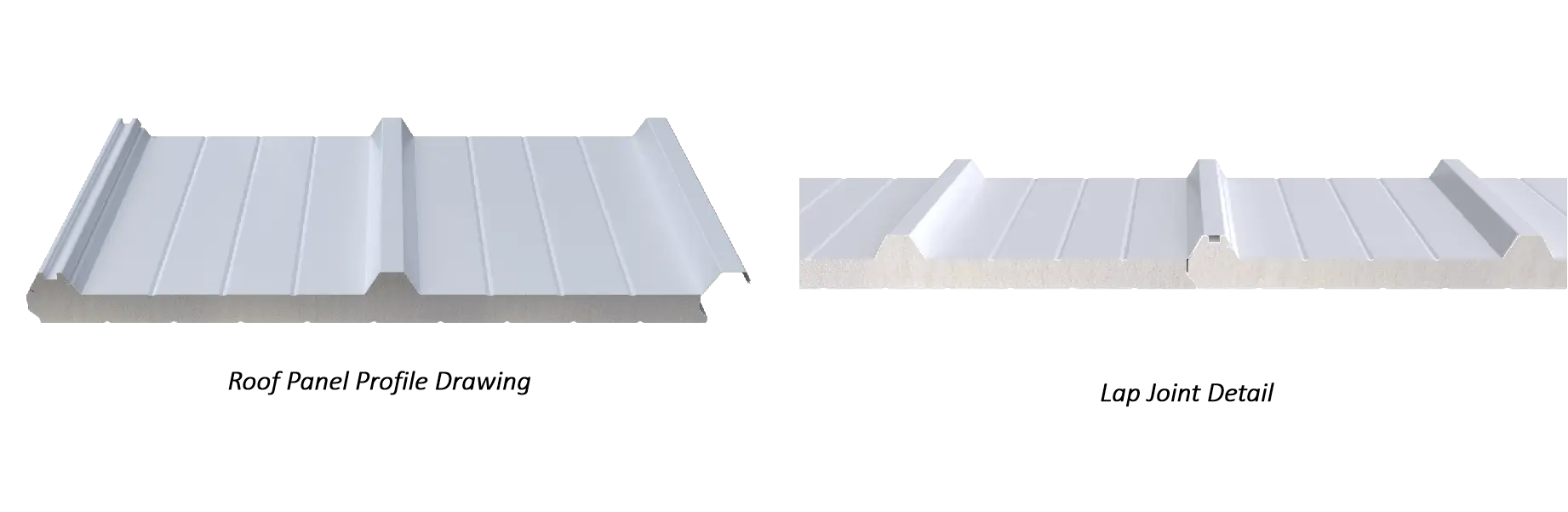

Dimention:Corrugation Height: 42mm. Corrugation Pitch: 333mm. Effective Width: 1000mm

Advantage:High Structural Rigidity, Excellent Drainage Performance, Class A Fire Rating, Positive Overlapping for Tight Sealing, Rapid Installation Standard

Thickness: 50mm, 75mm, 100mm,

150mm Note: Core material: Rock Wool/ Fiberglass Wool, with polyurethane edge sealing on both sides.

Dimention:Corrugation Height: 42mm. Corrugation Pitch: 333mm. Effective Width: 1000mm

Advantage: High structural strength with exceptional thermal insulation and energy efficiency. Fire resistance rating: B1 class (meets international engineering standards)

Standard Thickness: 50mm, 75mm, 100mm, 150mm

Dimention:Corrugation Height: 40mm. Corrugation Pitch: 500mm. Effective Width: 1000mm

Advantage: High structural strength with exceptional thermal insulation and energy efficiency. Fire resistance rating: B1 class (meets international engineering standards)

Standard Thickness: 50mm, 75mm, 100mm, 150mm

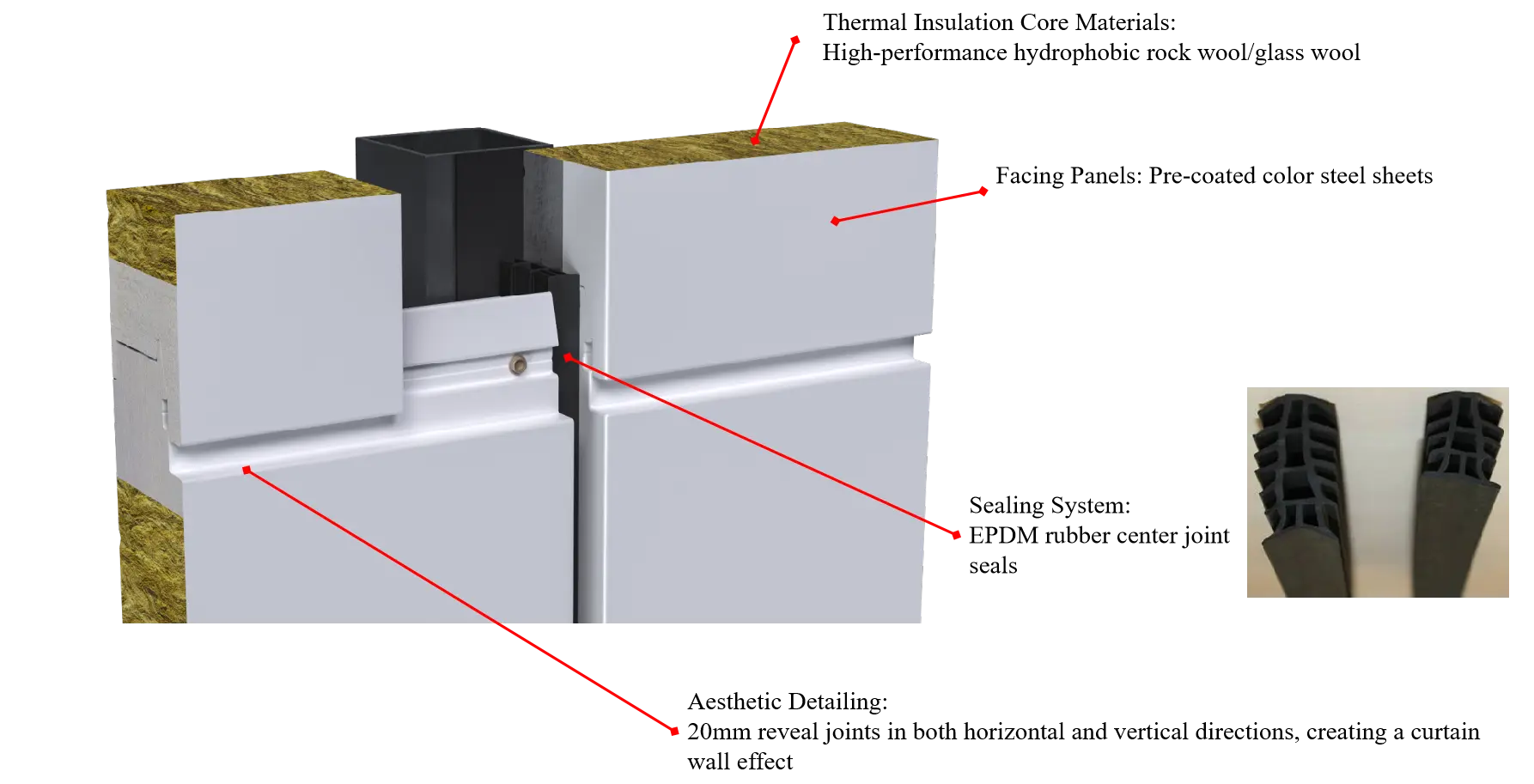

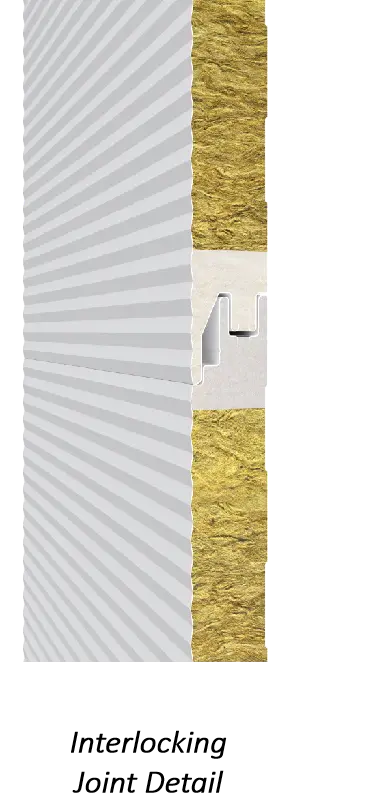

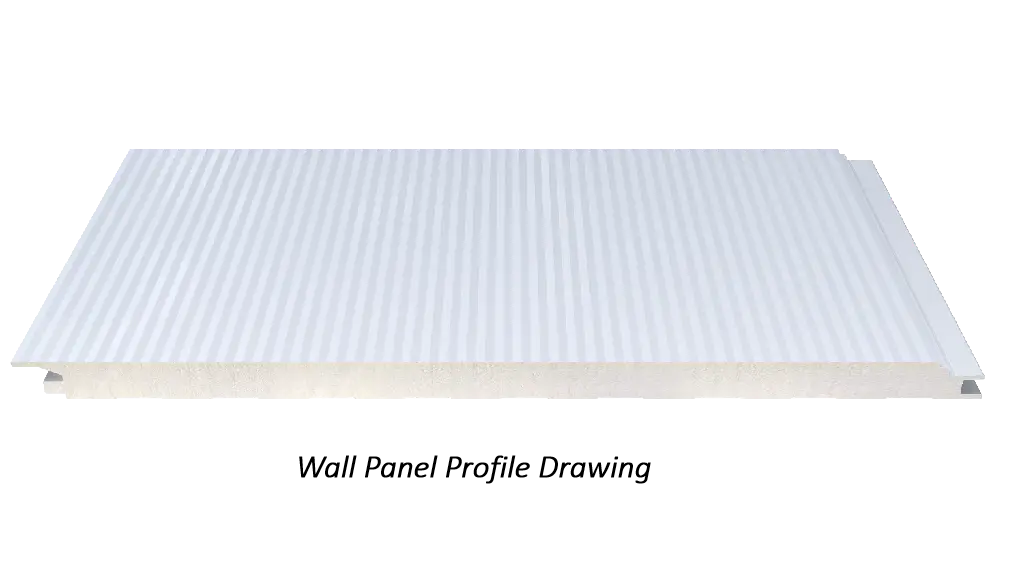

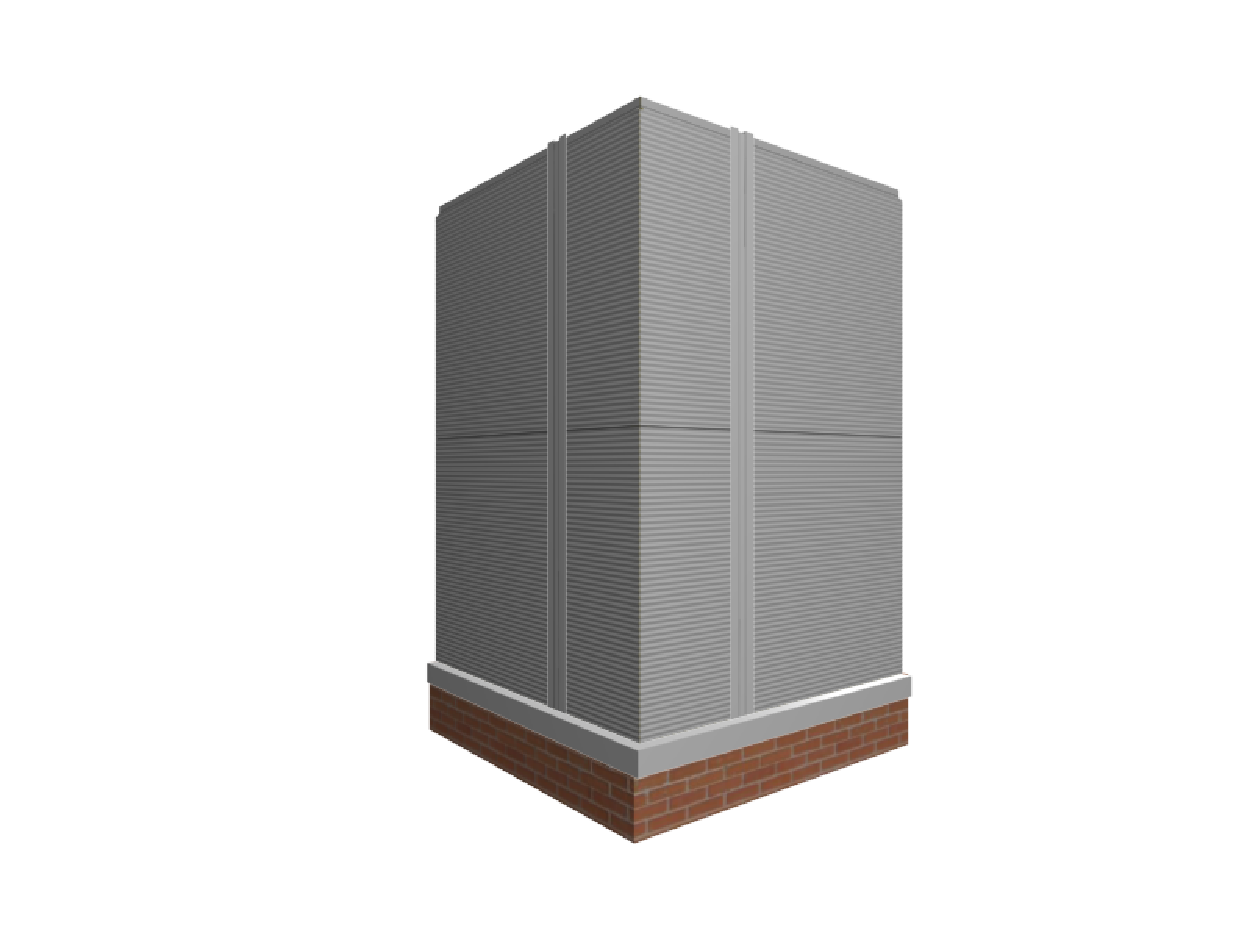

Product Features: High overall strength, excellent sealing performance, decorative effect, rapid and convenient installation

Effective Width: 1000mm (concealed fastener connection). Optional range: 500mm–1000mm

Standard Thickness: 50mm, 75mm, 100mm, 150mm

Note: Core material is fiberglass/rock wool, with polyurethane side-sealed edges.

roduct Features: PClass A fire rating (non-combustible), High-strength Rock Wool, Decorative appearance, Rapid and convenient installation

Effective Width: 1000mm (concealed fastener connection), optional range: 500mm–1000mm

Standard Thickness: 50mm, 75mm, 100mm, 150mm

Note: Core material exclusively is rock wool.

Product Features: High structural integrity with thermal insulation & energy efficiency, Class B1 fire rating (self-extinguishing), Ideal for high-insulation projects and international applications

Effective Width: 1000mm (customizable) , concealed fastener connection.

Standard Thickness: 50mm, 75mm, 100mm, 125mm, 150mm

Core Material: Polyisocyanurate (PIR), Class B1 certified

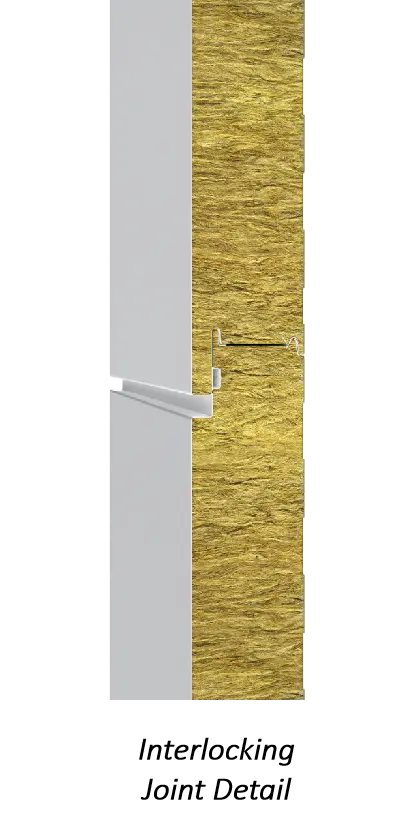

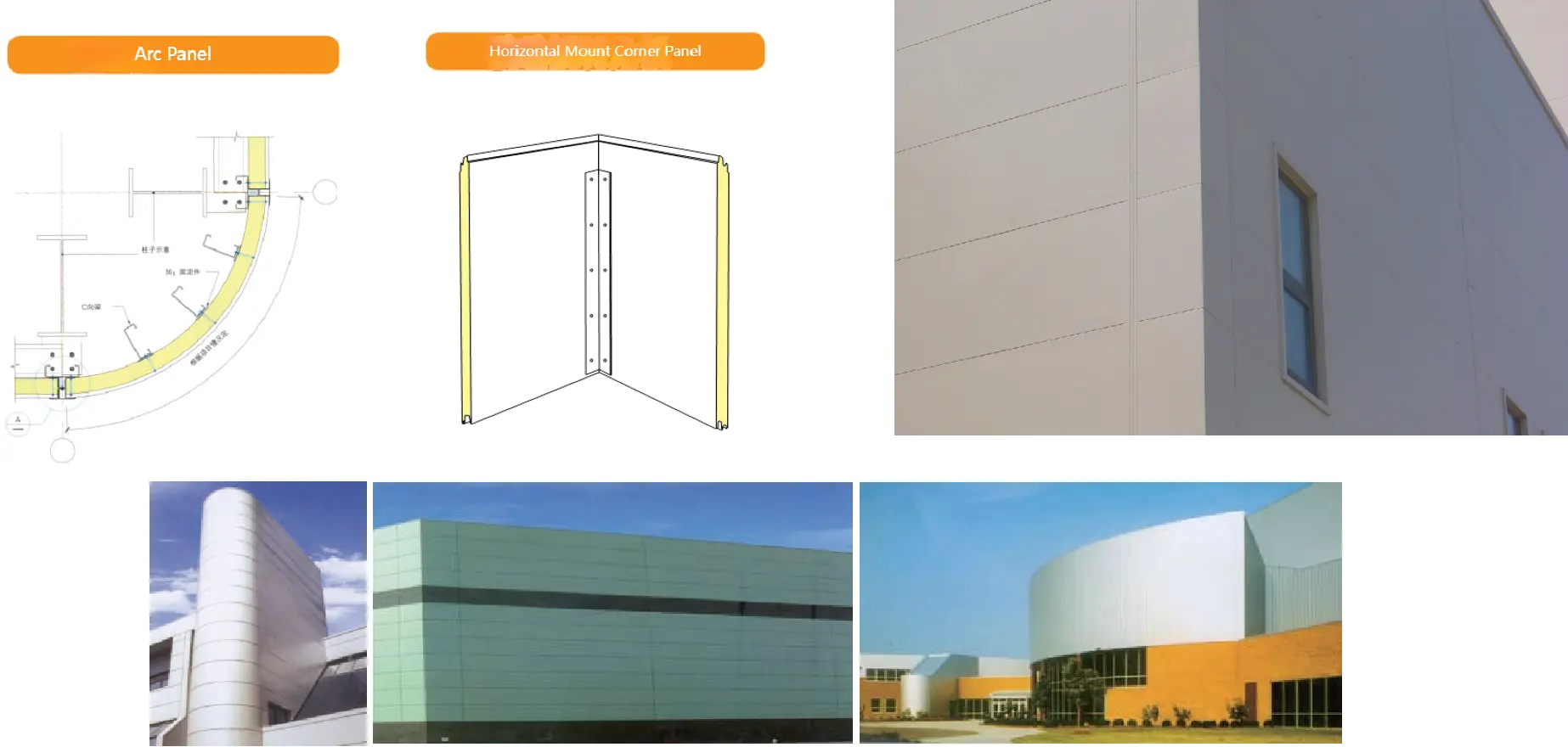

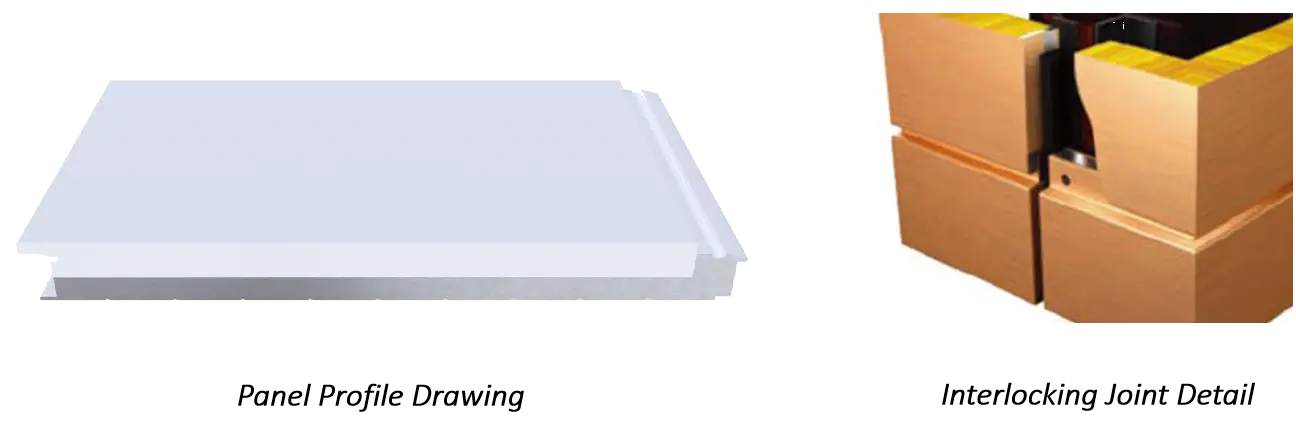

Advantages: Flat, smooth, and elegant surface with a robust metallic texture, delivering a curtain wall-like visual effect.

Effective Width: 1000mm (adjustable per client requirements), featuring concealed screw fastening.

Standard Thickness: 50mm, 75mm, 100mm, 125mm, 150mm.

Note: Core material predominantly rock wool with dual-side polyurethane edge-sealing