Wanhua Building Energy-Savingsystem Solutions

SPRAYED RIGID FOAM POLYURETHANE EXTERIOR INSULATION SYSTEM

Product Overview/Brief

Polyurethane a thermosetting flame-retardant foam material, is formed by on-site multi-layer spraying of polymethylene polyphenyl isocyanate (commonly known as “black material”) and a polyether/polyester polyol blend (commonly known as “white material”) using specialized spraying equipment. It exhibits excellent physical and chemical properties, including waterproofing, thermal insulation, and flame resistance

Product Performance

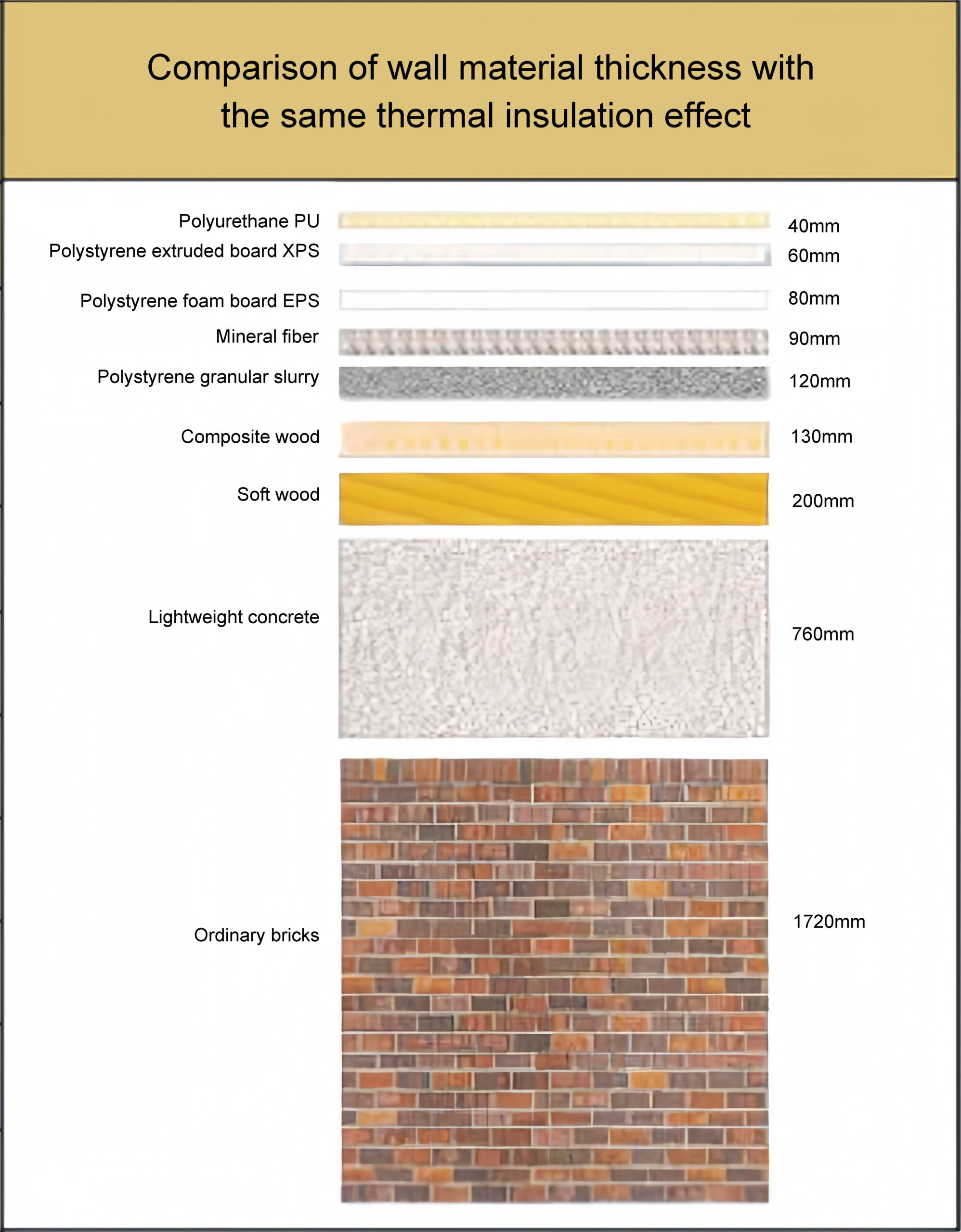

Outstanding Thermal Insulation Performance

The thermal conductivity (as low as 0.020 W/(m·K)), and superior closed-cell structure effectively mitigates heat transfer through convection, conduction, and radiation. This structure ensures long-term stability in thermal resistance.

Excellent Waterproof Performance

Over 95% closed-cell ratio with hydrophobic properties ensures minimal water vapor permeability, effectively blocking moisture infiltration to achieve integrated thermal insulation and waterproofing with excellent performance.

Outstanding Flame Retardancy

Rigid polyurethane foam, as the thermosetting material, forms a carbonized protective layer upon exposure to fire. Wanhua’s polyurethane combines additive-type (external flame retardants) and structural-type (inherent molecular design) approaches, achieving synergistic fire resistance. And the flame-retardant performance shows no significant degradation over years of use.

Outstanding Aging Resistance Performance

Polyurethane demonstrates a service life of up to 70 years, providing long-term energy-saving and thermal insulation benefits. Under normal operating conditions, the thermal insulation performance of rigid polyurethane foam consistently meets requirements throughout its lifespan.

Broad Operating Temperature Range

Polyurethane maintains stable performance across an extensive temperature range of -50°C to 150°C, with short-term exposure tolerance up to 250°C without structural damage. This makes it the insulation material with the widest applicable temperature range, suitable for both extreme cold and high-temperature environments

High Bonding Strength & System Integrity

The liquid polyurethane molecules directly infiltrate into the microscopic pores of the substrate surface, rapidly expand and cure at a tens-of-times expansion ratio. they form a secure mechanical interlock with the substrate, achieving 100% seamless bonding to ensure system safety and prevent detachment

Excellent Substrate Compatibility

The on-site spray application technology effectively addresses challenges posed by complex structural details, multiple joints, and uneven surfaces.

Performance

WANEFOAM®332 Series

| Items | Index |

| Density, kg/m³ | ≥45 |

| Thermal conductivity, W/(m·k) | ≤0.024 |

| Compression performance (deformation 10%), kPa | ≥200 |

| Dimensional stability (70℃, 48h), % | ≤1.5 |

| Tensile bond strength (with cement mortar, room temperature), MPa | ≥0.10 |

| Water absorption, % | ≤3 |

| Oxygen index, % | ≥30 |

WANEFOAM®326 Series

| Items | Index |

| Density, kg/m³ | ≥37 |

| Thermal conductivity, W/(m·k) | ≤0.024 |

| Compression performance (deformation 10%), kPa | ≥150 |

| Dimensional stability (70℃, 48h), % | ≤1.5 |

| Closed porosity, % | ≥90 |

| Water absorption, %, | ≤3 |

| Oxygen index, % | ≥26 |

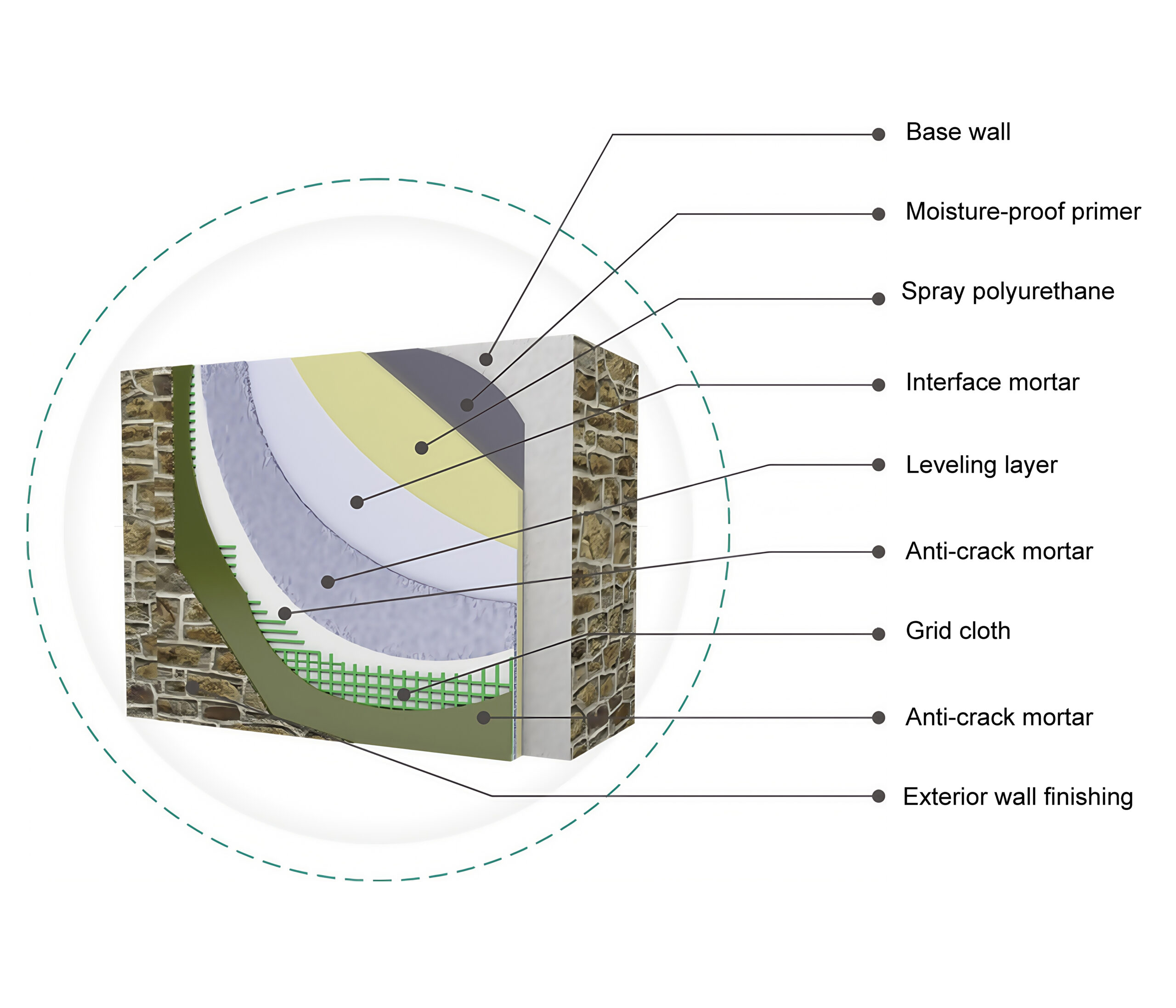

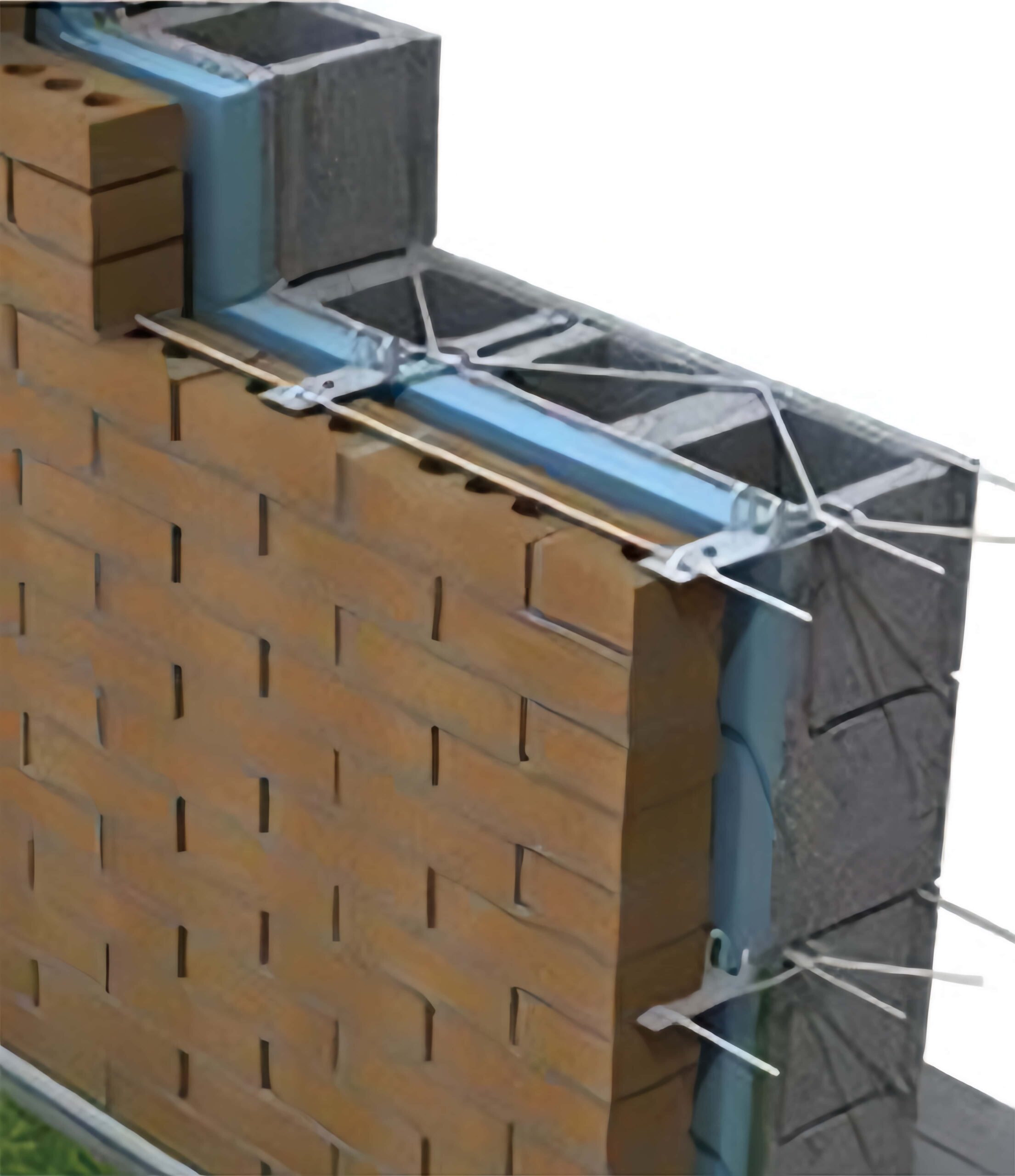

System Display

The Sprayed Rigid Polyurethane Foam Exterior Wall Insulation System consists of Polyurethane Primer (when necessary), Sprayed Rigid Polyurethane Foam Insulation Layer, Interface Mortar, Lightweight Leveling Mortar, finishing layer, Decorative Finish, etc.This non-load-bearing structure is located on the exterior surface of the building, providing thermal insulation and energy-saving benefits

Spray moistureproof primer Spray rigid polyurethane foam Lightweight leveling mortar Rendering coat application

THIN PLASTER EXTERNAL WALL INSULATION SYSTEM

Polyurethane Rock Wool Composite Panel

Specification

Standard Dimensions:1200mm*600mm (customizable) Insulation Layer Thickness:30mm-200mm

Class A Fire Resistance

Application

- building exterior wall insulationof Class A Fire Resistance

- Fire barrier of organic insulation materials

- Energy efficiency retrofitting of existing buildings

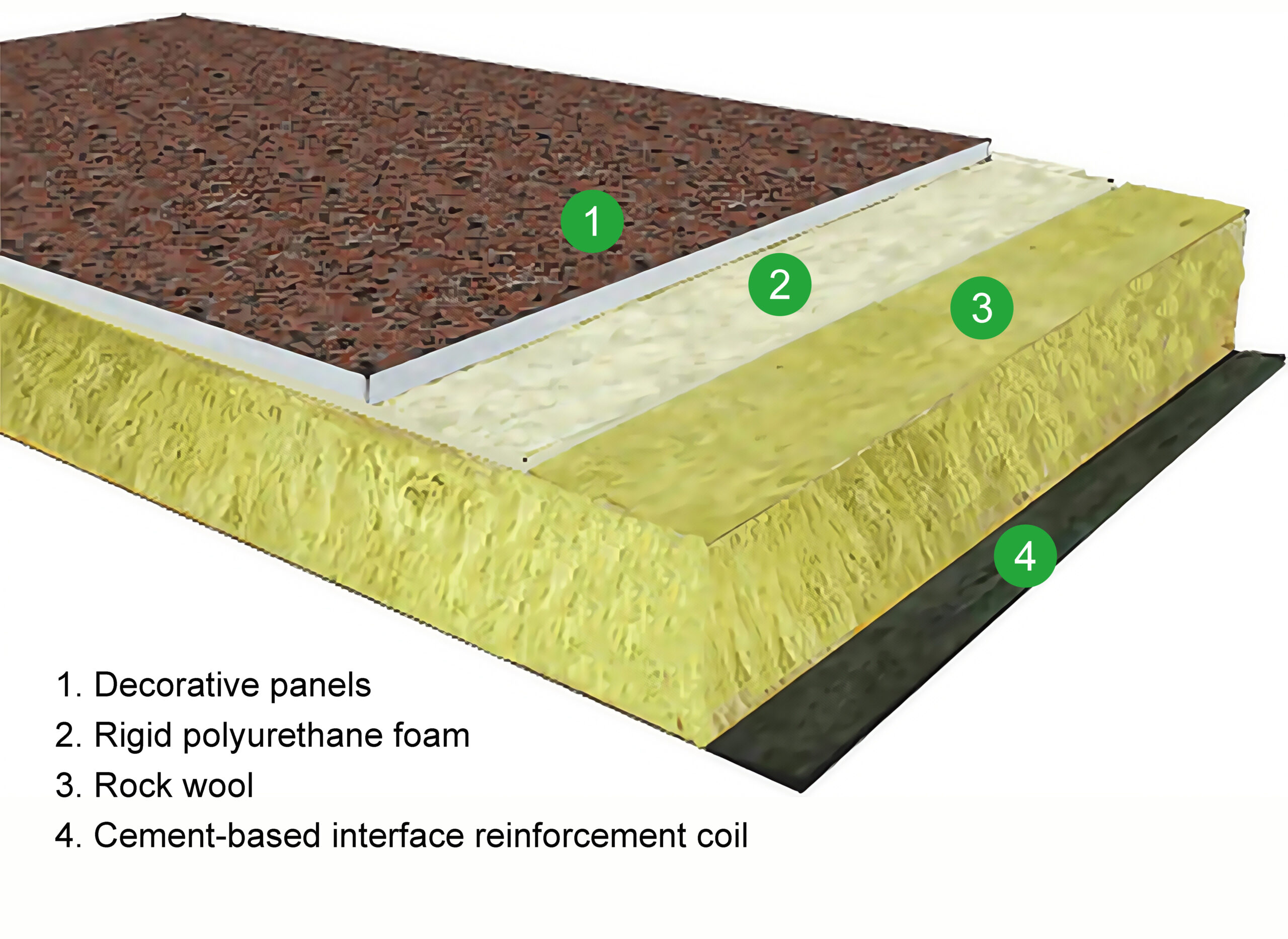

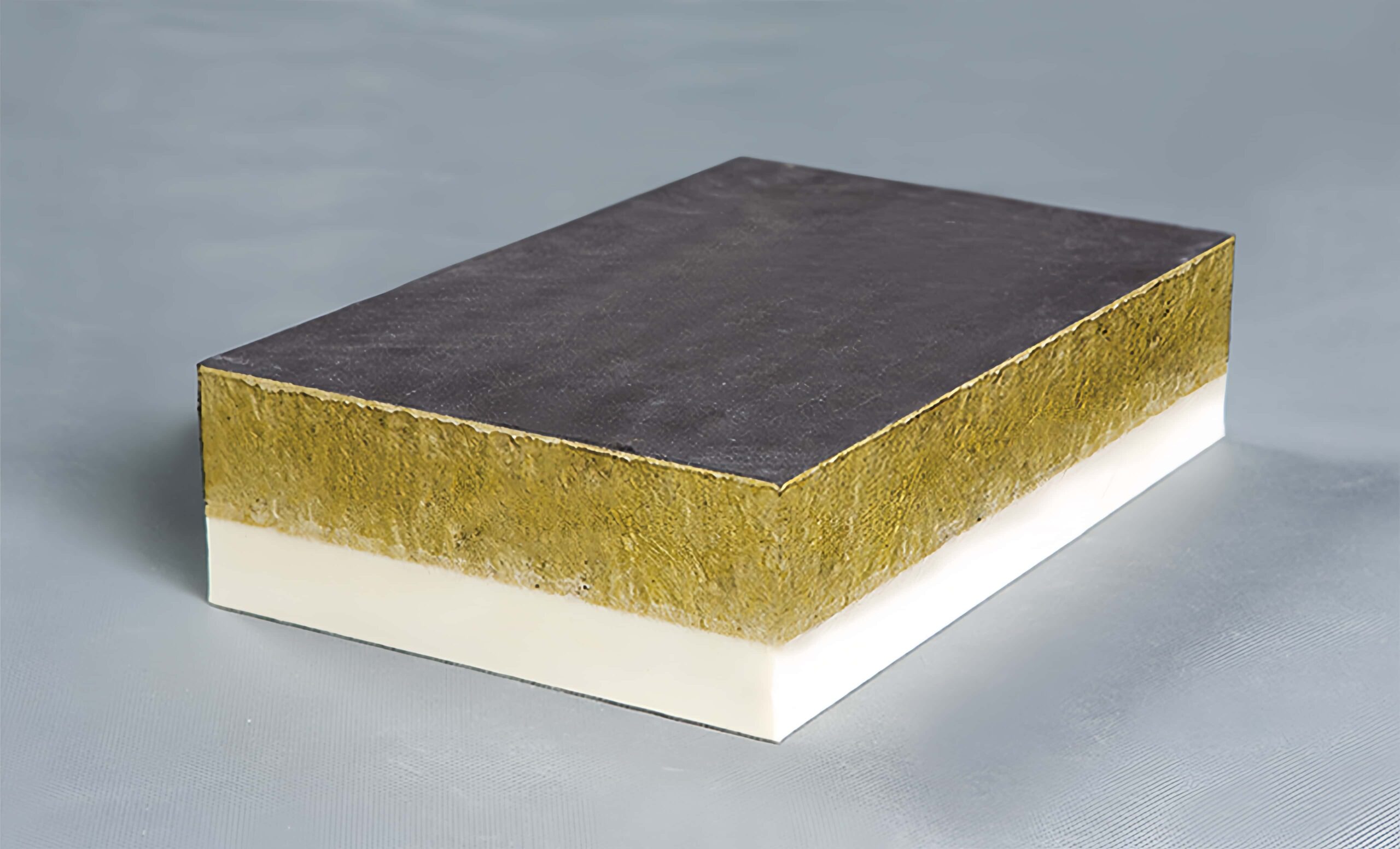

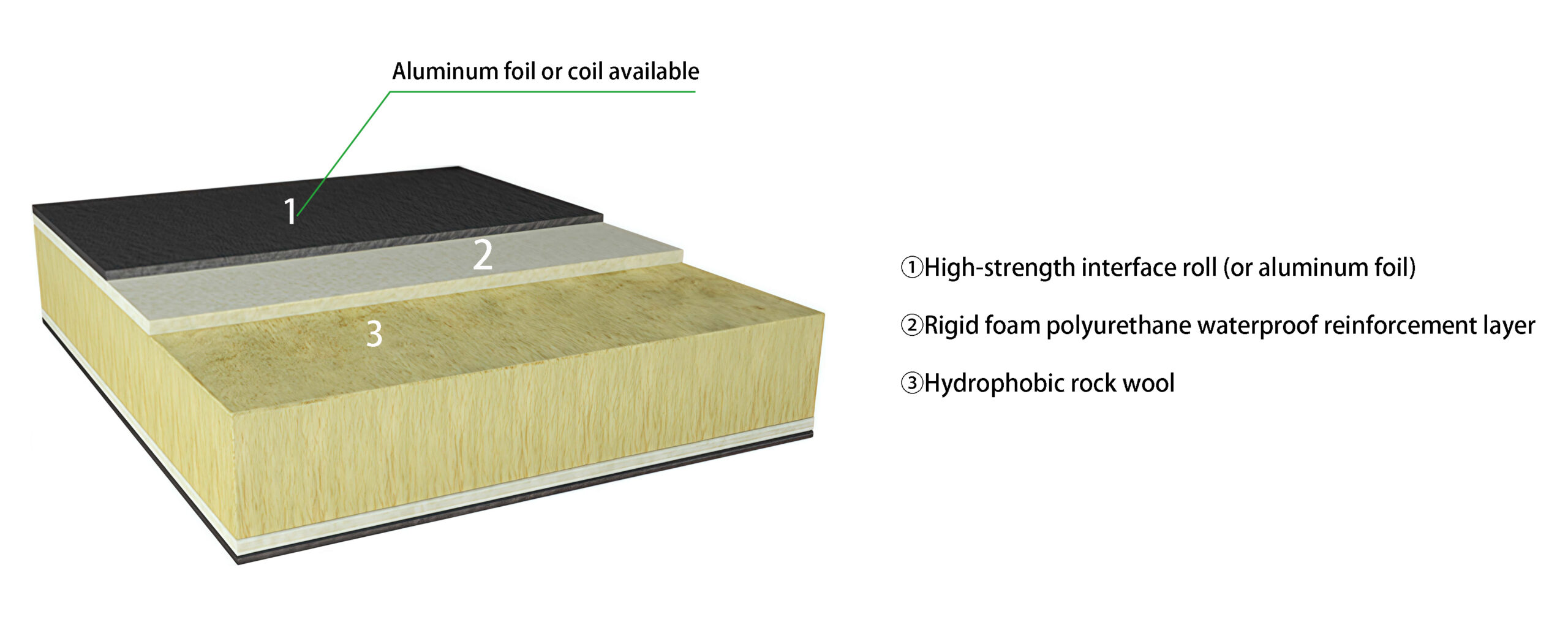

The Polyurethane-Mineral Wool Composite Panel (abbreviated as PRR) is a novel insulated wall material with vertically-aligned mineral wool as the core substrate. Through the continuous foaming process, rigid polyurethane foam is integrated with the mineral wool to form a monolithic structure. Both upper and lower surfaces are co-laminated with interface-reinforced facing layers in a single-step molding process

Product Features

◎Waterproof and Moisture-Resistant

During the production process, liquid polyurethane uniformly covers both the upper and lower surfaces of vertically aligned rock wool panels and penetrates into the rock wool. This forms a continuous closed-cell polyurethane waterproof barrier, effectively addressing the inherent issue of moisture absorption and deliquescence in rock wool

◎Outstanding Mechanical Performance

Leveraging the superior self-adhesive properties of polyurethane, the flowing liquid polyurethane penetrates into the rock wool at a molecular level, repairing broken fibers caused during cutting and forming an interlocking physical bonding structure. This achieves 100% cavity-free connection, resulting in a tensile strength 15 times higher than horizontally aligned rock wool and twice that of vertically aligned rock wool

◎Bidirectional Affinity Interface Reinforcement membrane with High Bond Strength

The upper and lower surfaces of the rock wool are laminated with factory-prefabricated interface reinforcement membrane. The membrane is composed of cement, mortar, and additives, etc., which shares a similar composition with adhesive mortar and polymer mortar, ensuring excellent interfacial compatibility. This design guarantees the tensile bond strength between the PRR insulation panel, the base wall, and the protective layer.

◎Optimization of Construction Environment to Minimize Health Risks

Through full encapsulation of rock wool and eliminating debris generation during cutting, this approach significantly reduces worker exposure to harmful fibers and prevents environmental pollution caused by rock wool dust

Five Major Performance Enhancements

Enhanced Mechanical Safety\ Superior Waterproof Performance\ Optimized Energy Efficiency\ Reduced Material Usage\Lower Labor Costs

| Polyurethane rock wool composite board | Ordinary rock wool board | |

| Effective bonding area | ≥50% | 100% full adhesion |

| Thickness of plaster layer | 4~6mm | 7~10mm |

| Reinforcement mesh | Single layer glass fiber mesh | Double-layer glass fiber mesh or steel wire mesh |

| Diameter of anchor disk | 60mm | 140mm |

| Labor cost | Low cost | Higher cost |

| Construction environment | Friendly construction interface | Harmful to skin and respiratory system |

| Waterproof interface treatment | Prefabricated | On-site painting |

Performance Indicators

| Project | Polyurethane rock wool composite board | |||

| system | Weather resistance | Appearance | There are no visible cracks on the surface, no powdering, no peeling, and no hollowing in the protective layer | |

| Tensile bond strength, kPa | 130 | |||

| Freeze-thaw resistance | Appearance | After 30 freeze-thaw cycles, there are no visible cracks, powdering, peeling, and hollowing in the protective layer. | ||

| Tensile bond strength, kPa | 140 | |||

| Board | Tensile strength perpendicular to the board surface, kPa | 130 | ||

| Compression strength (deformation 10%), kPa | 80 | |||

| Thermal conductivity (average temperature 25℃), w/(m.k) | ≤0.040 | |||

| Water absorption, kg/m² (partial immersion) | 24h | 0.2 | ||

| 28d | 0.4 | |||

| Hydrophobicity, % | 99.4 | |||

| Shear strength longitudinal, kPa | 102 | |||

Performance Comparison

①Construction Process Comparison

Two coats and three coatings, the thickness of the plastering layer is 7-10mm One coat and two coatings, the thickness of the plastering layer is 4~6mm

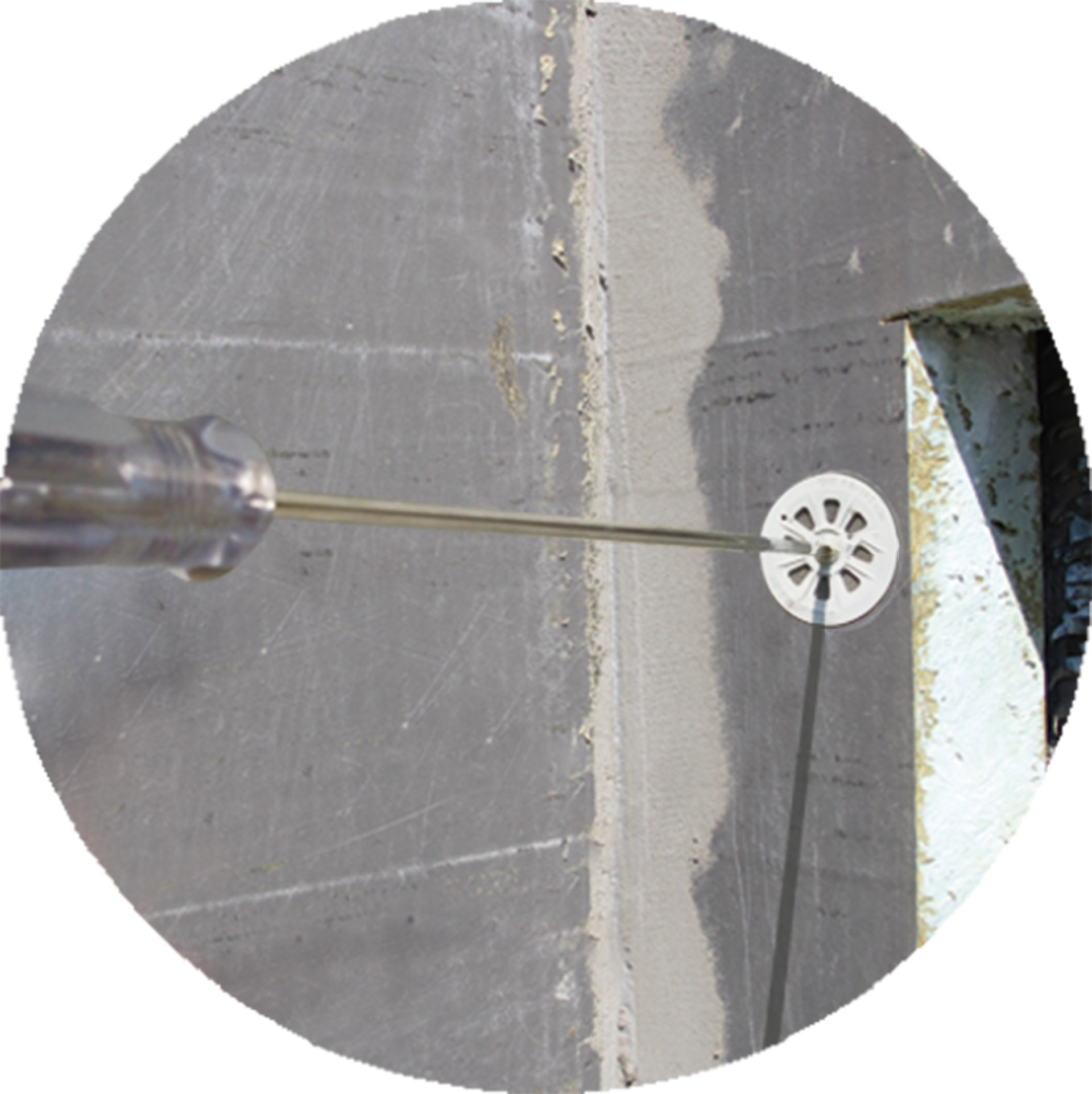

②Anchor Bolt Comparison

Double disc anchor bolt Anchor bolt diameter 140mm Single disc anchor bolt Anchor bolt diameter 60mm

③Anchor Bolt Comparison

Deformation occurs after force is applied No obvious change after force is applied

④ Construction period comparison

Compared with traditional rock wool systems, polyurethane rock wool composite panels require fewer construction procedures and reduce the project timeline by 1/3.

Polyurethane rock wool composite board

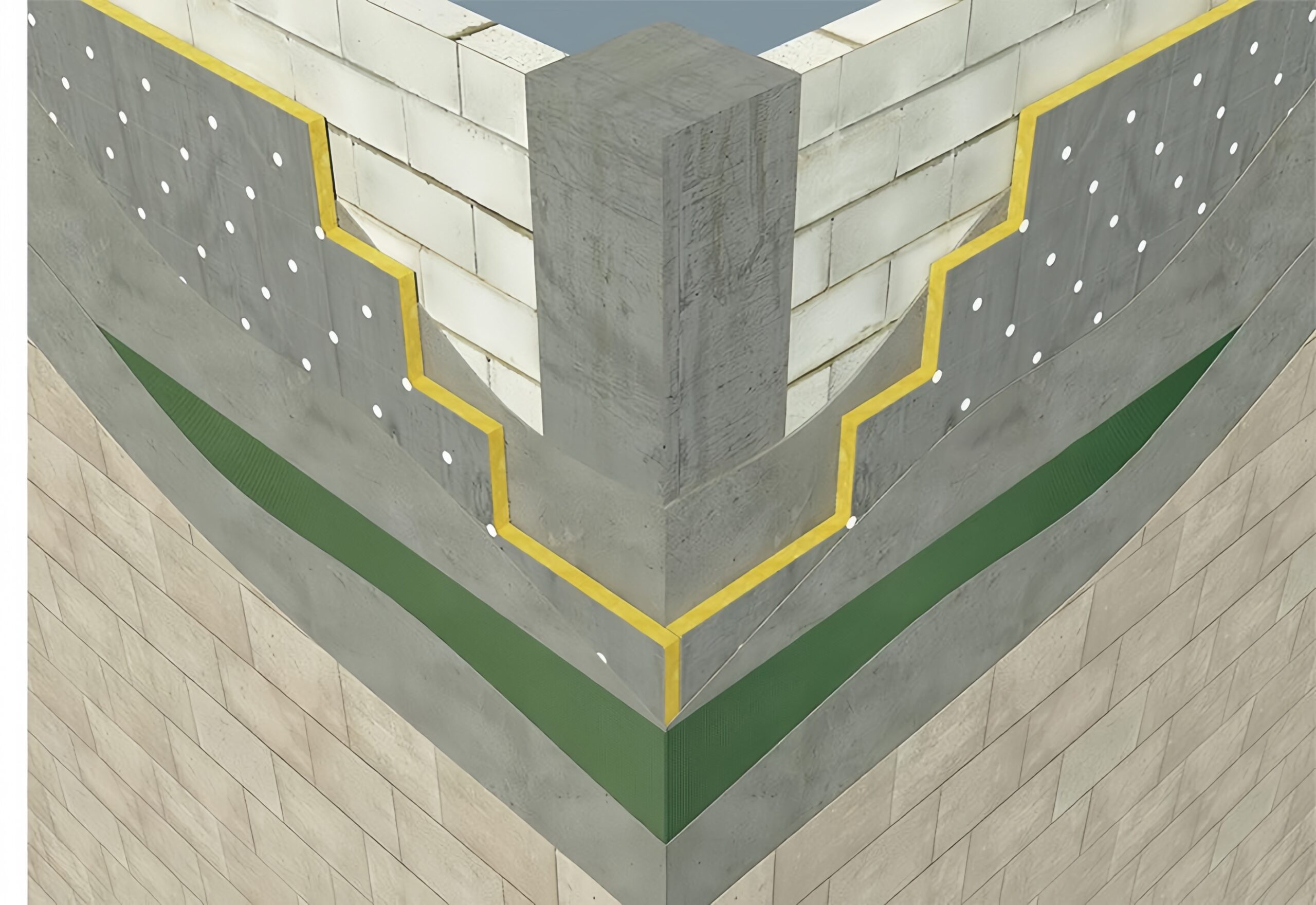

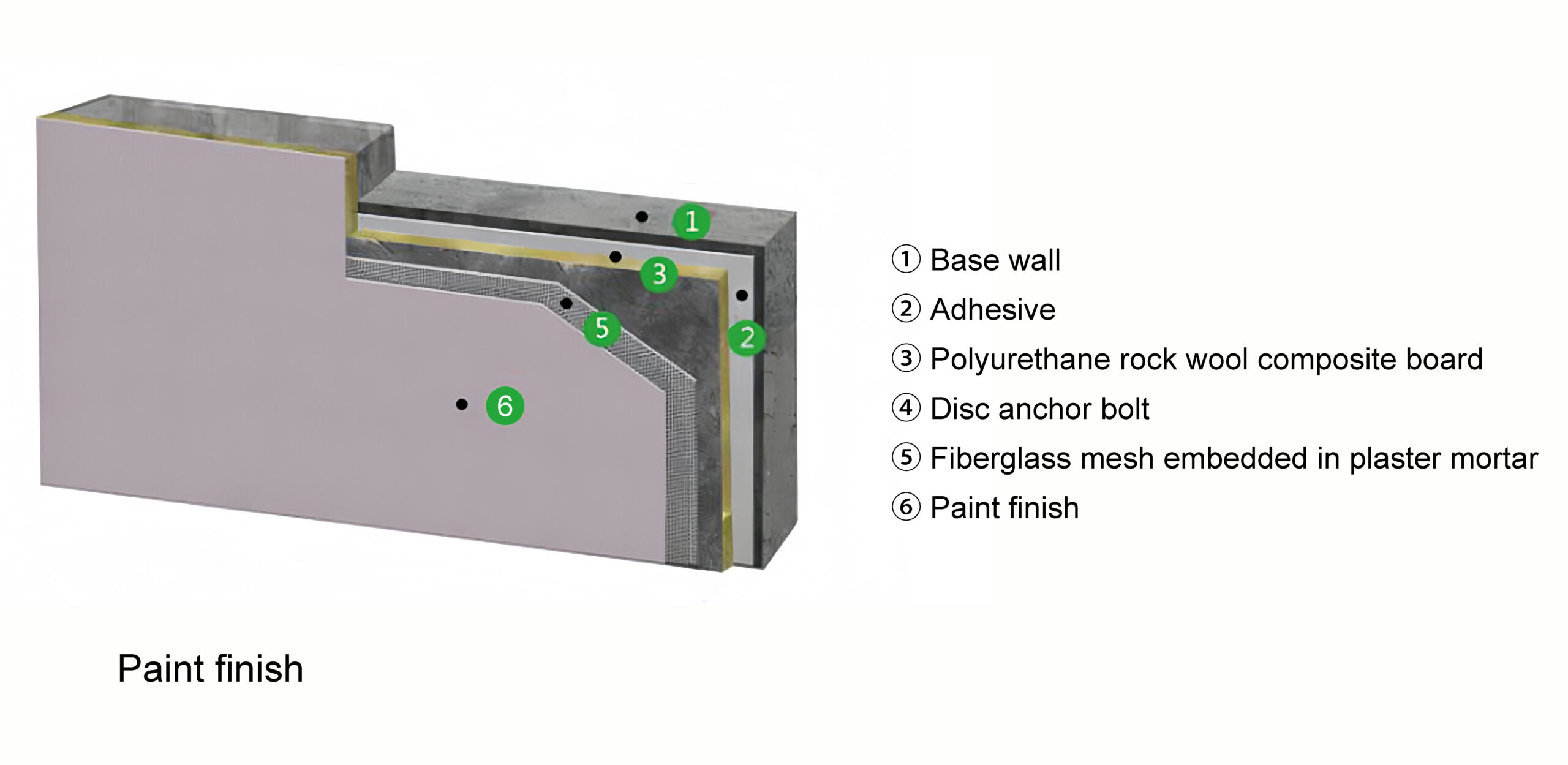

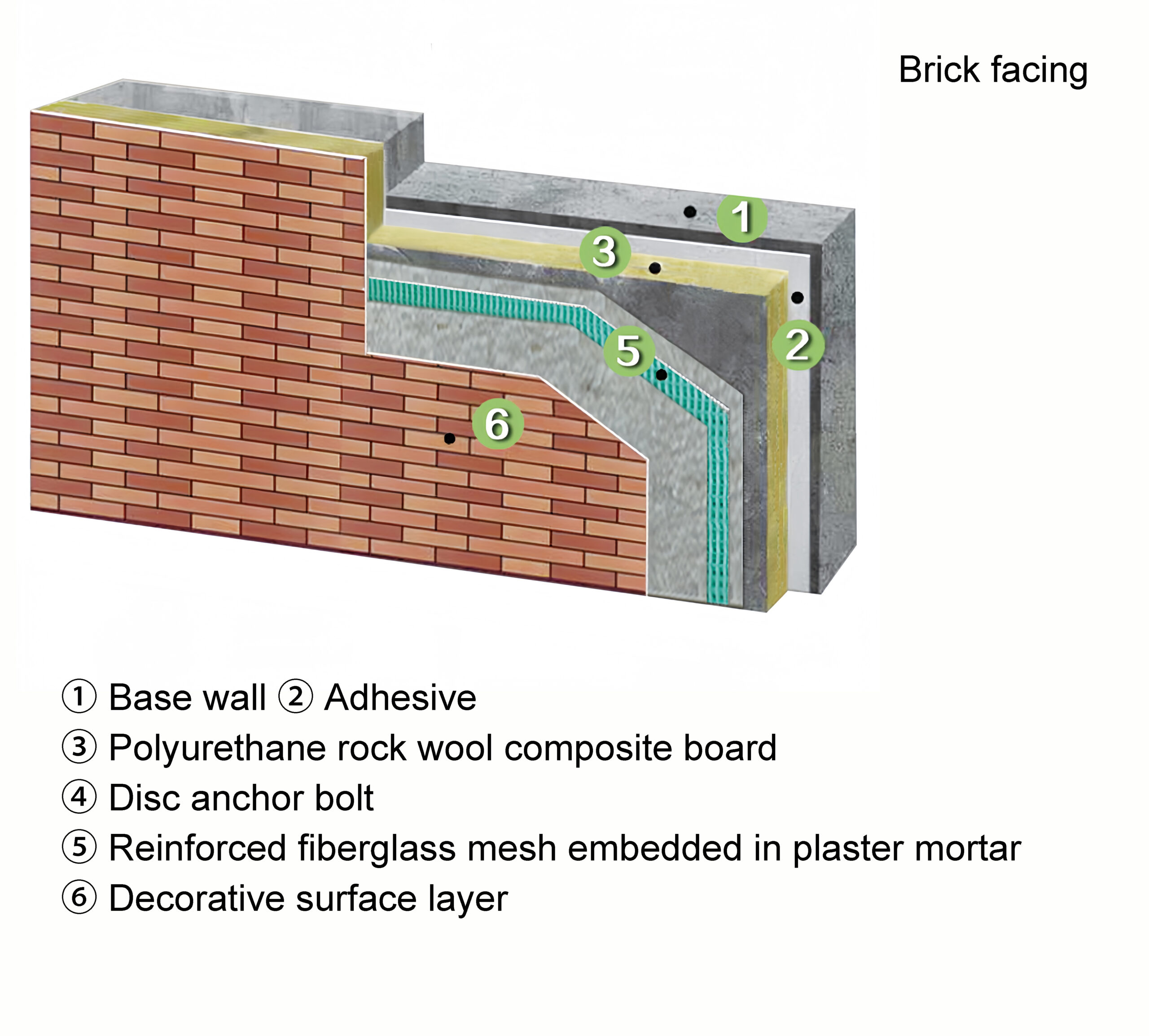

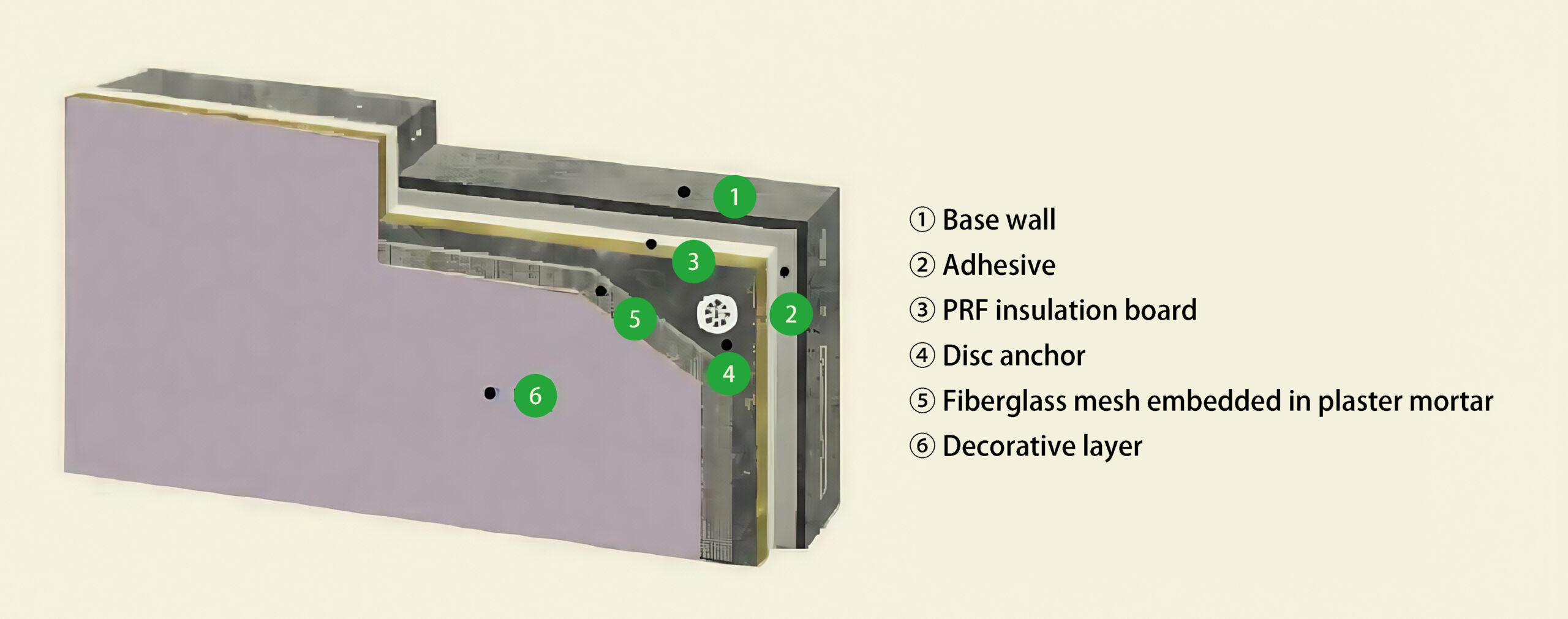

System

Polyurethane Rock Wool Composite panel Thin Plaster System is composed of polyurethane rock wool composite panel, adhesive, plastic expansion anchors, alkali-resistant fiberglass mesh, polymer mortar, and finishing materials. It is suitable for installation on exterior walls to provide thermal insulation and decoration as a non-load-bearing structure.

Note: For tile finishes, reinforced alkali-resistant fiberglass mesh should be used.

Construction technology

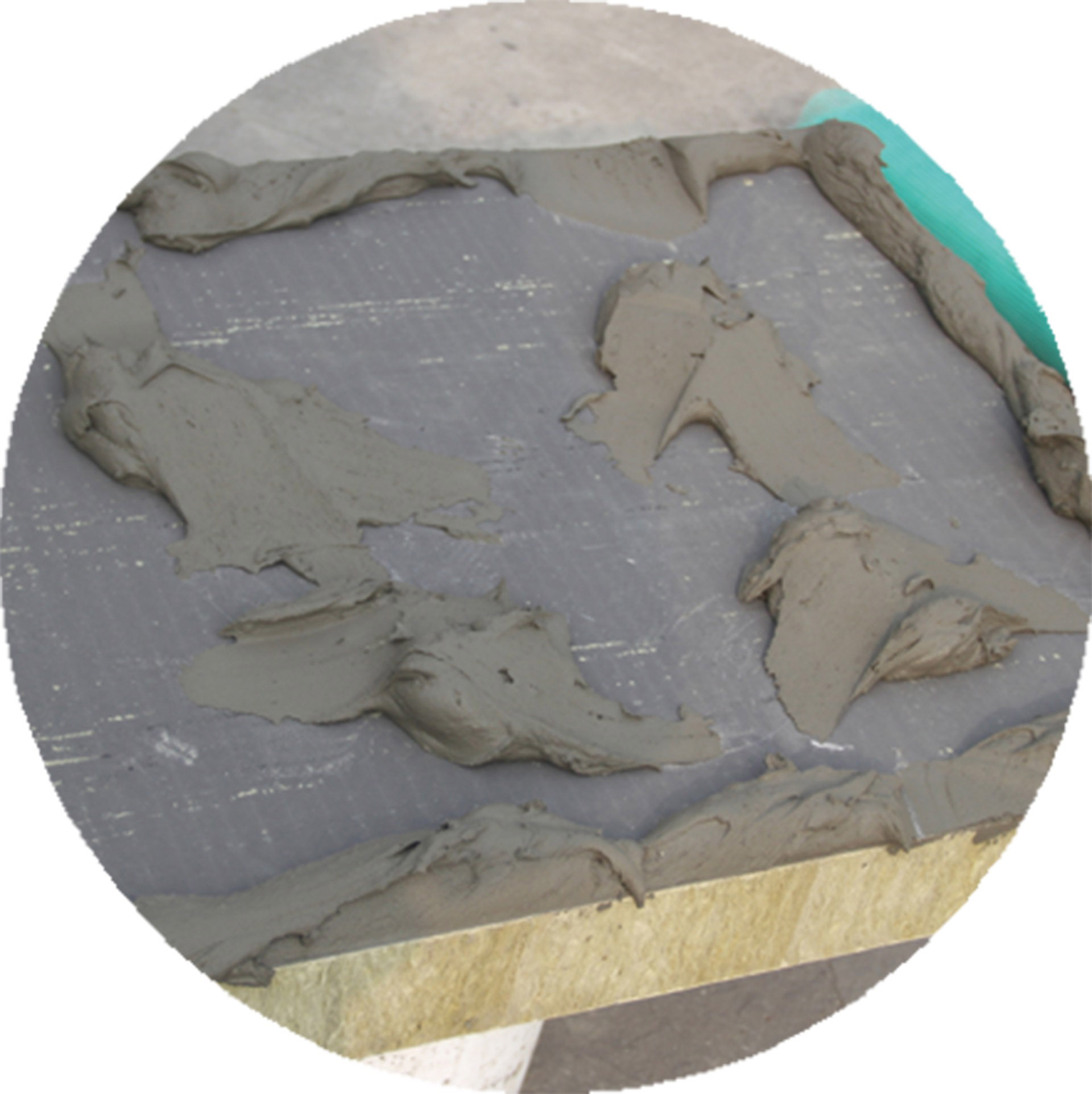

Adopt “paste + anchor” fixing method ~ mainly bonding, supplemented by anchoring, double insurance system with high safety

① Base inspection ② Base treatment ③ Wire laying control ④ Mixing bonding mortar

⑤ Pasting the flip net ⑥ Applying adhesive ⑦ Pasting the insulation board ⑧ Drilling

⑨ Anchoring ⑩ Applying surface mortar ⑪ Pressing and embedding fiberglass meshv ⑫ External finishing construction

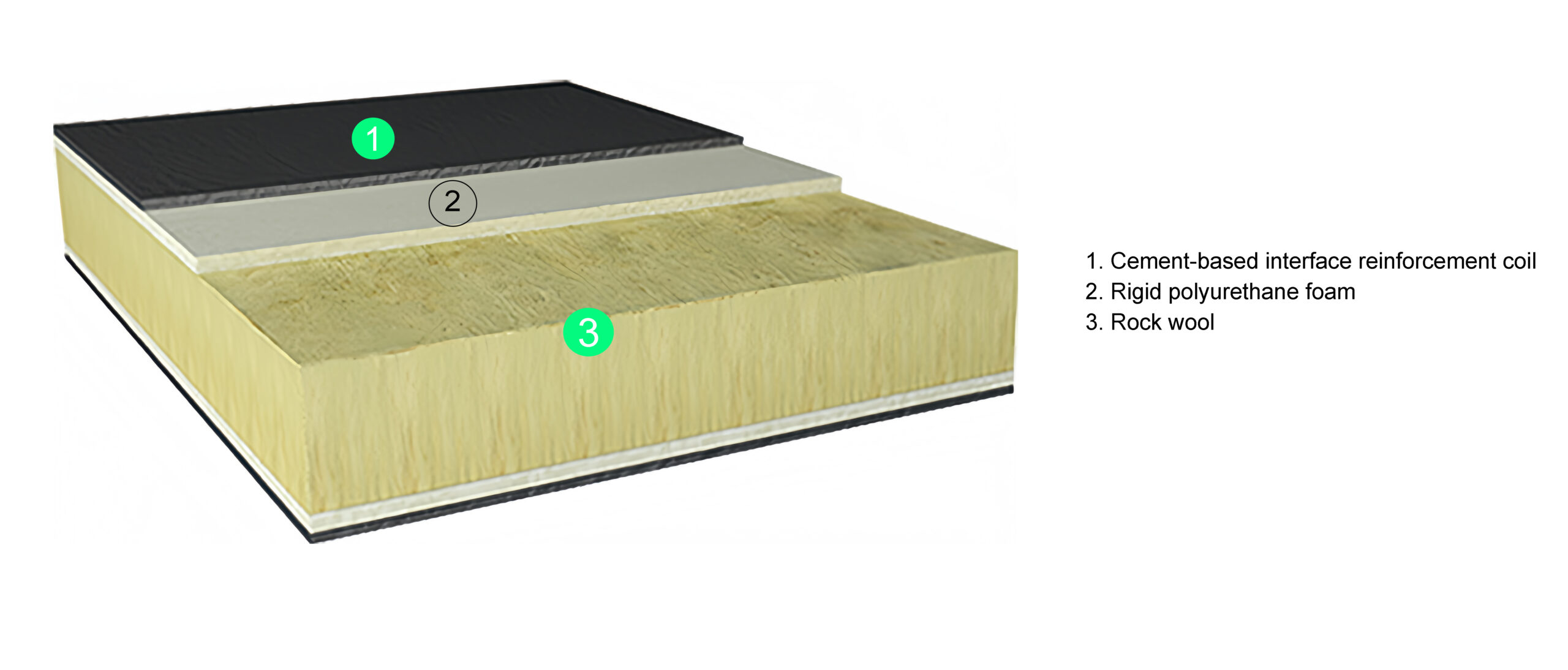

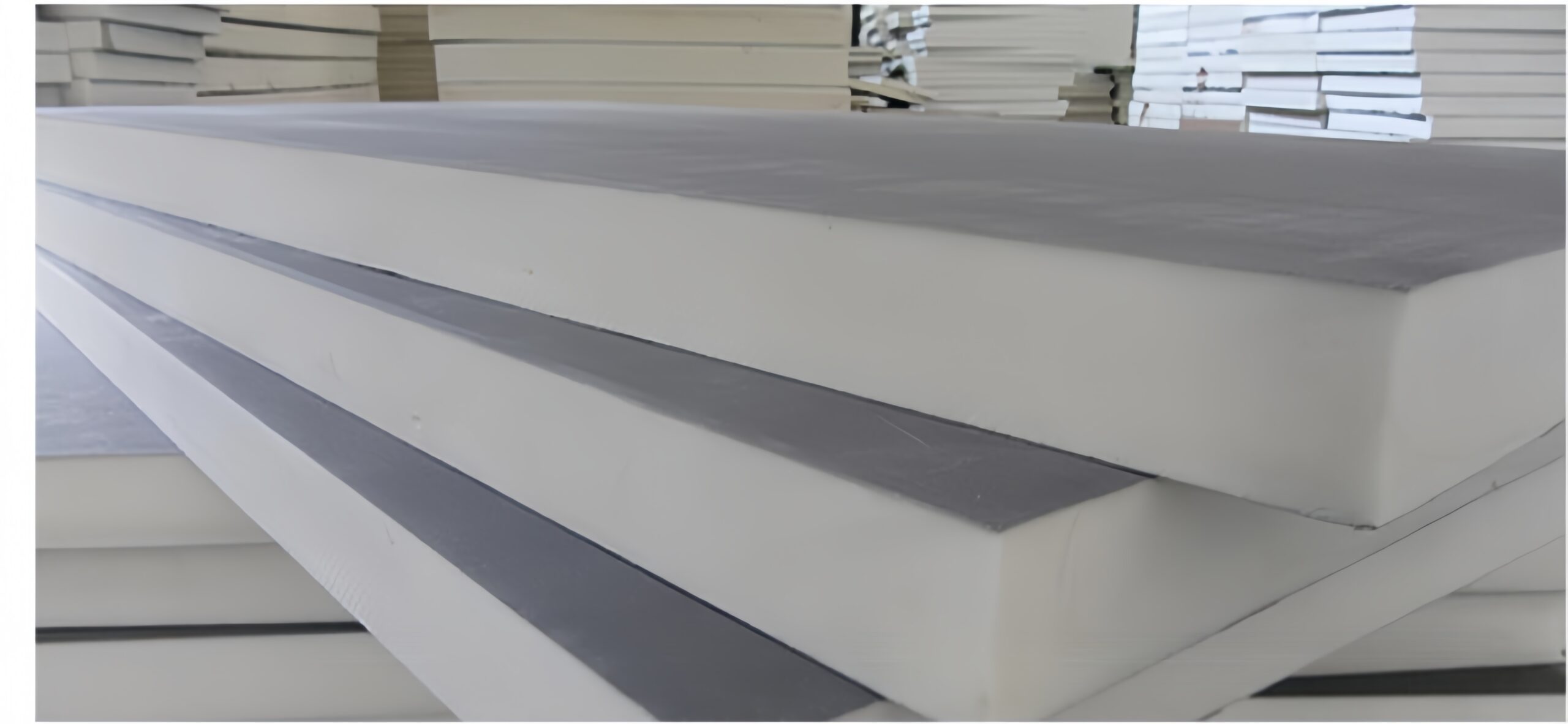

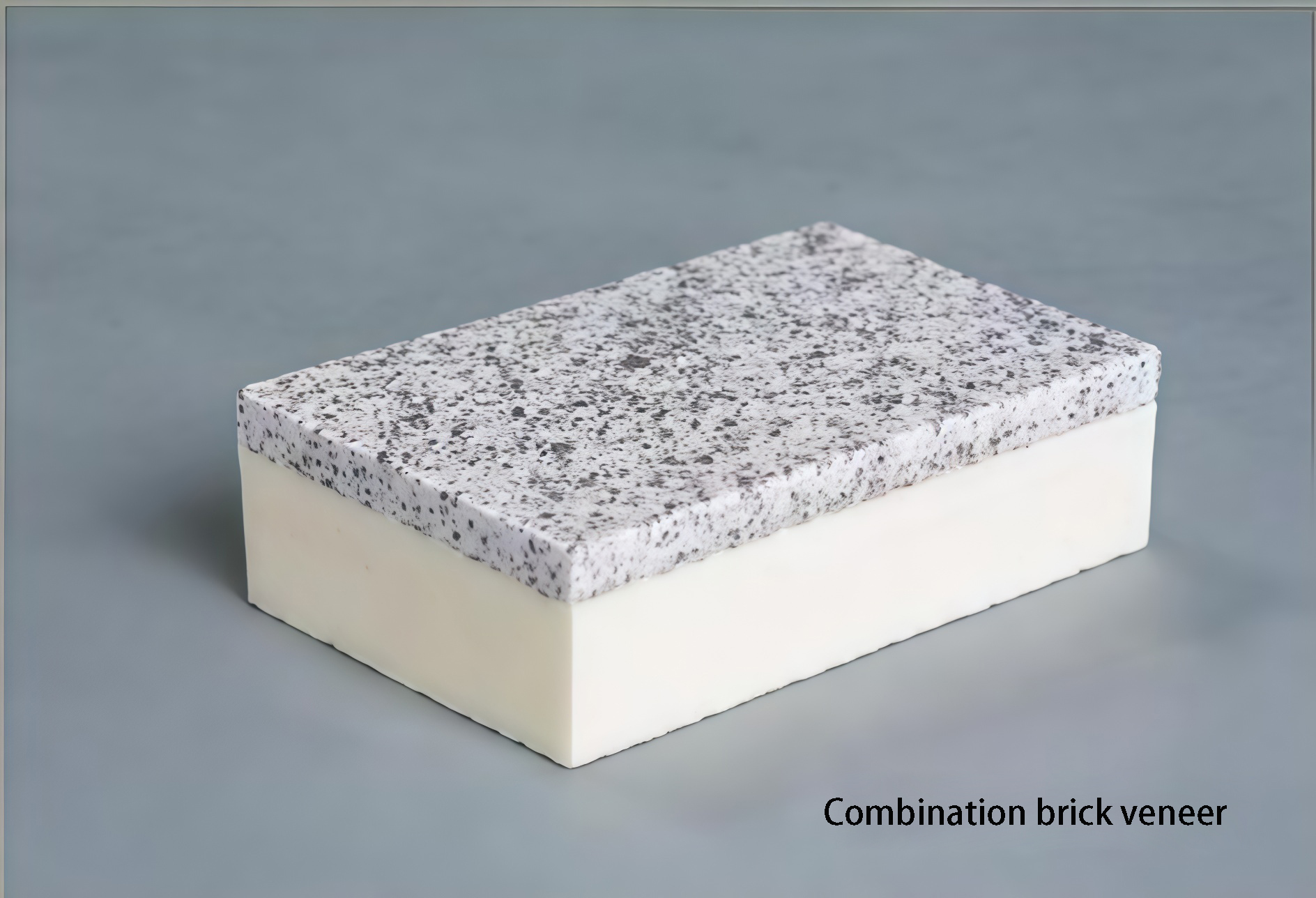

Rigid polyurethane foam composite board

Product specifications

Standard size: 1200mm*600mm (customizable) Insulation layer thickness: 20mm-150mm

Rigid polyurethane foam composite panel is the insulation one formed by bonding polyurethane insulation core with cement-based interface reinforcement membrane through specialized continuous production line in factories. (Abbreviation: PIR panel)

Features

◎Outstanding thermal insulation with the thinnest insulation layer

Rigid polyurethane foam (PUR/PIR) exhibits an ultra-low thermal conductivity of 0.018–0.024 W/(m·K), making it an ideal thermal insulation material. Under equivalent thermal resistance requirements, the insulation layer thickness is minimized, reducing structural self-weight moment and significantly enhancing safety

◎Wide operating temperature range

The operating temperature range of rigid polyurethane foam is -50℃~150℃, and the short-term operating temperature can reach 250℃ without any damage. It has a wide operating temperature range and can be used in severe cold and high temperature areas.

◎Fire resistance & flame retardancy

Rigid polyurethane foam (PUR) is thermosetting material. When exposed to fire, no melt dripping occurs and the carbonized char layer forms on the surface, effectively suppressing flame spread.

◎Waterproof Performance

Rigid polyurethane foam features closed-cell structure with closed-cell content exceeding 95% and low water absorption, effectively blocking moisture penetration. This makes it an ideal integrated waterproofing and insulation material

◎Chemical Corrosion Resistance

The material exhibits excellent physicochemical stability, resisting reactions with most corrosive chemicals.

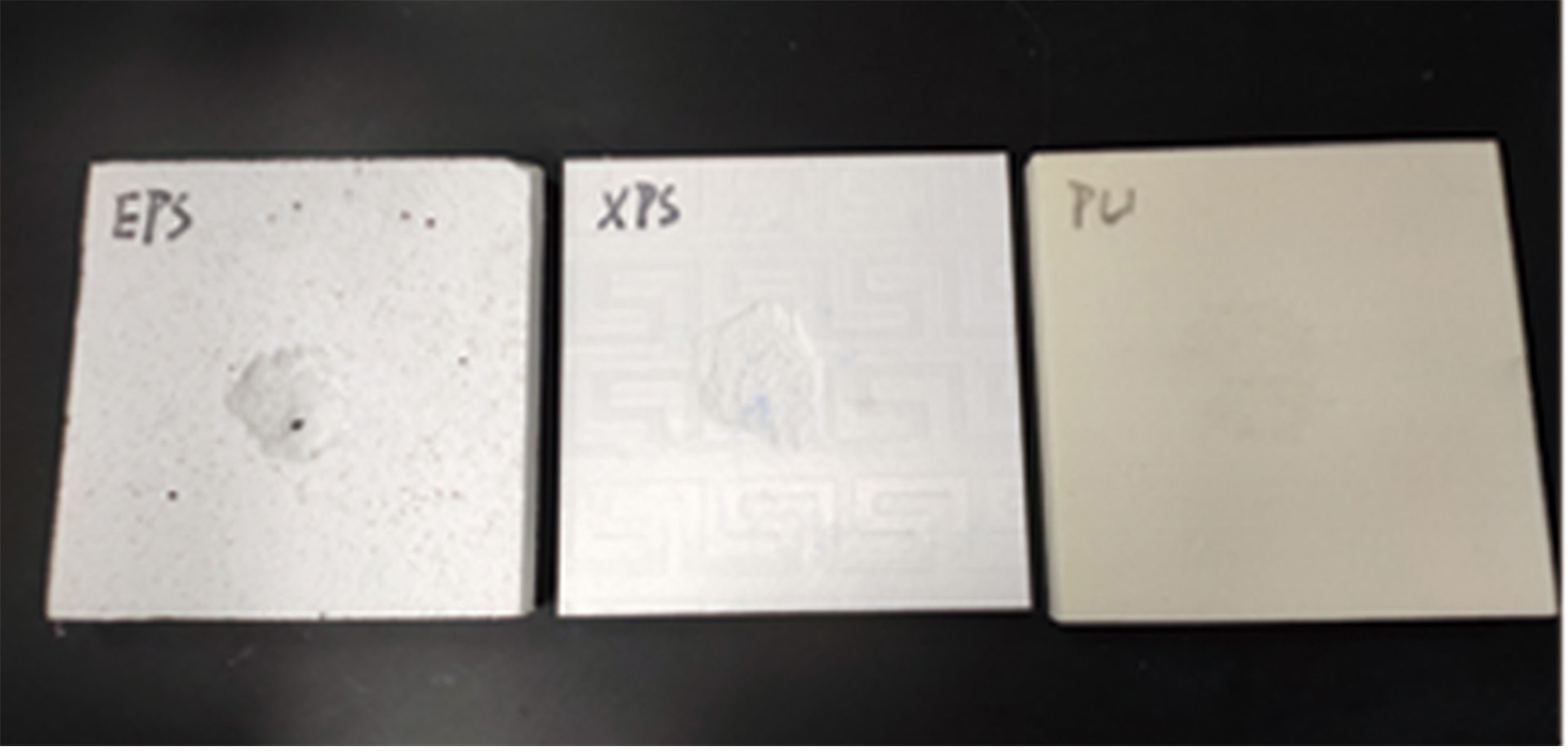

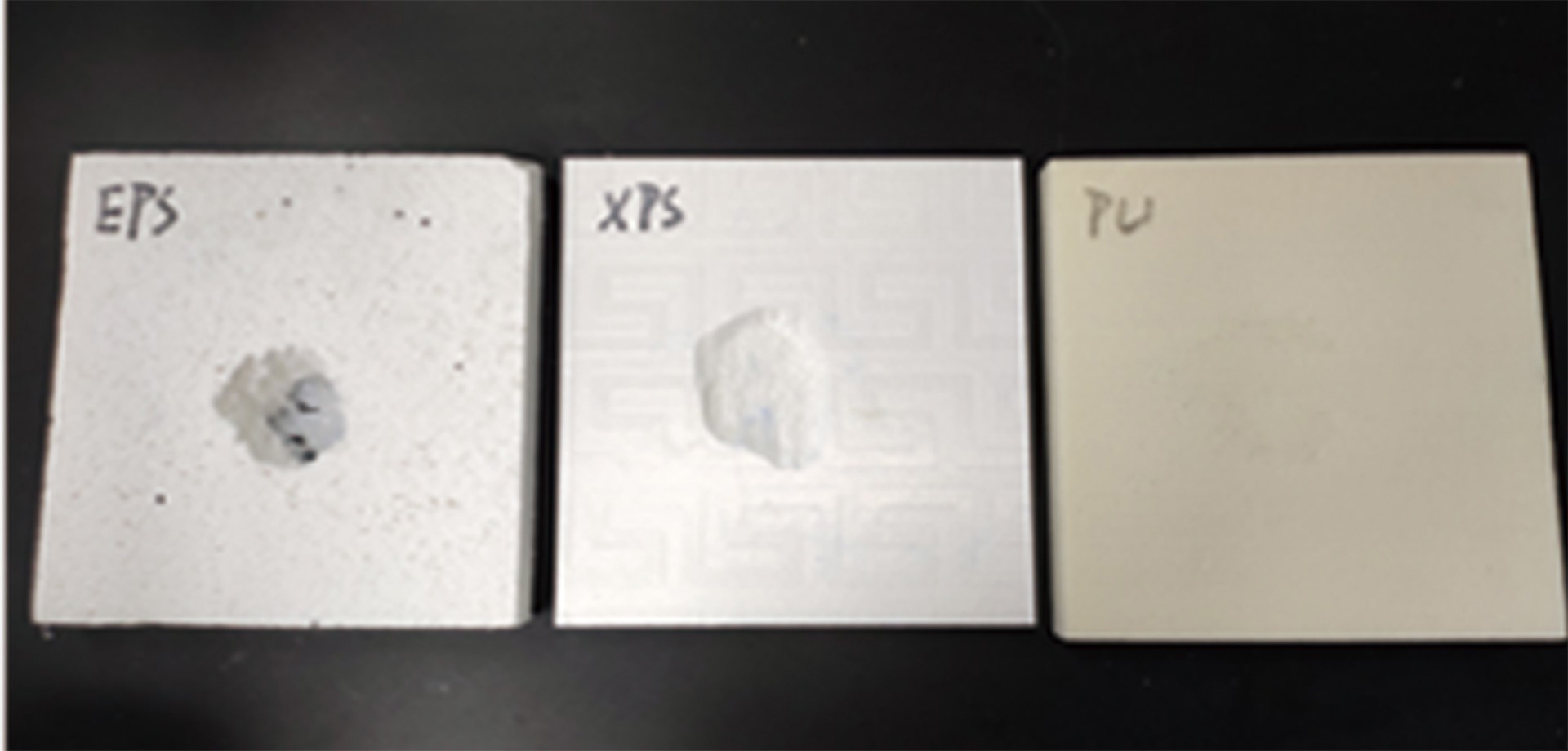

① Before the experiment

② 4 drops of acetone solution were added to each board

③ No reaction to PU

④ XPS formed a hole, EPS was penetrated, and PU had no reaction

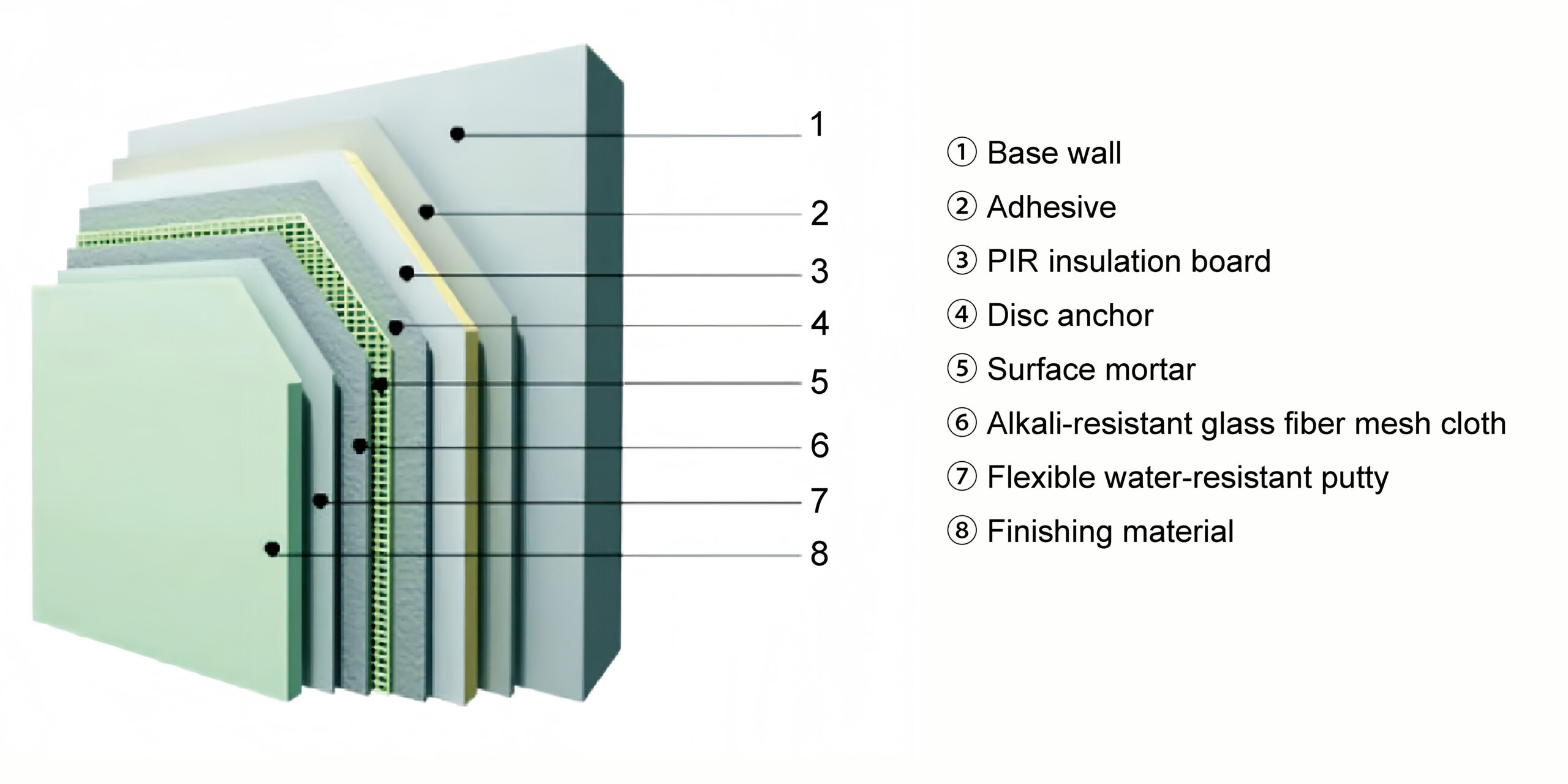

System Display

Construction technology

The fixing method of “adhesion + anchoring” is adopted, with bonding as the main method and anchoring as the auxiliary method, which provides double insurance and high system safety.

①Inspection and treatment of the base layer

②Construction preparation

③Putting control lines

④Preparing adhesives

⑤Paste the mesh cloth

⑥Paste the insulation board

⑦Prepare the plastering mortar

⑧Treatment of fiberglass mesh at the door and window openings and the closing parts

⑨Apply the plastering mortar and embed the fiberglass mesh

⑩Reinforcement of anchor bolts

⑪Exterior finishing construction

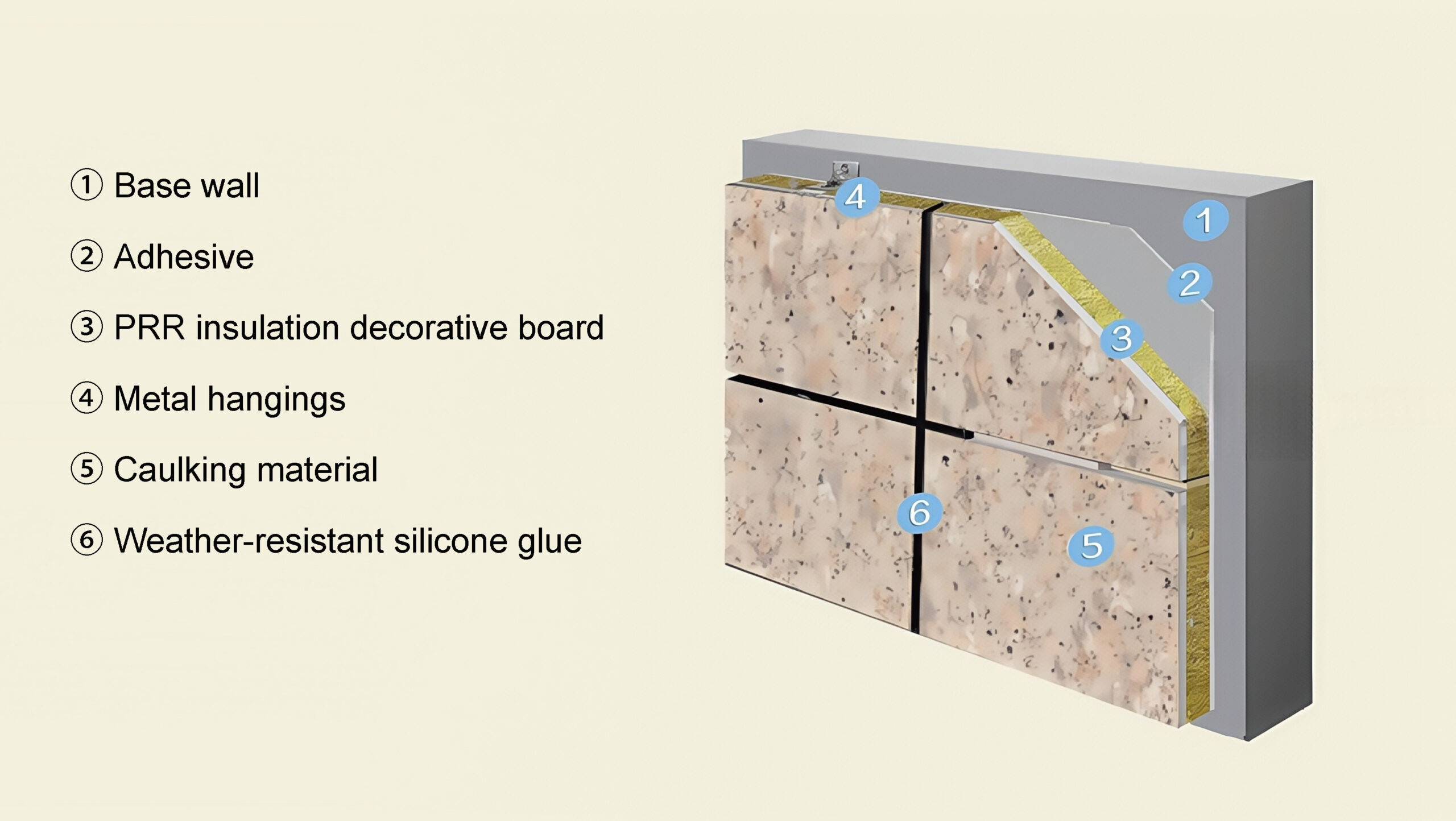

DECORATIVE INSULATION BOARD EXTERIOR INSULATION SYSTEM

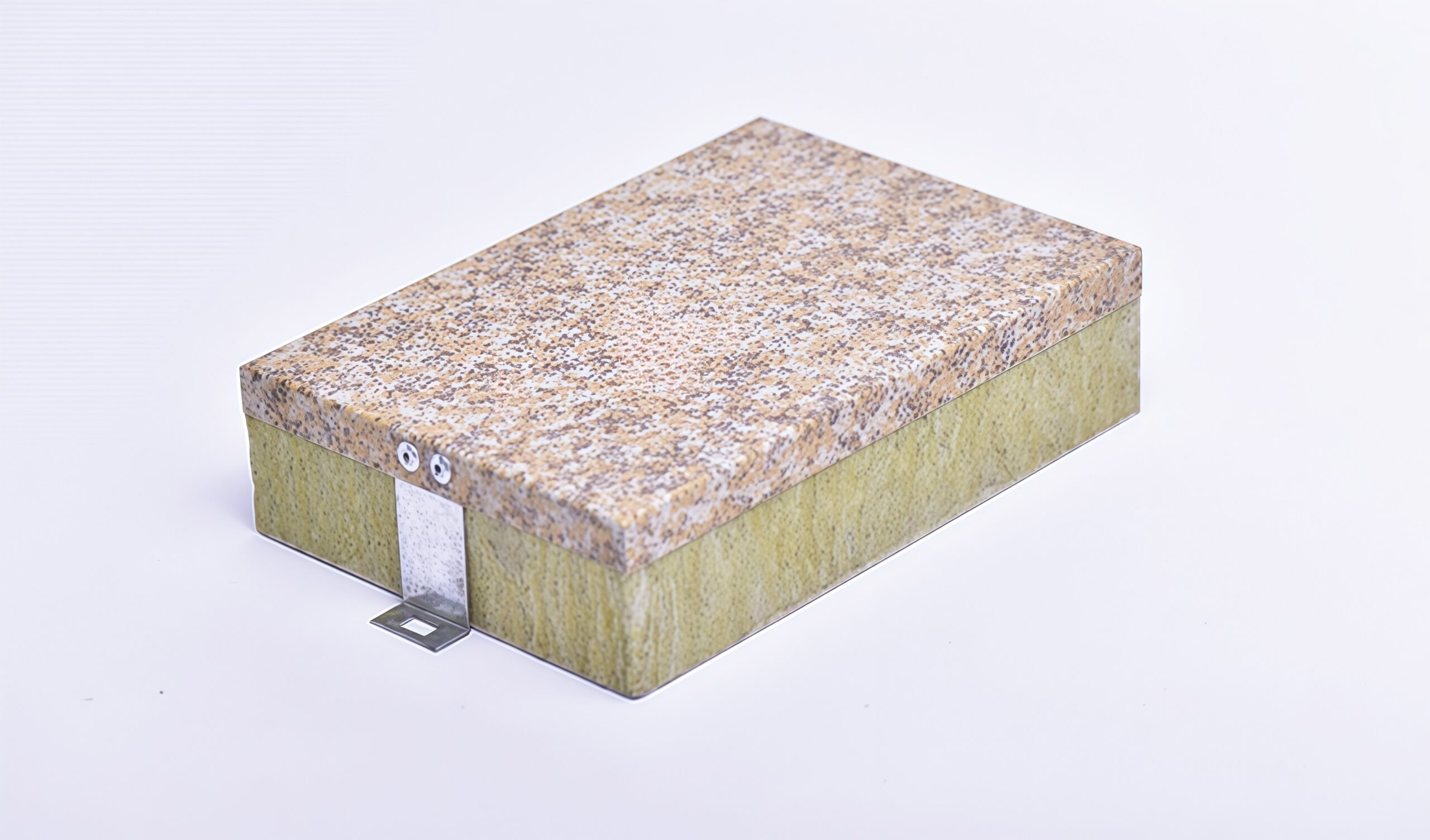

PRR Insulation Decorative Board

Product specifications

Standard size: 1200mm*600mm (customizable) Insulation layer thickness: 20mm-150mm

Class A fire protection

Application scope

Building exterior wall insulation with Class A fire protection requirements

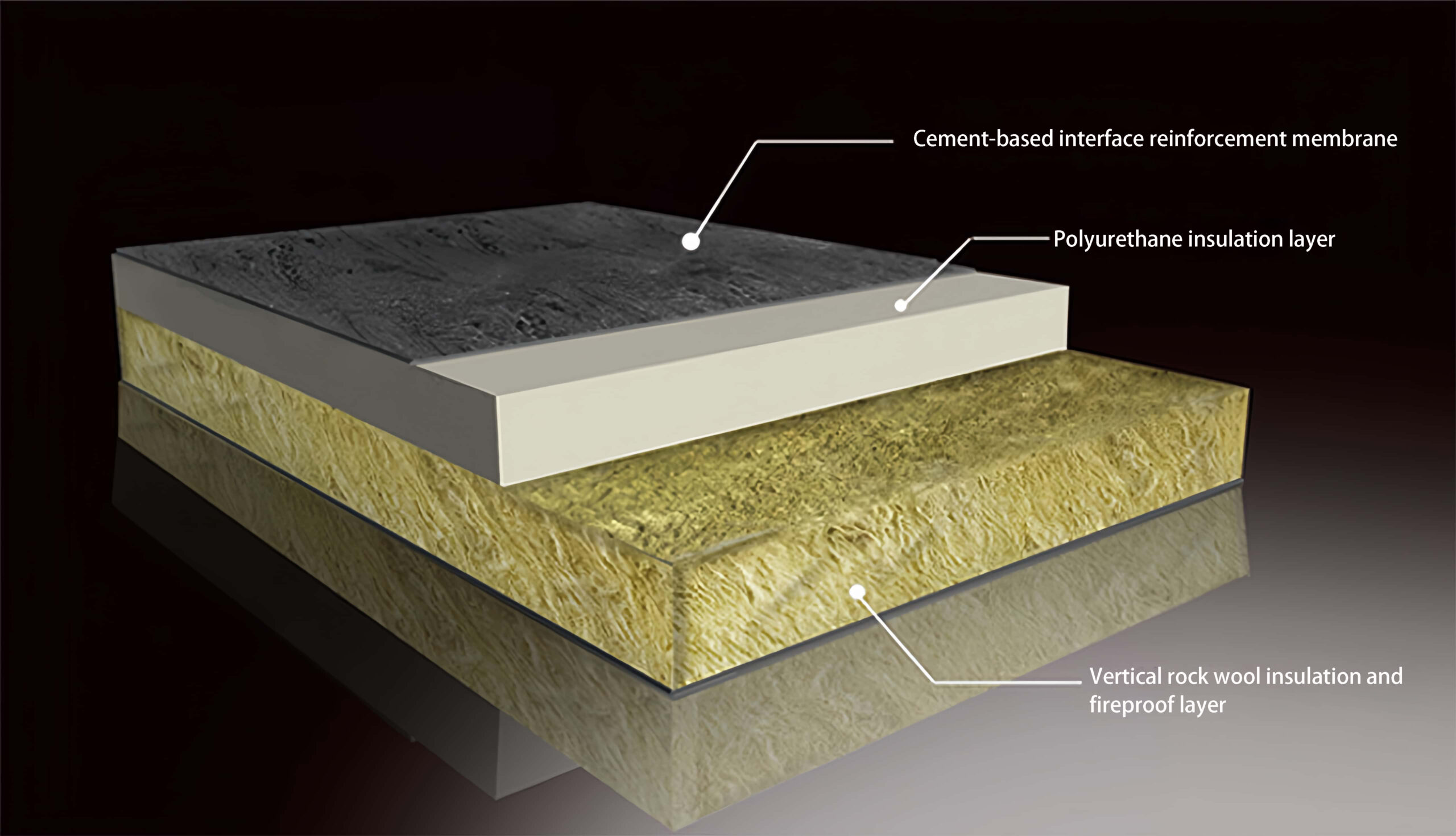

PRR Decorated insulation panel is a new type of integrated wall material with vertical-fiber rock wool as the core, integrated with rigid polyurethane foam through continuous foaming technology. The upper

Surface is prefabricated decorative panel and the lower surface is interface-reinforced membrane (one-step molding)

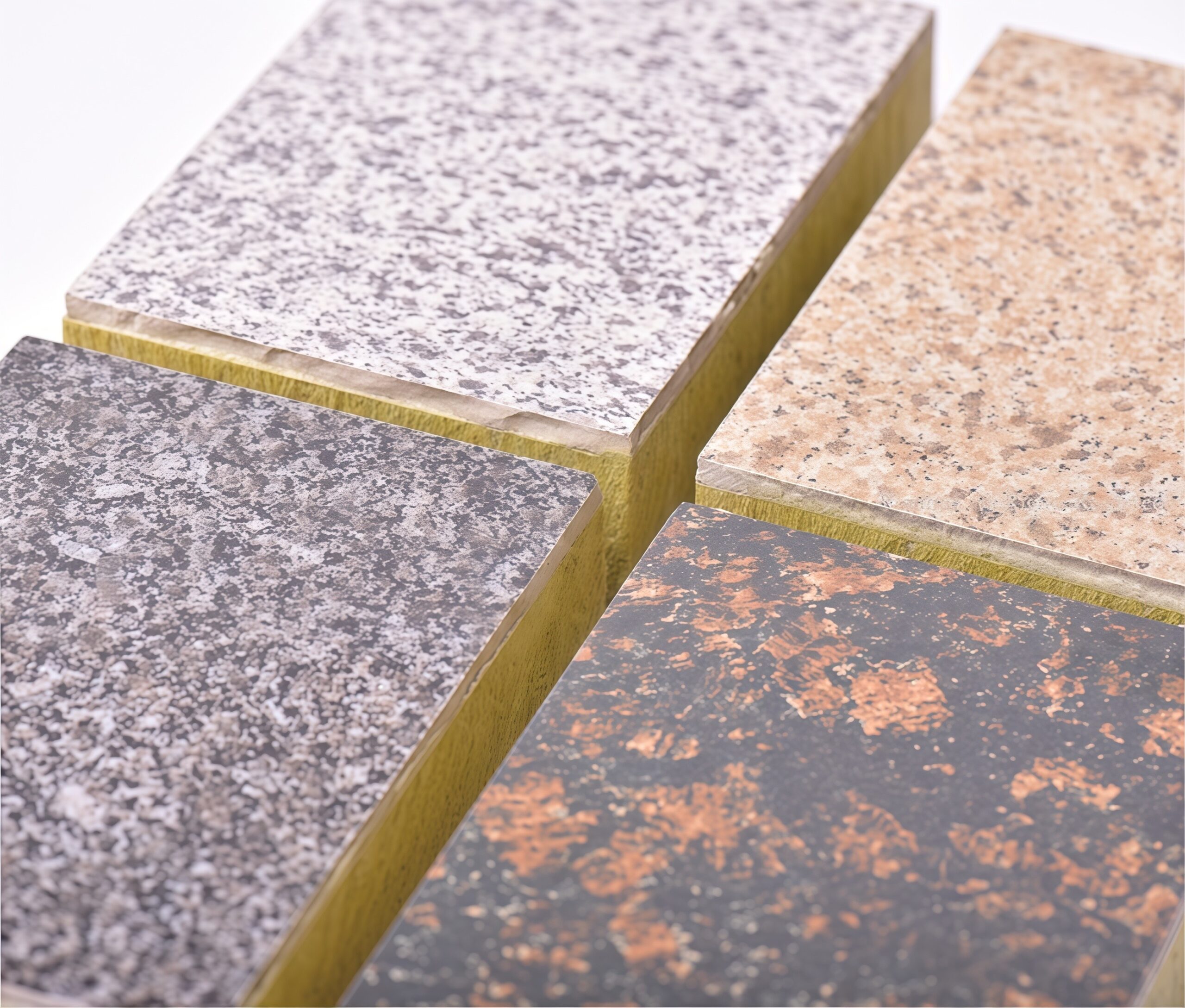

Six Major Finish Series

Ceramic Thin Panel

thin thickness, Lightweight, High hardness, Decorative, Self-cleaning with rainwater, Radiation-free, colorfast

Metal cladding

Lightweight, excellent seismic resistance, high workability, suitable for diverse architectural shapes across building components.

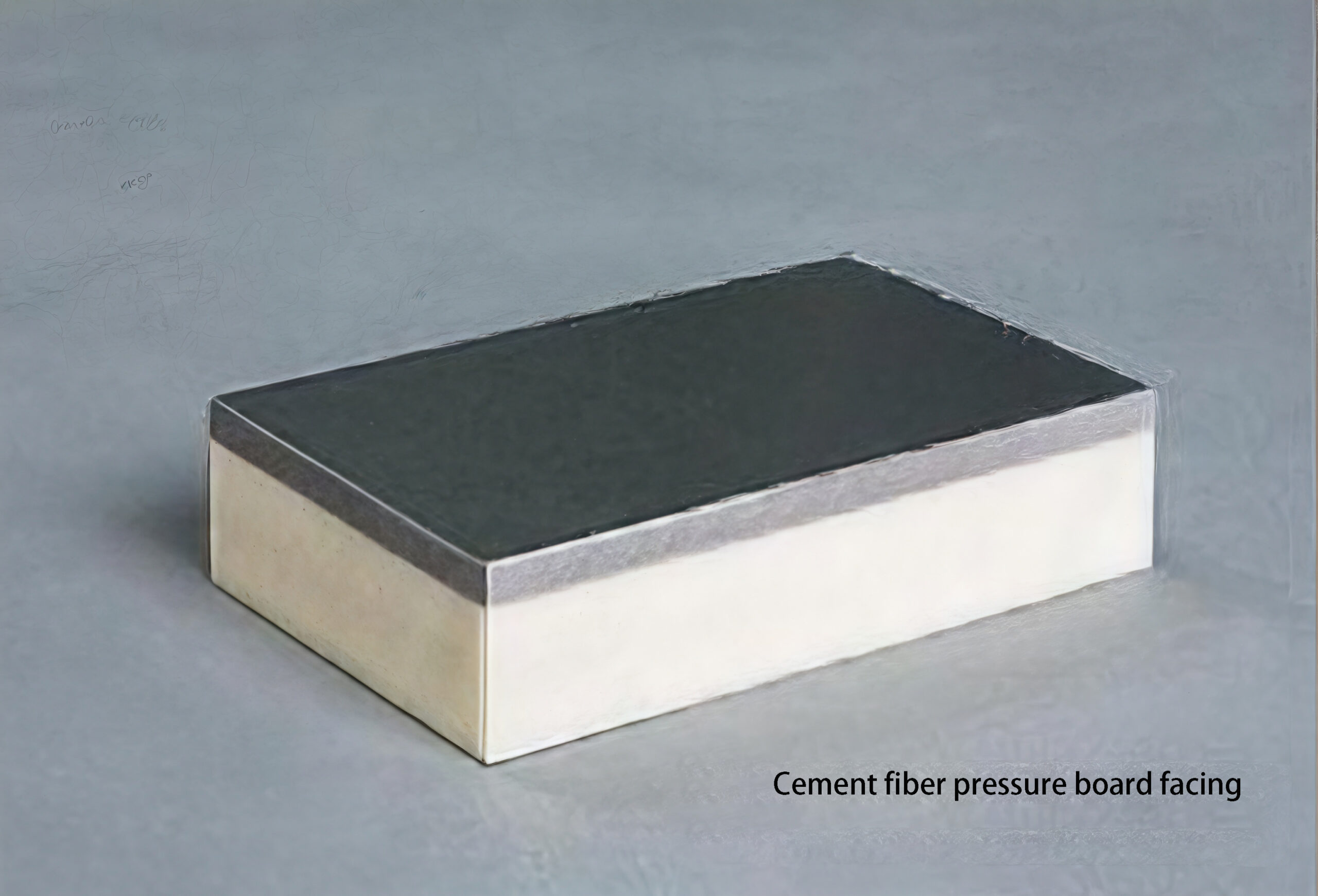

Fiber Cement Pressure Board

Fluorocarbon Paint (Flat Coating), Stone-like Texture Paint (Textured Coating), Color Uniformity,Crack Resistance, Waterproof & Moisture-proof, Low Deformation Rate, Fire-resistant & Insulating, Lightweight & High Strength

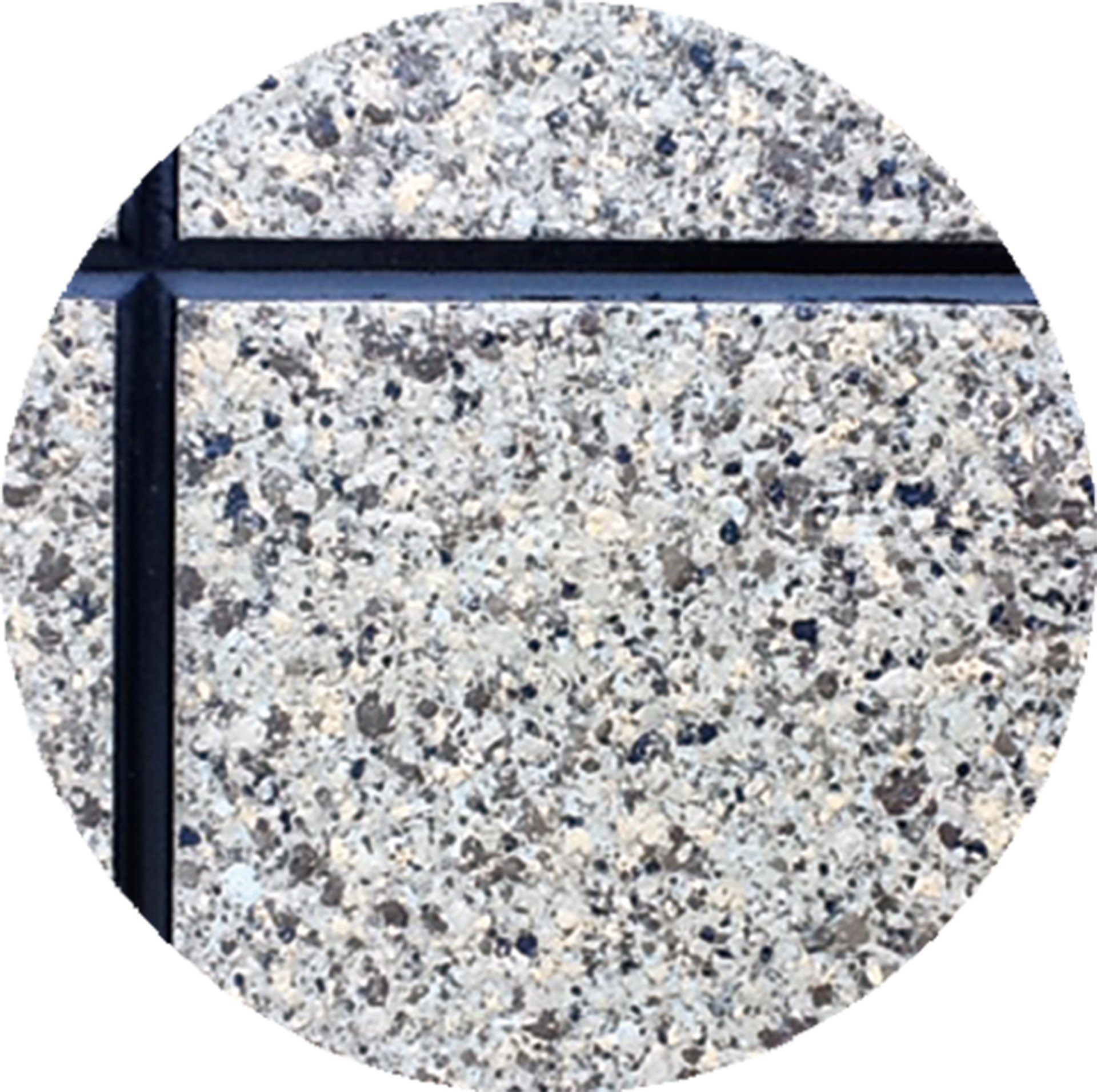

Natural Stone Facade

Use 8-12mm natural stone, High-end and elegant, Hard texture, Dense structure, High compressive strength, Long-lasting durability, Exquisite texture

饰面.jpg)

Flexible Ceramic Series

Diverse shapes & realistic stone imitation, Lightweight & flexible, Crack and earthquake resistant, Weather-resistant & eco-friendly

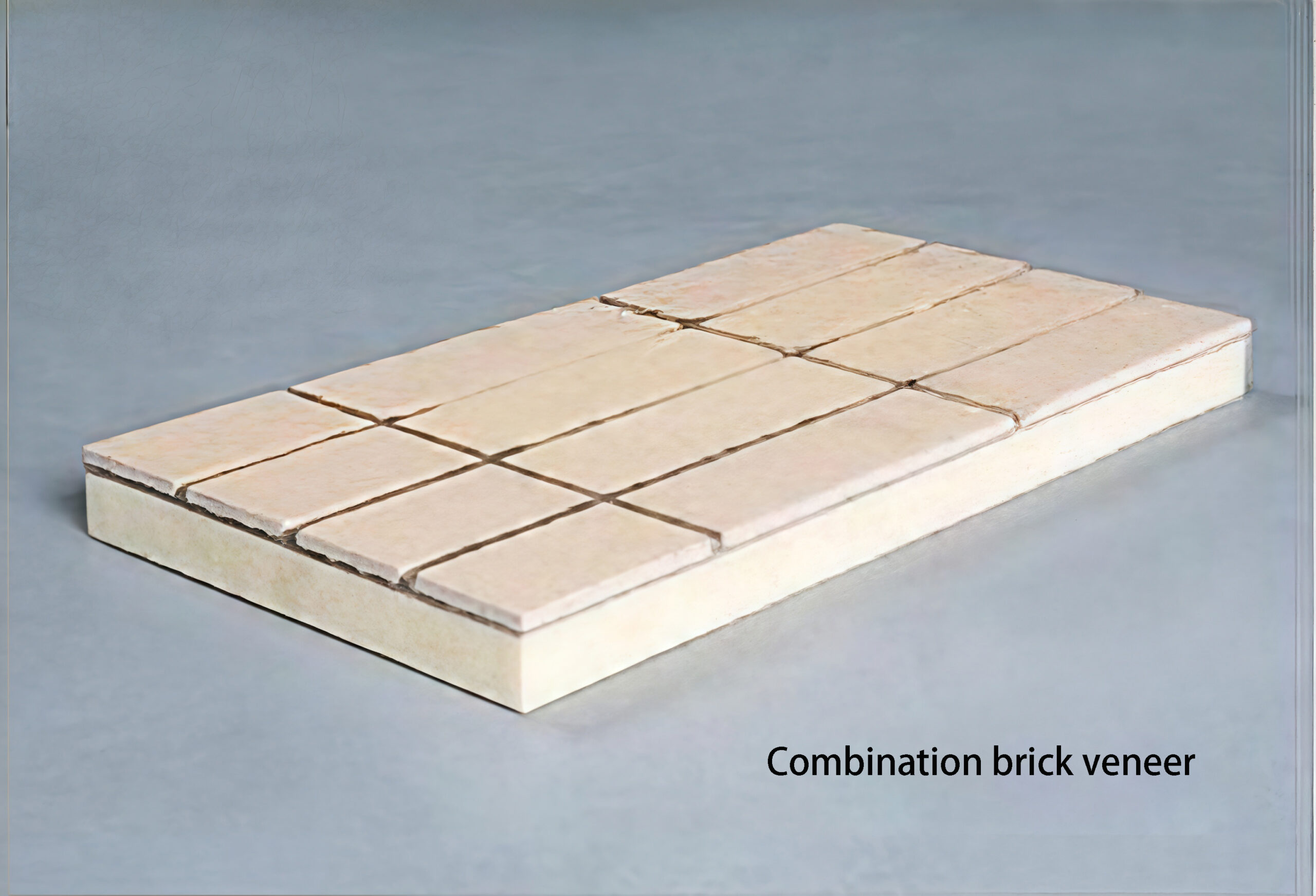

Composite Tile Facade

Vibrant colors & aesthetic shapes, Wear/pressure/sunlight resistant, Fade-resistant, Structural texture customization

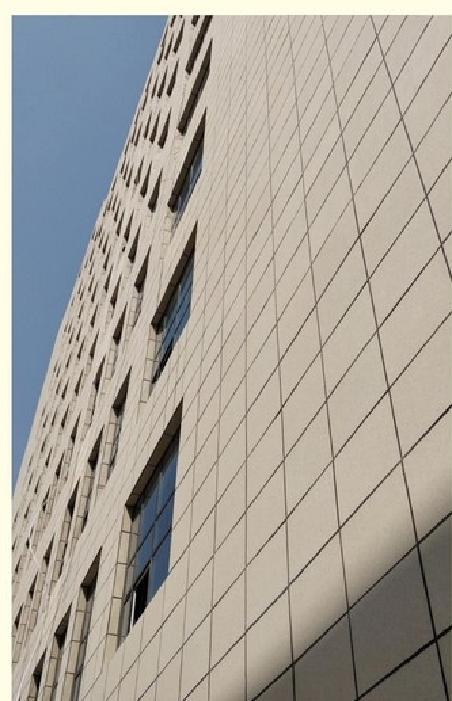

Pictures of the ceramic thin plate imitation stone effect show: the similarity of the exterior surface is over 95%.

Ceramic Thin Panels are fired under 6,000-ton pressure and 1200°C high temperature, possessing outstanding advantages of “thin, large-sized, lightweight, and high hardness.

Ceramic Thin Panel has water absorption rate <0.03% with dual-zero waterproofing, outperforming stone materials in water resistance. Compared to ceramic thin panels, dry-hung stone panels are heavier and their porous structure compromises waterproofing in rock wool insulation systems, particularly evident in high-rise buildings. Ceramic thin panels have become the preferred material in the decoration industry for personalized and high-quality architectural solutions.

Features

◎ Thin decorative panels, rich decorative effects

Diverse choices of decorative materials to meet the personalized needs of architectural styles.

◎ Double insurance of pasting + anchoring, high safety

The principle of bonding as the main method and anchoring as the auxiliary method, and any anchoring must not sacrifice the bonding strength.

◎ Excellent mechanical properties

Using the excellent self-adhesive properties of polyurethane, the flowing liquid polyurethane penetrates into the rock wool in the form of molecules, forming an infiltration-type physical bite, 100%

No cavity connection, which improves the mechanical properties of rock wool.

◎ The interface layer has no cavities and does not fall off

The insulation layer, protective layer, and decorative layer of the thermal insulation decorative panel system are prefabricated in the factory and are 100% cavity-free.

◎ Simple operation, fewer construction procedures, and short construction period

The insulation layer and decorative layer are constructed at one time, with fewer types of work, simple procedures, short construction period, and reduced labor costs.

◎ Three-way waterproof system with good waterproof performance

The partition joints between the panels of the thermal insulation decorative panel system are the most vulnerable parts of thermal bridge and waterproofing. To solve this problem, we have developed a polyurethane caulking agent with low foaming multiple and easy operation. After the construction is completed, all the thermal insulation decorative panels will be connected into a whole, which not only improves the waterproof performance of the system but also avoids the generation of thermal bridges.

Product comparison

PRR insulation decorative board VS ordinary rock wool insulation decorative board

| Project | Wanhua PRR insulation decorative board | Rock wool insulation decorative board on the market |

| Production process | Continuous method/microporous infiltration self-adhesive foaming/high production efficiency Capacity: 2500m² per shift, 8 hours per line | Adhesive method/intermittent/low production efficiency Capacity: 800m² per 8 hours |

| Backing material | Cement-based reinforced roll | Calcium silicate board |

| Backing Features | Thickness: 0.45mm, Reduces insulation board weight, Easy handling & transportation, High safety | The 4mm thickness increases the dead load of the decorated insulation panel system and results in low shear resistance |

| The embedded reinforcement mesh effectively distributes stress and mitigates deformation of insulation boards. | High water absorption, poor water and freeze-thaw durability, and incompatibility between calcium silicate boards and adhesive mortar,lead to delamination risks. | |

| The material is composed of emulsion and other components, exhibiting low water absorption, excellent water and freeze-thaw resistance, as well as high compatibility with mortar. | The system fails to effectively distribute thermal expansion-contraction stresses; some manufacturers attempt perforation mitigation, yet strength degradation persists during freeze-thaw cycles. |

PRR Insulation Decorative Board

System Display

Construction technology

“Bonding + anchoring” double insurance, high system safety

1. Base inspection 2. Line control 3. Drilling

4. Install anchor bolts 5. Fix hanging parts 6. Apply mortar

7. Install thermal insulation decorative integrated board 8. Anchoring 9. Apply weather-resistant glue

Final effect

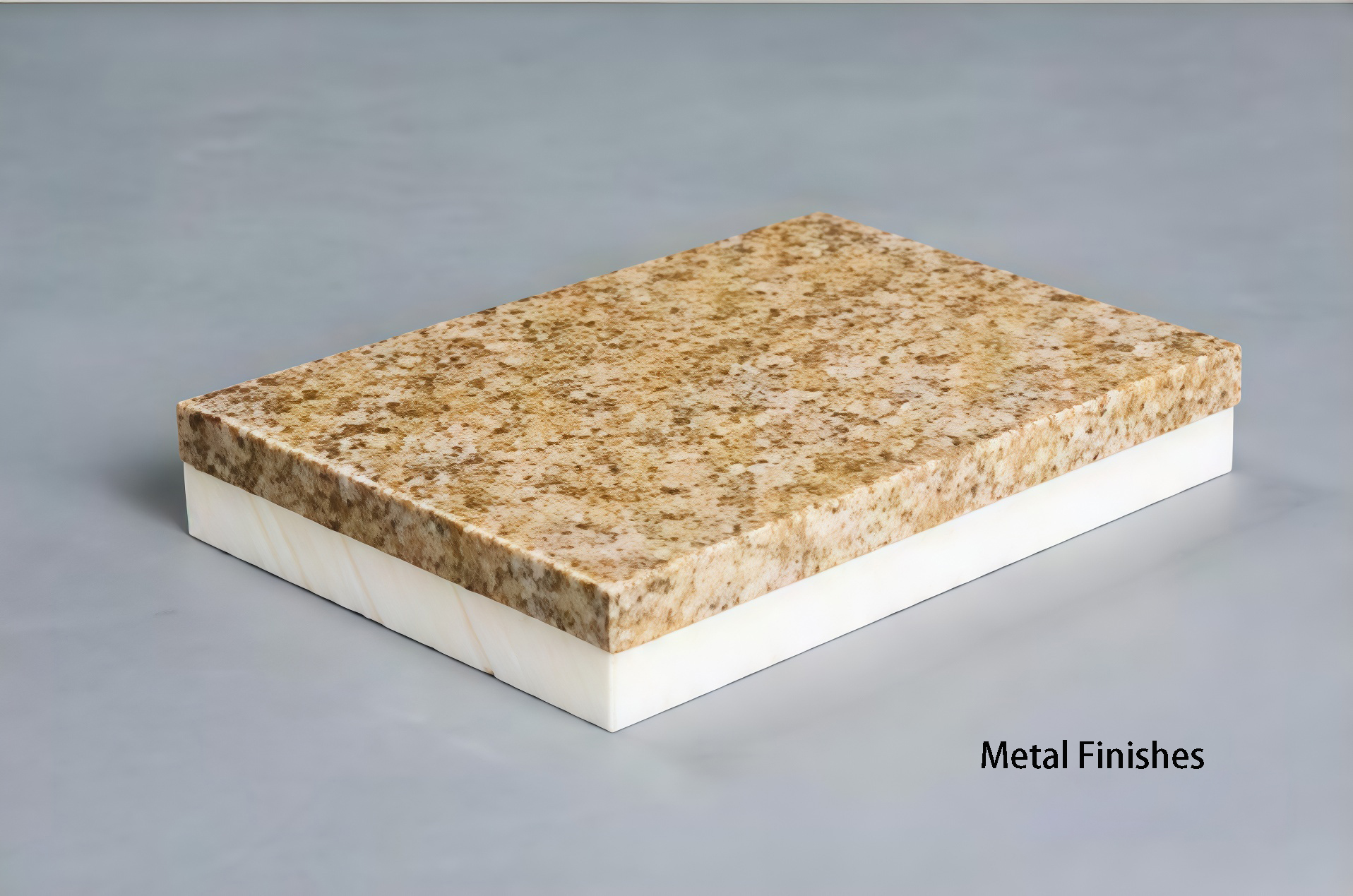

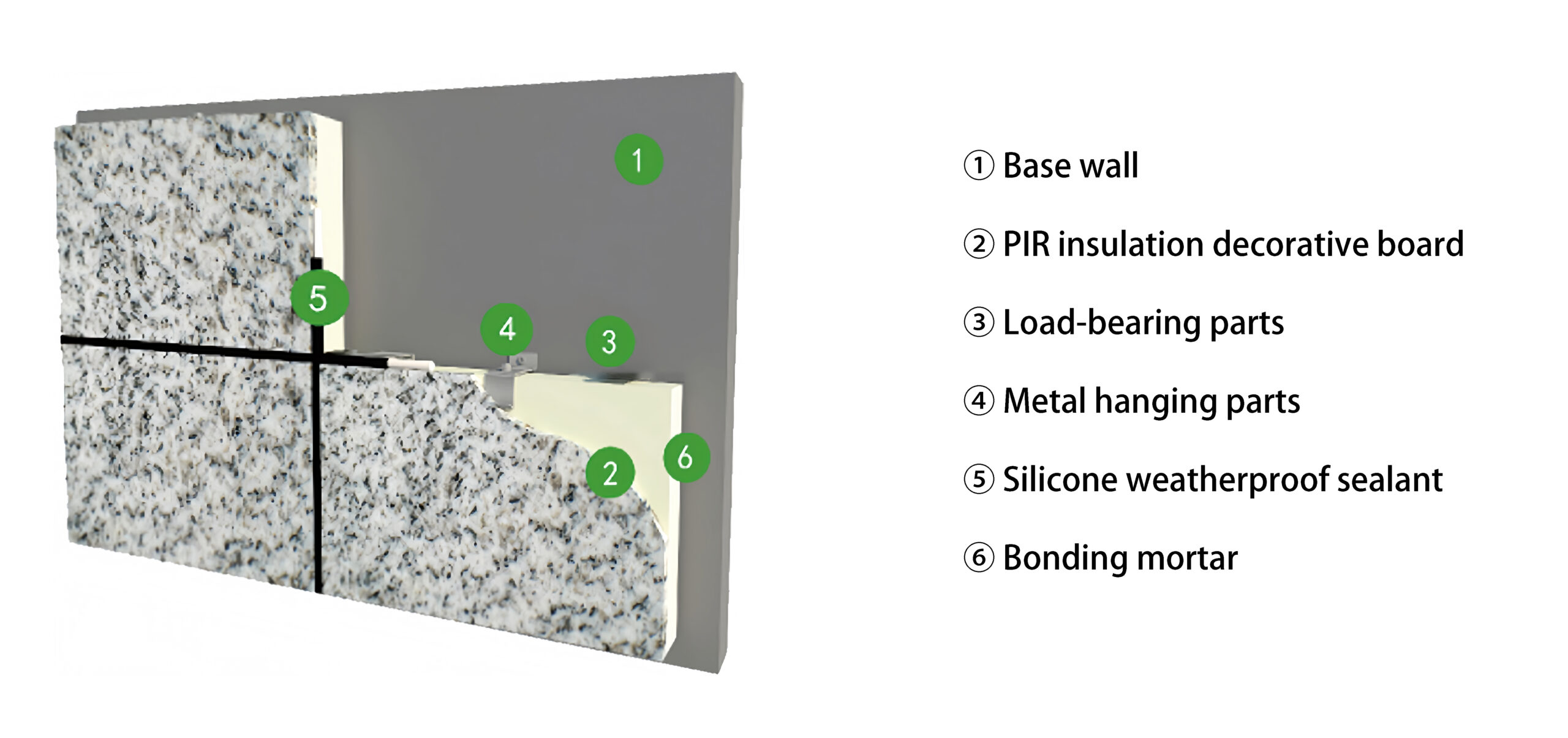

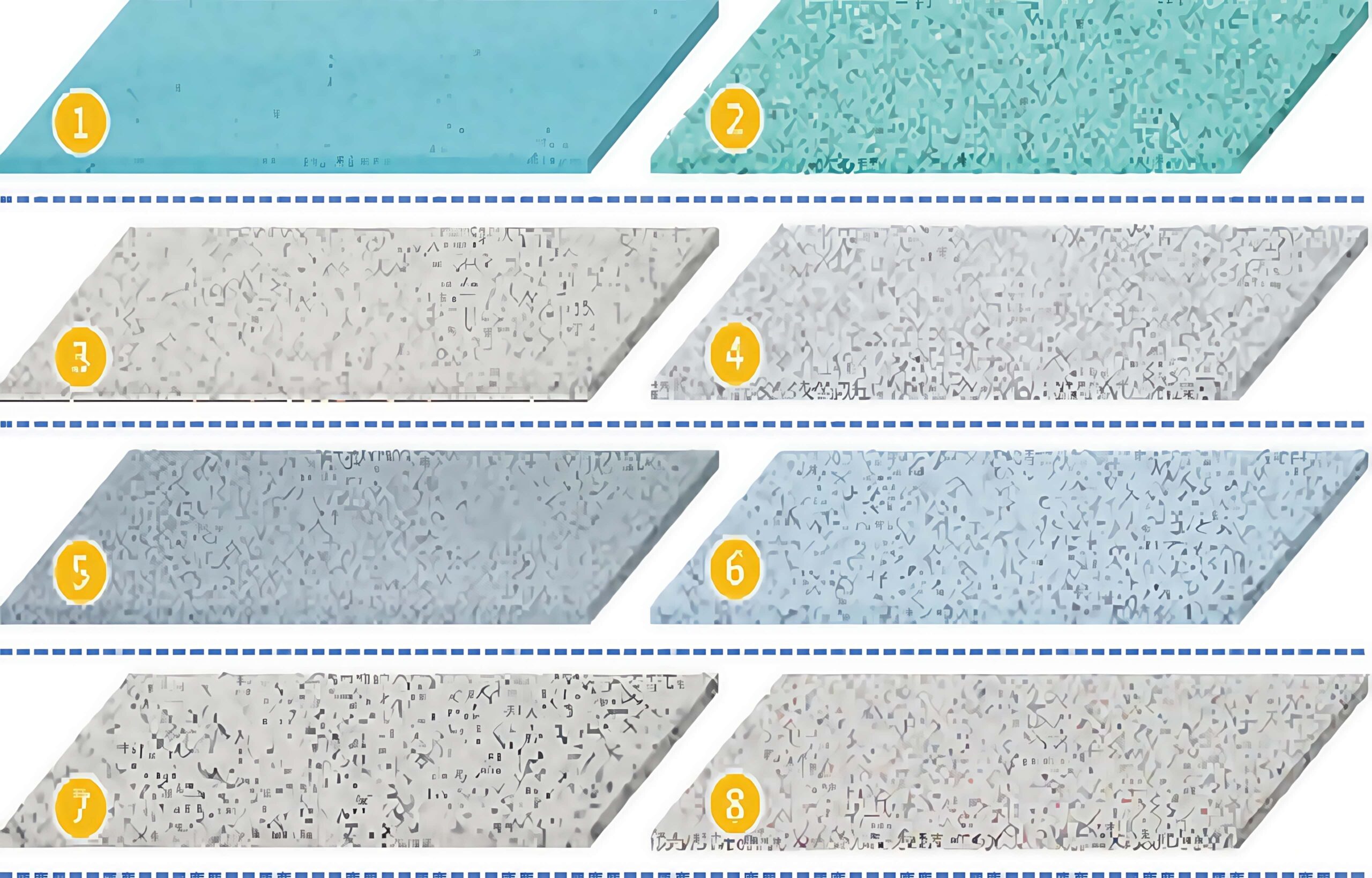

PIR Insulation Decorative Panels

Product specifications

Standard size: 1200mm*600mm (customizable) Insulation layer thickness: 20mm-100mm

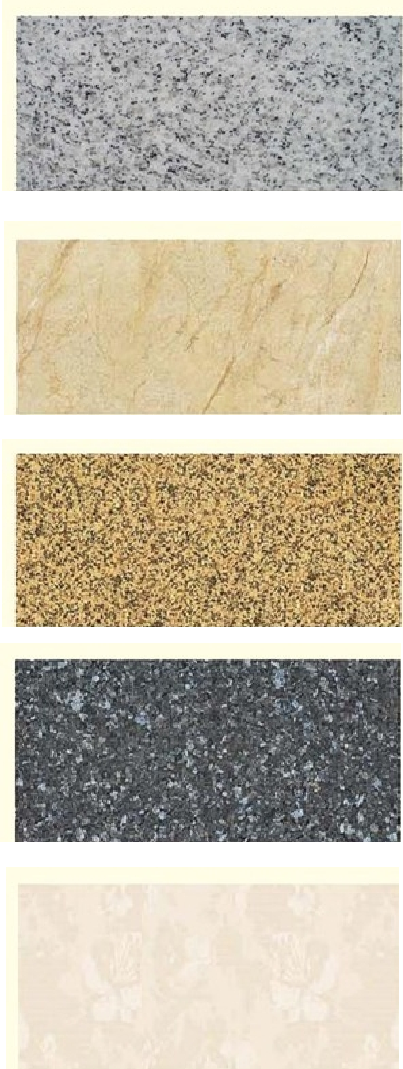

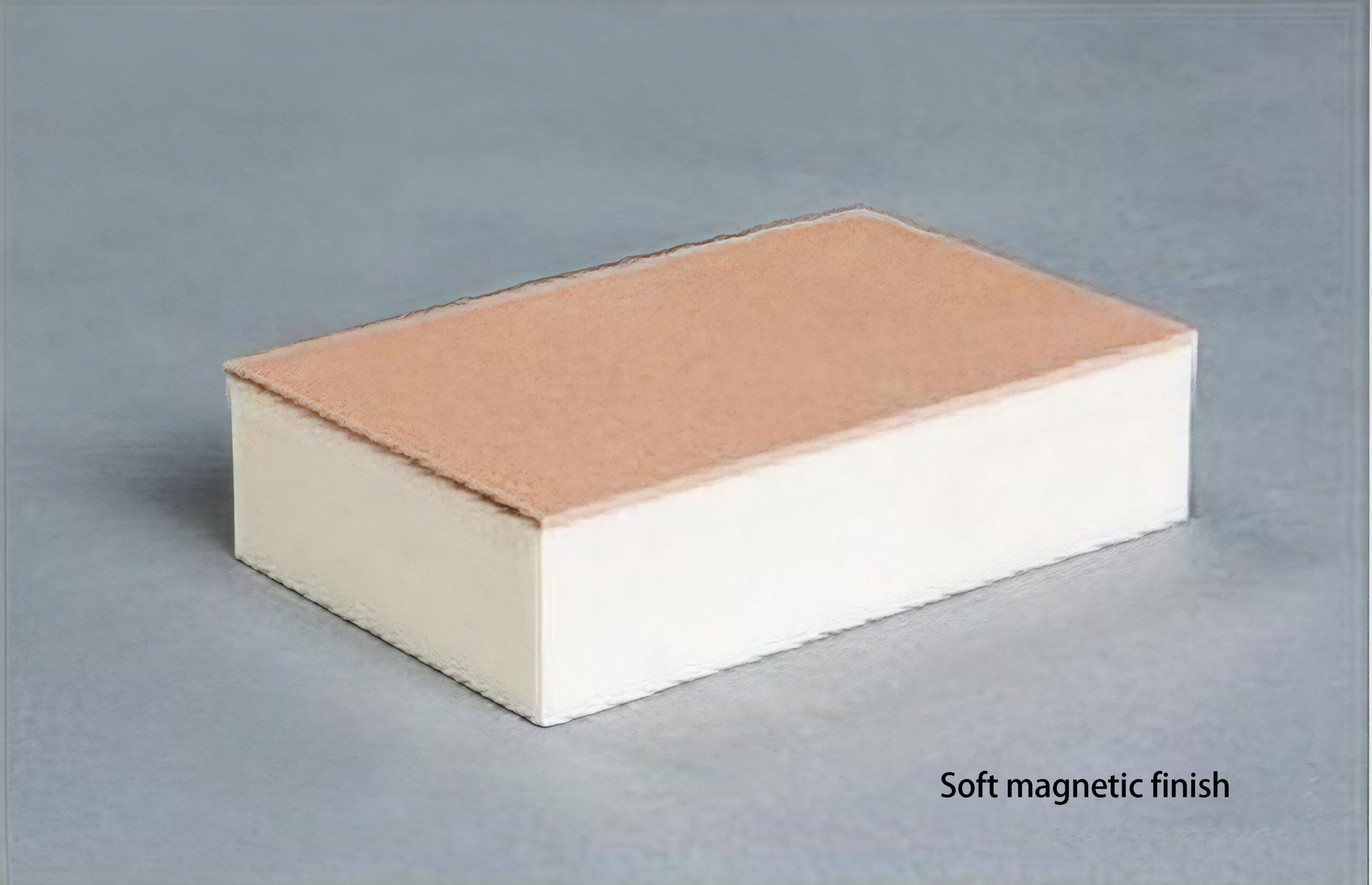

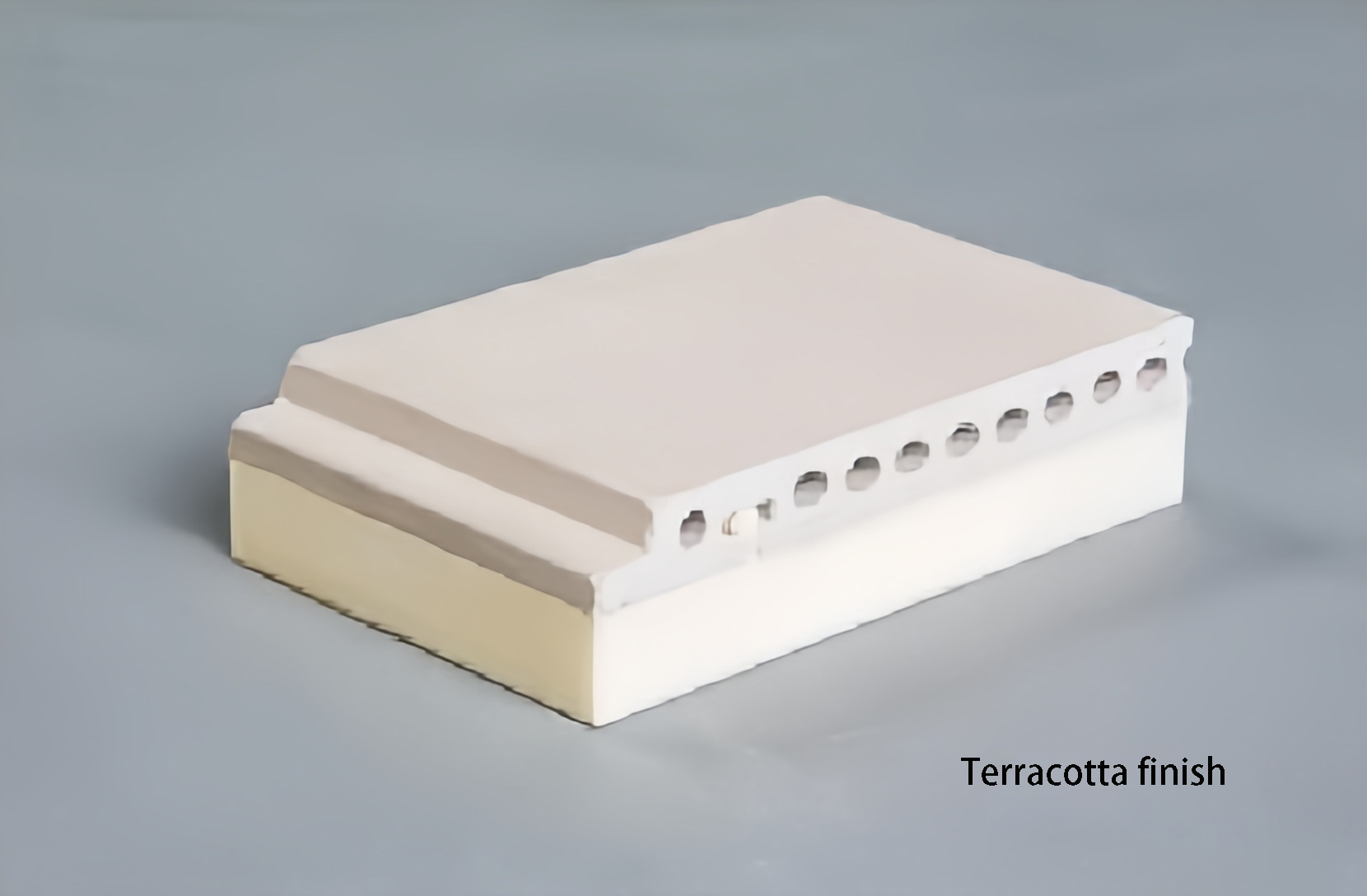

PIR decorated insulation panel is a novel wall insulation board integrating thermal insulation and decoration, manufactured by continuously laminating rigid polyurethane foam (PIR) with decorative facing panels in the factory. Decorative facing options include thin stone, ceramic thin plates, cement fiber-reinforced pressure boards, metal cladding panels, composite facing tiles, thick ceramic tiles, terracotta, and soft magnetic materials.

Eight finishing series

PIR Insulation Decorative Panels

System Display

System Features

· Multiple finishing materials with rich decorative effects

· Core material is highly flame-retardant PIR rigid foam polyurethane with no flame propagation

· Low thermal conductivity with outstanding energy-saving and thermal insulation effects

· Light weight reduces the weight of the building structure

· Good chemical corrosion resistance with the same lifespan as the building

Construction technology

“Paste + anchor” double insurance, good safety performance

① Site survey

② Inspection and treatment of the base

③ Actual size measurement of the building facade

④ Computer grid optimization processing

⑤ Pull the flatness control line and draw the dividing line

⑥ Optimize the board layout and prepare the material list

⑦ Prepare materials and equipment

⑧ Install load-bearing parts

⑨ Paste the insulation decorative board

⑩ Fix the metal pendant

⑪ Silicone weatherproof sealant to fill the gaps and process the grid joints

⑫ Board surface cleaning

⑬ Filing the completion acceptance data

PRF ROCK WOOL COMPOSITING POLYURETHANE RIGID FIRE INSULATION BOARD EXTERNAL THERMAL INSULATION SYSTEM

Product specifications

Standard size: 1200mm*600mm (customizable) Insulation layer thickness: 60mm-150mm

Class A fire protection

Application scope

1. Building exterior wall insulation with Class A fire protection requirements

2. Severe cold and cold areas with high energy saving requirements

3. 83% building energy saving and near zero energy consumption buildings

*No need to install fireproof doors and windows

*No need for fireproof isolation belts

*No need for grade A insulation materials

*No application height*No restrictions on locations

PRF Rock Wool Compositing Polyurethane Fire-resistant Insulation Panel

Rock Wool Compositing Polyurethane Fire-resistant Insulation Panel is the next-generation insulation product integrating thermal insulation and fire resistance. It is prefabricated via a continuous foaming process where rigid polyurethane foam is injected between vertically aligned rock wool fibers and reinforced membrane, leveraging the penetration capability and self-adhesive properties of polyurethane. (Abbreviation: PRF Panel)

The minimum thickness of Vertically aligned rock wool layer is 45mm, and polyurethane layer thickness is determined by thermal transmittance requirements of the wall.

Features

◎ Outstanding Fire Resistance Performance

The system features a 50mm-thick protective outer layer and a structural rock wool barrier that blocks heat transfer and oxygen infiltration into the polyurethane core. This mechanism prevents oxidative degradation of the polyurethane material, endowing the entire system with stable fire resistance and thermal radiation resistance capabilities.

| Standard requirements | Rock wool composite polyurethane fireproof insulation board |

| The combustion performance of the insulation material shall not be lower than B2 grade | Polyurethane combustion performance is B2 or B1 |

| The walls on both sides of the insulation material shall be made of non-combustible materials and the thickness shall not be less than 50mm | Reinforced concrete or masonry wall ≥50mm; Rock wool + plastering layer ≥50mm |

| There shall be no cavity between the insulation material and the walls on both sides | Traditional thin plastering process, no cavity |

Corresponding specifications:

When the building exterior wall uses insulation materials and the walls on both sides to form a cavity-free composite insulation structure, the fire resistance limit of the structure shall comply with the relevant provisions of GB50016; when the combustion performance of the insulation material is B₁ or B₂, the walls (or protective layers) on both sides of the insulation material shall be made of non-combustible materials and the thickness shall not be less than 50mm.

——–Excerpt from 6.7.3 of GB 50016, Code for Fire Protection Design of Buildings.

Window fire test:

Test method: GB/T 29416 Fire test method for external insulation system of building exterior wall Sample: 20mm rigid polyurethane foam + 45mm rock wool

-scaled.jpg)

Test results: The system integrity is good, the polyurethane surface is carbonized without burning, and the rock wool on the outer surface can effectively block the spread of flames and delay the transfer of heat.

Features

◎Superior Mechanical Properties

PRF panels are manufactured via microporous infiltration self-adhesive foaming technology on continuous production lines. Liquid polyurethane is directly cast onto vertically aligned rock wool fibers, forming AB composite structure through single-step foaming and curing, with Cavity-free bonding.

Self-Repairing Properties of Polyurethane

Liquid polyurethane penetrates rock wool voids, repairing fiber fractures caused by cutting or impact.

◎Moisture Resistance & Waterproofing

Polyurethane forms continuous waterproof barriers within rock wool during foaming,

The inner polyurethane layer isolates rock wool from indoor humidity, preventing vapor-induced delamination (critical failure point in masonry walls without surface leveling).

During production, liquid polyurethane infiltrates rock wool to form a continuous sealed waterproof barrier, leveraging polyurethane’s superior hydrophobicity to mitigate rock wool’s hygroscopic weakness. The inner polyurethane insulation layer further isolates rock wool from moisture vapor, ensuring long-term thermal performance stability.

Note:

Field studies indicate that rock wool delamination/cracking failures originate from masonry walls (especially unleveled surfaces) due to indoor vapor diffusion.

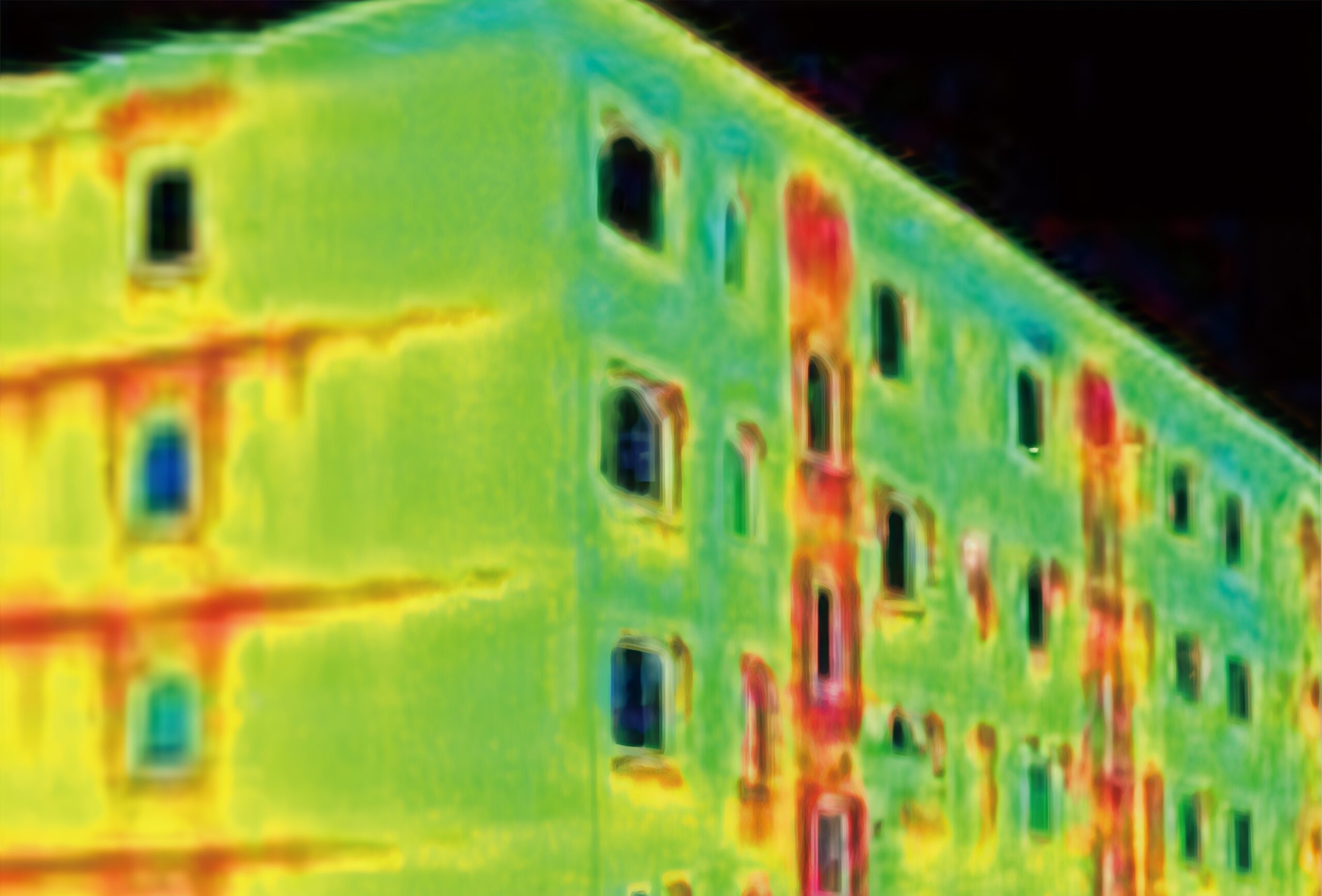

◎Low Thermal Conductivity & Thermal Bridge Elimination

Optimized Thermal Conductivity

The rigid polyurethane foam (PUR) with ultra-low thermal conductivity compensates for the insulation deficiency of standalone rock wool panels

No Thermal Bridge

Compared to GL/FS/LTS structural systems, PRF panels eliminate thermal bridging at balconies, canopies.

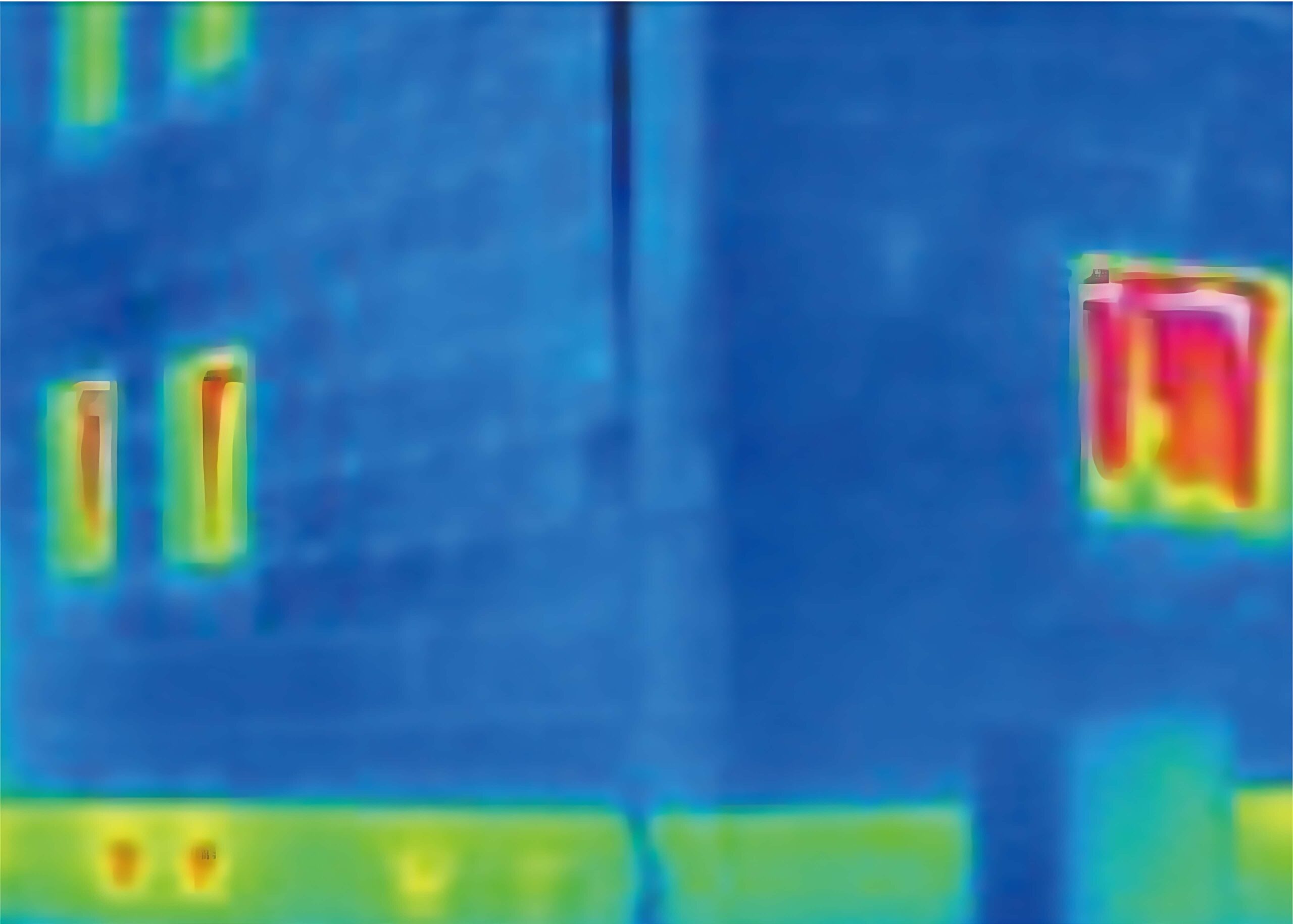

Infrared imaging device actual measurement

◎Superior Interface Performance

PRF panels integrate reinforcement membranes on both surfaces, eliminating on-site primer application. The panels are precision-manufactured in calibrated laminators, achieving dimensional accuracy, surface flatness,thin rendering layer, material & labor efficiency.

◎Simplified workflow, shortening project timelines, low System costs.

Energy-saving design

Ultra-low thermal conductivity of rigid polyurethane foam (PUR) compensates for the insulation limitations of standalone rock wool panels. Achieves 83% building energy savings and meets nearly zero-energy building standards.

Thermal Parameters:

PU Thermal conductivity: 0.020-0.024 W/(m·K), Adjustment factor: 1.10

Rock wool strips Thermal conductivity: 0.045 W/(m·K), Outdoor adjustment factor: 1.10 (for severe cold & cold climate zones)

Additional references: GB 50176 Appendix B, GB/T 51350

| Heat transfer coefficient | Reinforced concrete(mm) | Rock wool board(mm) | Rock wool composite polyurethane fireproof insulation board (mm) | |

| PU | RF | |||

| 0.3 | 200 | 135 | 55 | 45 |

| 0.2 | 200 | 210 | 95 | 45 |

| 0.15 | 200 | 285 | 135 | 45 |

| 0.1 | 200 | 430 | 215 | 45 |

| The converted thermal resistance of the inner and outer surfaces of the wall is 0.15 | ||||

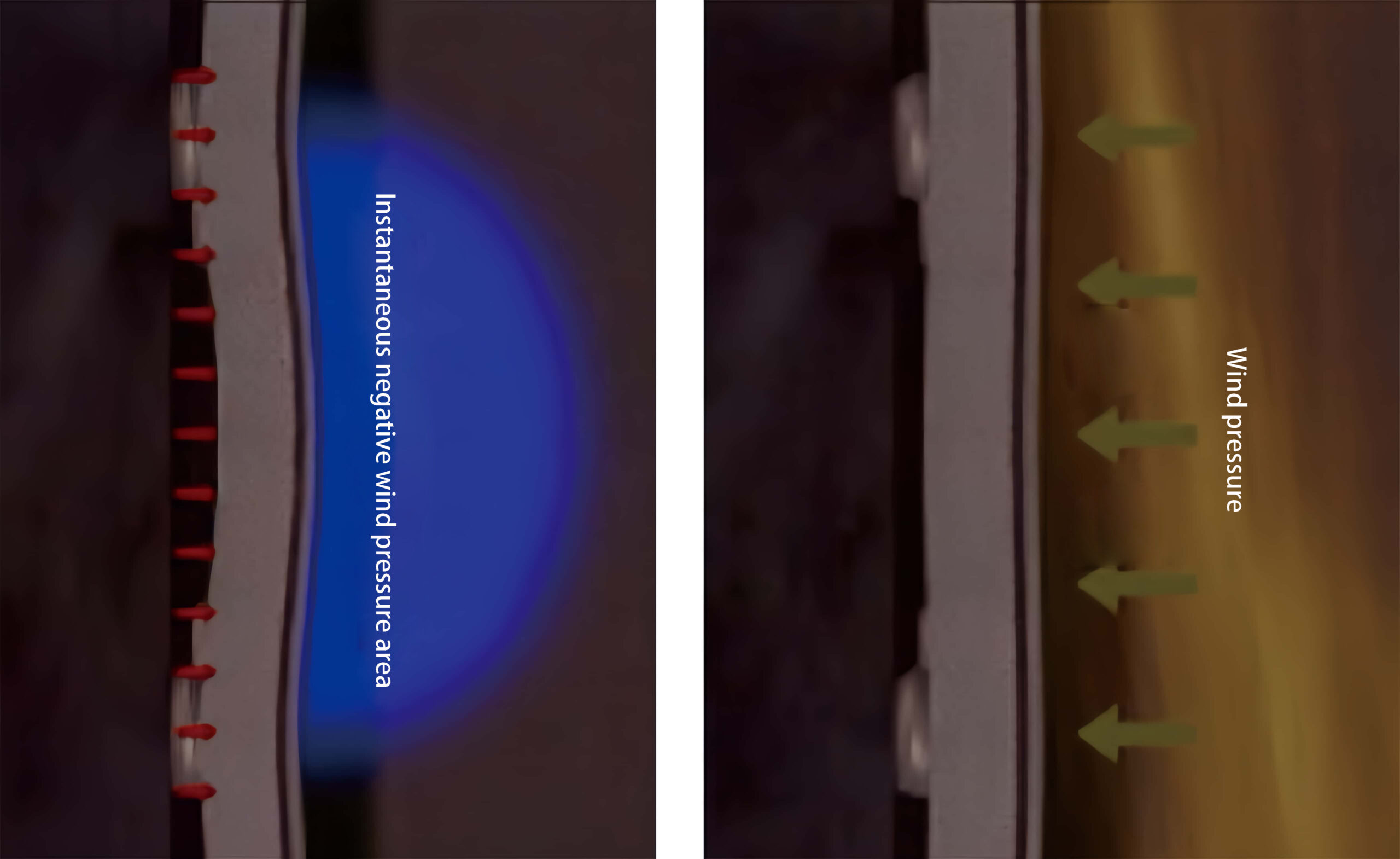

Wind Load Resistance Mechanism

Dual Fixation Strategy:

PRF system employs “adhesive bonding + mechanical anchoring”, prioritizing adhesive strength while using anchors as supplementary reinforcement. Anchors must never compromise the bond integrity.

Pre-curing stage: Anchors act as temporary stabilizers and prevent displacement during adhesive setting

Post-curing stage: Anchors become safety redundancy, ensuring 100% panel retention even under complete adhesive failure

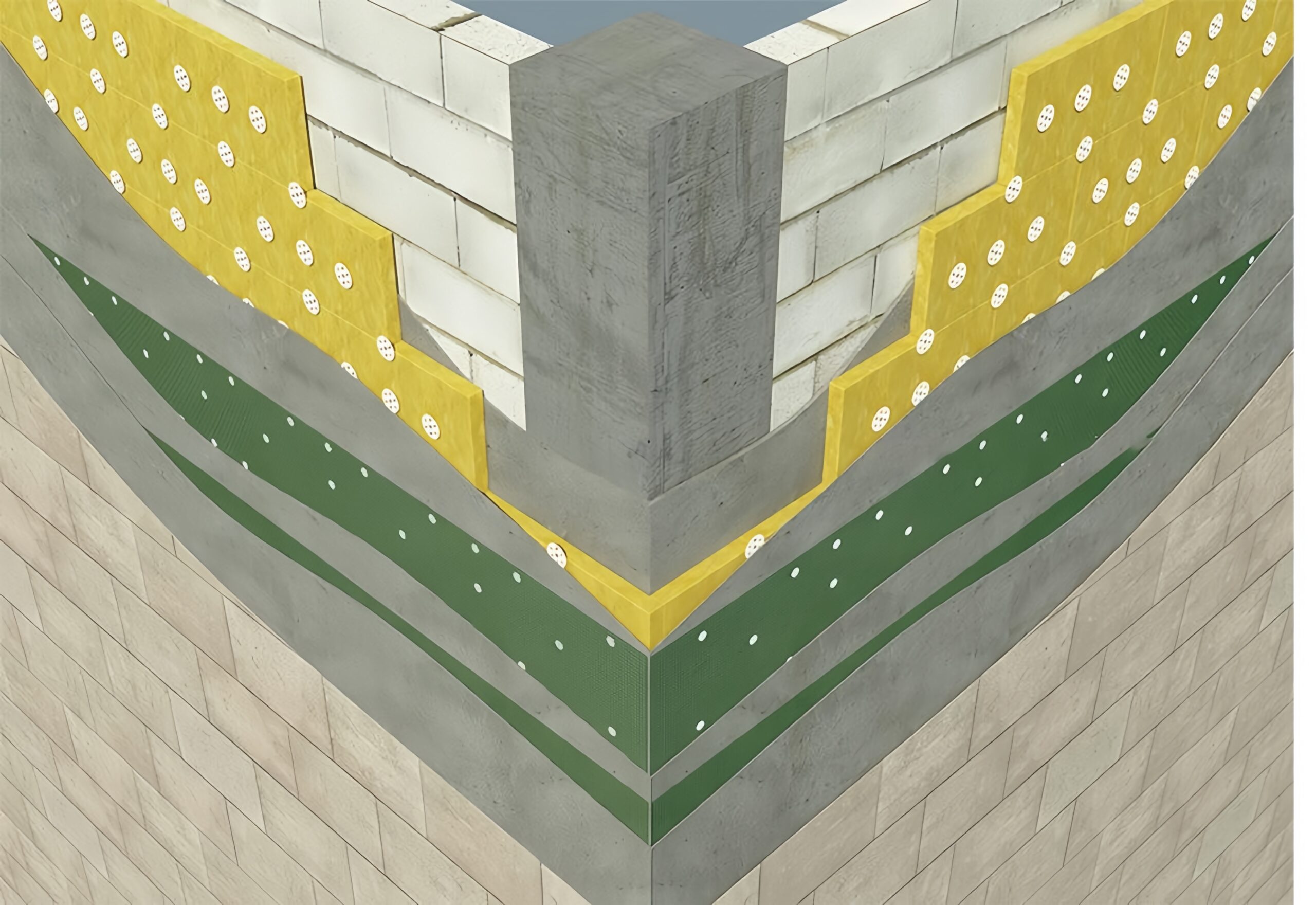

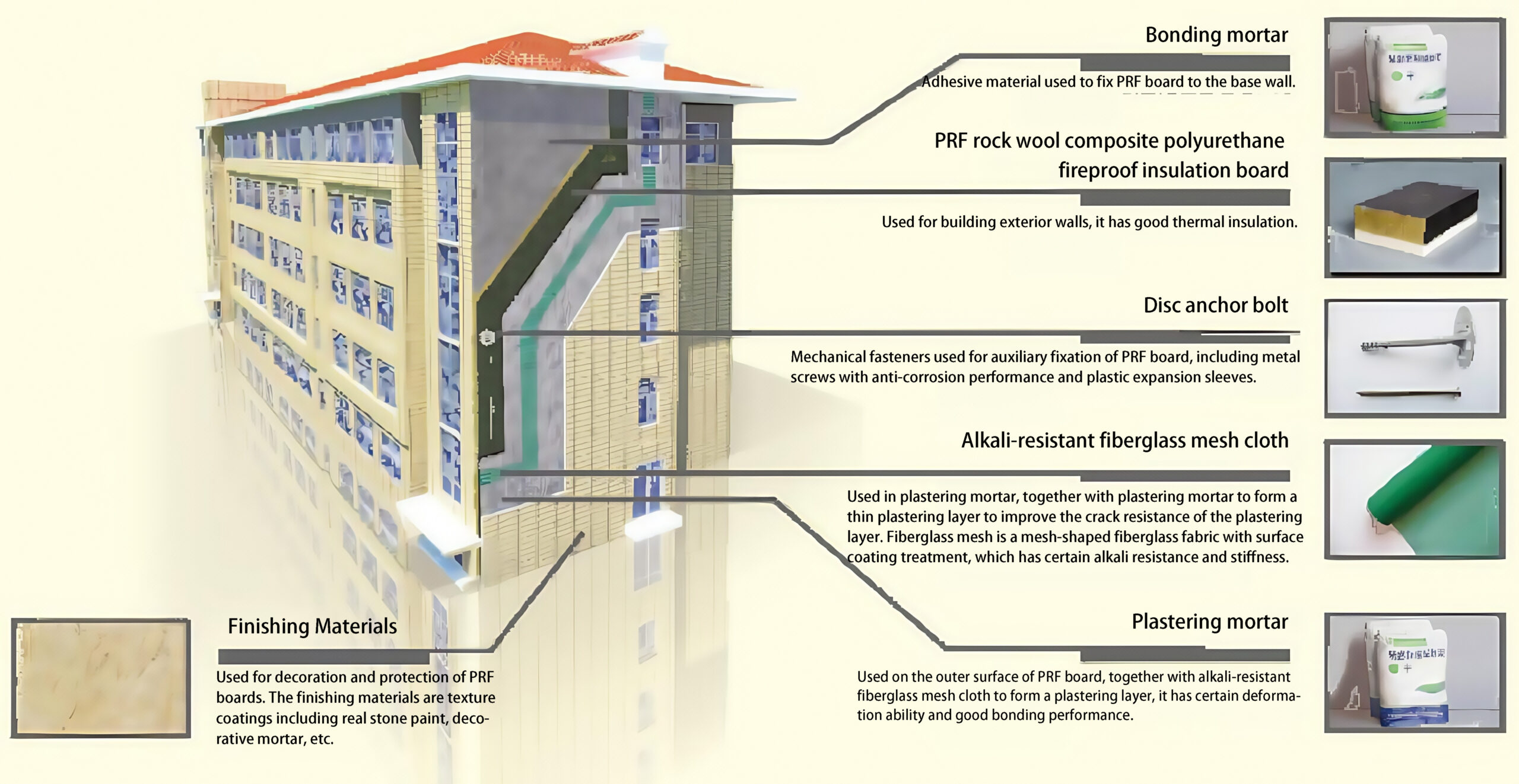

System Display

The PRF Rock Wool Compositing Polyurethane Fireproof Insulation Board External Wall Thermal Insulation System consists of PRF boards, adhesive, plastic expansion anchors (when necessary), alkali-resistant fiberglass mesh, polymer mortar, flexible waterproof putty, and finishing materials. It is designed for installation on the exterior walls of buildings to provide thermal insulation, fire resistance, and decorative functions, serving as a non-load-bearing structure.

Shortcomings of Traditional Building Structure Integrated Insulation and Fireproofing Systems

◎Many cross-constructions with civil engineering and steel bars, complex construction

◎General shear strength and poor seismic resistance

◎Limited technical means for filling the wall part, unable to achieve integrated insulation and fire protection of the building structure. ◎Insufficient thermal performance of the cantilevered parts such as beams, columns, and balconies

◎High lateral pressure on concrete, easy to deform

Construction Key Steps

Base wall inspection and treatment—place control line, stir adhesive—paste insulation board—anchor insulation board—plastering layer construction—exterior finishing construction

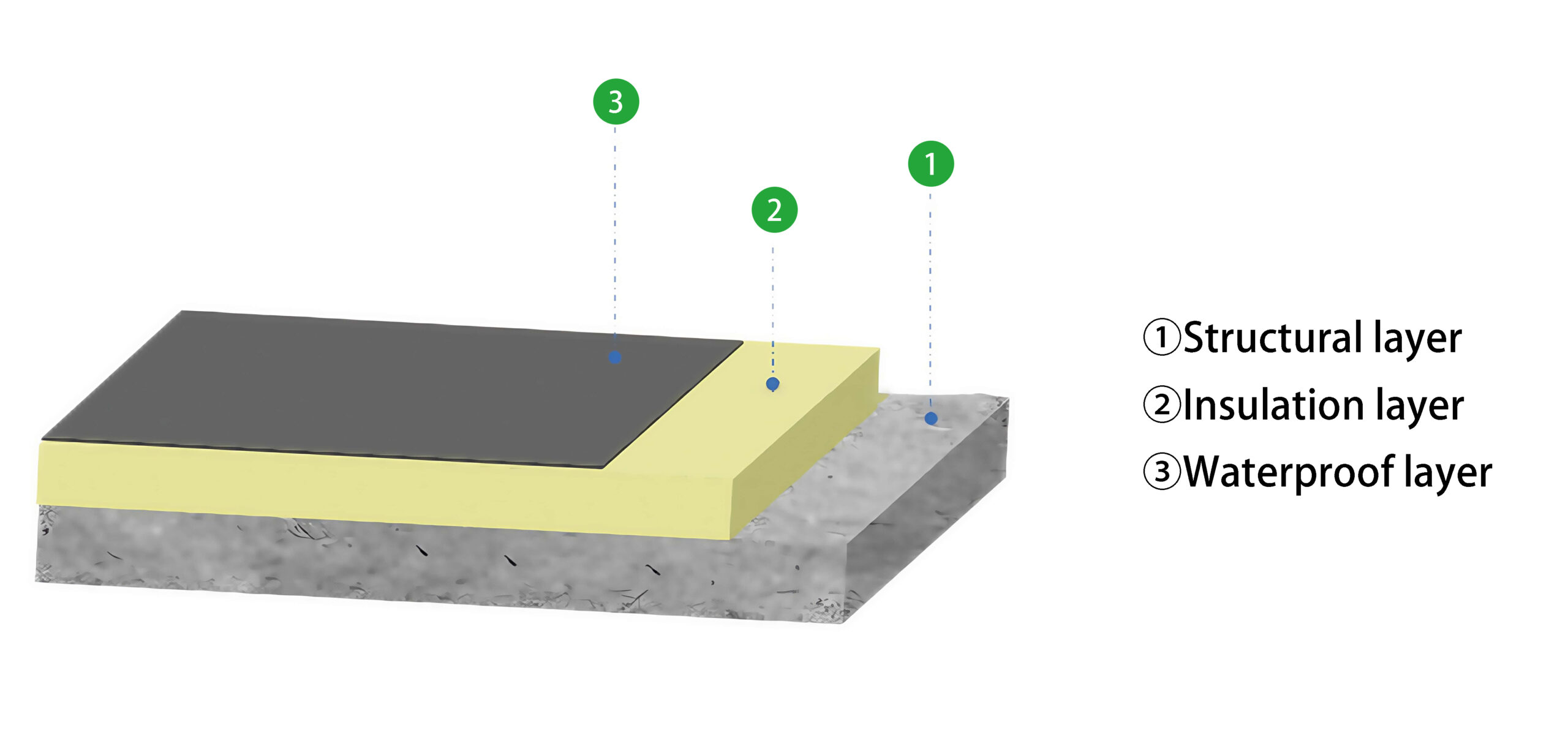

INTEGRATED ROOF THERMAL INSULATION AND WATERPROOF SYSTEM

System Introduction

Polymethylene polyphenyl isocyanate (commonly known as black material) and combined polyether/polyester polyol (commonly known as white material) are sprayed on the roof continuously multiple times using special spraying equipment on site to form a thermosetting flame-retardant foam with thermal insulation and waterproofing functions, which together with the ready-made waterproof membrane forms an integrated roof thermal insulation and waterproofing system.

System Features

◎ The waterproof layer is more stable and has good waterproof performance

The closed-cell rate of polyurethane itself reaches 92%-96%, which makes the system insulation layer waterproof, hydrophobic, and has extremely low water absorption. It can effectively hinder the penetration of water vapor, so as to achieve the good effect of insulation and waterproofing. The upgraded reaction adhesive modification technology is integrated with the tire base, making the coil body more stable and durable, and the bonding is more durable. There are chemical cross-linking bonds in the interface sealing part, and the bonding is firm and irreversible.

◎ The insulation layer has its own insulation and waterproof coefficient and excellent insulation performance

The excellent closed-cell structure, the closed-cell rate exceeds 95%, is hydrophobic, and has extremely low water absorption. It can effectively hinder the penetration of water vapor, so as to achieve the good effect of insulation and waterproofing.

◎ Convenient and efficient construction

The production and construction of the waterproof layer are completed synchronously on site by mechanization. It is made on site, and the waterproof layer is made to be waterproof.

◎Excellent aging resistance

Polyurethane has a service life of up to 70 years and can provide energy-saving and heat-insulating effects for a long time. Under normal operation, the heat-insulating and heat-insulating properties of rigid foam can meet the use requirements from beginning to end.

◎Wide temperature range

The operating temperature range of polyurethane is -50℃~150℃, and the short-term operating temperature can reach 250℃ without any damage. It is the insulation material with the widest operating temperature range and can be used in severe cold and high temperature areas.

◎High bonding strength and good system safety

The liquid molecules directly penetrate into the microscopic pores on the surface of the base layer, and quickly start to solidify at a rate of dozens of times the expansion, forming a firm bite with the base layer in microscopic form, achieving 100% seamless bonding with the base layer, and ensuring the safety of the system without falling off.

◎Good matching with the foundation

The on-site spraying construction process can solve the unfavorable factors such as complex on-site structure, multiple nodes, and poor flatness.

Performance Indicators

| Project | Technical indicators | |

| Tensile properties | Tensile force/(N/50MM) | ≥100 |

| Elongation at maximum tensile force/% | ≥50 | |

| Tear strength of nail rod/N | ≥80 | |

| Heat resistance (105℃/2H) | No flow or dripping, sliding ≤ 2.0MM | |

| Low temperature flexibility (-20℃) | No cracks | |

| Water impermeability (0.3MPA,120MIN) | Waterproof | |

| Water penetration resistance/0.6MPA | No water leakage | |

| Bond strength/MPA | With cement mortar base (untreated) | ≥0.4 |

| With cement mortar base (water immersion treatment) | ||

| With metal base | ||

| Stress relaxation/% | ≤35 | |

| Joint deformation capacity | 5000 cycles without damage | |

| Crack bridging capacity/MM | ≥1.5 | |

System Display

DOME INSULATION SYSTEM

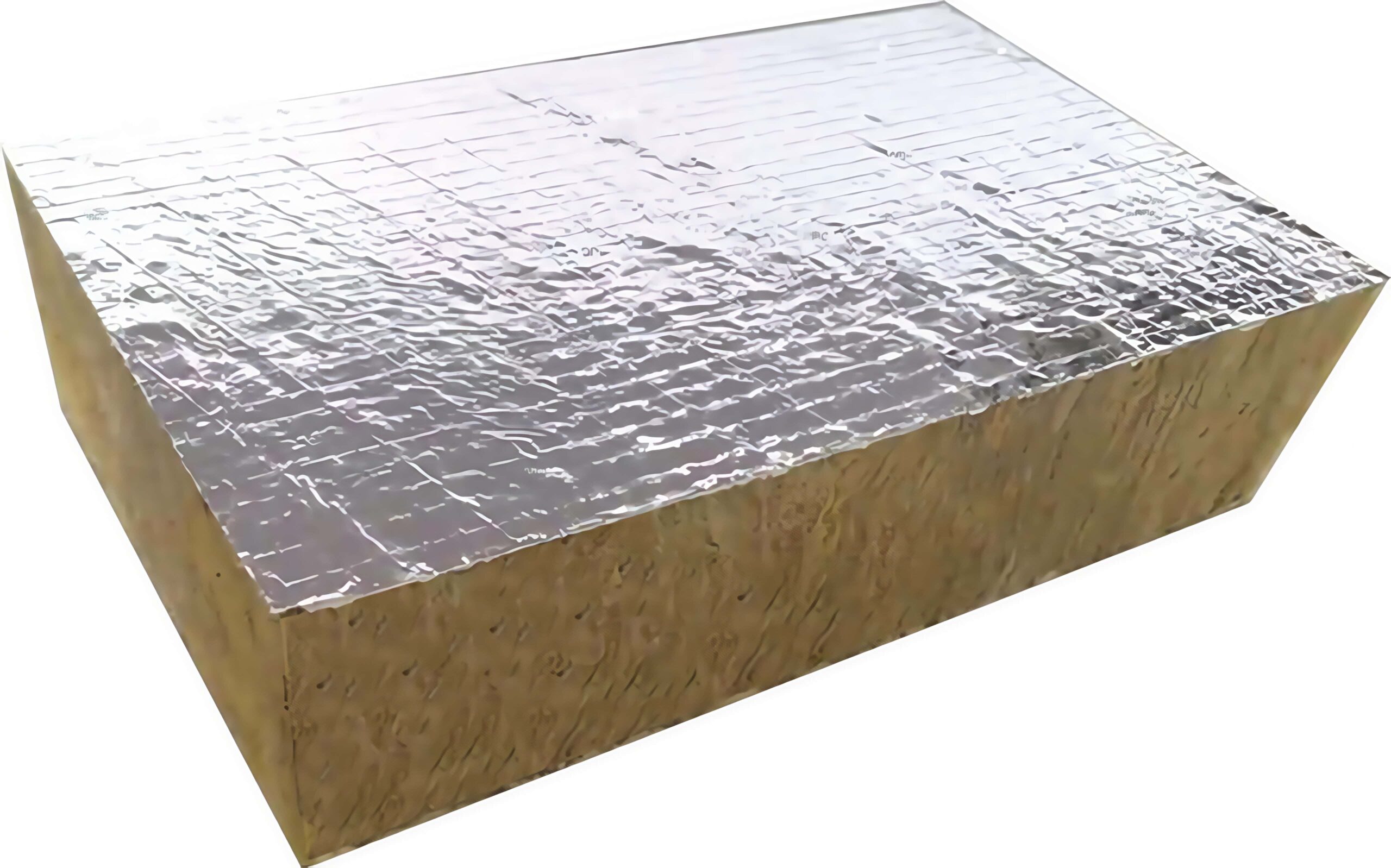

Dome roof insulation board

Product specifications

Standard size: 1200mm*600mm (customizable) Insulation layer thickness: 30mm-200mm

Wanhua Dome Roof Insulation Panel is a new type of thermal insulation material with vertically aligned rock wool fibers as the core, formed by continuous production line technology that integrates cement-based interface-reinforced membranes and rock wool cores through polyurethane foam adhesive in a single-step composite process (abbreviated as Dome Insulation Panel).

Specifically designed for single-layer roof insulation systems, the Dome Insulation Panel combines fire resistance and thermal insulation with moisture resistance, structural stability, and noise reduction, serving as a multifunctional roofing solution.

Features

◎A-level fireproof

The dome insulation board uses rock wool as the insulation core material, and its combustion performance is A-level after being tested by Tianjin Fire Department.

It can avoid fire hazards during construction and after delivery.

◎ Strong compressive resistance

The dome insulation board connects small vertical rock wool strips into a whole through polyurethane and high-strength interface coils, expanding the material size specifications and enhancing the physical and mechanical properties of the board such as point load and compressive strength.

| National Building Energy Conservation Quality Supervision and Inspection Center | |||||

| National Center of Quality Supervision and Testing for Building Energy Conservation | |||||

| Report No.(No.):NBEC-2018CX-0072 Page 2 of 2(Page 2 of 2) | |||||

| Inspection items | Technical requirements | Test results | Single judgment | ||

| Requirement of standard | cncls | ||||

| 1 | “Dome” roof insulation board | Compression strength | ≥60kPa | 95kPa | Conforms to |

| 2 | Point load | ≥800N | 1345N | Conforms to | |

| Core Material | Density | 100kg/m³~120kg/m³ | 115kg/m³ | Conforms to | |

◎ High dimensional flatness

The upper and lower surfaces of the dome insulation board are compounded with interface reinforcement coils, and are processed and formed in a fixed-length laminator at one time, with less dimensional deviation and high flatness, reducing the amount of auxiliary materials and construction difficulty.

The factory-measured flatness of the dome insulation board is ≤2.0mm, while the flatness of ordinary rock wool board is ≤6.0mm

Ordinary rock wool boards have poor flatness, making it difficult to lay a waterproof layer and prone to water accumulation.

Wanhua Dome roof panels have high flatness, high pressure resistance and no water accumulation.

◎ Low thermal conductivity and good energy-saving benefits

The dome insulation board is produced using microporous infiltration self-adhesive foaming technology, with uniform material distribution by spray gun and 100% cavity-free bonding.

The thermal conductivity of polyurethane is 0.018~0.024W/(m·k), evenly distributed on the upper and lower surfaces of the insulation board. Polyurethane fills the gaps in the rock wool to prevent air convection, forming a closed and complete thermal insulation layer with excellent thermal insulation effect.

Product Performance

| Items | unit | Ordinary rock wool board | Dome insulation board | Standard basis |

| Density | kg /m³ | 160 | 100~120 | GB/T19686 Rock wool insulation products for construction |

| Thermal conductivity (23±2℃) | w/(m ·K) | ≤0.040 | ≤0.040 | |

| Compressive strength (10% deformation) | kPa | 40 | ≥80 | |

| Point load | N | 500 | ≥1000 | |

| Water repellency | % | ≥98 % | ≥99.8% | |

| Short-term water absorption (partial immersion in water for 24h) | kg/m² | ≤0.5 | ≤0.4 | |

| Tensile strength perpendicular to the board surface | MPa | 0 | ≥0.10 |

Performance Indicators

| Product Performance | unit | Dome insulation board | |

| size | Length | mm | ±2.0 |

| Width | mm | ±2.0 | |

| Thickness | mm | 0~2.0 | |

| Density | kg/m³ | 100~120 | |

| Compression strength (10% deformation) | kPa | ≥80 | |

| Point load (compression deformation 5mm) | N | ≥1000 | |

| Water repellency | % | ≥99.8 | |

| Short-term water absorption (partial immersion in water for 24h) | kg/m² | ≤0.40 | |

| Acidity coefficient | ≥1.8 | ||

| Thermal conductivity (23±2℃) | w/(m ·K) | ≤0.040 | |

| Combustion performance | Class A non-flammable | ||

| Tensile strength perpendicular to the board surface | MPa | ≥0.10 | |

| Dimensional stability (70℃, 48h) | % | ≤0.2 | |

| Noise reduction coefficient NRC | ≥0.5 | ||

Dome insulation board VS ordinary rock wool board

① Comparison of roof panel compression strength test:

| Item No. | Compression strength of horizontal rock wool board (deformation within 10%, KPa) | Dome insulation board compression strength (deformation within 10%, KPa) | ||||

| Experimental Data | Bulk density 120 kg/m³ | Bulk weight 140kg/m³ | Bulk weight 180kg/m³ | Bulk weight 100~120kg/m³ | Bulk weight 140kg/m³ | |

| 1 | 22 | 51 | 100 | 100 | 210 | |

| 2 | 23 | 41 | 95 | 110 | 190 | |

| 3 | 24 | 49 | 100 | 130 | 190 | |

| 4 | 19 | 53 | 100 | 110 | 170 | |

| 5 | 20 | 49 | 97 | 110 | 200 | |

| 6 | 26 | 34 | 100 | 120 | 210 | |

| Data average | 22.3 | 46.17 | 98.67 | 113.33 | 195 | |

② Comparison of roof panel point load strength test:

Deformation after force No obvious change after stress

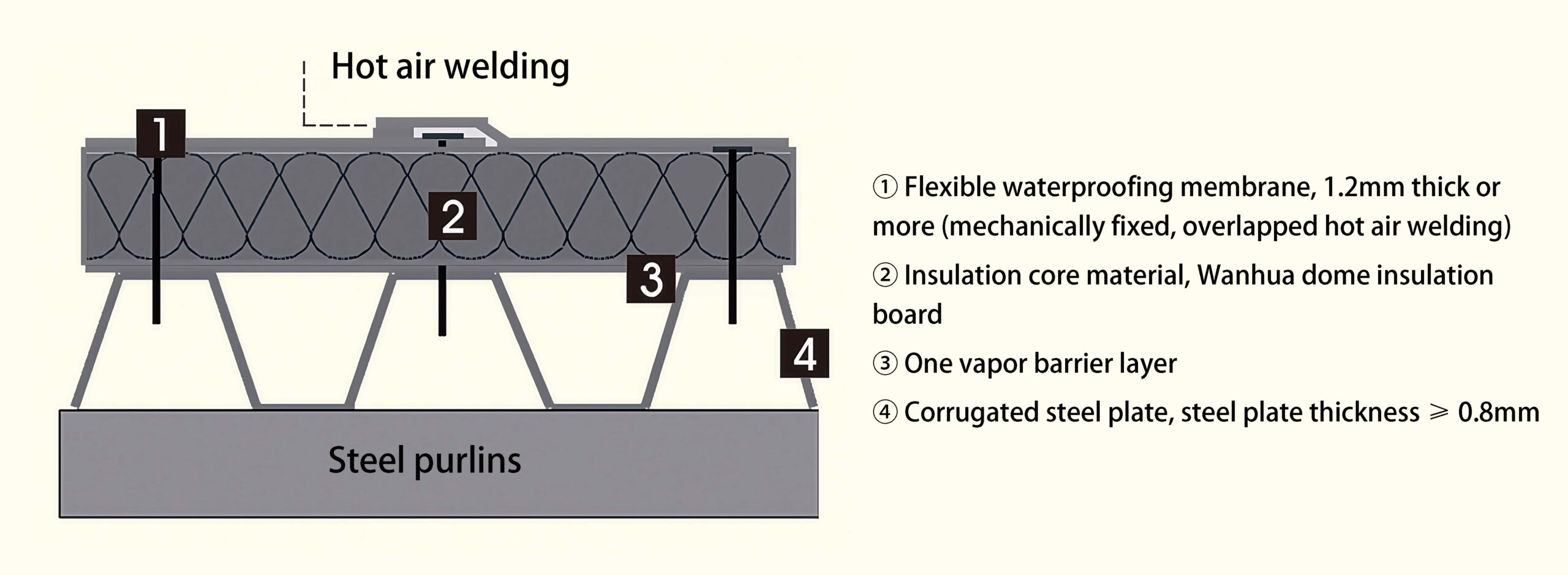

System Display

Wanhua Dome Roof Thermal Insulation System is structural assembly comprising vapor barrier layer, dome-shaped roof insulation boards, waterproof membrane layers, and fixing materials (e.g., adhesives, anchors). It is mechanically integrated into a unified whole with the roof enclosure structure through mechanical connections.

Specifically designed for flexible waterproof roofing systems, this solution delivers exceptional performance in thermal insulation, fire resistance, waterproofing, anti-penetration and compressive resistance, crack resistance, and high surface flatness.

Single layer waterproof membrane roofing system

Single layer waterproof membrane roofing system profile

Construction technology

Construction method: Mechanical fixing method

1. Clean the base

2. Lay the vapor barrier

3. Lay the insulation board

4. Mark the position

5. Place the non-perforating nail kit

6. Fix with nails

7. Lay the coil

8. Weld the coil

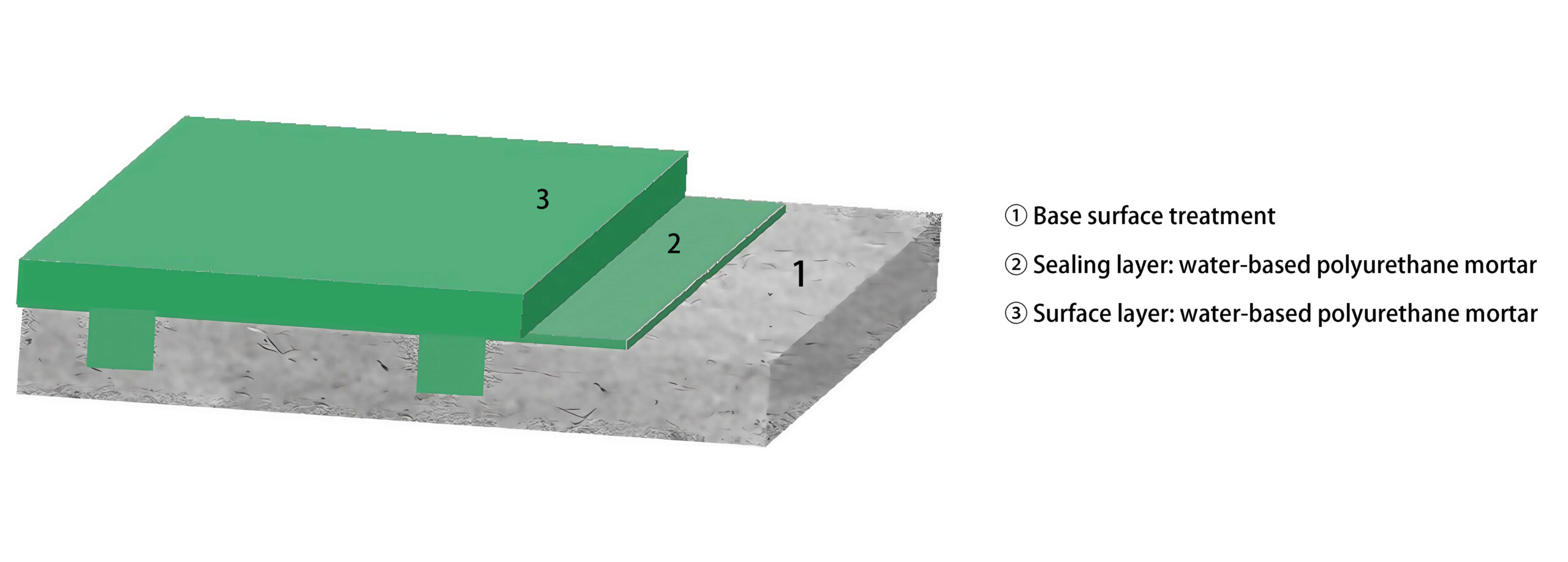

Floor Coating System

Waterborne Polyurethane Mortar Flooring System

System Overview

A multi-component, colored, waterborne self-leveling mortar floor coating formulated with high-performance polyurethane resin as the base material, combined with special cement, graded silica sand, and active pigments. The coating exhibits exceptional impact resistance, damage tolerance, chemical resistance, and scrub resistance, capable of withstanding medium to heavy loads. It is suitable for slaughterhouse workshops, food processing plants, central kitchens, and similar environments.

Main advantages

◎Resistant to high and low temperature environments Suitable for high or low temperature environments of -40℃~120℃, and can withstand short-term thermal shocks of 140℃.

◎Resistant to severe chemical corrosion Resistant to chemical corrosion such as various organic and inorganic acids, alkalis, amines, salts, solvents, etc.

◎Resistant to severe mechanical shock Resistant to extreme mechanical stress of rollers of heavy machinery and loading and handling carts.

◎Food grade hygienic and clean The surface is easy to clean, inhibits the growth of microorganisms and mold, and is food grade FDA certified.

◎Excellent anti-slip performance Unique molecular structure and different surface textures meet the anti-slip requirements of different environments.

Performance Indicators

| Serial number | Project | Technical indicators | |

| 1 | State in container | ≥ | After stirring, it is in a uniform state without any lumps. |

| 2 | Vicat softening point/℃ | ≥ | 140 |

| 3 | Compressive strength (7d)/MPa | ≥ | 40 |

| 4 | Flexural strength (7d)/MPa | ≤ | 10 |

| 5 | Abrasion resistance (500g/100r)/g | ≥ | 0.15 |

| 6 | Anti-slip properties (dry friction coefficient) | ≥ | 0.6 |

| 7 | Tensile bond strength/MPa | 2 | |

| 8 | Impact resistance (1000g steel ball) | No cracks or peeling on the surface | |

| 9 | Water resistance (168h) | No blistering, no peeling, no cracks, no discoloration | |

| 10 | Alkali resistance (20% NaOH, 72h) | No blistering, no peeling, no cracks, slight discoloration is allowed | |

| 11 | Acid resistance (10% H2S04, 48h) | No blistering, no peeling, no cracks, slight discoloration is allowed | |

| 12 | Oil resistance (120# solvent oil, 72h) | No blistering, no peeling, no cracks, slight discoloration is allowed | |

| 13 | Salt water resistance (3%NaCl, 168h) | No blistering, no peeling, no cracks, slight discoloration is allowed | |

Construction process

Surface treatment > Cutting anchor grooves > Applying primer > Applying topcoat

Rich flooring product series

Ultra-wear-resistant polyurethane flooring system

Performance characteristics

◎ Rough surface, matte, non-slip;

◎ Good weather resistance, no yellowing under ultraviolet radiation;

◎ Excellent pressure resistance, wear resistance, scratch resistance;

◎ Excellent anti-corrosion and mildew resistance, resistant to corrosion by water, oil, alkali and other chemical substances.

Scope of application

Floors such as factories and underground parking garages that require wear resistance, anti-skid and anti-corrosion can solve problems such as easy scratches, poor wear resistance and poor anti-skid safety.

Concrete integral floor system

Performance characteristics

Using steel fiber, armor seam, wear-resistant aggregate and liquid hardener, through special construction technology, it improves the flatness and wear resistance of the ground and extends its service life.

Scope of application

Especially suitable for high-standard ground, such as logistics warehousing, modern industrial plants, underground parking garages, etc.

Epoxy Terrazzo Art Floor System Performance Features

◎ Seamless as a whole, no cracking;

◎ Wear-resistant, long service life;

◎ Rich colors and orthopedics are available, with excellent decorative effect.

Scope of application

Applicable to urban construction of five museums and one center, hospitals, schools, airports, high-speed rail stations, exhibition halls, etc.

Solvent-free epoxy floating colored sand floor system

Performance characteristics

◎Excellent compression and impact resistance;

◎Outstanding decorative effect, safe and non-slip;

◎Good wear resistance and stain resistance;

◎Seamless and clean floor, easy to clean and maintain.

Scope of application

Applicable to places with high decoration requirements such as medicine, tobacco, train depots, offices, shopping malls, etc.

Sports venue floor system performance characteristics

◎Including silicon PU court, EPDM plastic track, etc.

Scope of application

Applicable to various sports venues such as basketball courts, tennis courts, track and field stadiums, playgrounds, etc.

Permeable pavement system Performance characteristics

◎It has outstanding weather resistance and water permeability, as well as excellent anti-skid function, and is the best material for urban permeable pavement.

Scope of application

Applicable to park greenways, sidewalks, community roads, bicycle lanes and other occasions.