WANHUA Energy-Saving Wanefoam ® 5000 Series

Sponge city

Sponge city refers to a city that, like a sponge, has good “elasticity” in adapting to environmental changes and responding to natural disasters. When it rains, it absorbs water, stores water, percolates water and purify water. When it is needed, it releases and uses the stored water to achieve “no water accumulation in light rain, no waterlogging in heavy rain and no black and smelly water”. At the same time, reduce the urban “heat island effect”.

To build a sponge city, you need a “spongy body”. The urban “spongy body” includes not only river systems such as rivers, lakes and ponds, but also supporting urban facilities such as green Spaces, gardens and permeable roads. Rainwater infiltration through these “cavernous body”, stagnation, purification, reuse, and finally the remaining runoff through the pipe network, pumping station outside the discharge, so as to effectively improve the standard of urban drainage system, reduce the pressure of urban waterlogging. Underground water resources are stored in large quantities to improve the “heat island effect” of the city, which is conducive to the rapid cooling of the city in summer, thus saving air conditioning power consumption, reducing energy consumption and carbon dioxide emissions, etc.

Green environmental protection

Builder of green sponge city

Wanhua energy-saving relying on advanced polyurethane technology, with green, environmental protection and energy saving for the idea, always walk in the industry forefront, focus on the dynamics and development of cities, sponge WANEFORM®5000 developed polyurethane adhesives series permeable pavement glue, and permeable polyurethane macadam mixture pavement construction, integrating consultation, design, materials, construc- tion, to provide you with energy conservation and environmental protection products and integration services.

Waneform®5000 series of permeable pavement adhesive, does not contain volatile solvent, solid content ≥96%, from the source to ensure the product green environmental protection.

Wanhua energy-saving polyurethane gravel mixture permeable pavement system, the construction process without pungent smell, no chemical reaction, no toxic gas discharge, green environmental protection, is the construction of green sponge city environmental protection pavement material.

Wanhua energy-saving polyurethane gravel mixture permeable road surface makes the earth swagger scene, let the walk is full of laughter, let the family warm, let the city is full of warmth.

Polyurethane gravel mixture permeable pavement

Permeable pavement materials as a carrier of “sponge city” construction arises at the historic moment, the traditional permeable pavement, floods are permeable brick pavement cement concrete pavement, the permeable asphalt pavement, these are all based on cement or asphalt as a cementing materials, asphalt aggregate material easy peeling, water damage is serious, cement decorative material shortage, low compressive flexural strength, easy to fracture and pore blockage. Therefore, as a new type of permeable pavement material, polyurethane gravel mixture has been widely used in China due to its excellent performance characteristics.

Structure type of pervious pavement made of polyurethane gravel mixture

The structural design of the pervious pavement made of polyurethane gravel mixture should be considered in combination with load grade, foundation bearing capacity, soil uniformity and other factors, and should meet the requirements of structural strength, water permeability and water storage. The pervious pavement structure types of Wanhua energy saving polyurethane gravel mixture are mainly divided into two types:

Fully permeable pavement

Fully permeable pavement requires that the surface layer, base layer, cushion layer and subgrade of the road have good permeabil- ity. It requires that the rainwater quickly penetrates from the surface layer to the subgrade within a specified period of time, and drains out the subgrade area in an organized way. After water resources enter the underground, groundwater can be replenished after a period of circulation.

Fully permeable pavement is mainly applicable to parking lots, sidewalks and other traffic places. Due to the high requirement for the permeability of roadbed, this road construction method has not been widely used in China.

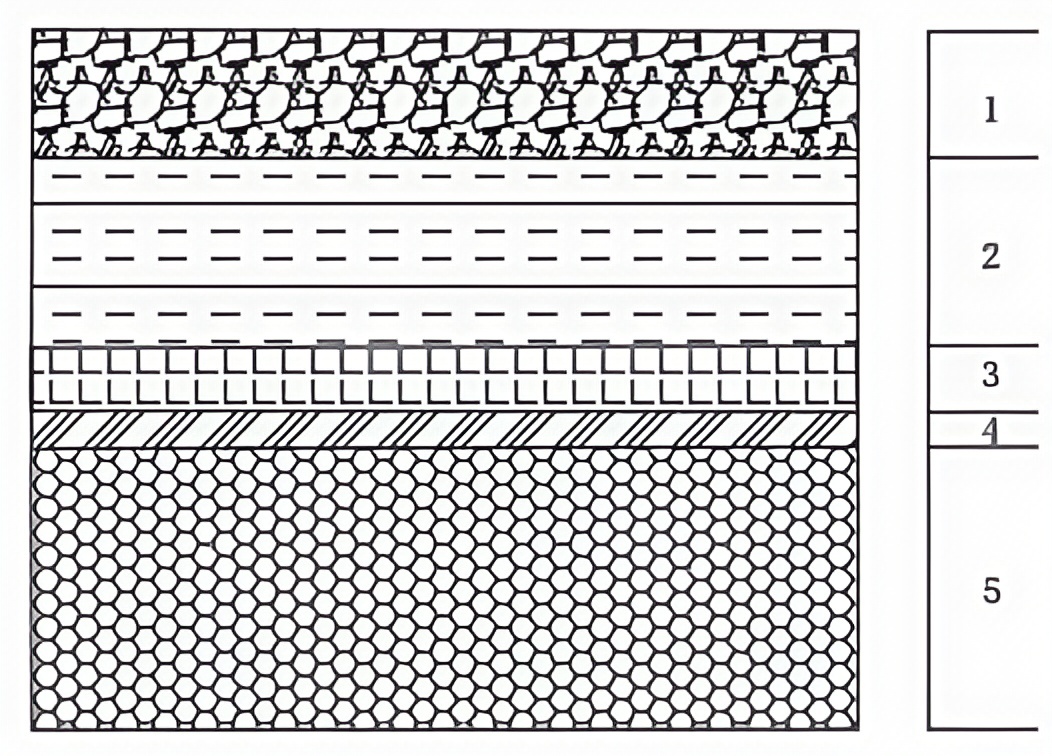

Fully permeable structure

Surface water seeps into the roadbed through the surface layer, base layer and cushion layer

1-Polyurethane permeable surface layer;

2-Permeable base layer;

3-Permeable cushion layer;

4-Filter isolation layer;

5-Roadbed

Semi-permeable pavement

A water-proof layer is arranged on the top surface of the semi-per- vious pavement, and only surface water is allowed to permeate from the surface layer to the base layer or cushion layer. In the base and cushion layer, it can quickly flow into the drainage facilities laid in the road through the longitudinal and transverse slopes and exit the road structure side by side.

The rainwater of this type of road surface is blocked by the waterproof layer on the top of the roadbed, so it cannot enter the roadbed without considering the permeable performance of the soil of the roadbed. Meanwhile, the permeable layer is composed of surface layer, base layer and cushion layer, and has a thick water storage layer with large water absorption capacity.

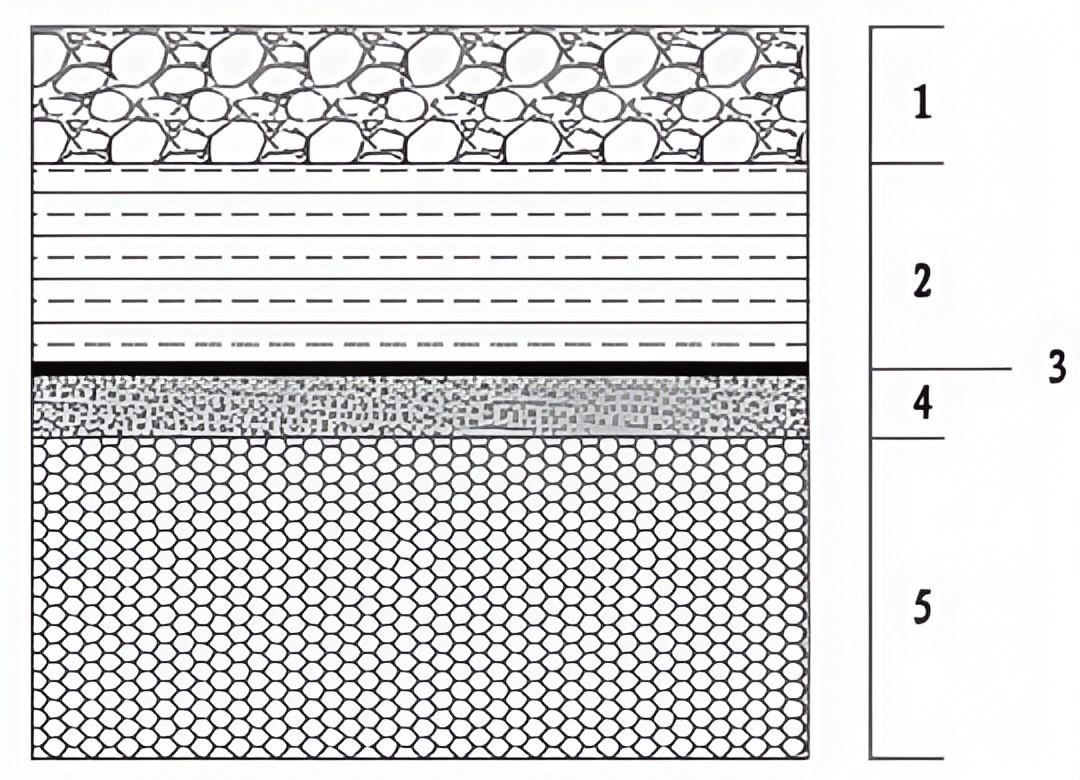

Semi-permeable structure

Surface water enters the base layer (or cushion layer) from the surface layer and then is discharged into the adjacent drainage facilities

1-Polyurethane permeable surface layer;

2-Permeable base layer;

3-Waterproof isolation layer;

4-Cushion layer;

5-Roadbed

Advantages of pervious pavement made of polyurethane gravel mixture

①Rich color, decorative pavement, increase the overall environment beauty

②High water and air permeability, effectively improving the temperature and humidity of the surrounding environment

③Strong water resistance, frost resistance, corrosion resistance and permanent deformation resistance;

④Efficient construction, fast opening, convenient health maintenance, convenient and fast maintenance

⑤It has a good reflection effect on light and alleviates the urban “heat island effect”

Application site of pervious pavement made of polyurethane gravel mixture

Polyurethane gravel mixture permeable pavement is suitable for new and expanded urban sidewalks, non-motorized driveway, pedestrian plaza, park greenway and other slow traffic systems as well as bus parking lot.

Polyurethane gravel mixture permeable pavement construction process

Mix and shop on trial——Mixing and transporting——Health maintenance and management——Spread and compacted

Polyurethane adhesive

As the binder of polyurethane gravel mixture, the quality of polyurethane gravel mixture directly affects the pavement performance of polyurethane gravel mixture. Wanhua Energy Saving can provide high quality polyurethane adhesive products – WANFORM® 5001 and WANFORM® 5002 for permeable pavement.

Polyurethane adhesive

WANEFOAM®5001

Product introduction

WANEFOAM®5001 is A two-component polyurethane adhesive without solvent, which part A multivariate and additives as the main raw material, part B with modified methylene phenyl isocyanate as the main raw material, according to A: B = 100:65 quality after mixing ratio,pour into the rubble,stir evenly PuTan on the road, after compaction, leveling, curing polyurethane pavement. WANEFOAM® 5001 is a green, environmental friendly and beautiful adhesive material for application prospect. sponge city was made by the permeable permeable pavement, which has a broad

Performance indicators

| Experimental items | Units of measurement | Technical requirements | |

| No flow time | min | 20-80 | |

| Tensile strength | MPa | ≥25 | |

| Elongation at break | % | ≥15 | |

| Solid content | % | ≥96 | |

| Viscosity (25℃) | MPa.s | Component A | 300-800 |

| Component B | 100-400 | ||

Method of use

After mixing WANEFOAM® 5001 evenly according to the quality ratio of A: B = 100:65, pour the crushed stone into it. After stirring, the crushed stone is evenly coated with polyurethane adhesive. After stirring, the crushed stone is evenly spread on the road surface, compaction, leveling and curing are done.

WANEFOAM®5002

Product introduction

WANEFOAM® 5001 is A two-component polyurethane adhesive without solvent, which part A multivariate and additives as the main raw material, part B with modified methylene phenyl isocyanate as the main raw material, according to A: B = 100:65 quality after mixing ratio, pour into the rubble, stir evenly PuTan on the road, after compaction, leveling, curing polyurethane sponge city was made by the permeable pavement. WANEFOAM ® 5001 is a green, environmental friendly and beautiful adhesive material for permeable pavement, which has a broad application prospect.

Performance indicators

| Experimental items | Units of measurement | Technical requirements | |

| No flow time | min | 10-60 | |

| Tensile strength | MPa | ≥15 | |

| Elongation at break | % | ≥25 | |

| Solid content | % | ≥96 | |

| Viscosity (25℃) | MPa.s | Component A | 300-800 |

| Component B | 1500-3000 | ||

Method of use

After mixing WANEFOAM® 5002 evenly according to the quality ratio of A: B = 100:65, pour the crushed stone into it. After stirring, the crushed stone is evenly coated with polyurethane adhesive. After stirring, the crushed stone is evenly spread on the road surface, compaction, leveling and curing are done.

Integrated service

Full lifecycle services

Wanhua energy conservation can systematically provide permeable pavement full life cycle services, including exploration and design, technical consulting, sample proofing, paving construction, maintenance management, etc., a full range of high standards, high station service, so that users have no worries.

Whole-process service

Wanhua Energy Saving adhere to the “quality bottom line, safety red line”, from raw material procurement, factory to production, delivery, the whole process of quality inspection and control, the construction site to implement the project manager responsibility system, to ensure zero accidents, high quality construction.

Custom service

Wanhua Energy Conservation can provide customized services according to customer needs, which can not only specifically solve the problem of permeable pavement in sponge city, but also provide differentiated polyurethane adhesive products with excellent quality and environmental protection, contributing its own strength to the construction of ecological city.