Energy-Saving Ski Resort Brochure

Integration of ice and snow venues

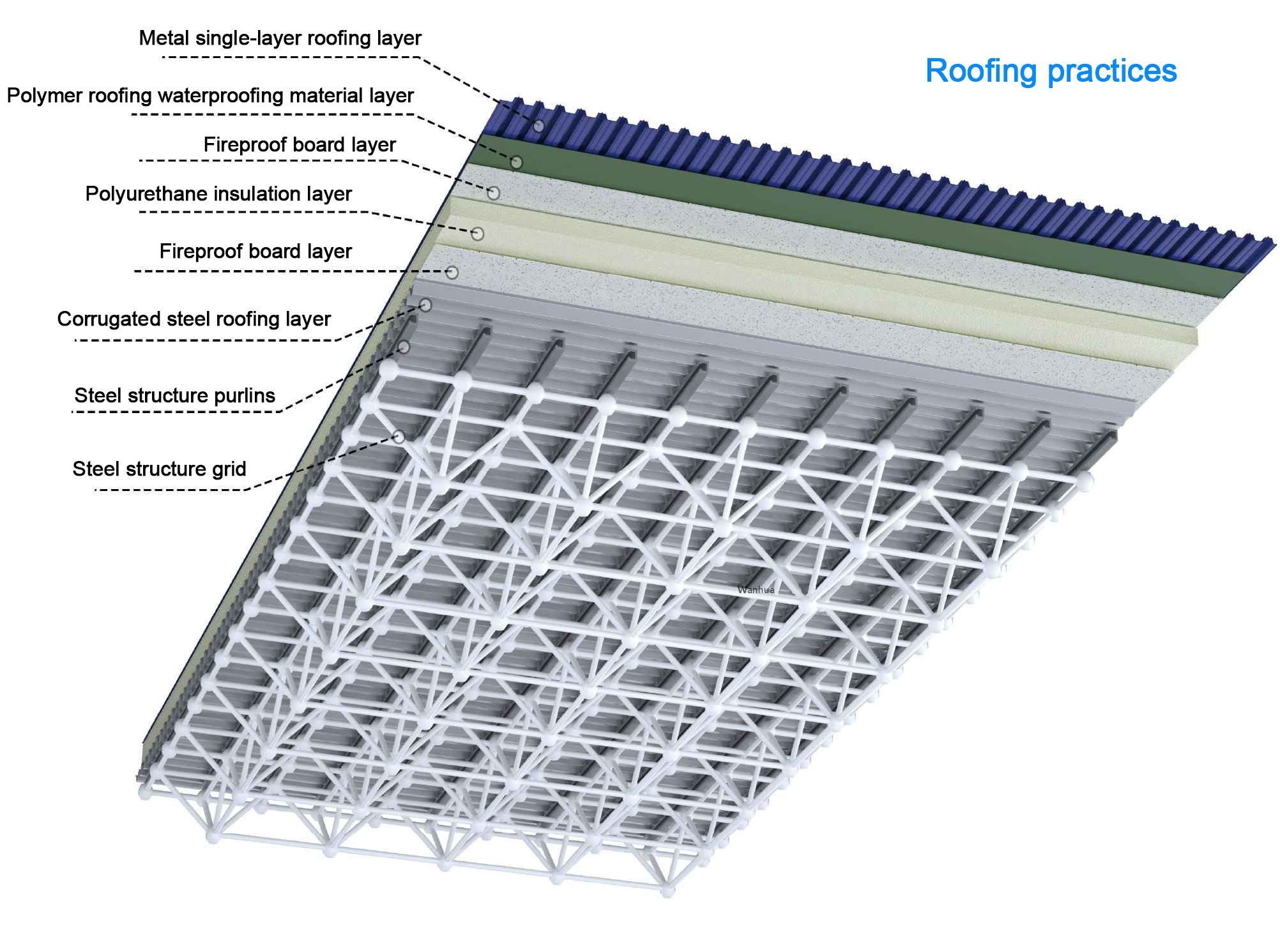

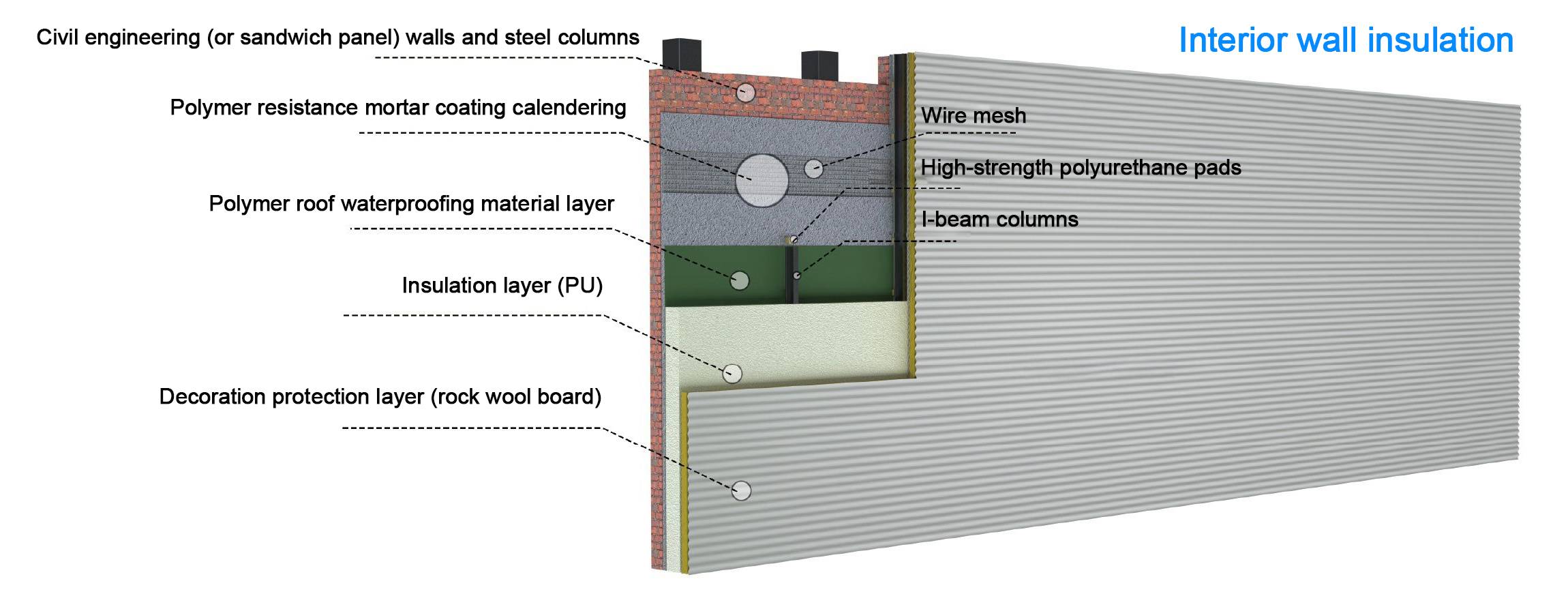

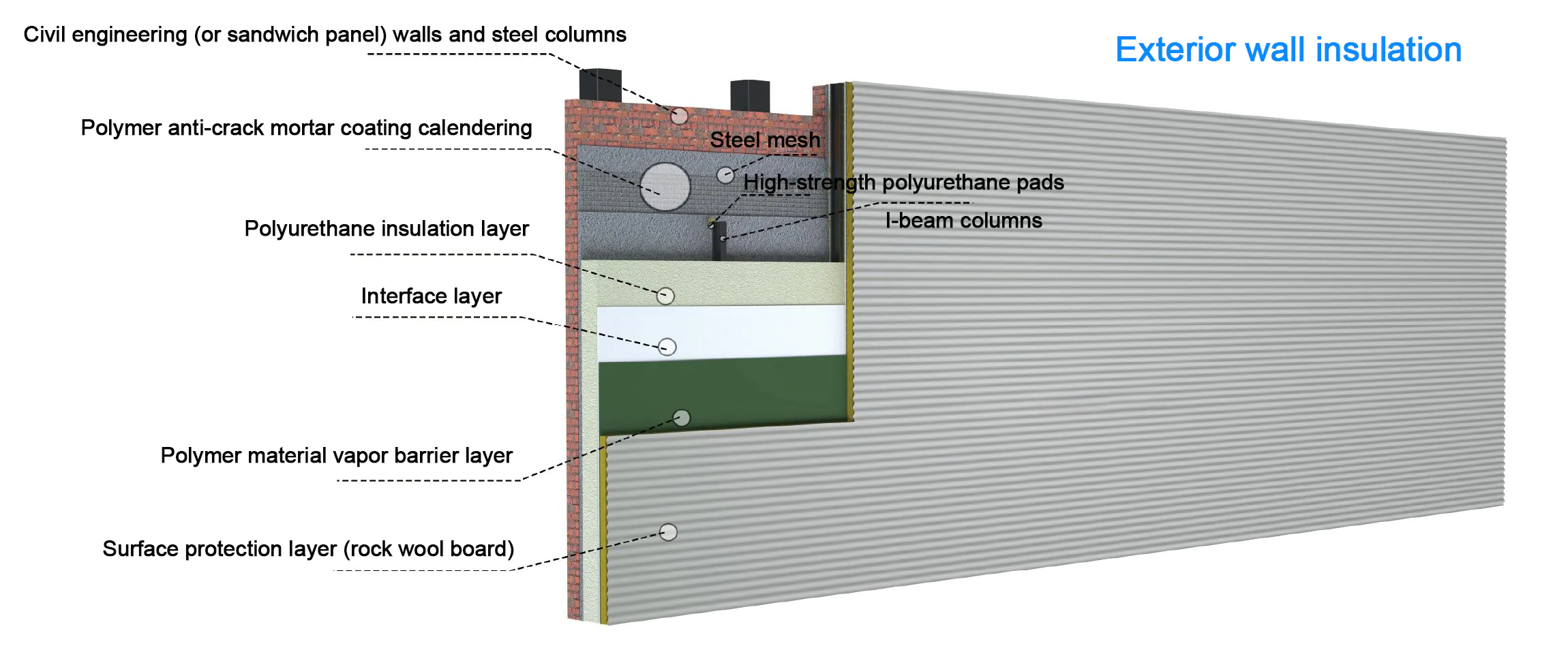

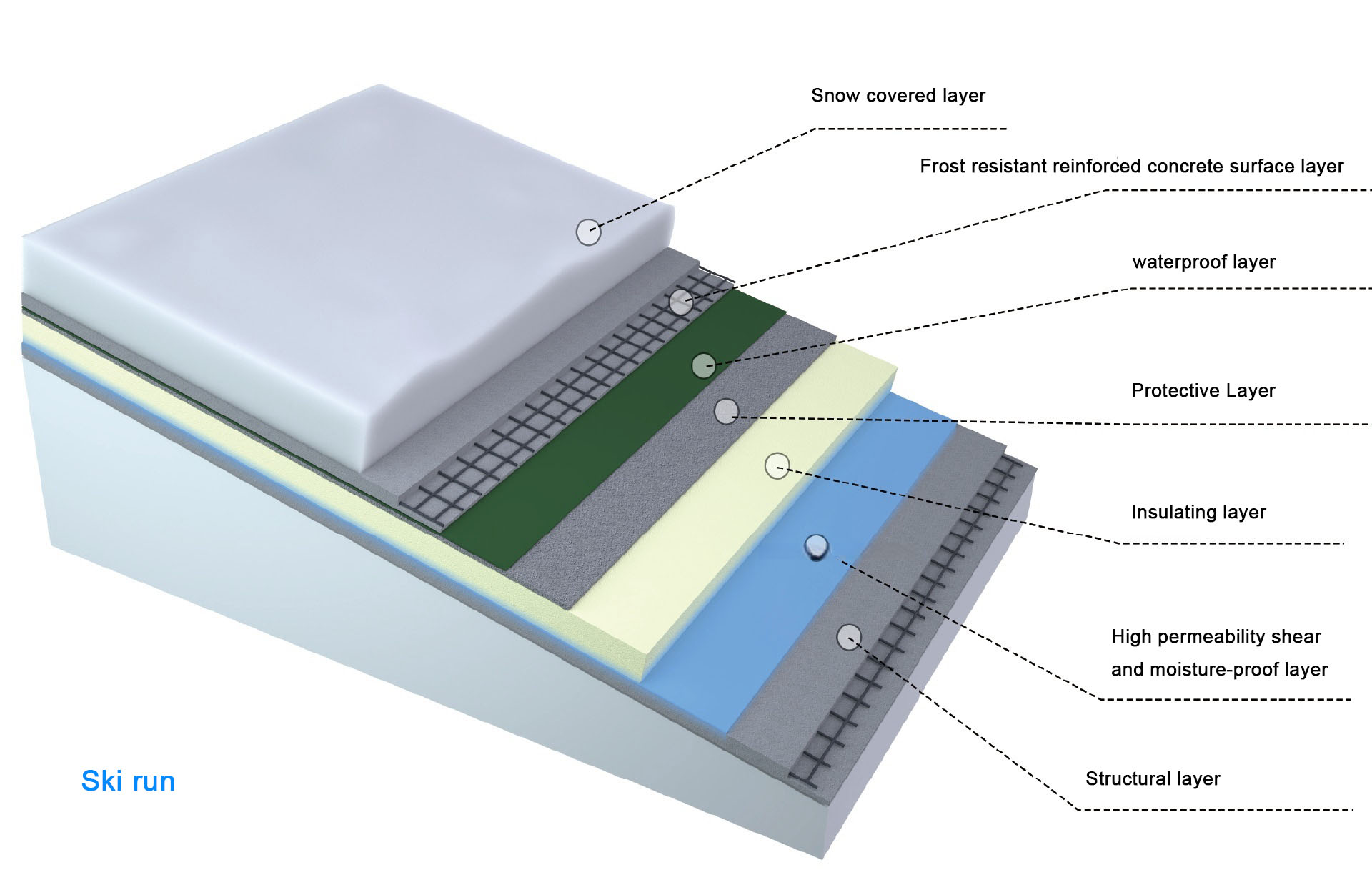

In order to improve the construction level of indoor ice and snow stadiums , the problems of low temperature and air tightness of the buildings are solved more efficiently in view of the characteristics of low temperature , high humidity and large energy consumption.

wanhua energy saving gather potential and create energy , specializing in the standardization construction of indoor ice and snow stadium heat preservation , steam insulation and waterproof.

Green and environmentally friendly, technologically advanced, and economically reasonable, Wanhua Energy Saving relies on advanced polyurethane technology. After more than ten years of deep development, it has continuously extended its products to contribute to improving the construction level of indoor ice and snow venues, promoting the development of ice and snow sports and ice and snow culture, and ensuring the safety of indoor ice and snow venues. Construction quality and engineering quality.

PRODUCT INTRODUCTION

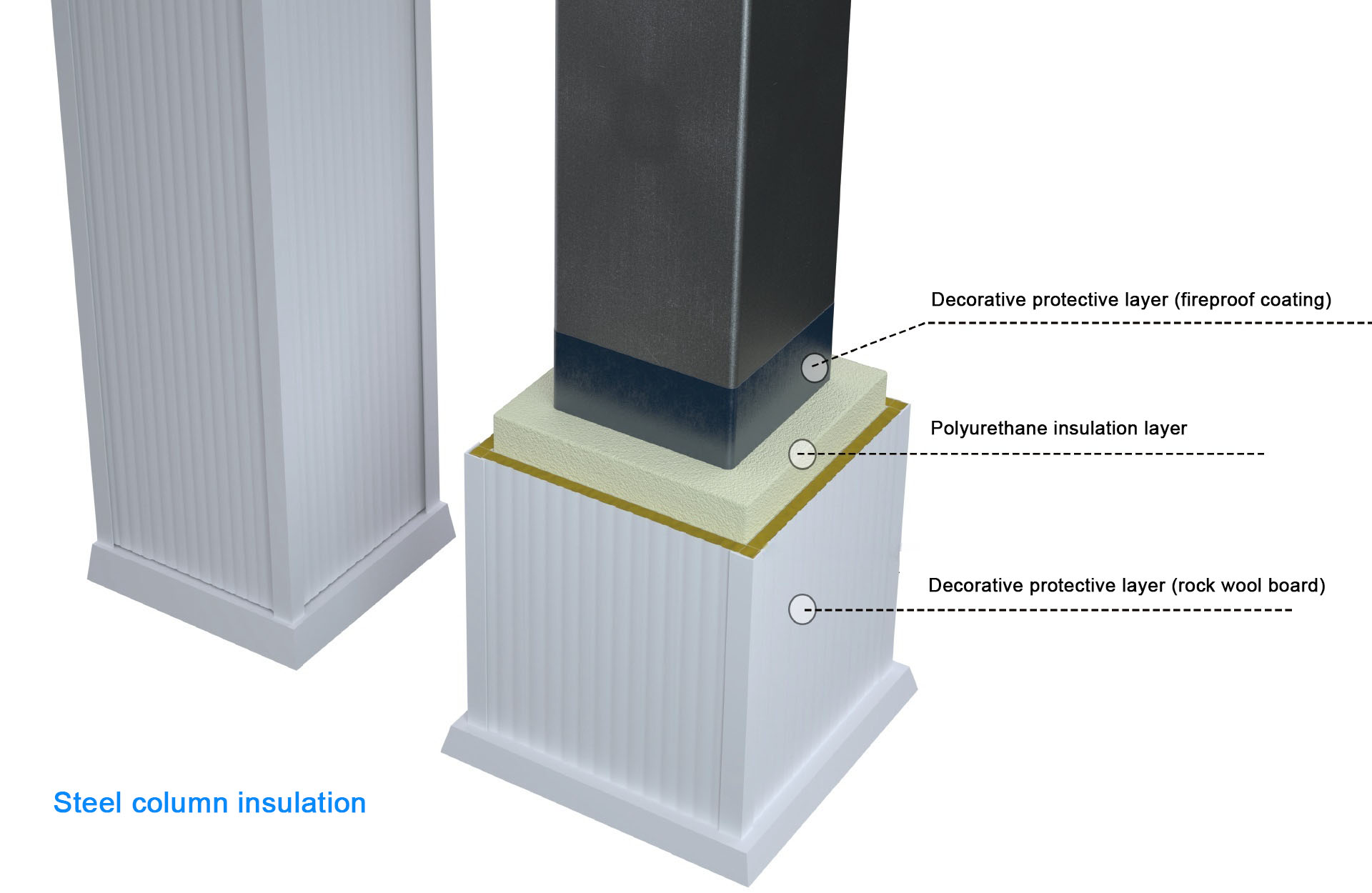

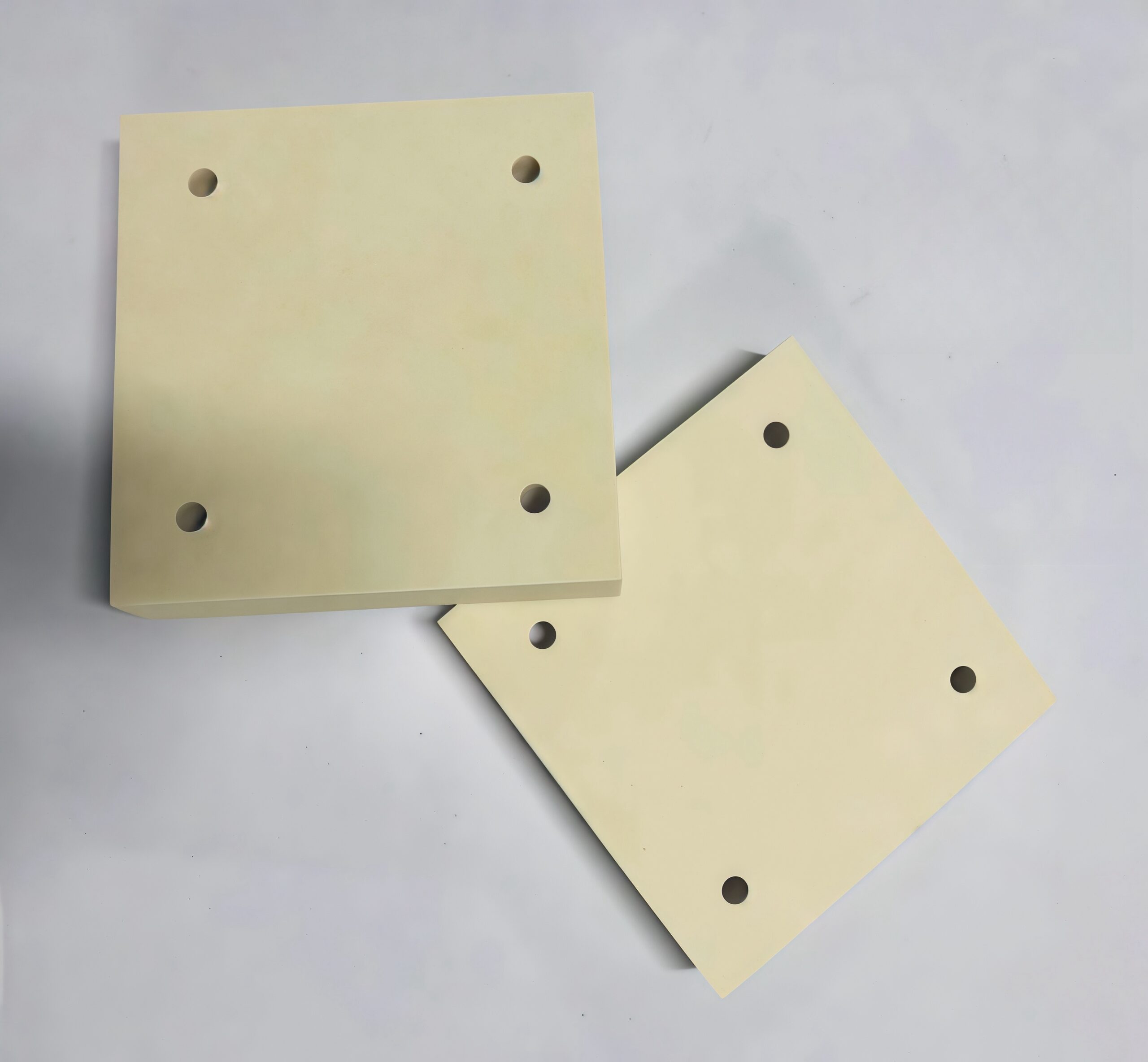

Rigid polyurethane insulation pad

Hard polyurethane insulation pad is one of the materials designated by the National Energy Conservation Center. Its high compressive strength, low thermal conductivity, water absorption performance is basically zero, chemical and physical properties are relatively stable, and it can play a role well within the design life of cold storage. It is the most reliable system at this stage.Hard polyurethane insulation pad is divided into wall pad and column pad, made of Wanhua energy-saving special formula of high hard polyurethane composite materials, wall pad between the steel column and wall to form a heat insulation bridge, the column pad between the steel column foot and the ground concrete base to form a heat insulation bridge. At the same time, it has a special formula and manufacturing process of high compression resistance, so that it has no water absorption, anti-condensation, corrosion resistance, insoluble and other properties. After the pad is installed on the wall or column, the surface of the pad is compatible with the column, and will not corrode the steel structure column, which is safe and reliable.

·Efficient and energy-saving

·Stable high pressure resistance

·Anti condensation

·Easy and fast installation

Characteristics and effect of rigid polyurethane insulation pad

Thermal insulation performance

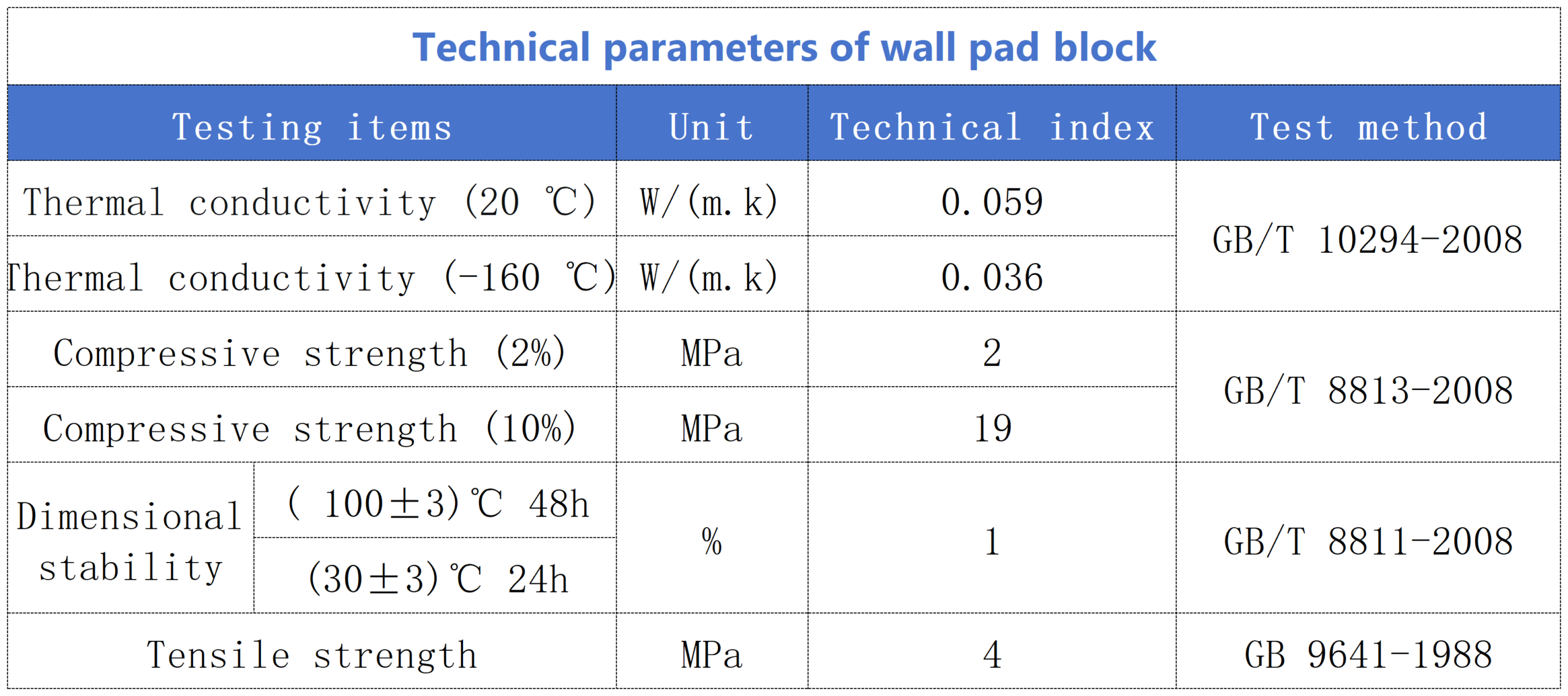

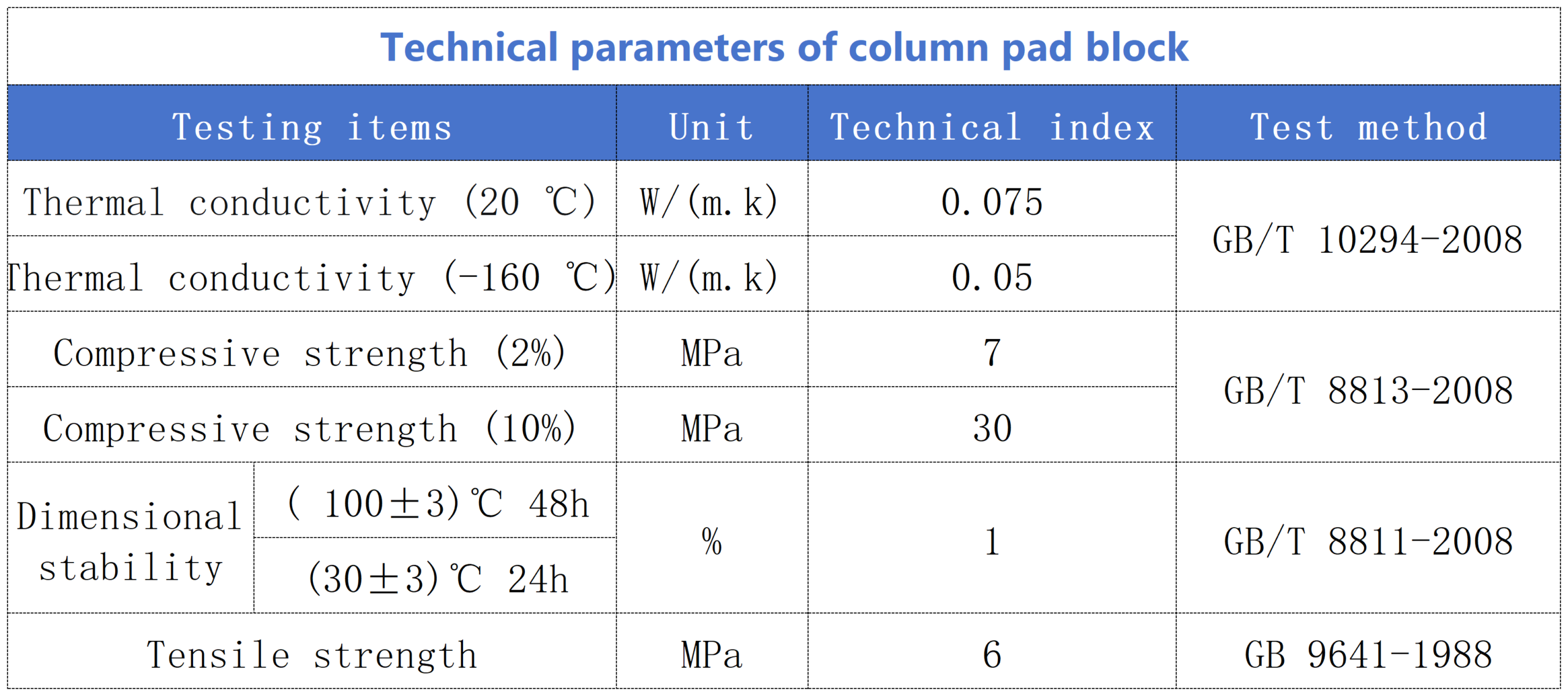

Hard polyurethane insulation pad has low thermal conductivity and good thermal insulation effect.

Compression resistance and creep under long-term load

The compressive strength of rigid polyurethane insulation pad is very high, and the creep under long-term load is extremely small. It is sufficient to bear the pressure of the column foot of the overall steel structure for a long time, and there is no possibility of temperature insulation performance decline and damage due to the compression, deformation or breaking of the thermal insulation material.

Resistance to water and moisture

Hard polyurethane insulation pad has a close closed cell honeycomb structure, chemical properties are also very stable, so the water resistance is very good, its water absorption rate < 1% (V/V). Even if it is completely immersed in water, the compressive performance is almost unchanged.

Tensile properties

The rigid polyurethane insulation pad has good tensile properties. The breaking strength of wall pad is about 4MPa, and the elongation at break is about 10.86%. The breaking strength of the column pad is about 6MPa, and the elongation at break is about 10.3%.

Dimensional stability

The dimensional stability of rigid polyurethane insulation pad changes very little, and the rate of change in three directions of length, width and thickness is less than 1%.

Polyurethane Sprayed Thermal Insulation (WANEFOAM ®6000 Series)

• SMALL THERMAL CONDUCTIVITY

• GREEN ENVIRONMENTAL PROTECTION

• GOOD FLAME RETARDANT EFFECT

• GOOD DIMENSIONAL STABILITY

• EASY SITE CONSTRUCTION

Polyurethane Sprayed Thermal Insulation

(WANEFOAM ®6000 Series)

Small thermal conductivity: indoor ice and snow venues are low-temperature and high-humidity buildings, with temperatures ranging from -1C to -8C and indoor humidity above 60%. Therefore, thermal insulation materials with good thermal insulation performance, low volume water absorption and small long-term thermal attenuation shouldbe selected first.

Green environmental protection:

Good flame retardant effect: the thermal insulation materials of indoor ice and snow venues should meet the national requirements for fire prevention.

Good dimensional stability: the thermal insulation material with poor dimensional stability may have cavities at corners and junctions after cooling and shrinkage, forming no thermal insulation area, leading to serious condensation problem.

Easy site construction: site construction quality seriously affects the thermal insulation durability performance, so we should choose the thermal insulation scheme that is easy to site construction.

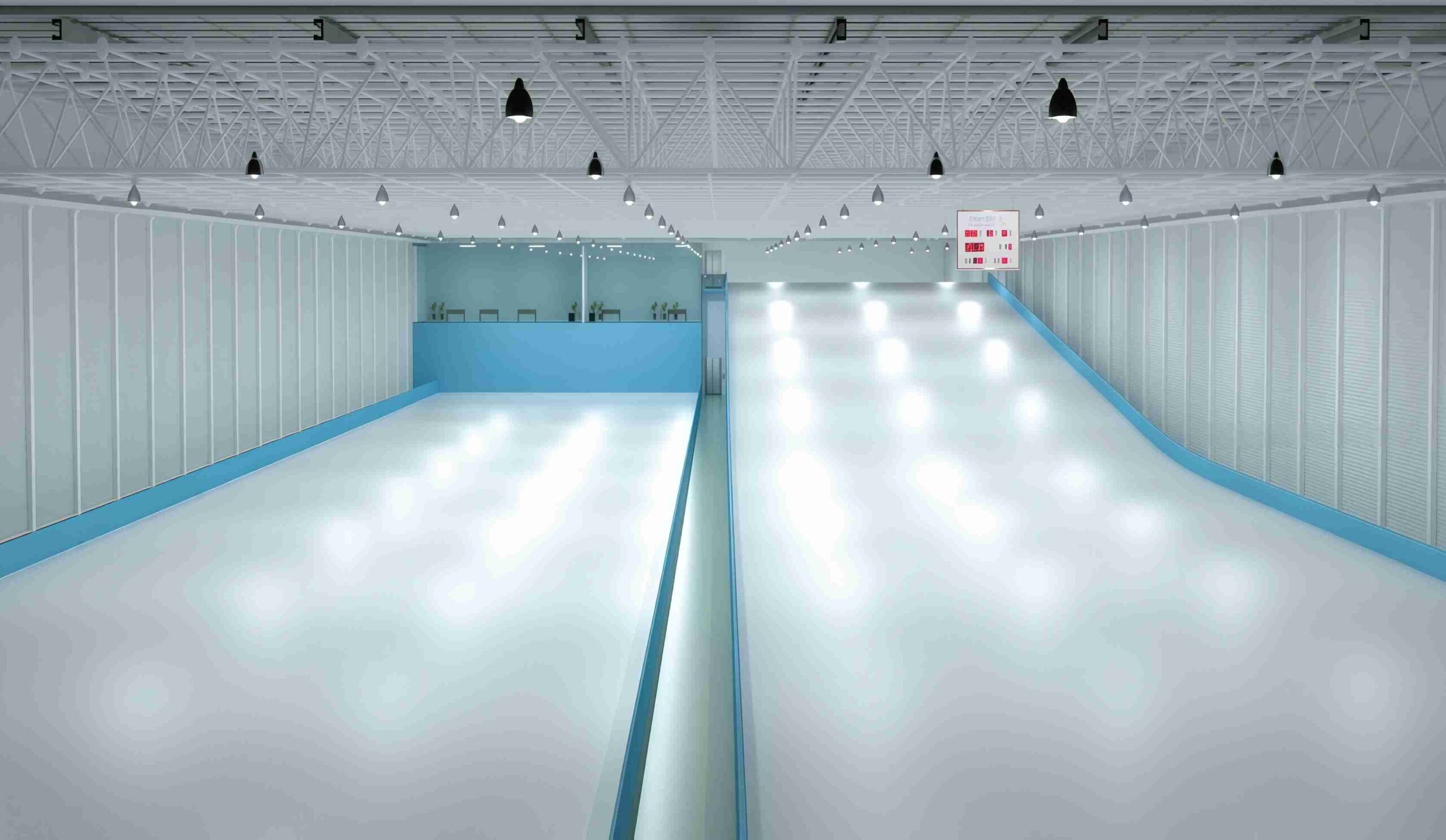

Zhangjiajie Ice and Snow World Ski Resort renderings

Cold storage board insulation (WanPanel ®series)

Wanhua energy-saving imported automatic continuous production line, wall surface smoothness effective guarantee, Italy imported Hennecke-OMS foaming machine, "6+1" component foaming system, 38 meters double crawler machine, in the accuracy and stability of the obvious advantages.

Polyurethane rock wool composite board

Wanhua energy-saving polyurethane rock wool composite board is made of rock wool as core material. Through continuous foaming technology, hard foaming polyurethane and rock wool are fused into one body to meet the special requirements of ski resort engineering. At the same time, the board has its own strength and aesthetic performance.

Good thermal insulation performance

the gap of rock wool is filled in the process of polyurethane foaming to form a closed thermal insulation layer to prevent air convection and reduce the thermal conductivity of the product

Excellent waterproof and moistureproof

the polyurethane is completely evenly covered on the surface of the rock wool and seeps into the rock wool board to form a continuous closed-cell polyurethane waterproof isolation layer, which overcomes the defect of water absorption and deliquency of the rock wool.

Strong resistance to deformation

the flow of liquid polyurethane into the rock wool in the form of molecules, the formation of infiltration physical bite, polyurethane excellent self-bonding performance, 100% no cavity connection, good dimensional stability, not easy to crack, and can achieve the same life span and building.

Rock wool cold storage board

Wanhua energy saving rock wool cold storage board takes basalt and other hot ore as the main raw material, rock wool board is made by high temperature melting into fiber, adding an appropriate amount of binder, curing and processing.

Low thermal conductivity

thermal conductivity 0.041-0.045W/m.K

Good fire performance

meet the requirements of class A fire

Good air tightness

according to the evaluation and classification standard of air tightness performance of building curtain wall in China, the rock wool sample room can reach the overall air tightness level 2

Light thermal defect

Rock wool board is closely linked, the distribution of insulation materials is uniform, there is little air penetration and other parts, in the case of no flooding or condensation, rock wool can be used normally, short-term immersion after repeated freeze-thaw, will not cause rock wool board freezing crack damage.

Polyurea

Polyurea technology is a new product and technology developed successfully to adapt to the long-term andfull-effect protection of concrete and metal components. It creatively combines the material technology with theconstruction technology perfectly, and maximizes the performance of materials and engineering quality to be perfectly reflected and guaranteed.

The large span light steel roof and slide facilities of the ski hail are characterized by complex structures such as lap joints of components, steep slopes, perforated components and skylights, as well as vibration characteristics under the action of skiing and wind. Spraying polyurea is applied to the ground foundation waterproofing or roof waterproofing of ski gym, which has the following advantages:

(1) has good flexibility, aging resistance and mechanical strength, can cover the subtle cracks, can resist skiing sliding shear force, wind and other vibration or deformation without cracking; Even if the substrate micro-deformation orcracking, the coating itself is not easy to fracture, always maintain the grip of the base.

(2) In the construction of rolling waterproof material on complex curved surface, there is inevitably a large number of welding construction joints, and it is easy toage in the open air environment, which may cause hidden dangers to the waterproof and durability of the structure. In concrete, metal and other curved surfaces, facades, even if the installation of drainage gutters, gutter, fan and pipe fittings and other complex components, polyurea can also be close to the base surface to form a "skin type" waterproof, maintain the original reproduction and the overall no seam, to avoid the leakage may be caused by lapping joints.

(3) combined with polyurethane spray insulation, the formation of the overall seamless waterproof insulation integration system, in order to ensure the thermal performance of polyurethane spray insulation at the same time, polyurea can also give insulation layer protection, prevent insulation layer damage, put an end to snow leakage.

(4) Excellent low temperature resistance, can be used under -30C for a long time, to meet the use requirements of the low temperature environment of the ski hall.

(5) in line with the level 1 waterproof design requirements, can replace the traditional two waterproof practices, can also be used as the roof exposed decorative surface layer, improve the efficiency of energy conservation and emission reduction of the ski pavilion building.

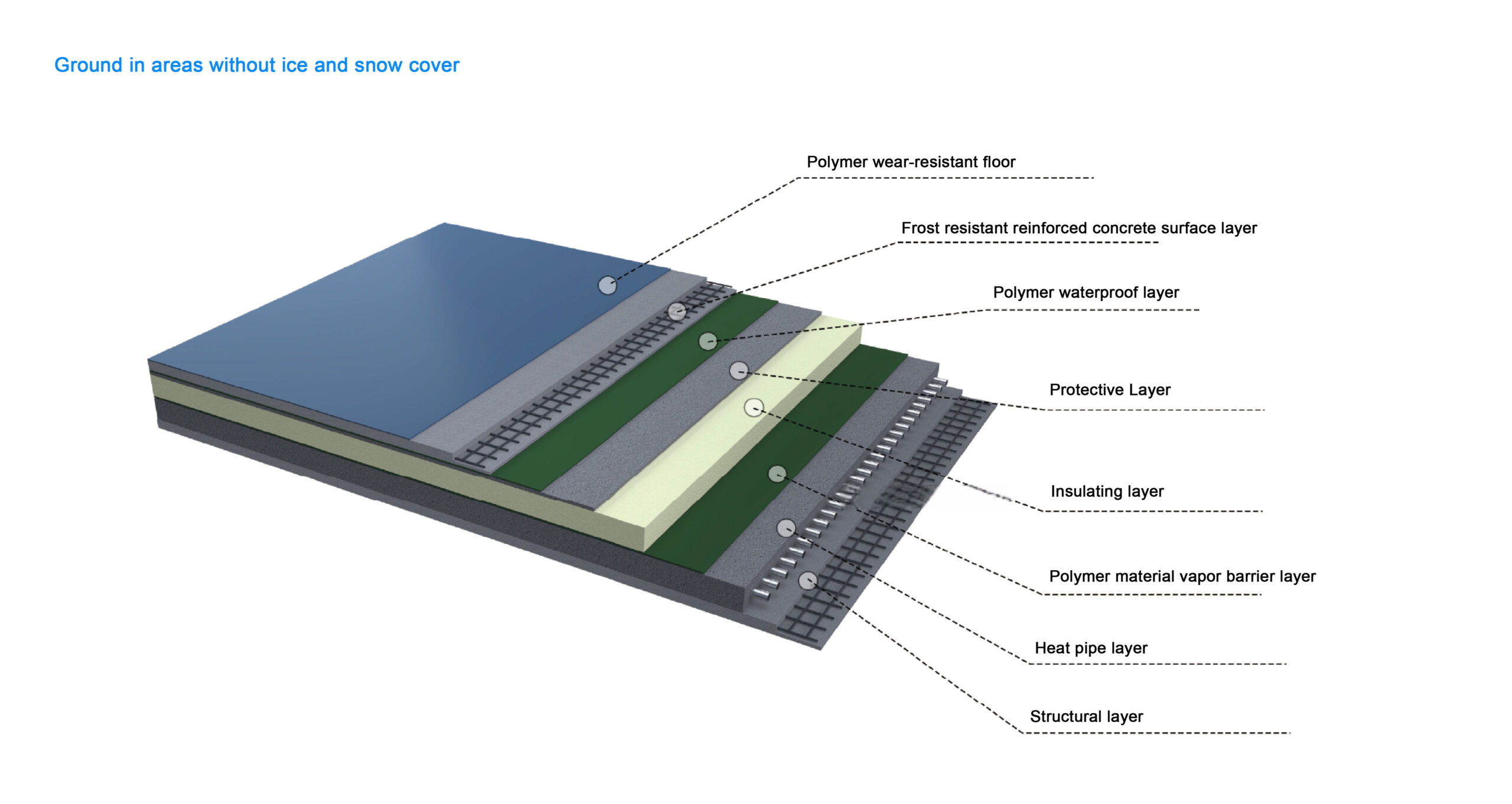

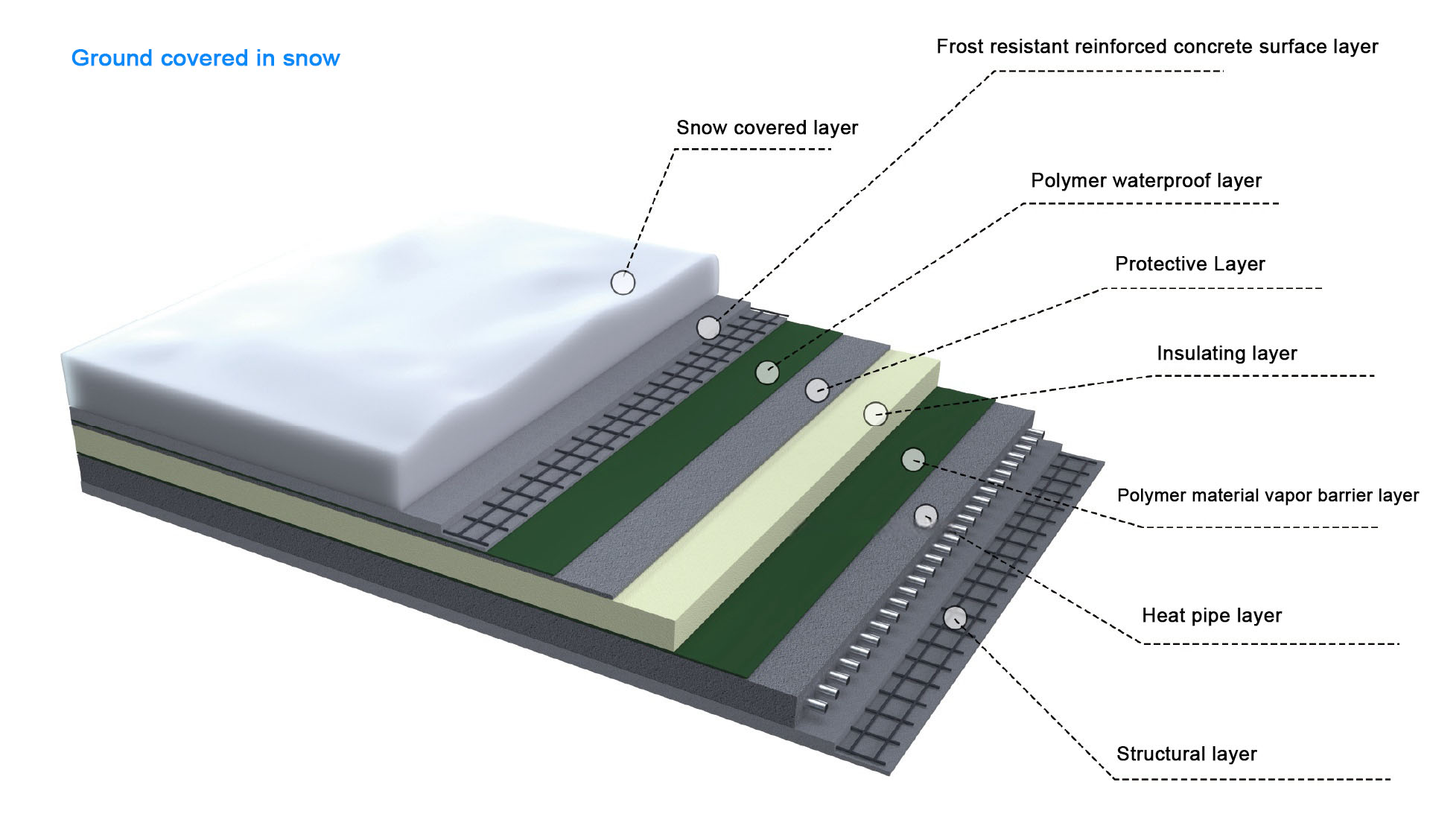

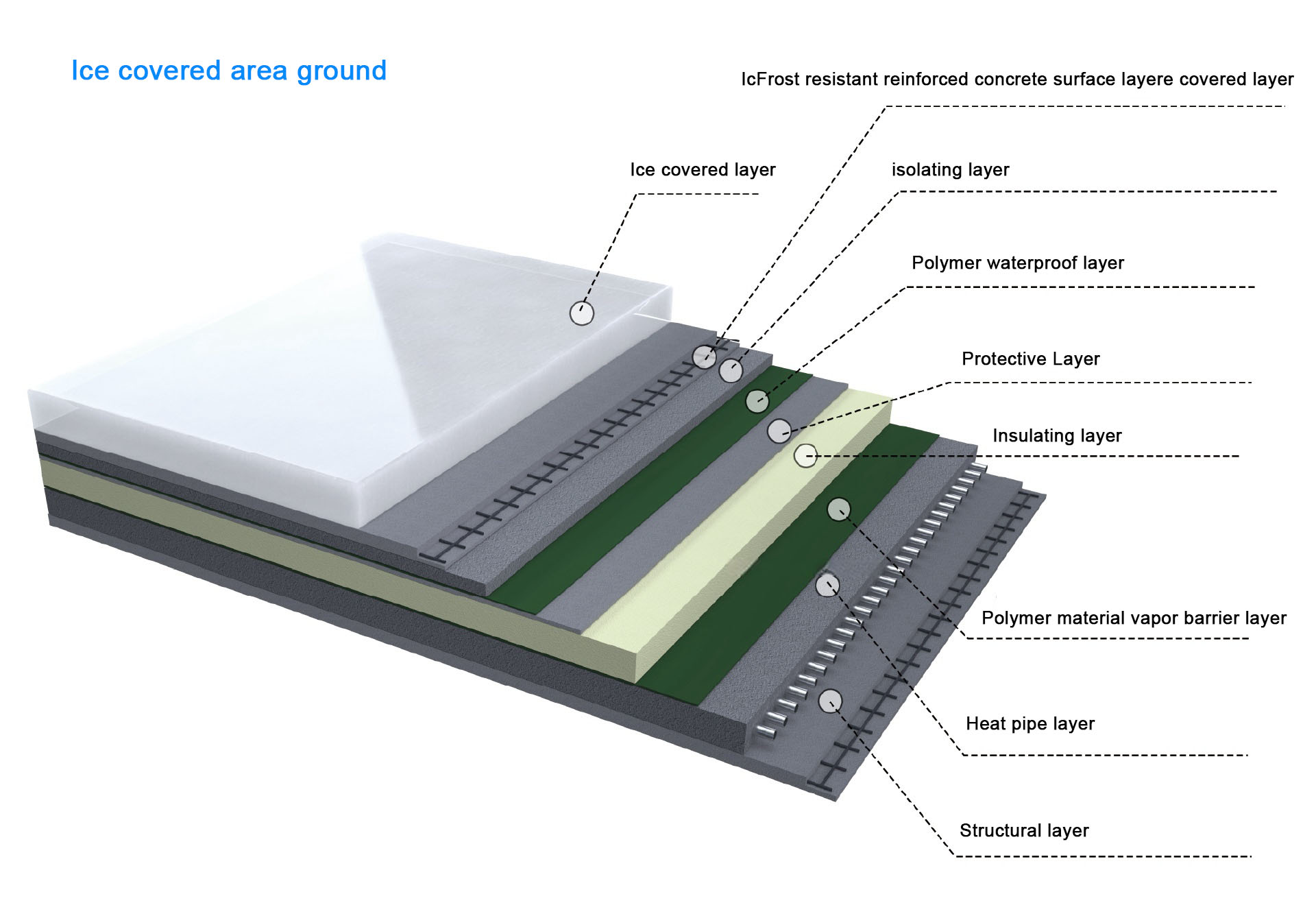

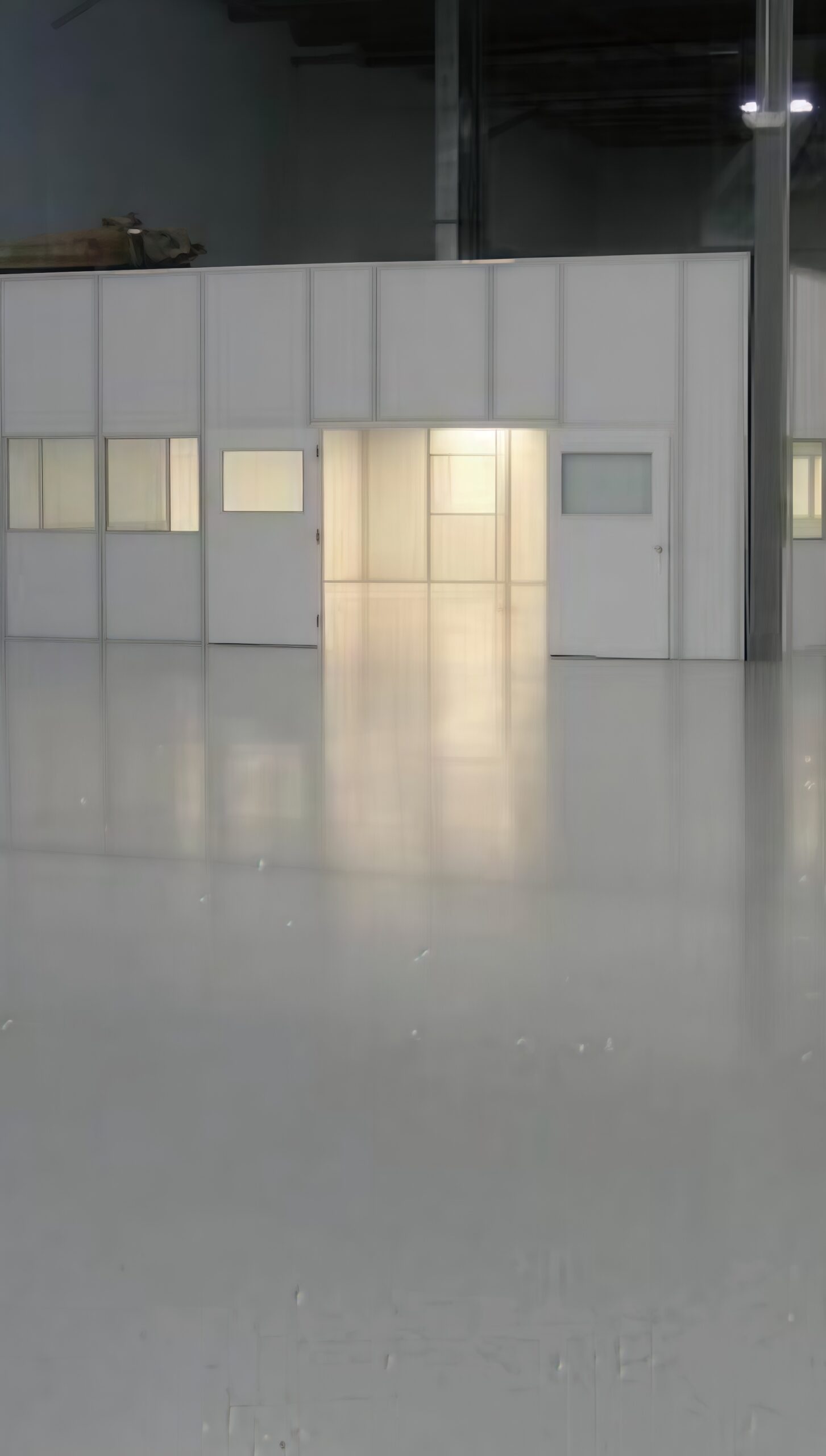

Floors (WanShieldSeries)

·Waterborne polyurethane mortar series

·Super wear-resistant polyurethane series

·Emery abrasive hardening series

Waterborne polyurethane mortar series

The multi-component color water-based self-leveling mortar floor material is made of high-performance polyurethane resin as base material and special cement,graded silica sand and active pigment as aggregate. It is suitable for the ground of ski gym, and the supporting equipment room, central kitchen, etc. It has the following advantages.

·Green environmental protection, very low VOC, free of heavy metals, no peculiar smell during use, in line with food-grade hygiene requirements.

·the use of temperature range -40 ~ 120C. In the low temperature environment of the ski gym, the coating and the concrete substrate have no displacement difference, no delamination, no cracking, and maintain their physical properties in the extreme temperature alternating environment.

·between high-performance polyurethane and high strength cement silica sand chemical hybrid composite, coating damage resistance, impact or deformation toughness, no crack or delamination, can achieve the same life as the building.

·Conform to the A-level fire protection requirements, improve the safety of the ski pavilion buildings, and ensure the safety of passengers' lives and property.

·dense coating, tolerance to various organic acids, alkali, amine, salt and other solutions, resistance to snow water penetration, protection and extend the use cycle of insulation layer.

·the coating is anti-impact, anti-impact, can withstand sleigh, skateboard and other medium to heavy load.

Super wear-resistant polyurethane series

The product introduces materials with high hardness and high wear resistance, which greatly improves the wear resistance and scratch resistance of the floor coating system, and can fully meet the requirements of high frequency, high wear resistance, metal scratchingl resistance and no noise.

·Rough surface, matte, anti-skid;

·good weather resistance, UV irradiation is not yellowing;

·excellent compression resistance, wear resistance, scratch resistance;

·Excellent dustproof, overall seamless, easy to clean;

·excellent anti-corrosion and mildew resistance, water, oil, alkali and other chemical corrosion.

·It is suitable for the ground of the open parking lot and underground garage supporting the ski gym, which can solve the problems of the ground such as easy scratch, poor wear resistance, reflection, strong tire noise, residual tire marks and poor anti-skid safety.

Emery abrasive hardening series

Emery abrasive wear-resisting aggregate using dry sowing method, its evenly spread on the concrete surface of the initial setting stage, after curingthe surface spray sealing curing agent. The product can fill concrete in the formation of a large number of capillary holes, make the surface of concretemore dense, improve the hardness of concrete surface, wear resistance and strength, prevent the surface from ash or the penetration of solutionerosion, prolong the service life of concrete. It is suitable for economic floor coating of parking lot, shopping mall, warehouse workshop and so on.