Industrial Building Envelope System

MAIN PRODUCTS

Main raw materials of products

Wanhua Polyurethane

Relying on the National Polyurethane Engineering Technology Research Center, we have achieved independent production of key raw materials such as isocyanates, polyether polyols, polyesters, catalysts, and flame retardant products, ensuring product quality from the source and optimizing costs.

The adoption of eco-friendly pentane blowing agents, which are non-ozone depleting and exhibit low global warming potential, aligns with the strategic objectives of carbon peaking and carbon neutrality.

By adopting imported seven-component foaming machine (HENNECKE-OMS) for continuous production, we achieve precise and intelligent control throughout the entire manufacturing process. Mature process technology ensures exceptional product stability.

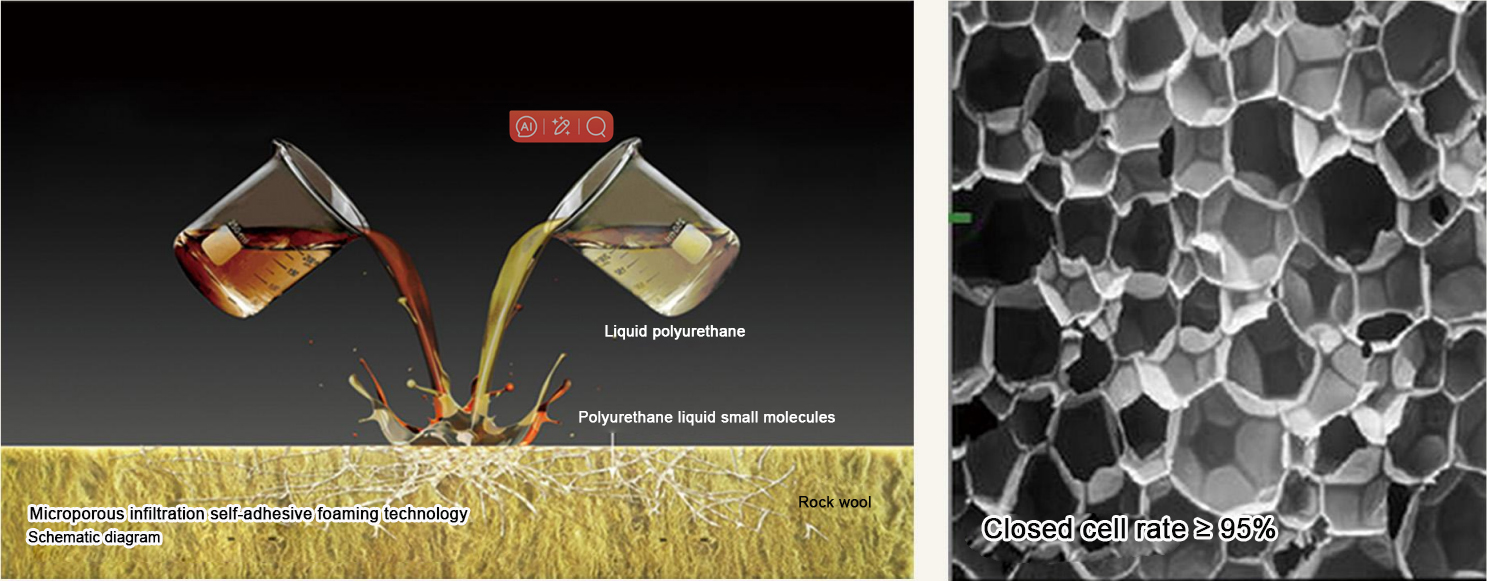

PRR Polyurethane-Modified PRR

Polyurethane-modified rock wool adopts microporous infiltration bonding technology, leveraging the superior self-adhesive properties of polyurethane. Liquid polyurethane raw material is sprayed under controlled pressure via spray gun, penetrating into vertical-strand rock wool at the molecular level. It rapidly foams and solidifies with an expansion rate exceeding thirtyfold, forming a seamless integrated structure of insulation, waterproofing, and bonding layers after full curing. The liquid polyurethane fills gaps in the rock wool, repairing broken fibers caused by cutting or mechanical impact, thereby preserving the material’s intrinsic strength and enhancing impact resistance. This effectively prevents damage during transportation, storage, and application.

Polyurethane-modified rock wool has been tested and certified with A-grade fire performance, effectively eliminating fire hazards during both construction and post-occupancy phases.

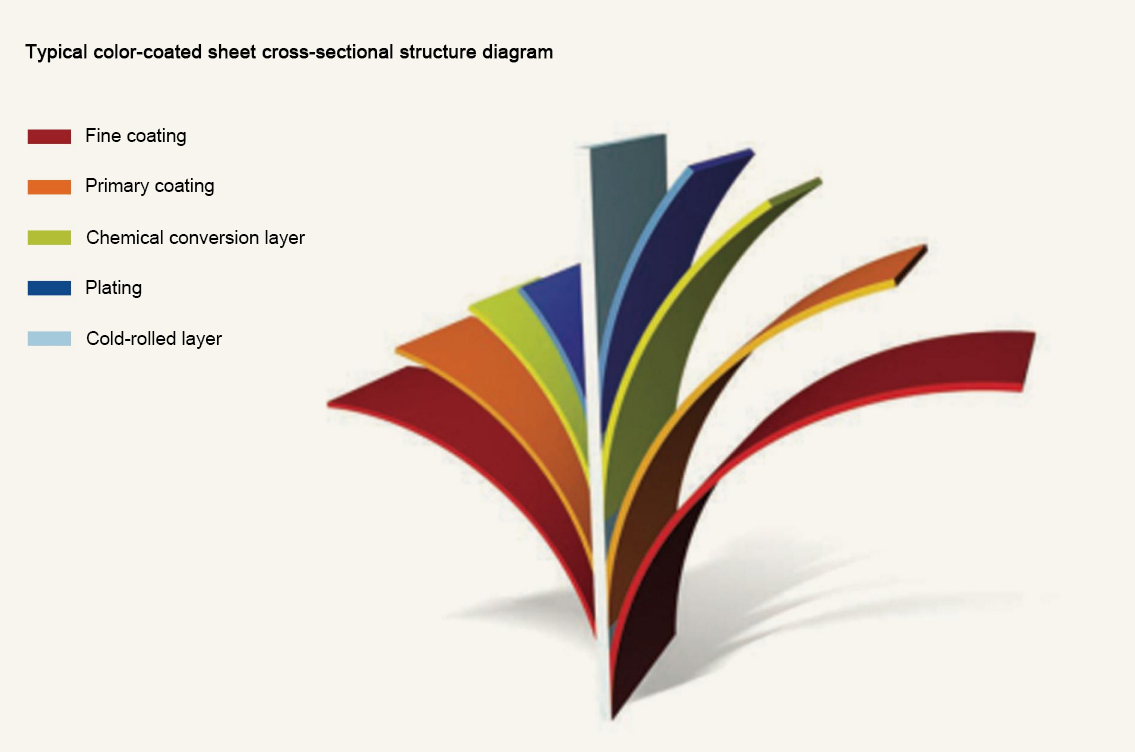

Color-Coated Steel Panels (CCSP)

Wanhua EnergySav collaborates with leading domestic and international raw material suppliers to provide high-performance and durable products. The structure of CCSP is as follows:

Recommended Classification and Performance of Color-Coated Steel Panels (CCSP)

| Paint type | Recommended thickness of front/back paint film (μm) | Zinc (aluminum zinc) content (g/m²) | Service life (years) |

| Polyvinylidene fluoride/fluorocarbon (PVDF) | =20/7 | Z150/AZ100 | 20 |

| High Weathering Resistant Polyester (HDP) | ≥20/7 | Z150/AZ100 | 15 |

| Silicon modified polyester (SMP) | ≥20/7 | Z150/AZ100 | 8-10 |

| Polyester (PE) | ≥20/7 | Z150/AZ100 | 5-8 |

In addition to the recommended types mentioned above, for projects with special requirements, our company can provide customized raw materials.

Strategic partners include brands such as Bluescope, Baosteel, Yieh Phui, Ma Steel, Guanzhou, Shougang, etc.

Metal-faced wall system

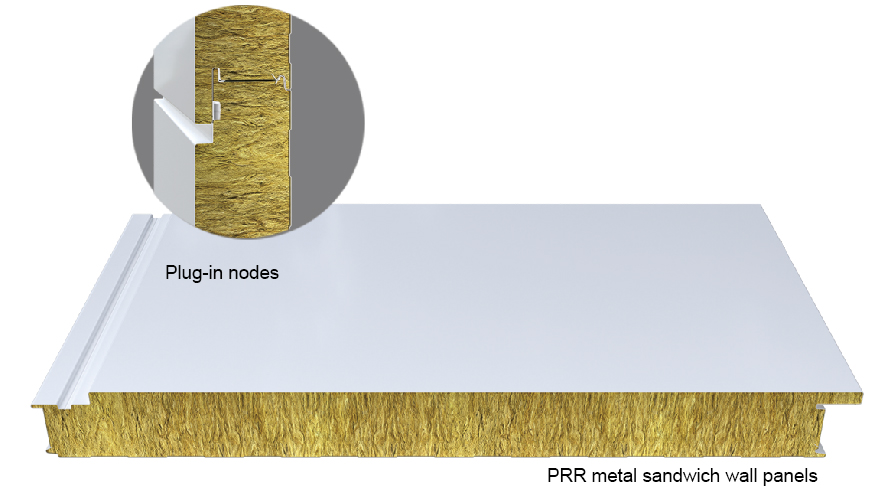

Huajian™ · PRR Metal-faced Sandwich Wall Panel

PRR wall panel uses rock wool as the core material, with two layers of high-quality metal plates as surface panels. After roll forming, the slit rock wool is rotated 90 degrees to form vertical fibers with enhanced strength. Through high-strength polyurethane adhesive, the core material and metal panels are tightly bonded to create a flat, aesthetically pleasing building panel. It features high strength, Class A fire resistance, thermal insulation, energy efficiency, and excellent sound insulation

Product Specifications Selection Table

| Standard width (mm) | 1000, optional 500-1000 |

| Thickness of the whole board (mm) | 50,75,100,150 |

| Length of the board (mm) | ≤15000 |

| Thickness of the outer metal surface | Outer steel plate: 0.5-0.8 Outer aluminum plate: 0.7-1.0 |

| Thickness of the inner metal surface | Inner steel plate: 0.4~0.6 Inner aluminum plate: 0.5~0.7 |

| Type of core material | PRR |

| Density of core material (kg/m3) | PRR:100~140 |

Product Performance Features

Exceptional Fire Resistance:Class A fire resistance

Enhanced Thermal Insulation: Utilizes polyurethane-modified rock wool, achieving 10% higher insulation efficiency compared to conventional materials

Superior Structural Integrity: Combines vertically aligned high-strength basalt fiber wool with polyurethane adhesive, ensuring robust bonding to metal surfaces and overall panel strength.

Excellent Sound Insulation: Sound insulation exceeds 30 dB, effectively reducing external noise interference

Aesthetic Design:Features horizontal alignment, eliminating the industrial appearance of traditional composite panels

PRR Meta-faced Sandwich Wall Panel Performance and Thermal Property Selection Table

This table is calculated based on the following parameters: PRR bulk density of 120kg/m³, outer steel plate thickness of 0.6mm, and inner steel plate thickness of 0.5mm.

|

Core material |

Board thickness | Support type | Load (kN/m²)/Maximum unsupported span (m) Allowable deformation ≤L/150 | Board weight (kg/m²) |

Heat transfer coefficient |

|||||

| 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | |||||

|

PRR |

50 | Continuous

/ Simply supported |

4.05 | 3.4 | 3.01 | 2.77 | 2.38 | 2 | 15.5 | 0.76 |

|

75 |

4.45 | 3.96 | 3.43 | 3.18 | 2.7 | 2.03 | 18.49 | 0.53 | ||

| 100 | 5.61 | 4.92 | 4.38 | 3.95 | 3.52 | 2.97 | 21.5 |

0.4 |

||

| 150 | 7.1 | 5.92 | 5.32 | 4.55 | 4.03 | 3.57 | 27.48 |

0.27 |

||

Huashi™ · PRR Metal-faced Sandwich Wall Panel

PRR wall panel uses rock wool or glass wool with PIR seal edges as the core material, combined with two layers of high-quality metal panels. Through advanced composite technology, it forms an aesthetically pleasing, flat building panel with high strength, excellent fire resistance, thermal insulation, energy efficiency, and superior sound insulation

Product Specifications Selection Table

| Standard width (mm) | 1000, optional 500~1000 |

| Thickness of the whole board (mm) | 50,75,100,150,200 |

| Length of the board (mm) | ≤15000 |

| Thickness of the outer metal surface | Outer steel plate: 0.5~0.8 Outer aluminum plate: 0.7~1.0 |

| Thickness of the inner metal surface | Inner steel plate: 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Type of core material | PIR+PRR |

| Density of core material (kg/m³) | PRR |

Product Performance

High Structural Integrity

Utilizes vertically aligned high-strength basalt fiber wool, enhancing bonding strength. The polyurethane-sealed joints at interlocking connections further reinforce structural stability.

Superior Sealing Performance

Precision-engineered interlocking joints and end-sealing treatments ensure excellent air/water tightness

Aesthetic Design

Hidden-fastener connections eliminate visible screws. Diverse color options harmonize with architectural styles.

Rapid Installation

Prefabricated panels with standardized dimensions improve construction efficiency and reduce labor costs.

PRR metal sandwich wall panel performance and thermal performance selection table

This table is calculated based on PRR bulk density of 120kg/m², outer steel plate thickness of 0.6mm, and inner steel plate thickness of 0.5mm

|

Core material |

Board thickness | Support type | Load (kN/m²)/Maximum unsupported span (m) Allowable deformation ≤L/150 | Board weight (kg/m²) |

Heat transfer coefficient |

|||||

| 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | |||||

|

PRR |

50 | Continuous

/ Simply supported |

4.23 | 3.65 | 3.2 | 2.95 | 2.58 | 2.15 | 15.13 | 0.76 |

|

75 |

4.92 | 4.23 | 3.75 | 3.35 | 2.9 | 2.23 | 18.49 | 0.53 | ||

| 100 | 5.61 | 4.92 | 4.38 | 3.95 | 3.52 | 2.97 | 21.5 |

0.4 |

||

| 150 | 7.44 | 6.25 | 5.57 | 4.85 | 4.34 | 3.81 | 27.48 |

0.27 |

||

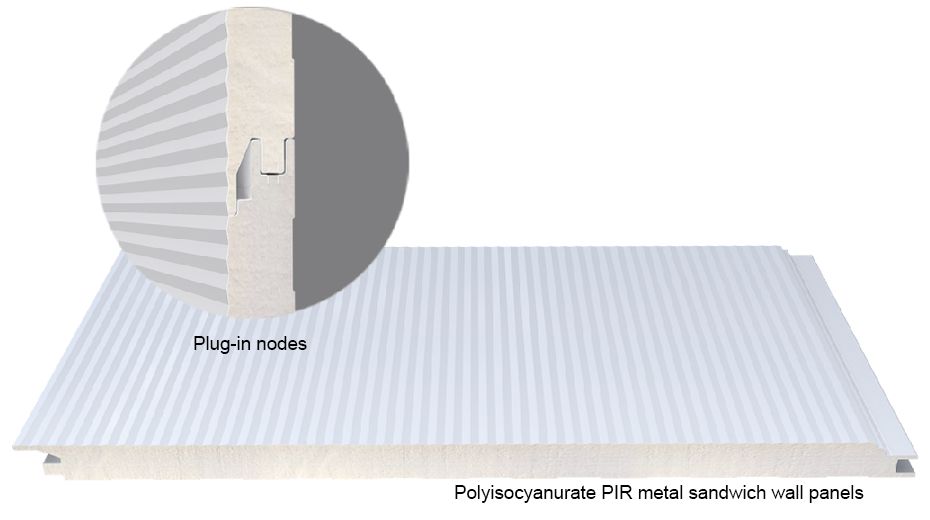

Huaneng™ · Polyisocyanurate (PIR) Metal-faced Sandwich Wall Panel

The Polyisocyanurate (PIR) Wall Panel uses polyisocyanurate (PIR) as the core material, formed into aesthetically pleasing and flat building panels. After fabrication, the panel exhibits high strength, excellent thermal insulation and energy efficiency, with combustion performance reaching Class B1 fire rating

Product Specifications Selection Table

| Standard width (mm) | 1000, optional 500-1000 |

| Thickness of the whole board (mm) | 50,75,100,150,200 |

| Board length (mm) | s15000 |

| Outer metal surface thickness | Outer steel plate: 0.5~0.8 Outer aluminum plate: 0.7~1.0 |

| Inner metal surface thickness | Inner steel plate: 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Core material type | PIR |

| Core material density (kg/m3) | 40±2 |

Product Performance

High Energy Efficiency

Exceptional thermal insulation performance significantly reduces building energy consumption.

Superior Fire Resistance

Thermosetting insulation material with non-flame propagation characteristics

Robust Durability

High-strength panel with excellent mechanical properties and structural integrity

Water/Air Tightness

Hydrophobic polyurethane combined with interlocking joint structure ensures outstanding air/water sealing performance.

Aesthetic Facade Design

Horizontal arrangement with hidden fastener joint design and diverse surfaces

Polyisocyanurate PIR metal sandwich wall panel performance and thermal performance selection table

This table is calculated based on the rock wool density of 120kg/m³, the outer steel plate thickness of 0.6mm, and the inner steel plate thickness of 0.5mm

|

Core material |

Board thickness | Support type | Load (kN/m²)/Maximum unsupported span (m) Allowable deformation ≤L/150 | Board weight (kg/m²) | Heat transfer coefficient | |||||

| 0.6 | 0.8 | 1 | 1.2 | 1.5 | 2 | |||||

|

PRR |

50 | Continuous

/ Simply supported |

4.7 | 3.92 | 3.35 | 3.03 | 2.71 | 2.4 | 10.15 | 0.48 |

|

75 |

5.2 | 4.55 | 3.91 | 3.52 | 3.04 | 2.53 | 11.18 | 0.32 | ||

| 100 | 5.96 | 5.11 | 4.54 | 4.11 | 3.85 | 3.3 | 12.22 |

0.24 |

||

| 150 | 7.96 | 6.45 | 5.72 | 5.06 | 4.7 | 4.12 | 14.3 |

0.16 |

||

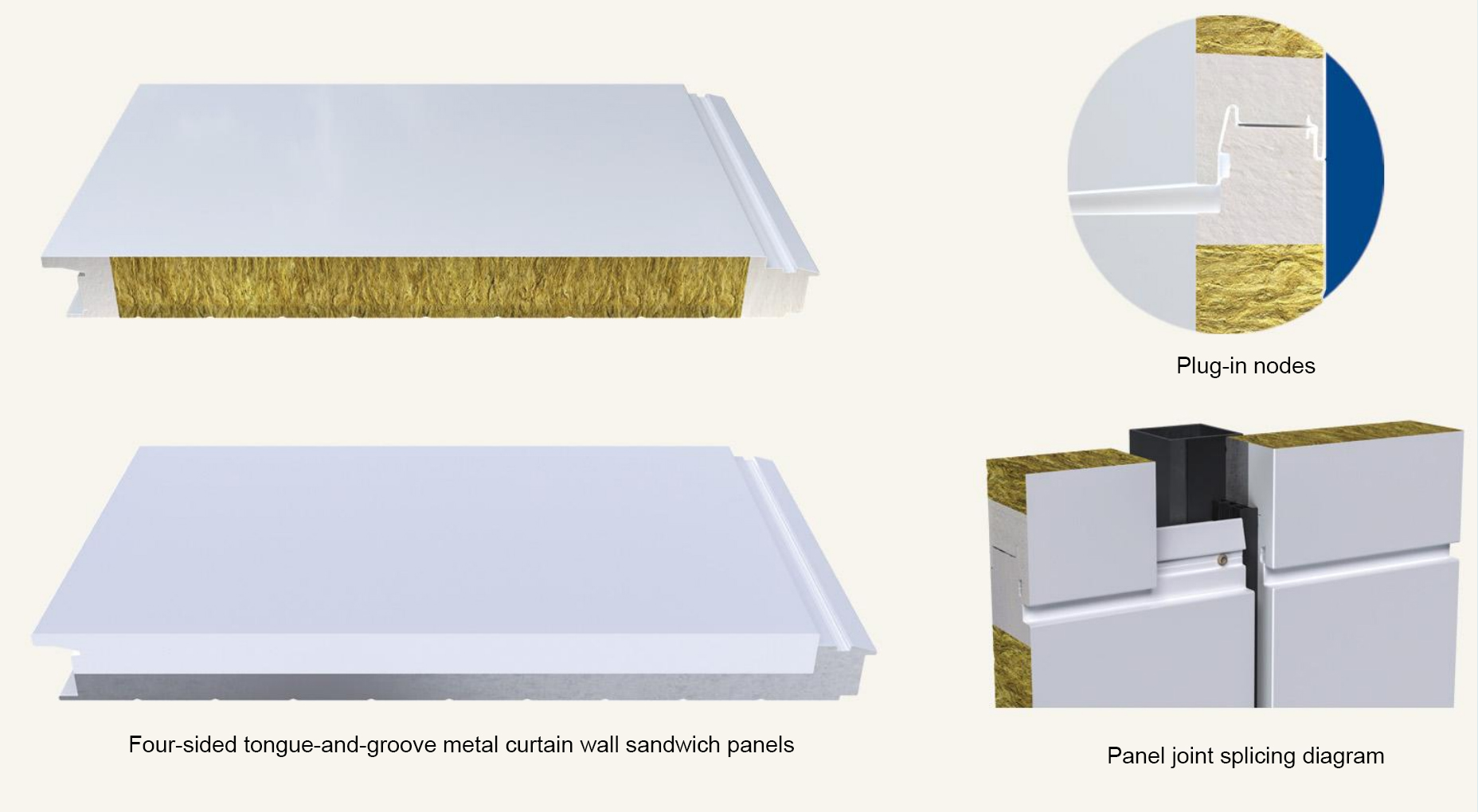

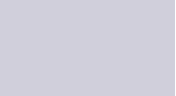

Huaxuan –Four-Sided Tongue-and-Groove Metal-faced Curtain Wall Sandwich Panel

Curtain wall panel is produced by using a continuous production line where rock wool or fiberglass wool serves as the core material, sealed with polyisocyanurate (PIR) edge bands. After continuous forming, the panel undergoes secondary edge folding to achieve fully enclosed curtain wall panel.

This product not only inherits the advantages of metal sandwich panels, but also integrates the functionality and aesthetics of prefabricated metal curtain walls. It significantly enhances the visual appeal and holistic design of building exteriors with thermal insulation.

Product Specifications Selection Table

| Standard width (mm) | 1000, optional 500~1000 |

| Thickness of the whole board (mm) | 50,75,100,150 |

| Length of the board (mm) | ≤15000 |

| Thickness of the outer metal surface | Outer steel plate: 0.5-0.8 Outer aluminum plate: 0.7-1.0 |

| Thickness of the inner metal surface | Inner steel plate 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Type of core material | PIR+PRR |

| Density of core material (kg/m³) | PIR=40±2 PRR≥100 |

Product Performance

Superior Sealing Performance

Non-silicone resin caulking joints achieve curtain wall-like effects with excellent sealing performance.

Aesthetic Design

Smooth and flat surface with elegant appearance, enhanced by the strong metallic finish

Rapid Installation

Fast and convenient panel installation improves construction efficiency and reduces labor costs

Easy Maintenance

Modular design allows for quick disassembly and hassle-free repairs

Selection table of performance and thermal performance of four-sided tongue-and-groove metal curtain wall sandwich panels

|

Core material

|

Board thickness |

Support type |

Load (kN/m²)/Maximum unsupported span (m) Allowable deformation ≤ L150 | Plate weight (kg/m3) |

Heat transfer coefficient |

|||||

|

0.6 |

0.8 | 1 | 1.2 | 1.5 |

2 |

|||||

|

PRR

|

50 | Continuous

/ Simply supported

|

4.23 | 3.65 | 3.2 | 2.95 | 2.58 | 2.15 | 15.13 | 0.76 |

|

75 |

4.92 |

4.23 | 3.75 | 3.35 | 2.9 | 2.23 | 17.94 |

0.53 |

||

|

100 |

5.61 | 4.92 | 4.38 | 3.95 | 3.52 | 2.97 | 20.75 |

0.4 |

||

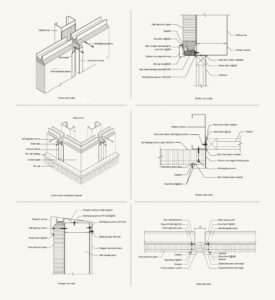

Wall System Structure and Joint Details

Surface Finish Selection

Water Ripple Flat Ribbing Glossy Flat Embossed Printing

Decorative seam

0mm Decorative seam 20mm Decorative seam

Metal-faced roof system

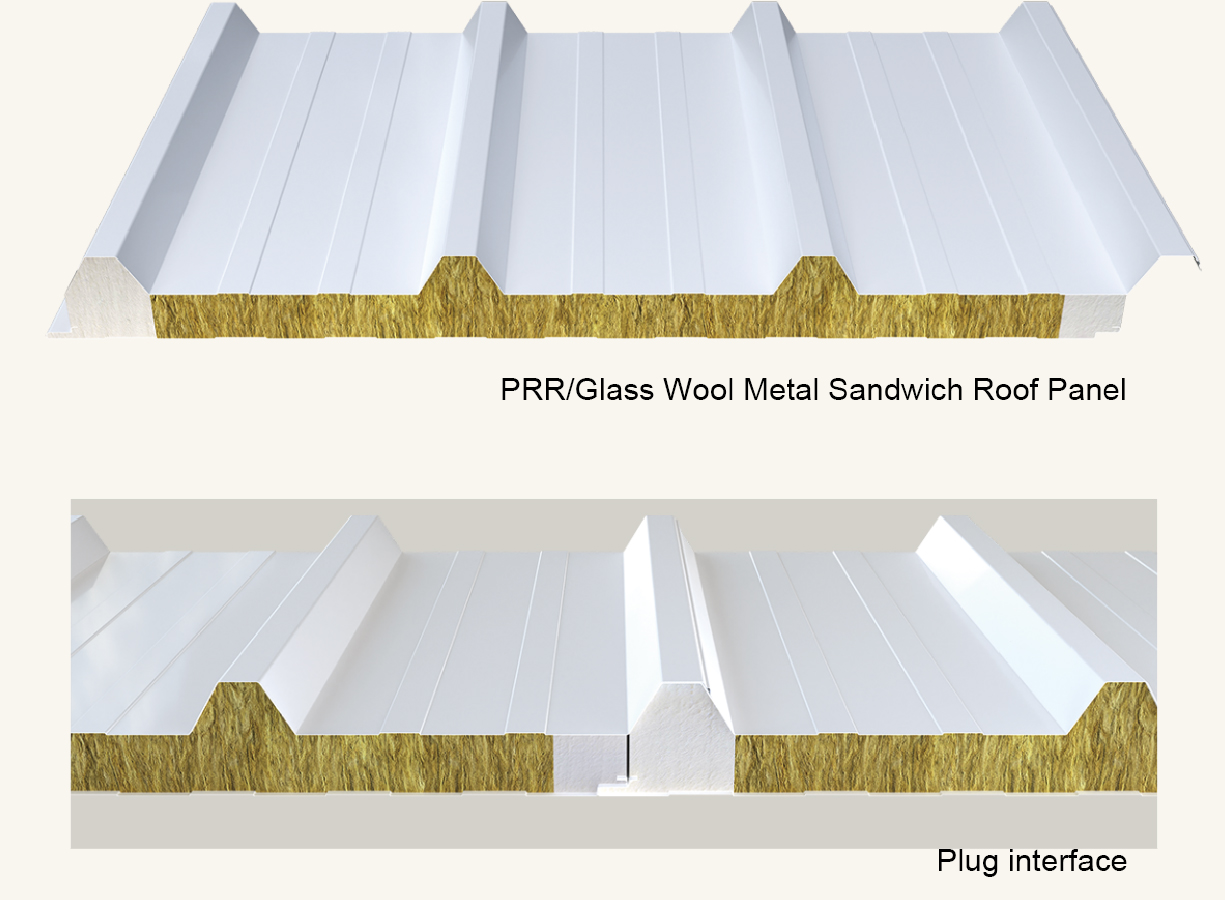

Huashi™ · PRR/Glass Wool Metal-faced Sandwich Roof Panel

The PRR/Glass Wool Roof Panel uses rock wool or glass wool combined with PIR edge sealing as the core material. Through high-strength bonding between the core and metal panels, it enhances air tightness and water resistance at joints, effectively preventing thermal bridging. This integrated roofing solution offers waterproofing, installation convenience, and aesthetic appeal, featuring high strength, exceptional fire resistance, thermal insulation, and energy efficiency

Product Specifications Selection Table

| Standard width (mm) | 1000 |

| Corrugation Pitch (mm) | Crest 42mm, wave distance 333mm |

| Thickness of the whole board (mm) | 50,75,100,150 |

| Length of the board (mm) | ≤18000 |

| Thickness of the outer metal surface | Outer steel plate: 0.5-0.8 Outer aluminum plate: 0.7-1.0 |

| Thickness of the inner metal surface | Inner steel plate: 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Type of core material | PIR+PRR PIR+glass wool |

| Density of core material (kg/m³) | Glass wool: 64 PRR:100-140 |

PRR/glass wool metal sandwich roof panel performance and thermal performance selection table

This table is calculated based on PRR bulk density of 120kg/m³, outer steel plate thickness of 0.6mm, and inner steel plate thickness of 0.5mm. For more parameters, please consult our engineers

|

Core material |

Board thickness |

Support type |

Load (kN/m²) Maximum unsupported hoof length (m) Allowable deformation ≤ L200 |

Board weight (kg/m²) |

Heat transfer coefficient | |||||

| 0.6 | 0.8 | 1 | 1.2 | 1.5 |

2 |

|||||

|

PRR |

50 | Continuous

/ Simply supported |

3.75 | 3.31 | 2.96 | 2.72 | 2.39 | 2.06 | 15.74 | 0.75 |

|

75 |

4.8 | 4.23 | 3.75 | 3.42 | 2.97 | 2.31 | 18.68 | 0.53 | ||

|

100 |

5.76 |

5.03 | 4.48 | 4.07 | 3.59 | 3.07 | 21.62 | 0.41 | ||

|

150 |

7.5 | 6.52 | 5.82 | 5.27 | 4.59 | 4.01 | 27.51 | 0.31 | ||

| Glass Silk Wool | 50 | Continuous

/ Simply supported |

3.84 | 3.39 | 3.1 | 2.87 | 2.54 | 2.55 | 13.1 |

0.69 |

|

75 |

5.62 |

5.11 | 4.63 | 4.19 | 3.71 | 3.16 | 14.73 | 0.47 | ||

|

100 |

6.92 | 6.2 | 5.58 | 5.1 | 4.63 | 3.9 | 16.36 |

0.36 |

||

| 150 | 8.21 | 7.24 | 6.36 | 5.71 | 5.06 | 4.2 | 19.61 |

0.33 |

||

Product Performance

Enhanced Thermal Insulation

Utilize polyurethane-modified rock wool, achieving 10% improvement in thermal insulation efficiency compared to conventional materials.

Superior Structural Integrity

Employ vertically aligned high-strength basalt fiber wool and PIR edge sealing at interlocking joints, ensuring higher bonding strength and air tightness at connection points.

Excellent Drainage Performance

Feature a high-wave peak design that enhances load-bearing capacity while balancing water flow.

Rapid Installation

Simplified assembly process reduces labor costs and significantly improves construction efficiency

Metal-faced roof system

Huashi™ · PRR/Glass Wool Metal-faced Sandwich Roof Panel

The PRR/Glass Wool Roof Panel uses rock wool or glass wool combined with PIR edge sealing as the core material. Through high-strength bonding between the core and metal panels, it enhances air tightness and water resistance at joints, effectively preventing thermal bridging. This integrated roofing solution offers waterproofing, installation convenience, and aesthetic appeal, featuring high strength, exceptional fire resistance, thermal insulation, and energy efficiency

Product Specifications Selection Table

| Standard width (mm) | 1000 |

| Crest distance (mm) | Crest 42mm, wave distance 333mm |

| Thickness of the whole board (mm) | 50,75,100,150 |

| Board length (mm) | ≤18000 |

| Outer metal surface thickness | Outer steel plate: 0.5-0.8 Outer aluminum plate: 0.7-1.0 |

| Inner metal surface thickness | Inner steel plate: 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Core material type | PIR+PRR PIR+glass wool |

| Core material density (kg/m³) | Glass wool: 64 PRR:100-140 |

PRR/glass wool metal sandwich roof panel performance and thermal performance selection table

This table is calculated based on PRR bulk density of 120kg/m³, outer steel plate thickness of 0.6mm

inner steel plate thickness of 0.5mm. For more parameters, please consult our engineers

|

Core material |

Board thickness | Support type | Load (kN/m²) Maximum unsupported hoof length (m) Allowable deformation ≤ L200 | Board weight (kg/m²) | Heat transfer coefficient | |||||

|

0.6 |

0.8 | 1 | 1.2 | 1.5 |

2 |

|||||

|

PRR |

50 | Continuous

/ Simply supported |

3.75 | 3.31 | 2.96 | 2.72 | 2.39 | 2.06 | 15.74 | 0.75 |

|

75 |

4.8 | 4.23 | 3.75 | 3.42 | 2.97 | 2.31 | 18.68 | 0.53 | ||

|

100 |

5.76 | 5.03 | 4.48 | 4.07 | 3.59 | 3.07 | 21.62 | 0.41 | ||

|

150 |

7.5 | 6.52 | 5.82 | 5.27 | 4.59 | 4.01 | 27.51 | 0.31 | ||

| Glass Silk Wool |

50 |

Continuous

/ Simply supported |

3.84 | 3.39 | 3.1 | 2.87 | 2.54 | 2.55 | 13.1 | 0.69 |

|

75 |

5.62 | 5.11 | 4.63 | 4.19 | 3.71 | 3.16 | 14.73 |

0.47 |

||

|

100 |

6.92 | 6.2 | 5.58 | 5.1 | 4.63 | 3.9 | 16.36 |

0.36 |

||

| 150 | 8.21 | 7.24 | 6.36 | 5.71 | 5.06 | 4.2 | 19.61 |

0.33 |

||

Product Performance

Enhanced Thermal Insulation

Utilize polyurethane-modified rock wool, achieving 10% improvement in thermal insulation efficiency compared to conventional materials.

Superior Structural Integrity

Employ vertically aligned high-strength basalt fiber wool and PIR edge sealing at interlocking joints, ensuring higher bonding strength and air tightness at connection points.

Excellent Drainage Performance

Feature a high-wave peak design that enhances load-bearing capacity while balancing water flow.

Rapid Installation

Simplified assembly process reduces labor costs and significantly improves construction efficiency

Roofing product series

HuanengTM·Polyisocyanurate (PIR) Metal Sandwich Roof Panel

Polyisocyanurate (PIR) Metal Sandwich Roof Panel uses modified isocyanurate (PIR) as the core material, which is tightly bonded to the metal panel to improve the air tightness and water tightness of the overlap, effectively prevent the occurrence of cold and hot bridges, and become a waterproof, convenient, and beautiful integrated building roof panel.

After forming, the board has the characteristics of high strength, thermal insulation and energy saving, and the fire resistance can reach B1 level, which provides an excellent choice for building roof systems with relatively high thermal insulation requirements.

-300x91.png)

Polyisocyanurate (PIR) metal sandwich roof panel (exposed nail type) Exposed nail type plug-in interface form

-300x96.png)

Polyisocyanurate (PIR) metal sandwich roof panel (hidden nail type) Hidden nail type plug-in interface form

Product Specifications Selection Table

| Standard width (mm) | 1000 |

| Crest distance (mm) | Crest 42mm, Wavelength 333mm |

| Whole board thickness (mm) | 50,75,100,150 |

| Board length (mm) | ≤18000 |

| Outer metal surface thickness | Outer steel plate: 0.5-0.8 Outer aluminum plate: 0.7-1.0 |

| Inner metal surface thickness | Inner steel plate: 0.4-0.6 Inner aluminum plate: 0.5-0.7 |

| Core material type | PIR |

| Core material density (kom³) | ≥40 |

Polyisocyanurate (PIR) metal sandwich roof panel performance and thermal performance selection table

This table is calculated based on PIR bulk density 40kg/m², outer steel plate thickness 0.6mm, inner steel plate thickness 0.5mm. For more parameters, please consult our engineers

| Core material | Board thickness | Support type |

Load (kN/m³)/Maximum unsupported span (m) Allowable deformation ≤ L150 |

Board weight (kg/m²) |

Heat transfer coefficient |

|||||

|

0.6 |

0.8 | 1 | 1.2 | 1.5 |

2 |

|||||

|

PIR |

50 | Continuous

/ Simply supported |

4.88 | 4.02 | 3.48 | 3.11 | 2.85 | 2.49 | 10.65 | 0.48 |

|

75 |

5.34 | 4.68 | 4.07 | 3.69 | 3.18 | 2.66 | 11.68 | 0.32 | ||

| 100 | 6.12 | 5.23 | 4.67 | 4.23 | 3.98 | 3.55 | 12.72 |

0.24 |

||

| 150 | 8.11 | 6.63 | 5.86 | 5.2 | 4.87 | 4.3 | 14.8 |

0.16 |

||

Product Performance

High Energy Efficiency:

Exceptional thermal insulation performance reduces building energy consumption.

Fire Resistance:

Utilize thermosetting insulation material with non-flame-spreading properties.

Structural Integrity:

High-strength panels with superior mechanical properties.

High-Rib Design:

Enhance load-bearing capacity while optimizing rainwater drainage.

Water/Air Tightness:

Hydrophobic polyurethane combined with interlocking joint structure ensures excellent sealing performance

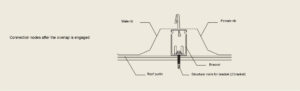

Standing seam composite roofing panels

The standing seam roofing system is a prefabricated panel system formed by rolling the color-coated panels, and together with the insulation materials, roofing baseboards and other supporting accessories, it forms a complete roofing system, suitable for large-span roofs over 20 meters. Single-layer corrugated steel roofing panels (the thickness of the panels can be produced: 0.5mm~0.7mm):

360° bite

YX75-470 YX66-394-788

180° bite

YX54-410-820 YX76-380-760

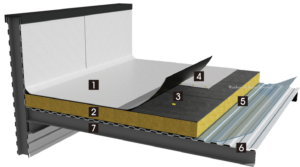

Standing seam roof construction diagram

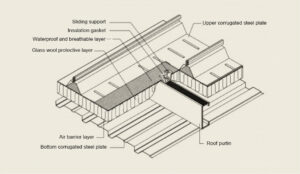

Schematic diagram of the structure of double-layer corrugated steel plate composite insulation roof

Advantages of Standing Seam Roof Panels

Superb wind uplift resistance: After being seamed and locked with the support at a 360° angle, a strong connection is formed between the profiled steel sheet and the support. This turns the roof into an integrated structure, effectively ensuring the wind – resistance and snow – load capacity of the entire roof.

Hidden support installation: There are no screws penetrating the surface, which guarantees the overall waterproof performance of the roof.

Special sliding bearings: After the panel and the bearing fastener are locked together, it can effectively release the thermal stress deformation of the panel.

Fully – engaged lap joints: Featuring a high – wave peak design and combined with corresponding special waterproof accessories, the overall waterproof performance of the roof is enhanced, completely eliminating the risk of water leakage.

Dome roof system/Loogspan roof system

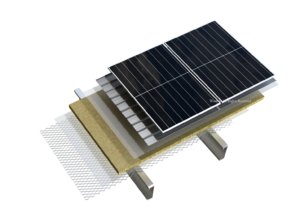

WANHUA Dome Roof Insulation Panel is a novel thermal insulation material which uses vertical-filament rock wool as the core layer. It is formed through the continuous production line where the cement-based reinforced interface membrane and rock wool core are bonded in a single step using polyurethane foam adhesive (abbreviated as: Dome Insulation Panel).

This panel is specifically designed and developed for various single-layer roofing insulation systems. It integrates multiple functions such as fire-resistant insulation, moisture-resistant and waterproof properties, structural stability, and sound absorption/noise reduction, making it a comprehensive solution for modern roofing applications

Product Specifications

Standard dimensions: 1200mm × 600mm (customizable)

Insulation layer thickness: 30mm-200mm

① Flexible waterproofing membrane

② Wanhua dome roof insulation board

③ Insulation board membrane fixings

④ Membrane fixings

⑤ WH20 polypropylene vapor barrier

⑥ Corrugated steel sheet

⑦ Steel purlin

Performance advantages of Wanhua Dome Metal Roof Panels

1. Excellent physical properties: high-strength interface coils and vertical filament rock wool are combined into a whole through polyurethane, which increases the load strength of the panel

2. Good waterproof and moisture-proof performance: liquid polyurethane penetrates into the gaps of rock wool to form a waterproof and moisture-proof sealing layer, overcoming the disadvantage of rock wool absorbing water 3. Fireproof performance: combustion performance is Class A;

4. Good energy-saving benefits: polyurethane forms a closed thermal insulation layer on the upper and lower surfaces of rock wool, preventing air convection and low heat transfer coefficient; 5. Optimized construction environment: Reduce the pollution of rock wool floccules and dust to the environment

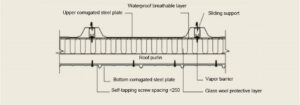

WANHUA BIPV Roof System

The Building Integrated Photovoltaic (BIPV) system is an application that integrates solar power generation products into building structures, combining photovoltaic energy production with architectural functionality. With societal advancements, BIPV has become the preferred choice for an increasing number of new construction projects

1. Photovoltaic modules

2. Standing seam roof panels

3. Waterproof breathable membrane

4. Insulation materials

5. Vapor barrier membrane

6. Steel wire mesh or steel bottom plate

7. Steel purlins

Simple structure, fast construction, more than 50% labor saving during construction period

High aluminum zinc coating, strong anti-corrosion performance, 25-year warranty

Strong wind resistance, pull-out strength more than 10 times higher than general working conditions

Light weight, saving about 10-20% of the steel used in the secondary structure compared with single panels under the same conditions